Documentos de Académico

Documentos de Profesional

Documentos de Cultura

LPG Vaporizers

Cargado por

sizwehTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

LPG Vaporizers

Cargado por

sizwehCopyright:

Formatos disponibles

Alternate Energy Systems, Inc.

A Corporation devoted to Energy Oriented Needs

Technical Paper on LPG Vaporizers and LPG Vaporizer/Mixer Systems

INTRODUCTION Alternate Energy Systems, Inc., a corporation devoted to the solution of energy-oriented needs, represents the culmination of years of experience, knowledge, skill and proven results. We're a company operated by experts. People with a vast knowledge of the industry. People who are aware of energy problems - and know how to solve them. Every member of AES has been closely involved with the energy needs in the past and continues to offer a more valid and precise solution to the energy needs of the present and future. With total capability to handle your needs from start to finish, we are continuously aware that what we're doing is vital to the continued success and operation of those who use our equipment. For every dollar invested with an Alternate Energy System, we see to it that maximum return is realized quickly and efficiently. WHAT IS A PROPANE STANDBY PLANT? A "standby plant" - as the term implies, is something standing by to do a job. A propane standby plant, offered to industrial and utility users of natural gas, is a system that is an alternate source of energy in the event the natural gas source is curtailed or shutoff. While some facilities use oil as a standby plant, oil is not a direct replacement for natural gas and will not burn in natural gas burners or applications. Thus, oil requires a separate set of burners, controls and piping. Propane or LPG is an ideal standby fuel for natural gas because, propane when mixed with air, will duplicate the burning characteristics of

natural gas and allows the user to utilize existing natural gas burners, piping and controls. A propane system generally consists of: PROPANE STORAGE TANK(s); A PUMP to transfer LPG to the Vaporizer; A VAPORIZER to convert the liquid propane to a gas; A MIXER or BLENDER to mix the vaporized propane with air. WHY USE A STANDBY SYSTEM? While there are many reasons a standby system is used, the principal reason is insurance against interruption of normal natural gas supply. Another incentive is that many utility companies offer what is known as an "interruptible rate" to industrial customers. First - interruption of natural gas? Many are not aware that natural gas utilities purchase or contract from a pipeline, a certain amount of natural gas for a certain period. This supplies both residential users as well as industrial users. However, the residential user is the priority user and, during an unusually long winter or unexpected cold spells, the residential user will consume more natural gas than anticipated - leaving less for the industrial user. For the industrial user, not receiving their full requirement of natural gas can cause costly damage to parts and equipment if gas flow is interrupted at a critical moment or, it may even cause a complete plant shutdown. Utility firms, aware of the dilemma of industrial users, encourage the installation of some sort of standby system in the event natural gas is interrupted. As an incentive, most utility companies offer what is known as an "interruptible" rate to those with standby systems. This rate, usually substantially lower

TechPaper2.doc

Printed 2/15/00 6:17 PM

Alternate Energy Systems, Inc. 210 Prospect Park Peachtree City, GA 30269, USA

Phone (770) 487-8596 Fax (770) 631-4306 e-mail: info@altenergy.com http://www.altenergy.com

Technical Paper on LPG Vaporizers and LPG Vaporizer/Mixer Systems Page 2 of 2

than the "firm" rate, is enjoyed year around, even if the supply of natural gas is never interrupted. Should the utility company give notice of an interruption (sometimes less than 24 hours), the industrial facility continues operation by switching over to their standby system. Since the "interruptible rate" is enjoyed every day of the year, not just during cold months when gas is most critical, it is possible to amortize the cost of a standby facility, including the installation, over a very short period of time, usually in less than two years. WHAT IS A PEAKLOAD SHAVING PLANT? Peakload Shaving is a term used by the utility companies. As we said before, utilities purchase a certain amount of gas over a fixed period of time. The best laid plans cannot take into consideration unexpected cold spells, a burst line or other events that could happen to disrupt the planned quota. If the utility should need more gas than it has contracted, they pay a premium price if the gas is available, to begin with. So, to insure extra gas and avoid premium price for gas above the contracted amount, many utility companies use propane, mixed with air, to duplicate the BTU content of natural gas. This mixed gas is then used to supplement the utility's gas supply, allowing a more consistent fuel rate from their supplier and help meet peak demand loads. WHO USES A STANDBY PLANT? Utilities and municipalities, clay product manufacturers, glass makers, bakeries, metal processing firms, textile industries, chemical companies or, any industrial company that uses natural gas in any of its processes. WHAT IS LP-GAS? LP-Gas or LPG is the abbreviation for liquefied petroleum gas, with the most commonly known being propane and butane. At normal atmospheric pressure and temperatures, LP-Gas is in

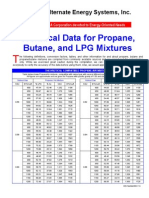

the gaseous state. However, it is converted to the liquid state with moderate pressure. This is why LPG is transported and stored in tanks or containers having at least 250 psi working pressure. The main source of LPG is natural gas and crude oil mixtures as they come from active oil and natural gas wells. Though propane is similar to natural gas (methane), propane has 2520 BTU per cubic foot, compared to 1050 BTU per cubic foot for natural gas. That is why propane, when mixed in proper proportion with air, is an excellent supplement or replacement to natural gas. Physical Properties of Propane: a) BTU per gal. = 91,500 b) Specific Gravity of liquid @ 60 F (Water = 1.0) = 0.509 c) Specific Gravity of gas @ 60 F (Air = 1.0) = 1.522 d) Cubic feet of gas per gal. = 36.20 e) Boiling Point of Liquid @ Sea Level when released to air = -44 F f) Vapor Pressure @ 60 F = 92 psi g) Vapor Pressure @ 100 F = 172 psi

WHAT IS A PROPANE VAPORIZER? A propane vaporizer is actually a boiler. However, instead of boiling water, it boils propane or other LPG. It may sound strange that heat is required to vaporize propane when propane will boil (and evaporate) at - 44 F but, when propane vaporizes by expansion alone, it causes a refrigeration action that would freeze valves and burner nozzles. Therefore, heat is required to offset the refrigeration action. There are two types of LPG vaporizers. A direct fired type uses a portion of the propane it vaporizes to supply the heat for the vaporization process. The indirect fired type uses an outside source of heat, such as steam, hot water, or electricity, to vaporize the propane.

Alternate Energy Systems, Inc. 210 Prospect Park Peachtree City, GA 30269, USA

Phone (770) 487-8596 Fax (770) 631-4306 e-mail: info@altenergy.com http://www.altenergy.com

TechPaper2.doc

Printed 2/15/00 6:17 PM

Technical Paper on LPG Vaporizers and LPG Vaporizer/Mixer Systems Page 3 of 3

MIXERS AND BLENDERS After the liquid propane has been vaporized, it needs to be mixed in proper proportion with air to duplicate the characteristics of natural gas. This is where mixers and blenders come in. There are several methods to mix air and LPG vapor but, probably the most simple method is to use a venturi and a nozzle. This method, as well as other methods, holds very accurate air-to-fuel ratios through a narrow range. This type mixer does not generally require compressed air for operation. However, the maximum achievable system pressure is somewhat limited. The mixture of air and vapor is fed into a surge tank, where it is maintained at a set pressure, and then drawn from the surge tank for use. This type system is usually recommended for intermittent periods of use and is very simple to operate. Blenders and modulating proportioning mixers are more complex but, are accurate and capable of mixing propane with air in large volumes at high pressure. These systems are recommended for continuous or long periods of usage, and are ideally suited for peakload shaving and larger installations. Regardless of the type vaporizer and mixer, a standby system can be designed for the requirements of small users, or the requirements of large industrial and utility users. In these times of uncertain oil prices and supplies, a standby system should be considered by all natural gas users. Just like we keep a spare tire for our automobile in the event of a flat, a standby system is a spare fuel supply in the event natural gas is interrupted or demand cannot be met.

(FM) or Industrial installations.

Risk

Insurers

(IRI)

We, as a manufacturer, go far beyond the requirements and codes and are continually working to produce equipment with the most modern engineering techniques available. DIRECT FIRED VAPORIZERS Requiring no electrical source for operations, the direct fired vaporizer is manufactured in capacities of 50, 80, 120, 160, 240, 360 and 480 gallons per hour propane vaporization at 0 F inlet temperature. Featuring a unique primary and secondary air burner that assures quick ignition, there are no openings or louvers at the base of the unit which could cause pilot outage problems. The units are manufactured with a bronze/brass liquid inlet valve, dual liquid level control to prevent liquid carryover, and stainless steel ball float with 600 psi pressure rating. Encased in a durable steel sheet metal cabinet, the door is easily removed for simple access and maintenance to burner assembly and temperature control valve. The vaporizing tube and all propane piping conform to the standards of Section VIII, Division I of the ASME Boiler & Pressure Vessel Code, NFPA #58, and are approved for Factory Mutual (FM) or Industrial Risk Insurers (IRI) installations. Model Number (AE) designates gallons per hour propane vaporization at 0 F inlet temperature. WATER BATH VAPORIZERS The horizontal water bath vaporizers are rectangular in design, with top and sides insulated with fiber board insulation to hold water bath temperature, and are covered with aluminum panels. The vaporizing tube and all propane piping conform to the standards of the ASME Boiler and Pressure Vessel Code, NFPA #58 and are approved for Factory Mutual (FM) or Industrial Risk Insurers (IRI) installations. Using a mixture of water and antifreeze solution as a heat exchange medium, the units are skid mounted, factory tested prior to shipment, ready for connection to properly sized electrical, liquid

ALTERNATE ENERGY SYSTEMS' VAPORIZERS

Printed 2/15/00 6:17 PM

Alternate Energy Systems manufactures a complete line of liquid LPG vaporizers (direct fired, indirect fired) in capacities from 80 GPH to 5500 GPH. The vaporizers are manufactured to the rigid codes of the American Society of Mechanical Engineers (ASME), latest edition of NFPA #58, and are approved for Factory Mutual

TechPaper2.doc

Alternate Energy Systems, Inc. 210 Prospect Park Peachtree City, GA 30269, USA

Phone (770) 487-8596 Fax (770) 631-4306 e-mail: info@altenergy.com http://www.altenergy.com

Technical Paper on LPG Vaporizers and LPG Vaporizer/Mixer Systems Page 4 of 4

propane inlet, and vapor outlet. The model number (WB) designates gallons per hour propane vaporization at 0 F inlet temperature. MODEL WB-200 THRU WB-350 These models are manufactured with a venturi type burner, standing pilot, and thermocouple. The burner controls are enclosed for protection from the elements. Standard safety devices include: (1) failsafe burner and pilot controls, (2) high water bath temperature limit, (3) low water limit, (4) low propane temperature switch, and (5) water temperature control. Electrical requirements are AC 120/220 V 50/60 Hz, 15 A, single phase. MODEL WB-450 THRU WB-2000 These models are manufactured with a power type burner, controlled by a flame safeguard system. The burner controls are enclosed for protection from the elements. Complete with first and second stage burner regulation, standard safety devices include: (1) high water bath temperature safety, (2) low water level safety, (3) flame failure lockout, (4) combustion air flow switch, (5) low burner gas pressure safety, and (6) high burner gas pressure safety. Failure on any of these conditions will cause the system to lockout and to sound an alarm. Electrical requirements are AC 120/220 V 50/60 Hz, 15 A, single phase. MODEL WB-2200 THRU WB-55OO These models are manufactured with a Power type burner controlled by a programmer with burner controls, which is enclosed for protection from the elements. Complete with first and second stage burner regulation, standard safety devices include: (1) high water bath temperature safety, (2) low water level safety, (3) flame failure lockout, (4) combustion air flow switch, (5) low burner gas pressure safety and (6) high burner gas pressure safety. Failure on any of these conditions will cause the unit to lock out and sound an alarm. Electrical requirements: AC 380/460 V 50/60 Hz, three phase. Alternate Energy Systems is supplying a step-down transformer for the control circuits.

STEAM VAPORIZERS Alternate Energy Systems has a complete line of vertical steam vaporizers in capacities of 40 to 2700 gallons per hour. The steam tube is of multipass design to transfer maximum heat to the liquid with tube bundle. All propane piping is conforming to the ASME Boiler and Pressure Vessel Code. The steam vaporizers are complete with steam temperature regulator, electric liquid level control, liquid inlet valve, solenoid valve, steam trap and steam back check valve. ELECTRIC VAPORIZERS Alternate Energy Systems has just introduced its newest unit, the LECTRAPAK electric vaporizer. Utilizing electric resistance heaters and designed for safety and dependability, the system meets all requirements of NFPA Pamphlet #58. LECTRAPAK is complete with liquid inlet solenoid valve, approved for LP-Gas at 250 psig and ASME approved safety relief valve. All electrical meets the requirements of NEC 70 for Class I, Group D, Division II locations. The vaporizer has full 100% turndown capability and is available in capacities of 25 kg/h and 50 kg/h.

ALTERNATE ENERGY SYSTEMS' MIXERS

Alternate Energy Systems, Inc. manufactures a complete line of propane-air blending and mixing systems, ranging in capacity from 7 MM BTU to 500 MM BTU per hour. Our complete line of venturi mixers and POM Mixers utilize the finest quality material and knowledge to meet the requirement of agencies and insurance companies governing the LPG industry. VENTURI MIXERS Intended and designed for outside service, these mixing systems only require 115 volt,

Alternate Energy Systems, Inc. 210 Prospect Park Peachtree City, GA 30269, USA

Phone (770) 487-8596 Fax (770) 631-4306 e-mail: info@altenergy.com http://www.altenergy.com

TechPaper2.doc

Printed 2/15/00 6:17 PM

Technical Paper on LPG Vaporizers and LPG Vaporizer/Mixer Systems Page 5 of 5

single phase electrical for operation. Using pressurized propane vapor through a venturi arrangement to inspirate air, the BTU content of the mixture is determined by regulated propane vapor pressure. The pressure in the integral surge tank is monitored by pressure switches. If the pressure drops below factory-set, customeradjustable setpoints, the venturi mixer is cycled on until the system pressure is again above the setpoint. Should the system pressure drop further, additional venturi mixers (in multi-venturi systems) are activated. Systems with capacities of 30 MM BTU per hour and higher use electronic pressure transducers and a programmable logic controller (PLC) instead of the mechanical pressure switches. The skid mounted systems are complete with surge tank, blow down, safety relief valve protection, high and low mix gas safety, low propane pressure safety and dual check valve system. Solenoid valves are explosion proof, and pressure switches and electronic pressure transducers are of standard type. All systems are manufactured to the requirements of the ASME code, latest edition of NFPA #58, and approved for Factory Mutual (FM) or Industrial Risk Insurers (IRI) installations. The Model number (HVS) of the venturi system designates millions of BTU per hour propane-air mixture. Standard models have an output pressure of 5 psi propane-air mixture. The output pressure can be adjusted between 4-9 psi. High pressure models with output pressure from 10 to 50 psi propane-air mixture are available and require compressed air for operation. PISTON OPERATED MIXERS P.O.M. The simplicity of Alternate Energy Systems' P.O.M. provide the ultimate in reliability and operation. Manufactured to meet or exceed industry specifications set forth by the ASME Boiler and Pressure Vessel Code and latest edition of NFPA #58, these systems require compressed air for operation. Using a uniquely designed rotatable piston valve to control flow, mixed gas and regulate the mixed gas BTU content, these units are virtually maintenance free and eliminate problems and restrictions

commonly associated with diaphragms and piston rings of conventional mixers. Once set, the unit will mix two gases at the same ratio, regardless of downstream demand. The units are supplied with LPG regulator, compressed air regulator, safety relief valve protection on the mixed gas line, and check valves on the air and propane inlet to prevent backflow. Standard units include a general purpose first outage control panel with PLC and electronic pressure transducers. They are designed to shut down in the event of (1) high mixed gas pressure, (2) low mixed gas pressure, (3) low propane vapor pressure, (4) low air pressure, and (5) excess differential pressure (gas-to-air). Failure on any of the conditions will cause the system to shut down. The cause of the failure will be indicated on the first outage control panel. The mixer remains in shutdown status until manually restarted. When used with the optional "Accu-Blend" system (a solid state controller combined with a signal from a gravitometer, calorimeter, Wobbe Index Meter or other BTU measuring device), the system will automatically control the BTU output.

ALTERNATE ENERGY SYSTEMS' MODULE UNITS

Alternate Energy Systems, Inc. manufactures the most complete line of packaged standby equipment available in the industry. These packages, complete with interconnecting piping and wiring, are ready for connection to liquid propane inlet, properly sized electrical, and mixed gas outlet. These skid mounted packages can be factory or field modified to accept flow control systems, specific gravity meter, special annunciator panels, or a large number of other options to allow the customization of any system to meet any specific specification.

TechPaper2.doc

Printed 2/15/00 6:17 PM

Alternate Energy Systems, Inc. 210 Prospect Park Peachtree City, GA 30269, USA

Phone (770) 487-8596 Fax (770) 631-4306 e-mail: info@altenergy.com http://www.altenergy.com

Technical Paper on LPG Vaporizers and LPG Vaporizer/Mixer Systems Page 6 of 6

DIRECT FIRED VAPORIZER WITH VENTURI MIXER MODULE These skid mounted, packaged systems utilize a direct fired vaporizer (or combination of vaporizers) with a venturi type mixing system. Designed for capacities ranging from 7 MM BTU to 40 MM BTU per hour, the units are manufactured to meet or exceed requirements of the ASME Pressure Vessel Code and latest edition of NFPA Pamphlet #58. Intended for intermittent service, the units are approved for Factory Mutual(FM) or Industrial Risk Insurers (IRI) installations. Standard design output pressure between 4 and 9 psi. Higher pressures of 10 to 50 psi are also available and require compressed air for operation. The vaporizer model number (AE) designates gallons per hour propane vaporization at 0 F inlet temperature, and the mixer model (HVS) designates millions of BTU per hour propane-air mixture. Models with capacity requirements of more than 120 GPH use a series of two or more vaporizers, manifolded together for correct GPH. Electrical requirements are AC 115/220 V, 50/60 Hz, single phase. WATER BATH VAPORIZER WITH VENTURI MIXER PACKAGE These skid mounted, packaged systems utilize a horizontal water bath type vaporizer with venturi type mixing system and are designed for capacities of 14 MM BTU to 250 MM BTU per hour. Manufactured to meet or exceed requirements of the ASME Pressure Vessel Code and latest edition of NFPA Pamphlet #58, they are approved for Factory Mutual (FM) or Industrial Risk Insurers (IRI) installations. Standard design output pressure between 4 and 9 psi propane-air mixture. Higher pressures of 10 to 50 psi are also available and require compressed air for operation. The vaporizer model number (WB) designates gallons per hour propane vaporization at 0 F inlet temperature, and the mixer model (HVS) designates millions of BTU per hour propane-air mixture. Electrical requirements vary with vaporizer/mixer size. The model number for the capacity requirement governs the type of

vaporizer, burner, and safety features. Refer to Sections Vaporizers and Mixers for more information. WATER BATH VAPORIZER MIXER PACKAGE WITH POM

These skid mounted, packaged systems utilize the water bath vaporizer and piston operated mixing system and are designed for capacities of 20 MM BTU to 500 MM BTU per hour. Complete with interconnecting piping and wiring, they are ready for connection to liquid propane inlet, properly sized electrical and mixed gas outlet. Requiring clean, dry compressed air for operation, the mixing system is usually mounted on top of the water bath vaporizer. Applicable for continuous duty or total stand-by, the units are designed for 20:1 turndown ratio. Complete with first outage annunciation, the systems have automatic safety shutdown with manual re-start. The vaporizer model number (WB) designates gallons per hour propane vaporization at 0 F inlet temperature, and the mixer is sized according to millions of BTU per hour propane-air mix requirements and system pressure requirements. Refer to Sections Vaporizers and Mixers for more information. OTHER MODULE UNITS Many of the vaporizers and mixing/blending systems manufactured by Alternate Energy Systems, can be manufactured inside portable, prefabricated buildings; palletized on structural steel skids to include compressors; or customized to meet the requirement of any user. For more information, contact your area distributor or the factory.

Alternate Energy Systems, Inc. 210 Prospect Park Peachtree City, GA 30269, USA

Phone (770) 487-8596 Fax (770) 631-4306 e-mail: info@altenergy.com http://www.altenergy.com

TechPaper2.doc

Printed 2/15/00 6:17 PM

Technical Paper on LPG Vaporizers and LPG Vaporizer/Mixer Systems Page 7 of 7

ALTERNATE ENERGY SYSTEMS' ACCESSORIES

Alternate Energy Systems has a complete line of accessories and LPG equipment to compliment and complete any propane standby system. We manufacture or carry a complete line of pump packages, valves, controls, metering systems, flow recorder/controller systems and tie-in assemblies.

Printed 2/15/00 6:17 PM

All equipment manufactured by Alternate Energy Systems is available in various configurations and with various options. Please consult your area distributor or the factory for your specific requirements. Alternate Energy Systems reserves the right to make changes or add improvements without notice and without accruing any obligation to make such changes or add such improvements to previously sold product.

TechPaper2.doc

Alternate Energy Systems, Inc. 210 Prospect Park Peachtree City, GA 30269, USA

Phone (770) 487-8596 Fax (770) 631-4306 e-mail: info@altenergy.com http://www.altenergy.com

Technical Paper on LPG Vaporizers and LPG Vaporizer/Mixer Systems Page 8 of 8

Alternate Energy Systems, Inc. 210 Prospect Park Peachtree City, GA 30269, USA

Phone (770) 487-8596 Fax (770) 631-4306 e-mail: info@altenergy.com http://www.altenergy.com

TechPaper2.doc

Printed 2/15/00 6:17 PM

También podría gustarte

- PropaneDocumento20 páginasPropaneNicolae MarinAún no hay calificaciones

- LNG Vaporization PDFDocumento18 páginasLNG Vaporization PDFihllhm100% (1)

- LNG Vaporizer PDFDocumento15 páginasLNG Vaporizer PDFIqbal MuhammadAún no hay calificaciones

- Vapor Recovery Unit (VRU) Principles: Oil Storage Vapor PressureDocumento5 páginasVapor Recovery Unit (VRU) Principles: Oil Storage Vapor PressureRicardo BecAún no hay calificaciones

- Simple Coil Vaporizer Converts LNG to GasDocumento4 páginasSimple Coil Vaporizer Converts LNG to GasSharon Lambert0% (1)

- Full Thesis PDFDocumento109 páginasFull Thesis PDFTanjib Rahman NiloyAún no hay calificaciones

- BOIL OFF GAS ANALYSISDocumento8 páginasBOIL OFF GAS ANALYSISJetul PatelAún no hay calificaciones

- Vaporizer SDocumento9 páginasVaporizer SdishankmpatelAún no hay calificaciones

- Stratification and Rollover in LNG TanksDocumento14 páginasStratification and Rollover in LNG Tanksleak100% (2)

- LPG Storage & Transfer ProceduresDocumento26 páginasLPG Storage & Transfer ProceduresKuldeepsingh Chandel100% (1)

- Simplify BOG Recondenser Design and OperationDocumento20 páginasSimplify BOG Recondenser Design and OperationvalmaxjeonAún no hay calificaciones

- Minimum Maximum LPG Energy Content (Btu/f)Documento5 páginasMinimum Maximum LPG Energy Content (Btu/f)Mirza Aatir SalmanAún no hay calificaciones

- Best Available Techniques For Hydrogen Production by Steam Methane ReformingDocumento18 páginasBest Available Techniques For Hydrogen Production by Steam Methane ReformingDuy NguyễnAún no hay calificaciones

- Natural Gas Production, Transportation - StorageDocumento36 páginasNatural Gas Production, Transportation - StorageNeeraj YadavAún no hay calificaciones

- LNG ExampleDocumento48 páginasLNG ExampleHeat.MotionAún no hay calificaciones

- LPG Tank Commissioning Training NotesDocumento32 páginasLPG Tank Commissioning Training NotesKajubi Edris100% (1)

- Safety Aspects of LNGDocumento10 páginasSafety Aspects of LNGNeil AlexAún no hay calificaciones

- Design NGV Mother and Daughter StationsDocumento2 páginasDesign NGV Mother and Daughter StationsShyam Prasad K SAún no hay calificaciones

- LNG Pumps, CMDocumento11 páginasLNG Pumps, CMRachitAún no hay calificaciones

- Day 04 Maintenance of LPG SystemDocumento11 páginasDay 04 Maintenance of LPG Systemkmas1612Aún no hay calificaciones

- Understand LNG RPTDocumento38 páginasUnderstand LNG RPTNoel ÑiquenAún no hay calificaciones

- Intertanko Gas and Marine Seminar: Blending/Commingling of LPG Cargoes On Board Gas CarriersDocumento19 páginasIntertanko Gas and Marine Seminar: Blending/Commingling of LPG Cargoes On Board Gas Carriersmouloud miloud100% (1)

- Practical water and gas systems site visitsDocumento26 páginasPractical water and gas systems site visitsCobra_007Aún no hay calificaciones

- LPGDocumento8 páginasLPGraritylimAún no hay calificaciones

- Ftops 2a - LPG-LNG Hazards and ControlDocumento26 páginasFtops 2a - LPG-LNG Hazards and ControlmyscriblkAún no hay calificaciones

- The Red Book MY3Documento47 páginasThe Red Book MY3Syed Arsalan AfsarAún no hay calificaciones

- Gas Properties: Molecular WeightDocumento2 páginasGas Properties: Molecular WeightDamar WibisonoAún no hay calificaciones

- Design of LNG Plant Facilities.: N.Bandyopadhyay - Consulting EngineerDocumento6 páginasDesign of LNG Plant Facilities.: N.Bandyopadhyay - Consulting EngineerHoàng KakaAún no hay calificaciones

- Cci LNG GuideDocumento28 páginasCci LNG GuidesabinvargheseAún no hay calificaciones

- Environmental Protection TechnologiesDocumento4 páginasEnvironmental Protection TechnologiesKostyantyn DrobotAún no hay calificaciones

- LPG Project 3Documento13 páginasLPG Project 3Jehirul IslamAún no hay calificaciones

- LPG Leakage & DetectionDocumento3 páginasLPG Leakage & DetectionSravan GopuAún no hay calificaciones

- 5) Ammonia Supply Systems For SCRDocumento63 páginas5) Ammonia Supply Systems For SCRleanhdang100% (1)

- Fire Prevention and Fighting EssentialsDocumento25 páginasFire Prevention and Fighting Essentialsmih abdouAún no hay calificaciones

- Cryogenic Refrigeration Cycle For Re-Liquefaction of LNG Boil-Off GasDocumento74 páginasCryogenic Refrigeration Cycle For Re-Liquefaction of LNG Boil-Off Gasعبد الحق قنيشAún no hay calificaciones

- Boiler Operation Made Easy - Procedure For Starting and Stopping A Boiler PDFDocumento13 páginasBoiler Operation Made Easy - Procedure For Starting and Stopping A Boiler PDFDavid WilliamsAún no hay calificaciones

- LNG Tank Design Analysis with LUSASDocumento7 páginasLNG Tank Design Analysis with LUSASMelvin MagbanuaAún no hay calificaciones

- Submerged Motor LNG Pumps Used in Send-Out SystemsDocumento6 páginasSubmerged Motor LNG Pumps Used in Send-Out SystemscsAún no hay calificaciones

- #To Study On Boiler Selection For "Process Industry" (Minor Project 3rd Year)Documento34 páginas#To Study On Boiler Selection For "Process Industry" (Minor Project 3rd Year)BHUSHAN MESHRAMAún no hay calificaciones

- Engineering Standard For Design LPG UnitsDocumento13 páginasEngineering Standard For Design LPG Unitslutfi awn100% (2)

- Manage diesel safely undergroundDocumento11 páginasManage diesel safely undergroundErwinApriandiAún no hay calificaciones

- A Project Work: Study of Carbon Emission in Transportation ProblemDocumento37 páginasA Project Work: Study of Carbon Emission in Transportation ProblemGaurav BajpaiAún no hay calificaciones

- Crude Oil Tank Mixer Data SheetDocumento3 páginasCrude Oil Tank Mixer Data Sheetsiska bedegul100% (1)

- Alternatives Considered for LNG Terminal TechnologiesDocumento4 páginasAlternatives Considered for LNG Terminal TechnologiesamirlngAún no hay calificaciones

- Simplify BOG Recondenser Design and OperationDocumento8 páginasSimplify BOG Recondenser Design and OperationWilfredo Suarez TorresAún no hay calificaciones

- Comm-Op Aspect Refrigerated LPG TerminalDocumento11 páginasComm-Op Aspect Refrigerated LPG TerminalMikiRoniWijayaAún no hay calificaciones

- Simple Method For Calculation of Cryogenic Transfer Line Cool DownDocumento8 páginasSimple Method For Calculation of Cryogenic Transfer Line Cool DownIgnacio ChaparroAún no hay calificaciones

- CNG Cylinder and LNG Tank Technology: Number 62 April 2012Documento36 páginasCNG Cylinder and LNG Tank Technology: Number 62 April 2012mihailspiridonAún no hay calificaciones

- Vol 4 SNG and LPG Systems OverviewDocumento57 páginasVol 4 SNG and LPG Systems OverviewHenry Suarez100% (3)

- Oil Refinery ProcessDocumento44 páginasOil Refinery ProcessJunaid IqbalAún no hay calificaciones

- 20170406-FINAL+LNG+EHS+Guideline April+2017Documento24 páginas20170406-FINAL+LNG+EHS+Guideline April+2017alyshahAún no hay calificaciones

- Design and Assessment of A Membrane and Absorption Based Carbon Dioxide Removal Process For Oxidative Coupling of MethaneDocumento11 páginasDesign and Assessment of A Membrane and Absorption Based Carbon Dioxide Removal Process For Oxidative Coupling of MethanechristiancandidoAún no hay calificaciones

- KG32903 Process Control and InstrumentationDocumento40 páginasKG32903 Process Control and InstrumentationhellothereAún no hay calificaciones

- Ammonia Sphere, Anhydrous Ammonia Spherical TanksDocumento3 páginasAmmonia Sphere, Anhydrous Ammonia Spherical Tanksdevika11Aún no hay calificaciones

- Hydrogen Cylinders and Transport Vessels: IGC Doc 100/03/EDocumento42 páginasHydrogen Cylinders and Transport Vessels: IGC Doc 100/03/EMomous Kamel OussaditAún no hay calificaciones

- Propane Storage Tanks and Vaporizers ExplainedDocumento11 páginasPropane Storage Tanks and Vaporizers ExplainedNicolae MarinAún no hay calificaciones

- POM BLENDING SYSTEMSDocumento8 páginasPOM BLENDING SYSTEMSpablo292Aún no hay calificaciones

- SNG From LPG and Air MixtureDocumento2 páginasSNG From LPG and Air Mixturerizkboss8312Aún no hay calificaciones

- Economizer Cond DOE 26bDocumento2 páginasEconomizer Cond DOE 26bBao NguyenAún no hay calificaciones

- SPE-172745-MS Innovative, Cost Effective and Simpler Technology To Recover Flare GasDocumento21 páginasSPE-172745-MS Innovative, Cost Effective and Simpler Technology To Recover Flare Gaswhoisme100% (1)

- Rubis Terminal GBDocumento21 páginasRubis Terminal GBsizwehAún no hay calificaciones

- Supporting Supply Chain Planning & SchedulingDocumento8 páginasSupporting Supply Chain Planning & SchedulingsizwehAún no hay calificaciones

- Roll Up SerrandaDocumento9 páginasRoll Up SerrandasizwehAún no hay calificaciones

- Wispeco Aluminium ProfilesDocumento22 páginasWispeco Aluminium ProfilesPatrick153Aún no hay calificaciones

- Trollope Mining ServicesDocumento3 páginasTrollope Mining ServicessizwehAún no hay calificaciones

- Vidagas LPGDocumento29 páginasVidagas LPGsizwehAún no hay calificaciones

- Mvelaserve ListingDocumento154 páginasMvelaserve ListingsizwehAún no hay calificaciones

- Trollope Mining ServicesDocumento6 páginasTrollope Mining ServicessizwehAún no hay calificaciones

- Mocambique Economic OutlookDocumento14 páginasMocambique Economic OutlooksizwehAún no hay calificaciones

- Evaluation of Compressed Natural Gas Fueling SystemsDocumento8 páginasEvaluation of Compressed Natural Gas Fueling SystemssizwehAún no hay calificaciones

- Mvelaphanda CircularDocumento134 páginasMvelaphanda CircularsizwehAún no hay calificaciones

- Mvela GroupDocumento97 páginasMvela GroupsizwehAún no hay calificaciones

- Mocambique EIA RequirementsDocumento23 páginasMocambique EIA Requirementssizweh100% (1)

- Fuel Price WorldwideDocumento7 páginasFuel Price WorldwideSoleai CoopAún no hay calificaciones

- Sustaining The ExpansionDocumento15 páginasSustaining The ExpansionsizwehAún no hay calificaciones

- Corken LPG Pumps and CompressorsDocumento24 páginasCorken LPG Pumps and Compressorssizweh100% (2)

- Sweetening LPG With AminesDocumento8 páginasSweetening LPG With AminessizwehAún no hay calificaciones

- Mocambican Economic OutlookDocumento11 páginasMocambican Economic OutlooksizwehAún no hay calificaciones

- LPG Vaporizer Air Mixing SystemsDocumento8 páginasLPG Vaporizer Air Mixing SystemssizwehAún no hay calificaciones

- Technical Data For LPGDocumento4 páginasTechnical Data For LPGsizwehAún no hay calificaciones

- LPG Blackmer PumpsDocumento16 páginasLPG Blackmer Pumpssizweh100% (1)

- LPG AccesoriesDocumento4 páginasLPG AccesoriessizwehAún no hay calificaciones

- Price Capping MechanismDocumento14 páginasPrice Capping MechanismsizwehAún no hay calificaciones

- Carriage of Liquefied GasesDocumento7 páginasCarriage of Liquefied GasessizwehAún no hay calificaciones

- LPG Vapour Air Mixing SystemsDocumento8 páginasLPG Vapour Air Mixing SystemssizwehAún no hay calificaciones

- LPG AccesoriesDocumento24 páginasLPG Accesoriessizweh100% (1)

- LPG CompressorDocumento38 páginasLPG Compressorsizweh100% (1)

- Methodology To Approve Maximum Prices For Piped GasDocumento42 páginasMethodology To Approve Maximum Prices For Piped GassizwehAún no hay calificaciones

- Human Science BookletDocumento12 páginasHuman Science BookletsizwehAún no hay calificaciones

- Implementing A Maintenance Strategic Plan Using TPM MethodologyDocumento13 páginasImplementing A Maintenance Strategic Plan Using TPM MethodologyJeyson Lendro ParedesAún no hay calificaciones

- PilotstarD AP02-S01 Mar09Documento168 páginasPilotstarD AP02-S01 Mar09Dharan NarayananAún no hay calificaciones

- The B-GON Solution: To Mist EliminationDocumento20 páginasThe B-GON Solution: To Mist EliminationDimitris Sardis LAún no hay calificaciones

- Complex Instruction Set ComputerDocumento17 páginasComplex Instruction Set ComputerkangkanpaulAún no hay calificaciones

- Ahmed Mohammed EL Desouky 2007Documento8 páginasAhmed Mohammed EL Desouky 2007Hazem MohamedAún no hay calificaciones

- CRCM Manual 2 9 16Documento33 páginasCRCM Manual 2 9 16Kamagara Roland AndrewAún no hay calificaciones

- Stand Cons T DetailsDocumento164 páginasStand Cons T DetailsmirfanjpcgmailcomAún no hay calificaciones

- Standardization of Welding ElectrodesDocumento8 páginasStandardization of Welding ElectrodesAqsa BanoAún no hay calificaciones

- CP 05 - Determine The Young S Modulus of A MaterialDocumento2 páginasCP 05 - Determine The Young S Modulus of A MaterialABBIE ROSEAún no hay calificaciones

- Bots and Automation Over Twitter During The U.S. Election: CompropDocumento5 páginasBots and Automation Over Twitter During The U.S. Election: CompropRaninha MoraisAún no hay calificaciones

- Why and Wherefores of Power System BlackoutsDocumento6 páginasWhy and Wherefores of Power System BlackoutsmentongAún no hay calificaciones

- Elective-II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)Documento6 páginasElective-II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)Adesh DeshbhratarAún no hay calificaciones

- International Log Building StandardsDocumento19 páginasInternational Log Building Standardsursind100% (1)

- SSP 099 18 Tfsi 132kw 20 Tfsi 162kw Ea888Documento60 páginasSSP 099 18 Tfsi 132kw 20 Tfsi 162kw Ea888Jose Ramón Orenes ClementeAún no hay calificaciones

- TAIL Project NewsletterDocumento9 páginasTAIL Project NewsletterAbdul R. MustaphaAún no hay calificaciones

- Risc Cisc in Microcontroller and MicroprocessorDocumento31 páginasRisc Cisc in Microcontroller and Microprocessormanvir kaurAún no hay calificaciones

- Abbreviations Plumbing Symbols: Fort Worth DistrictDocumento21 páginasAbbreviations Plumbing Symbols: Fort Worth DistrictDenzel NgAún no hay calificaciones

- Bel Adv Details For Senior Assistant Engineer Posts - Jobalertshub 2Documento5 páginasBel Adv Details For Senior Assistant Engineer Posts - Jobalertshub 2Palani AppanAún no hay calificaciones

- Vienna ModernDocumento85 páginasVienna ModernZain ZulfiqarAún no hay calificaciones

- DWTS, WDWTS: Improving MRI Image Reconstruction with Directional Wavelet ThresholdingDocumento1 páginaDWTS, WDWTS: Improving MRI Image Reconstruction with Directional Wavelet ThresholdingSumit ChakravartyAún no hay calificaciones

- Sennheiser MD 441Documento2 páginasSennheiser MD 441ndujaAún no hay calificaciones

- Extent, Yield, and SelectivityDocumento10 páginasExtent, Yield, and SelectivityKristopher Ray Simbulan PamintuanAún no hay calificaciones

- Process Level ChartDocumento2 páginasProcess Level ChartzaidinAún no hay calificaciones

- Spectral Analysis of The ECG SignalDocumento2 páginasSpectral Analysis of The ECG SignalCamilo BenitezAún no hay calificaciones

- Phase Diagrams IntroductionDocumento76 páginasPhase Diagrams IntroductionGikiTopiAún no hay calificaciones

- Fleet ManagementDocumento8 páginasFleet ManagementDiana LorenaAún no hay calificaciones

- Construction Companies in IndiaDocumento11 páginasConstruction Companies in Indiashobhit.goel33% (3)

- Zetron Model 30 Instruction Manual EarlyDocumento58 páginasZetron Model 30 Instruction Manual EarlyOscar EscobarAún no hay calificaciones

- G.25-GEMSS-G-02 Rev 01plant Design CriteriaDocumento13 páginasG.25-GEMSS-G-02 Rev 01plant Design Criteriamohammad kassarAún no hay calificaciones

- P613 HW # 2 Solutions for a 2D Electron GasDocumento4 páginasP613 HW # 2 Solutions for a 2D Electron GasRakeshAún no hay calificaciones