Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Scheme of Testing and Inspection For IS 613:2000

Cargado por

srj88eeeTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Scheme of Testing and Inspection For IS 613:2000

Cargado por

srj88eeeCopyright:

Formatos disponibles

BUREAU OF INDIAN STANDARDS (Central Marks Department - III)

Our Ref : CMD-III/16:613 Subject : Scheme of Testing and Inspection for IS 613:2000

17 Feb 2005

The Scheme of Testing and Inspection for IS 613:2000 Copper rods and bars for electrical purposes has been finalized as Doc : STI/ 613/2, Feb 2005 ( copy enclosed). The Finalized Document of immediate effect. STI stated above would come into force with

(C K VEDA) DCM-III Encl : as above Circulated to All ROs/BOs/IOs/BIS Labs Cc : CMD-I

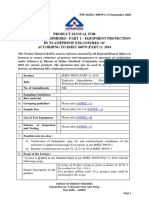

DOC:STI/613/2 February 2005 SCHEME OF TESTING AND INSPECTION FOR CERTIFICATION OF COPPER RODS AND BARS FOR ELECTRICAL PURPOSES ACCORDING TO IS 613:2000 (THIRD REVISION) 1. LABORATORY A laboratory shall be maintained which shall be suitably equipped and staffed where different tests given in the specification shall be carried out in accordance with the methods given in the specification. 2. TEST RECORDS - All records of tests, inspection and calibration shall be kept in suitable forms approved by the Bureau. 2.1 All testing apparatus/measuring instruments shall be periodically checked and calibrated and records of such checks/calibration shall be maintained. 2.2 Copies of any records and other connected papers that may be required by the Bureau shall be made available at any time on request. 3. QUALITY CONTROL It is recommended that, as far as possible, Statistical Quality Control (SQC) methods may be used for controlling the quality of the product during production as envisaged in this Scheme [See IS 397(Part I)::2003, IS 397(Part 2):2003 and IS 397(Part 3):2003]. 3.1 In addition, effort should be made to gradually introduce a Quality Management System in accordance with IS/ISO 9001.

4. STANDARD MARK The Standard Mark, as given in Column (1) of the First Schedule of the licence, shall be stamped on one of the ends of each copper rod and bar, provided always that copper rods/bar so marked conform to all the requirements of the specification. 4.1 OTHER MARKING - In addition, following information shall be given on suitable metal tag attached with each package: a) b) c) d) e) f) g) Name of the manufacturer and recognized trade mark, if any; Grade of material; Size ; Mass; Control Unit/Lot No.; Condition of supply; Date of Manufacture;

h)

Licence No. (CM/L..);

DOC:STI/613/2 February 2005 i) j) 5.0 For details of BIS Certification Scheme visit www.bis.org.in; and; Any information required by the purchaser;

Manufacturer may give all or some of the marking requirements on the products, in addition to metallic tage on the package if required.

6.0 LEVELS OF CONTROL - The tests, as indicated in Table 1 attached and at the levels of control specified therein, shall be carried out on the whole production of the factory which is covered by this scheme and appropriate records and charts maintained in accordance with paragraph 2.0 above. All the production which conforms to the Indian Standards and covered by the licence shall be marked with certification mark of the Bureau. 6.1 CONTROL UNIT Copper rods or Bars of one grade and temper & size manufactured from one heat shall constitute one control unit for the purpose of this scheme. 6.3 In respect of all other clauses of the specification the factory will maintain appropriate control and checks to ensure that their product conforms to the various requirements of this specification. 6.4 RAW MATERIALS - Routine analysis of each consignment of raw materials received in the factory, shall be carried out and proper records maintained. 7.0 REJECTIONS A separate record shall be maintained giving information relating to the rejection of the production not conforming to the requirements of the specification and the method of its disposal. Such material shall in no circumstances be stored together with that conforming to the specification. 8.0 SAMPLES The licensee shall supply, free of charge, the samples required in accordance with the Bureau of Indian Standards (Certification) Regulations, 1988, as subsequently amended, from the factory or godowns. The Bureau shall pay for the samples taken by it from the open market. 9.0 REPLACEMENT Whenever a complaint is received soon after the goods with Standard Marks have been purchased and used, and if there is adequate evidence that the goods have not been misused, defective goods or their components are

replaced or repaired free of cost by the licensee in case the complaint is proved to be genuine and the warranty period (where applicable) has not expired. The final authority to judge the conformity of the product to the Indian Standard shall be with the Bureau.

DOC:STI/613/2 February 2005 9.1 In the event of any damages caused by the goods bearing the Standard Mark, or claim being filed by the consumers against BIS Standard Mark and not conforming to the relevant Indian Standard, entire liability arising out of such non conforming product shall be of licensee and BIS shall not in any way be responsible in such cases. 10.0 STOP MARKING The marking of the product shall be stopped under intimation to the Bureau if, at any time, there is some difficulty in maintaining the conformity of their product to the specification, or the testing equipment goes out of order. The marking may be resumed as soon as the defects are removed under intimation to Bureau. 10.1 The marking of the product shall be stopped immediately if directed to do so by Bureau for any reason. The marking may then be resumed only after permission by the Bureau. The information regarding resumption of markings shall also be sent to the Bureau. 11.0 PRODUCTION DATA The licensee shall send to BIS as per the enclosed proforma-1 to be authenticated by a Chartered Accountant or by the manufacturer by giving an affidavit/undertaking, a statement of quantity produced, marked and exported by him and the trade value thereof at the end of each operative year of the licence. Table 1

DOC:STI/613/2 February 2005 IS 613:2000 COPPER RODS AND BARS FOR ELECTRICAL PURPOSES TABLE 1 LEVELS OF CONTROL (Para 6 of the Scheme of Testing and Inspection) TEST DETAILS Cl. Requirement Test Method Clause 6 8.1 & 8.2 Freedom from defect Chemical analysis 6 No. of Referen samples ce IS 3613 Each Rod/bar IS 440 1 IS 191(Pt. 5) or IS 191(Pt. 6) IS 1608 1 IS 1501 1 (Pts. 1 & 2) IS 1599 1 LEVELS OF CONTROL Fre-quency Remarks

Each Control Unit Each Heat

Visual Inspection No testing is required if the raw material is ISI Marked -

9.1

Tensile Test Hardness Bend test

Each Control Unit -do-do-

9.2

If agreed between purchaser manufacture

to the and

10

Dimensions

10.1, 10.2 & 10.3 11.1.1 or 11.1.2 & Table 5

IS 613

Each Control Unit

11

Electrical resistively test

IS 613 IS 3635

-do-

También podría gustarte

- Product Manual For Explosive Atmospheres - Part 1 - Equipment Protection by Flameproof Enlcosures "D" ACCORDING TO IS/IEC 60079 (PART 1) : 2014Documento7 páginasProduct Manual For Explosive Atmospheres - Part 1 - Equipment Protection by Flameproof Enlcosures "D" ACCORDING TO IS/IEC 60079 (PART 1) : 2014ranjith_007Aún no hay calificaciones

- QCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.Documento6 páginasQCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.abdul aziz100% (1)

- Salesforce Naming ConventionsDocumento25 páginasSalesforce Naming ConventionsRamAún no hay calificaciones

- Bureau of Indian Standards: Central Marks Department - IiiDocumento6 páginasBureau of Indian Standards: Central Marks Department - IiiVaiby CoolAún no hay calificaciones

- 814 PDFDocumento11 páginas814 PDFBrijesh SharmaAún no hay calificaciones

- 1363 Scheme of Testing of Hexagonal Bolts & NutsDocumento7 páginas1363 Scheme of Testing of Hexagonal Bolts & Nutsjra9090Aún no hay calificaciones

- 8887Documento7 páginas8887Aditya HundekarAún no hay calificaciones

- Sti 2062Documento7 páginasSti 2062fyzmfaAún no hay calificaciones

- StiDocumento5 páginasStiderabeasAún no hay calificaciones

- 14697Documento5 páginas14697BijuAún no hay calificaciones

- Sti4923 8 PDFDocumento7 páginasSti4923 8 PDFkprasad_56900Aún no hay calificaciones

- Sti - Is - 3589Documento5 páginasSti - Is - 3589hhr2412Aún no hay calificaciones

- Sti 2062Documento6 páginasSti 2062patrik710Aún no hay calificaciones

- Is 13849. 1993Documento6 páginasIs 13849. 1993poornachandraknAún no hay calificaciones

- Central Marks Department-Iii Our Ref: CMD-III/16:15490 30 Oct 2006 Subject: Sulphide Stress Cracking Resistance Test On CNG Cylinders As Per Is 15490:2004Documento9 páginasCentral Marks Department-Iii Our Ref: CMD-III/16:15490 30 Oct 2006 Subject: Sulphide Stress Cracking Resistance Test On CNG Cylinders As Per Is 15490:2004ravisharma1973Aún no hay calificaciones

- Is: 1592Documento4 páginasIs: 1592Daks ParkerAún no hay calificaciones

- Is Code For PSCDocumento9 páginasIs Code For PSCPooja UdupaAún no hay calificaciones

- CflsDocumento5 páginasCflsNeelam Ram MohanAún no hay calificaciones

- Quality Inspection and Testing of Household Sewing Machines HeadDocumento19 páginasQuality Inspection and Testing of Household Sewing Machines HeadHarshaDesuAún no hay calificaciones

- Our Ref: CMD-II (L) /16: 694: Central Marks Department-Ii (Legal)Documento12 páginasOur Ref: CMD-II (L) /16: 694: Central Marks Department-Ii (Legal)Pugalenthi SekarAún no hay calificaciones

- Is 4270Documento6 páginasIs 4270Punam RabhaAún no hay calificaciones

- Sti 2062 PDFDocumento7 páginasSti 2062 PDFNarendra VermaAún no hay calificaciones

- 3832 - 4-Chain Pulley BlockDocumento8 páginas3832 - 4-Chain Pulley BlockAshish PattanaikAún no hay calificaciones

- 2347Documento5 páginas2347Abhijeet MisraAún no hay calificaciones

- Sti 14220Documento5 páginasSti 14220Dgk RajuAún no hay calificaciones

- Is 13487 Isi Mark3Documento4 páginasIs 13487 Isi Mark3Vikas PhopaleAún no hay calificaciones

- Sti 3258Documento6 páginasSti 3258sutanuprojectsAún no hay calificaciones

- Is 9798Documento10 páginasIs 9798joysinhaAún no hay calificaciones

- Cylinders BIS 2Documento9 páginasCylinders BIS 2susheelAún no hay calificaciones

- DOC: STI/4985/10 September 2006Documento9 páginasDOC: STI/4985/10 September 2006Sunil Devdutt ThakoreAún no hay calificaciones

- 1855Documento5 páginas1855shashikant gaurAún no hay calificaciones

- STI/14846/1 Dec.2000Documento8 páginasSTI/14846/1 Dec.2000Tanmoy DuttaAún no hay calificaciones

- Sti 12823 1Documento4 páginasSti 12823 1raviteja036Aún no hay calificaciones

- STI59864Documento6 páginasSTI59864Paviter SinghAún no hay calificaciones

- PM Is 2067Documento8 páginasPM Is 2067Hexiqon LaboratoryAún no hay calificaciones

- Certification of Plywood For Concrete Shuttering WorkDocumento10 páginasCertification of Plywood For Concrete Shuttering WorkJGD123Aún no hay calificaciones

- PM - IS 374 Final - Compressed V2Documento9 páginasPM - IS 374 Final - Compressed V2bluewindinnovations2023Aún no hay calificaciones

- Scheme of Testing and Inspection For Certification of Carbon Steel Cast Billet Ingots Billets Blooms and Slabs For Re Rolling Into Seel For General Structural Purpose PDFDocumento6 páginasScheme of Testing and Inspection For Certification of Carbon Steel Cast Billet Ingots Billets Blooms and Slabs For Re Rolling Into Seel For General Structural Purpose PDFbipinagarwalAún no hay calificaciones

- GPH Proc Asst 00bop02 Ele 0001Documento103 páginasGPH Proc Asst 00bop02 Ele 0001Shuhan Mohammad Ariful HoqueAún no hay calificaciones

- Sti 87841Documento5 páginasSti 87841Surendra singh nathawatAún no hay calificaciones

- Is 16098 Part IIDocumento8 páginasIs 16098 Part IIMarketing Dept APEL 1100% (1)

- Sti-16289 18032015Documento7 páginasSti-16289 18032015PardeepGodara100% (1)

- STI IronBar NEW PDFDocumento13 páginasSTI IronBar NEW PDFLakshman KhanalAún no hay calificaciones

- Quality Control Manual: Function and ObjectiveDocumento6 páginasQuality Control Manual: Function and ObjectivechandraAún no hay calificaciones

- Total Technical Specs PDFDocumento259 páginasTotal Technical Specs PDFBhavesh KeraliaAún no hay calificaciones

- CM/PF 310 June 1989 Acceptance of Scheme of Testing and InspectionDocumento23 páginasCM/PF 310 June 1989 Acceptance of Scheme of Testing and InspectionGm BiosrAún no hay calificaciones

- Battery Charger TS Rev-0-31.12.22Documento29 páginasBattery Charger TS Rev-0-31.12.22DEVI PRASAD GREENSECUREAún no hay calificaciones

- FS 4003 - Naviational AidsDocumento15 páginasFS 4003 - Naviational Aidsrocket-vtAún no hay calificaciones

- Revised Draft Ammendment To IRS T29 MAR13Documento11 páginasRevised Draft Ammendment To IRS T29 MAR13Shipra MishraAún no hay calificaciones

- SATR-J-6406 Rev 0 PDFDocumento10 páginasSATR-J-6406 Rev 0 PDFAdel KlkAún no hay calificaciones

- Implementation Rules For Compulsory Certification of Electrical and Electronic ProductsDocumento14 páginasImplementation Rules For Compulsory Certification of Electrical and Electronic ProductsJayamali ArambewelaAún no hay calificaciones

- Technical Delivery Condition - GTU & SRUDocumento6 páginasTechnical Delivery Condition - GTU & SRUpratikbhardwajAún no hay calificaciones

- Sulphur Removal UnitDocumento73 páginasSulphur Removal UnitClaudio AmoreseAún no hay calificaciones

- Subject: STI For Hollow Steel Sections For Structural Use (Doc: STI /4923/9/october 2017) As Per IS 4923:2017Documento6 páginasSubject: STI For Hollow Steel Sections For Structural Use (Doc: STI /4923/9/october 2017) As Per IS 4923:2017TARUNKUMARAún no hay calificaciones

- Scheme of Testing and Inspection: According To IS 12950:1990Documento3 páginasScheme of Testing and Inspection: According To IS 12950:1990JeyaSeharan SAún no hay calificaciones

- Signal Directorate: Schedule of Technical Requirement (STR) For Signalling Cable For RailwaysDocumento14 páginasSignal Directorate: Schedule of Technical Requirement (STR) For Signalling Cable For Railwaysanon_485351313Aún no hay calificaciones

- CMD I 5 1Documento15 páginasCMD I 5 1Jyoti KushwahaAún no hay calificaciones

- QM SampleDocumento13 páginasQM SampleHoque AnamulAún no hay calificaciones

- ABS Cer'tDocumento3 páginasABS Cer'tgrenjithAún no hay calificaciones

- Calibaration Procedure Rev3Documento4 páginasCalibaration Procedure Rev3Zubair Ahmed KhaskheliAún no hay calificaciones

- D) Access Information Stored On Computer Files While Having A Limited Understanding of The Client's Hardware and Software FeaturesDocumento6 páginasD) Access Information Stored On Computer Files While Having A Limited Understanding of The Client's Hardware and Software FeaturesShanygane Delos SantosAún no hay calificaciones

- Asme B18.5.2.1M 1996Documento8 páginasAsme B18.5.2.1M 1996Jesse ChenAún no hay calificaciones

- Dr. Tadisina Kishen Kumar ReddyDocumento2 páginasDr. Tadisina Kishen Kumar ReddyReeta DuttaAún no hay calificaciones

- SGRAO Aircraft Operator Requirements V3.1Documento287 páginasSGRAO Aircraft Operator Requirements V3.1smr767Aún no hay calificaciones

- Quiz QuestionsDocumento8 páginasQuiz QuestionsSai NathAún no hay calificaciones

- Manufacturing Quality Process Engineer in Boston MA Resume Joseph MarkowiczDocumento2 páginasManufacturing Quality Process Engineer in Boston MA Resume Joseph MarkowiczJosephMarkowiczAún no hay calificaciones

- AGMA 925-A03 - Effect of Lubrification On Gear Surface Distress PDFDocumento58 páginasAGMA 925-A03 - Effect of Lubrification On Gear Surface Distress PDFAnonymous uL3JlWfh100% (6)

- Elements of An API 653 Tank InspectionDocumento4 páginasElements of An API 653 Tank Inspectioncamasa2011Aún no hay calificaciones

- World Audio Level Reference PDFDocumento1 páginaWorld Audio Level Reference PDFHector Herrera ChavezAún no hay calificaciones

- Gaurav Jain ResumeDocumento2 páginasGaurav Jain ResumeGaurav JainAún no hay calificaciones

- Milling MachinesDocumento18 páginasMilling Machinessamurai7_77100% (2)

- Daylight Reflecting SystemDocumento4 páginasDaylight Reflecting SystemSelva KumarAún no hay calificaciones

- OrgDocumento2 páginasOrgCariza Caballero100% (1)

- Designing Customer Focus at KONEDocumento15 páginasDesigning Customer Focus at KONETushar MalhotraAún no hay calificaciones

- Insulation Resistance NotesDocumento27 páginasInsulation Resistance NotessdvijayAún no hay calificaciones

- Config3 Vendor MasterDocumento17 páginasConfig3 Vendor Masteravi_sapmm123Aún no hay calificaciones

- Chapter 1Documento24 páginasChapter 1vovox1Aún no hay calificaciones

- Shielding RF Components at The Package LeveDocumento12 páginasShielding RF Components at The Package LeveSebastian ReguanAún no hay calificaciones

- Business PlanDocumento12 páginasBusiness PlanJhade Danes BalanlayAún no hay calificaciones

- RAK Maritime CityDocumento8 páginasRAK Maritime CityAnonymous 95dlTK1McAún no hay calificaciones

- Safe Work Method Statement WorksheetDocumento7 páginasSafe Work Method Statement WorksheetianllagasAún no hay calificaciones

- Hydraulic Breaker TOR Series: Break Anything... Except The BankDocumento6 páginasHydraulic Breaker TOR Series: Break Anything... Except The BankYeison RamirezAún no hay calificaciones

- Liebherr Customer Service Upgrade Kelly Visualization PDFDocumento4 páginasLiebherr Customer Service Upgrade Kelly Visualization PDFJuan Carlos Benitez MartinezAún no hay calificaciones

- Sap MM TutorialDocumento39 páginasSap MM Tutorialiqbal1439988Aún no hay calificaciones

- SAP Table RelationsDocumento16 páginasSAP Table Relationsanon_173235067Aún no hay calificaciones

- Advanced Control and Information Systems Handbook - 2003 (2003) (338s) PDFDocumento338 páginasAdvanced Control and Information Systems Handbook - 2003 (2003) (338s) PDFMatthew Irwin100% (1)

- L293d PDFDocumento17 páginasL293d PDF_BoxerAún no hay calificaciones

- S200 Acifm MNT 34 RPT XXXXXXX 01512Documento3 páginasS200 Acifm MNT 34 RPT XXXXXXX 01512fayasibrahimkuttyAún no hay calificaciones