Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Product Information Polyurethane Anti-Slip Floor Polyurethane Anti-Slip Floor Paint

Cargado por

rajayu20002724Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Product Information Polyurethane Anti-Slip Floor Polyurethane Anti-Slip Floor Paint

Cargado por

rajayu20002724Copyright:

Formatos disponibles

Product Information Polyurethane Anti-Slip Floor Polyurethane Anti-Slip Floor Paint

________________________________________________________________________________________________

Description: The Anti Slip Polyurethane Floor Paint is a hard wearing polyurethane single pack paint designed to seal and colour concrete floors. The product uses a high quality resin system with a fine textured finish so providing anti-slip properties for pedestrian traffic areas. Petrol and oil resistant, this product is ideal for general walkways, factory and garage floors and has excellent durability.

Nb. Whilst this product has excellent anti-slip properties and therefore provides enhanced slip resistance, it is not possible to guarantee a totally non-slip finish. The amount of slip resistance will be dependent on the conditions and any contaminants present.

Area of use: Interior and exterior applications not subject to rising damp (concrete should have a damp proof membrane). If in doubt tape a black plastic bag to the floor and leave it there for 24 hours, if there is any condensation on the underside of the bag there is an issue with trapped moisture or damp. Substrates: Concrete, stone and wooden floors Packing: 5 Litre and 20 Litre (4 x 5) 20 litre drums available to order (min order is 12 x 20) Physical Constants: Colours: Red (04C39), Green(14C39), Grey(00A05), Black, Blue(20D45) and Safety Yellow Finish: Semi gloss Volume solids: 50% Theoretical spreading rate: 12 -15 sq. metres per litre Actual Spreading rate: Typically 8-10 sq. metres per litre (this will vary depending on the porosity of the substrate) Flash point: 38C Specific gravity: 1.4 Dry to touch: 2 - 4 hours (20C) Over coating time: 16 - 48 hours

*The theoretical spreading rate has been calculated for the stated volume solids and dry film thickness. A practical

spreading rate will depend on the actual dry film thickness, the nature of the substrate, and the relevant consumption factor. The physical constants are subject to normal manufacturing tolerances.

Application Details: Application method: Brush/roller Conventional spray Airless spray Thinner: White Spirit Cleaning of tools: White Spirit Surface condition: The surface should be stable, firm, dry and free of dust, sand, loose old paint, dirt, grease and oil. New concrete should not be painted for at least 6-8 weeks after laying. Power floated (smooth & shiny concrete) floors should be acid etched or mechanically prepared to remove the shine and give some texture to the surface prior to be being sealed with the first 10%

New Venture Products Ltd

www.newventureproducts.co.uk

0845 430 4030

Product Information Polyurethane Anti-Slip Floor Polyurethane Anti-Slip Floor Paint

diluted coat. Careful note of the instructions should be taken when acid etching to ensure no residue is left which will affect the floor paint. Sealing/Priming: Bare concrete and other absorbent surfaces should be primed and sealed with the floor paint diluted by 10% with white spirit. The second coat should not be applied for at least 16 hours after the first. Preparation: When over coating previously painted floors any loose paint should be removed and existing paint lightly abraded, the surface should be clean, dry and free from dust and contaminants. If in doubt, particularly when being applied to large areas, a test patch should always be done first to check for adhesion. Warning - Do not apply too thickly (see recommended coverage figures) as this will adversely affect the strength and adhesion of the paint, it is better to apply more thin coats. Do Not use to fill holes or even up an uneven surface. Drying Times: Although the surface will be dry in approx 2 - 4 hours (20C) the second coat should not be applied for 16 hours (20C) but ideally before 120 hours. If the second coat is applied after 7 days intercoat adhesion will be improved if the surface is lightly scuffed first. The paint will however take 5 - 7 days to reach maximum strength and therefore we recommend that it is left for at least this period before receiving heavy use such as leaving a parked vehicle on it.

Nb. Whilst every effort is made to ensure consistency there can be slight colour variations between different batches. To ensure consistency we recommend that the final coat applied should all come from a single batch. When applying to large areas (50+ sq metres) or if you are in any doubt we always recommend that you put down a small test patch first in an inconspicuous area to check for adhesion and suitability.

See MSDS for further information. For additional guidance please contact New Venture Product Ltd.

New Venture Products Ltd

www.newventureproducts.co.uk

0845 430 4030

También podría gustarte

- Zinsser BrouchureDocumento2 páginasZinsser Brouchureislandboy33333Aún no hay calificaciones

- Anticorossive Epoxy FlooringDocumento2 páginasAnticorossive Epoxy Flooringtejas_tAún no hay calificaciones

- 0079 - Asian Wall PuttyDocumento5 páginas0079 - Asian Wall Puttypravi3434Aún no hay calificaciones

- Shield CreteDocumento2 páginasShield Cretechris77779Aún no hay calificaciones

- Tuffkote Protective CoatingsDocumento2 páginasTuffkote Protective CoatingsioginevraAún no hay calificaciones

- 11 EPB FLOOR Coating G 78 & M 86Documento2 páginas11 EPB FLOOR Coating G 78 & M 86shrikrishna rathodAún no hay calificaciones

- Specification For PaintingDocumento12 páginasSpecification For PaintingManvee Jain100% (1)

- Acrylic Resin Based Plaster Putty For Interior & Exterior: Green Building RatingDocumento2 páginasAcrylic Resin Based Plaster Putty For Interior & Exterior: Green Building RatingVetri Vel PrakashAún no hay calificaciones

- CMCI Floor Coat Seals, Cures & Dustproofs ConcreteDocumento2 páginasCMCI Floor Coat Seals, Cures & Dustproofs Concretepravi3434Aún no hay calificaciones

- Waterproof Concrete CoatingDocumento2 páginasWaterproof Concrete CoatingkalidindivenkatarajuAún no hay calificaciones

- ResiGard SL2Documento4 páginasResiGard SL2fhsn84Aún no hay calificaciones

- Hydroloc SmartcareDocumento2 páginasHydroloc SmartcareNikhil PatilAún no hay calificaciones

- Tractor EmulsionDocumento1 páginaTractor EmulsionMl JainAún no hay calificaciones

- Road Safety Booklet 30-10-2019Documento18 páginasRoad Safety Booklet 30-10-2019Salman AsadAún no hay calificaciones

- TDS Levelling - PlasterDocumento3 páginasTDS Levelling - PlasterNandhagopal DhandapaniAún no hay calificaciones

- Master Step Rubber Tile Installation GuideDocumento5 páginasMaster Step Rubber Tile Installation GuideShahid Basha SkAún no hay calificaciones

- Concrete FloorDocumento2 páginasConcrete FloorVasu LlanAún no hay calificaciones

- PaintmastercontractorstdsDocumento2 páginasPaintmastercontractorstdsMichael JoudalAún no hay calificaciones

- PaintmastersheentdsDocumento2 páginasPaintmastersheentdsMichael JoudalAún no hay calificaciones

- 0061 - Utsav Primer STDocumento2 páginas0061 - Utsav Primer STpravi3434Aún no hay calificaciones

- Paint Master Hi Cover - TDSDocumento2 páginasPaint Master Hi Cover - TDSMichael JoudalAún no hay calificaciones

- Clay Pattern Styling and Rigid Surface Casting in Today's Composite IndustryDocumento3 páginasClay Pattern Styling and Rigid Surface Casting in Today's Composite Industrybugsy77Aún no hay calificaciones

- Arocoat - Repair Paint Data SheetDocumento3 páginasArocoat - Repair Paint Data SheetIsboAún no hay calificaciones

- Super Cast Fosroc AdmixturesDocumento10 páginasSuper Cast Fosroc AdmixturesVedachalam ManiAún no hay calificaciones

- Asian Paints Tractor EmulsionDocumento2 páginasAsian Paints Tractor EmulsionAsian PaintsAún no hay calificaciones

- Al PUDocumento2 páginasAl PUpravi3434Aún no hay calificaciones

- Floor Coat Emulsion: Product DescriptionDocumento2 páginasFloor Coat Emulsion: Product DescriptionSubhajitAún no hay calificaciones

- PaintmasterultramatttdsDocumento2 páginasPaintmasterultramatttdsMichael JoudalAún no hay calificaciones

- Epoxy Painting Method GuideDocumento3 páginasEpoxy Painting Method GuideKaram MoatasemAún no hay calificaciones

- Anticorossive Aquaseal-Wb (Pu)Documento1 páginaAnticorossive Aquaseal-Wb (Pu)tejas_tAún no hay calificaciones

- Earthcote Tradition Product Datasheet 4 July 2012 V3Documento2 páginasEarthcote Tradition Product Datasheet 4 July 2012 V3guidogiglioAún no hay calificaciones

- PaintmasterroofpainttdsDocumento2 páginasPaintmasterroofpainttdsMichael JoudalAún no hay calificaciones

- ESD Flooring Installation GuideDocumento4 páginasESD Flooring Installation GuideSyed Fawad Hasan100% (1)

- Epoxy Grout DAVCODocumento2 páginasEpoxy Grout DAVCOcharibackupAún no hay calificaciones

- Car Parking System - 17.04.13Documento13 páginasCar Parking System - 17.04.13raj06740100% (1)

- Fairtop Fast Floor - Cementitious Self Levelling Flooring SystemsDocumento8 páginasFairtop Fast Floor - Cementitious Self Levelling Flooring SystemsfairmatechemicalAún no hay calificaciones

- Asianpaints Products Exterior Wall Putty1Documento3 páginasAsianpaints Products Exterior Wall Putty1Raj Kumar RijalAún no hay calificaciones

- Premium EmulsionDocumento1 páginaPremium Emulsionmuthiahmanikandan2032Aún no hay calificaciones

- PaintmastertextdsDocumento2 páginasPaintmastertextdsMichael JoudalAún no hay calificaciones

- Epoxy Resin Mortar for Concrete ProtectionDocumento2 páginasEpoxy Resin Mortar for Concrete ProtectionsudhialakkalAún no hay calificaciones

- Hydroloc SmartcareDocumento2 páginasHydroloc SmartcareAnkur TripathiAún no hay calificaciones

- Brush BondDocumento4 páginasBrush BondVenkata RaoAún no hay calificaciones

- Concrete Plaster Surface Finishing-Vetonit Finish WRDocumento1 páginaConcrete Plaster Surface Finishing-Vetonit Finish WRasif_rahman06Aún no hay calificaciones

- Polished PlasterDocumento3 páginasPolished PlasterZubair IrshadAún no hay calificaciones

- Hydroproof: Single Component Acrylic Polymer For Cement Based Waterproof Composite Coating MembraneDocumento2 páginasHydroproof: Single Component Acrylic Polymer For Cement Based Waterproof Composite Coating MembraneVenkata Raju KalidindiAún no hay calificaciones

- Super Sealer TDSDocumento2 páginasSuper Sealer TDSOmer TageldinAún no hay calificaciones

- Technical Data Sheet of EcocemDocumento2 páginasTechnical Data Sheet of EcocemJharna guchhaitAún no hay calificaciones

- Proposal - Ayush ParkDocumento25 páginasProposal - Ayush ParkAvinash PhaseAún no hay calificaciones

- High Build Epoxy SystemDocumento2 páginasHigh Build Epoxy SystemJonas TambunanAún no hay calificaciones

- Euco TopDocumento2 páginasEuco Toppravi3434Aún no hay calificaciones

- Paintmastertexture 7 TdsDocumento2 páginasPaintmastertexture 7 TdsMichael JoudalAún no hay calificaciones

- Detailers Dictionary Volume 2: The Industry StandardDe EverandDetailers Dictionary Volume 2: The Industry StandardAún no hay calificaciones

- How to Build a Simple Three Bedroom Shipping Container HouseDe EverandHow to Build a Simple Three Bedroom Shipping Container HouseCalificación: 4 de 5 estrellas4/5 (2)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionDe EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionAún no hay calificaciones

- Epoxy Resin Arts and Crafts for BeginnersDe EverandEpoxy Resin Arts and Crafts for BeginnersCalificación: 3 de 5 estrellas3/5 (5)

- How to Make Outdoor & Garden Furniture: Instructions for Tables, Chairs, Planters, Trellises & More from the Experts at American WoodworkerDe EverandHow to Make Outdoor & Garden Furniture: Instructions for Tables, Chairs, Planters, Trellises & More from the Experts at American WoodworkerCalificación: 4 de 5 estrellas4/5 (1)

- Analisys and application of dry cleaning materials on unvarnished pain surfacesDe EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesAún no hay calificaciones

- Fuel Savings and Efficiency CalculatorDocumento6 páginasFuel Savings and Efficiency Calculatorrajayu20002724Aún no hay calificaciones

- CHP SpreadsheetDocumento9 páginasCHP SpreadsheetSanjeev KachharaAún no hay calificaciones

- Energy Savings Calculator For Boiler ReplacementsDocumento14 páginasEnergy Savings Calculator For Boiler ReplacementsSanjeev KachharaAún no hay calificaciones

- HTTP Msdssearch - Dow.com PublishedLiteratureDOWCOM DH 003e 0901b8038003e635.PDF Filepath Liquidseps Pdfs Noreg 609-02017Documento8 páginasHTTP Msdssearch - Dow.com PublishedLiteratureDOWCOM DH 003e 0901b8038003e635.PDF Filepath Liquidseps Pdfs Noreg 609-02017Gheorghe IoanaAún no hay calificaciones

- Pre TreatmentDocumento2 páginasPre Treatmentrajayu20002724Aún no hay calificaciones

- CombustionDocumento35 páginasCombustionBernard Tan100% (1)

- Boiler Efficiency CalculationDocumento4 páginasBoiler Efficiency CalculationAhmad RahanAún no hay calificaciones

- FILMTEC Membranes System Operation: Record Keeping: Q TCF TCF P P P P P QDocumento4 páginasFILMTEC Membranes System Operation: Record Keeping: Q TCF TCF P P P P P QMohammad Ali ZamanAún no hay calificaciones

- Hydac HandbookDocumento22 páginasHydac Handbookrajayu20002724Aún no hay calificaciones

- System Design Suggestions For Troubleshooting SuccessDocumento2 páginasSystem Design Suggestions For Troubleshooting Successrajayu20002724Aún no hay calificaciones

- FILMTEC Membranes: Tech Manual ExcerptsDocumento5 páginasFILMTEC Membranes: Tech Manual ExcerptsgsaviAún no hay calificaciones

- Prevention of Fouling by OrganicsDocumento2 páginasPrevention of Fouling by Organicsrajayu20002724Aún no hay calificaciones

- Total Boiler SystemDocumento11 páginasTotal Boiler SystemWaleed EmaraAún no hay calificaciones

- Guidelines For Feedwater QualityDocumento2 páginasGuidelines For Feedwater Qualityrajayu20002724Aún no hay calificaciones

- Other Sanitization AgentsDocumento2 páginasOther Sanitization Agentsrajayu20002724Aún no hay calificaciones

- 600mw Operation ManualDocumento243 páginas600mw Operation Manualer4varun83% (6)

- PlantDocumento4 páginasPlanttatoo1Aún no hay calificaciones

- Flow FactorDocumento2 páginasFlow Factorrajayu20002724Aún no hay calificaciones

- 3 Collinsville Development StagesDocumento1 página3 Collinsville Development Stagesrajayu20002724Aún no hay calificaciones

- Boiler Water Treatment For Kiln DryingDocumento42 páginasBoiler Water Treatment For Kiln DryingSyavash EnshaAún no hay calificaciones

- fb026 enDocumento8 páginasfb026 enrajayu20002724Aún no hay calificaciones

- AMP103 Water Chemistry Final 130813Documento8 páginasAMP103 Water Chemistry Final 130813rajayu20002724Aún no hay calificaciones

- PSB 25Documento2 páginasPSB 25rajayu20002724Aún no hay calificaciones

- BSC Agri 5sem LabmanualDocumento47 páginasBSC Agri 5sem Labmanualrajayu20002724Aún no hay calificaciones

- Measurement Ranges-Once Through BoilerDocumento2 páginasMeasurement Ranges-Once Through Boilerrajayu20002724Aún no hay calificaciones

- 660 MW Vs 500 MWDocumento7 páginas660 MW Vs 500 MWrajayu20002724Aún no hay calificaciones

- 8 Collinsville Solar PV OperationsDocumento1 página8 Collinsville Solar PV Operationsrajayu20002724Aún no hay calificaciones

- Basic of Lubricants LubricationDocumento56 páginasBasic of Lubricants Lubricationkedir abduriAún no hay calificaciones

- Bearings in Centrifugal Pumps - Part IDocumento22 páginasBearings in Centrifugal Pumps - Part IAntonio SánchezAún no hay calificaciones

- Blended Distinctive EbookDocumento5 páginasBlended Distinctive Ebookrajayu20002724Aún no hay calificaciones

- Uee Notes-1Documento292 páginasUee Notes-1Mary Morse100% (1)

- Giacoqest 0164en-General CatalogueDocumento32 páginasGiacoqest 0164en-General CatalogueMartin CervasioAún no hay calificaciones

- Chem 111 Course Outline & RefferencesDocumento2 páginasChem 111 Course Outline & Refferenceswanluv123100% (1)

- Air Separation Unit PDFDocumento2 páginasAir Separation Unit PDFbodhi_cheAún no hay calificaciones

- ATP: The Cell's Energy CurrencyDocumento4 páginasATP: The Cell's Energy CurrencyVignesh100% (1)

- Sellos T-5610 T-5610QDocumento8 páginasSellos T-5610 T-5610QBenicio Joaquín Ferrero BrebesAún no hay calificaciones

- Class Xii 2016 2017 Main PDFDocumento16 páginasClass Xii 2016 2017 Main PDFsribalajicybercity100% (1)

- Evaluation of stucco binder for agglomeration in copper ore heap leachingDocumento8 páginasEvaluation of stucco binder for agglomeration in copper ore heap leachingDr. Khan MuhammadAún no hay calificaciones

- Irc 45 - 1972Documento36 páginasIrc 45 - 1972kapinjal_Aún no hay calificaciones

- GAMSAT TopicsDocumento7 páginasGAMSAT TopicsSewon KimAún no hay calificaciones

- Fractional Distillation: Experiment #5Documento14 páginasFractional Distillation: Experiment #5jamesAún no hay calificaciones

- Pelican Cases Catalog 2021Documento29 páginasPelican Cases Catalog 2021thanakornAún no hay calificaciones

- Newlands Law of Octaves Periodic TableDocumento5 páginasNewlands Law of Octaves Periodic TablePaarth Saxena X-B RNAún no hay calificaciones

- PT Cahayatiara Mustika Scientific Indonesia-Catalog 2016Documento212 páginasPT Cahayatiara Mustika Scientific Indonesia-Catalog 2016Dyah Noor Hidayati100% (1)

- Guided NotesDocumento4 páginasGuided NotesMahlodi LamolaAún no hay calificaciones

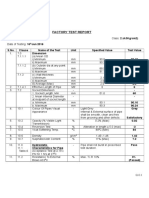

- FTRDocumento1 páginaFTRanon_127491670Aún no hay calificaciones

- Furnaces and BoilersDocumento23 páginasFurnaces and BoilersPraveen VaratharajanAún no hay calificaciones

- PILE FOUNDATION REPORTDocumento24 páginasPILE FOUNDATION REPORTGagan NagpalAún no hay calificaciones

- AucosticsDocumento98 páginasAucosticswendodavidAún no hay calificaciones

- Understanding the nonlinear dynamics of liquid flow with surge tanksDocumento12 páginasUnderstanding the nonlinear dynamics of liquid flow with surge tanksLouie Fajardo AbadAún no hay calificaciones

- Pla+phb Blend CompositeDocumento200 páginasPla+phb Blend Compositesush_24kumarAún no hay calificaciones

- Sae Ams 2418G-2006Documento9 páginasSae Ams 2418G-2006مرکز پژوهش متالورژی رازی RMRCAún no hay calificaciones

- Novaliches High School: 2. Dots in LEDS Represent A. Valence Electrons. B. Protons. C. Neutrons. D. ElectronsDocumento4 páginasNovaliches High School: 2. Dots in LEDS Represent A. Valence Electrons. B. Protons. C. Neutrons. D. ElectronsExtremelydarknessAún no hay calificaciones

- J. Chem. SOC.(A), 1971: Single-crystal Raman and Far-infrared Spectra of Tetrakis(thiourea)-nickel(ii) DichlorideDocumento3 páginasJ. Chem. SOC.(A), 1971: Single-crystal Raman and Far-infrared Spectra of Tetrakis(thiourea)-nickel(ii) DichlorideFernandaIbarraVázquezAún no hay calificaciones

- Presentacion CECABASE Rosario en InglésDocumento23 páginasPresentacion CECABASE Rosario en InglésLa FoliakAún no hay calificaciones

- Ap41s 81 2009Documento11 páginasAp41s 81 2009Anita VkAún no hay calificaciones

- Applications and Uncertainties Associated With Measurements Using FTIR SpectrometryDocumento37 páginasApplications and Uncertainties Associated With Measurements Using FTIR Spectrometrysalekojic5332Aún no hay calificaciones

- Factor Determination of Cerium Sulphate vs. Hydroquinone: Mettler ToledoDocumento3 páginasFactor Determination of Cerium Sulphate vs. Hydroquinone: Mettler ToledoBhupesh MulikAún no hay calificaciones

- ATP Synthesis and Oxidative Phosphorylation ExplainedDocumento5 páginasATP Synthesis and Oxidative Phosphorylation Explainedkman0722Aún no hay calificaciones