Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Biogas Power Plant Concept

Cargado por

luvisfact7616Descripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Biogas Power Plant Concept

Cargado por

luvisfact7616Copyright:

Formatos disponibles

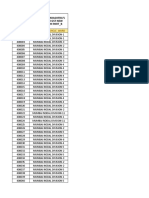

Biogas generated per kg of wet dung = 0.037cubic meter (1.

3 cubic feet) Each cow generates about 10 12 kg of dung per day. For total 500,000 nos of cow So on an average the dung generation per day = 500,000 * 10 = 50, 00,000 kg Biogas generated per day = 50, 00,000 * 0.037 cubic meter = 185,000 cubic meter 1 cubic meter of biogas is equivalent to 4.698 kwh of electricity Therefore, electricity equivalent from the biogas generated per day = 185,000 * 4.698 = 869,130 kwh Cost of 1 kwh of electricity = Rs.5 The price of equivalent electricity per day = 5 * 869,130 = Rs.43, 45,650 Some frequently asked questions in relation to bio-gas project Why to install Biogas plant 12 benefits of installing Biogas Plant: 1>saving fossil fuels, 2>saving time collecting firewood, 3>protecting forests, 4>using crop residues for animal fodder instead of fuel, 5>saving money, 6>saving cooking time, 7>improving hygienic conditions, 8>producing high-quality fertilizer, 9>enabling local mechanization and 10>electricity production, 11>improving the rural standard of living, 12>reducing air and water pollution.

What is biogas? Biogas is a byproduct of the decomposition of organic matter by anaerobic bacteria. Biogas is typically composed of 60% methane and 40% CO2. It is similar to natural gas which is composed of 99% methane. Biogas is a clean and renewable energy that may be substituted to natural gas to cook, to produce vapor, hot water or to generate electricity. At room pressure and temperature biogas is in gaseous form, not liquid like LPG (propane). Bottling biogas is a very expensive process. How does it work? Organic waste is put into a sealed tank called a digester (or bioreactor) where it is heated and agitated. In the absence of oxygen anaerobic bacteria consume the organic matter to multiply and produce biogas. What type of waste produces biogas? Any organic waste has the ability to produce biogas: human excreta, manure, animal slurry, fruit and vegetable waste, slaughterhouse waste, meat packing waste, dairy factory waste, brewery and distillery waste, etc. Fiber rich wastes like wood, leaves, etc. make poor feedstocks for digesters as they are difficult to digest. How much biogas can I get out of my waste? The amount of biogas you can extract from your organic waste depends on the waste itself and the design of the digester system. Some digesters can yield 20 m3 of biogas per tonne of waste while others can yield as much as 800 m3 per tonne. It all depends on waste quality, digester design and proper operation of the system. Where is biogas produced? Biogas is normally produced in nature by the anaerobic degradation of organic waste in soil, marshes, ocean, etc. Biogas is also produced in landfills where organic food waste degrades in anaerobic conditions. Biogas can be produced in anaerobic digesters. These are equipment (tanks) providing full control of the process and ensuring full biogas recovery. Since methane is a potent greenhouse gas, isnt it stupid to produce biogas? Methane has a greenhouse gas (GHG) heating factor 21 times higher than CO2.

Combustion of biogas converts methane into CO2 and reduces the GHG impact by over 20 times. By extracting methane out of waste and using it to produce heat and/or electricity we ensure that the waste will not degrade in an open environment therefore reducing direct methane atmospheric emissions. Moreover, the energy provided by the biogas is likely to displace fossil fuel which is the main contributor to GHG emissions. Biogas energy is considered carbon neutral, since carbon emitted by its combustion comes from carbon fixed by plants (natural carbon cycle). How much energy is in biogas? Each cubic meter (m3) of biogas contains the equivalent of 6 kWh of calorific energy. However, when we convert biogas to electricity, in a biogas powered electric generator, we get about 2 kWh of useable electricity, the rest turns into heat which can also be used for heating applications. 2 kWh is enough energy to power a 100 W light bulb for 20 hours or a 2000W hair dryer for 1 hour. What happens to the waste after digestion? Despite popular belief, the amount of waste going in the digester is almost equal to the amount coming out. However the quality of the waste is altered for the better (less odor, better fertilizer, organic load reduced, less polluting) Waste coming out of the digester can be separated (solid/liquid):the solid part can be composted and the liquid part can be used as liquid fertilizer or can be treated further and disposed. So why make biogas? It always costs money to get rid of waste. If it doesnt cost you anything, you are probably creating an environmental hazard. By putting a digester in your waste treatment chain you introduce a potential revenue center. For example: On a farm the manure is not considered to be a waste but a fertilizer. By installing a digester the farmer can profit from the biogas by reducing odors and enhancing the fertilizing value of the manure. In an agro-food industry the digester can be used as a primary waste treatment unit where the biogas is used to offset some energy cost in the plant and to reduce the size of the secondary waste treatment. How difficult is it to run a biogas plant? A biogas plant is like an animal. You must feed it every day and feed it the right stuff in the

right amount. Just like an animal if you dont take good care of it, it will become ill and will yield poor results. What are the financial incentives available under the bio-gas program from The Government of India? The Government of India is giving:(i) Central subsidy; (ii) Turn-key job fee linked with five years free maintenance warranty; (iii) Financial Support up to 50% of the applicable CFA, subject to sharing of 50% of the cost of repair by the beneficiary concerned for repair of old non-functional plants of more than 5 years; (iv) Training of users, masons and entrepreneurs; (v) Administrative charges to State Government Departments and agencies implementing the programme; (vi) Regional level Biogas Development and Training Centres; (vii) Publicity, Communication/ Extension. How much subsidy is given for biogas plants? The Central subsidy is given in fixed amounts for different categories of areas/ States/ Regions. It varies from Rs. 4000/- to Rs. 8000/- per plant for general category States & Rs. 14,700/- per plant for North Eastern Regions States including Sikkim except plain areas of Assam. The per KW Central Financial Assistance (CFA) of 1) Rs. 40,000 (3-20 KW), 2) Rs. 35,000 (>20 to 100 KW) 3) Rs. 30,000 (>100 to 250 KW) is available for the installation of bio-gas based power generation units. What is the cost of biogas plant? The cost of biogas plant varies from place to place and size of the plant. Average cost of 2 cubic meter size biogas plant is about Rs. 9,000/- . It is generally high about 30 per cent more in hilly areas and about 50 per cent more in North Eastern Region States. The average estimated cost of the most popular Deenbandhu type bio-gas model is, 1 M3 bio-gas plant will cost Rs 5500

2 M3 bio-gas plant will cost Rs 9000 3 M3 bio-gas plant will cost Rs 10 500 4 M3 bio-gas plant will cost Rs 13 500

También podría gustarte

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Note On Waaree Renewable Technologies LTDDocumento5 páginasNote On Waaree Renewable Technologies LTDluvisfact7616Aún no hay calificaciones

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Public Limited Company Requirements and AdvantagesDocumento1 páginaPublic Limited Company Requirements and Advantagesluvisfact7616Aún no hay calificaciones

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- SPADocumento4 páginasSPAluvisfact7616Aún no hay calificaciones

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (894)

- Due Deligence Scope of WorkDocumento1 páginaDue Deligence Scope of Workluvisfact7616Aún no hay calificaciones

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Reliance Mutual Fund Scheme Portfolio Holdings February 2013Documento280 páginasReliance Mutual Fund Scheme Portfolio Holdings February 2013luvisfact7616Aún no hay calificaciones

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Analysis of Form 15CA & 15CB for Non-Resident Import PaymentsDocumento4 páginasAnalysis of Form 15CA & 15CB for Non-Resident Import Paymentsluvisfact7616Aún no hay calificaciones

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- IM ChecklistDocumento4 páginasIM Checklistluvisfact7616Aún no hay calificaciones

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Stock Data ResultsDocumento11 páginasStock Data Resultsluvisfact7616Aún no hay calificaciones

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Reliance Monthly Portfolios 31 03 2013 FinalDocumento292 páginasReliance Monthly Portfolios 31 03 2013 Finalluvisfact7616Aún no hay calificaciones

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- Business Plan StepsDocumento1 páginaBusiness Plan Stepsluvisfact7616Aún no hay calificaciones

- Minutes FormatDocumento1 páginaMinutes Formatluvisfact7616Aún no hay calificaciones

- SPADocumento4 páginasSPAluvisfact7616Aún no hay calificaciones

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Rajasthan Tourism: Vasundhara Raje, Chief Minister, Rajasthan (Budget 2015-16)Documento2 páginasRajasthan Tourism: Vasundhara Raje, Chief Minister, Rajasthan (Budget 2015-16)luvisfact7616Aún no hay calificaciones

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- Filing Fees Under Direct TaxesDocumento4 páginasFiling Fees Under Direct Taxesluvisfact7616Aún no hay calificaciones

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- List of Investor For Wind Energy Power - Maharashtra EnergyDocumento78 páginasList of Investor For Wind Energy Power - Maharashtra Energyluvisfact7616Aún no hay calificaciones

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- MFGDocumento16 páginasMFGluvisfact7616Aún no hay calificaciones

- GST Sector - Ward - Circle RangeDocumento682 páginasGST Sector - Ward - Circle Rangeluvisfact761650% (10)

- Sr. No, Name, Company ListDocumento10 páginasSr. No, Name, Company Listluvisfact7616Aún no hay calificaciones

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- GST Sector - Ward - Circle RangeDocumento682 páginasGST Sector - Ward - Circle Rangeluvisfact761650% (10)

- FisDocumento1 páginaFisluvisfact7616Aún no hay calificaciones

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Agriculture Income TaxabilityDocumento15 páginasAgriculture Income Taxabilityluvisfact7616Aún no hay calificaciones

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- GST Sector - Ward - Circle RangeDocumento682 páginasGST Sector - Ward - Circle Rangeluvisfact761650% (10)

- Schedule IDocumento6 páginasSchedule IHanu4abapAún no hay calificaciones

- AutoComp SectorDocumento5 páginasAutoComp Sectorluvisfact7616Aún no hay calificaciones

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- Renewable Energy Machinery Depreciation RatesDocumento1 páginaRenewable Energy Machinery Depreciation Ratesluvisfact7616Aún no hay calificaciones

- Mumbai Companies 2008Documento4 páginasMumbai Companies 2008luvisfact7616Aún no hay calificaciones

- Deed of Hypothecation - Draft TemplateDocumento18 páginasDeed of Hypothecation - Draft Templateluvisfact7616Aún no hay calificaciones

- Schedule IDocumento6 páginasSchedule IHanu4abapAún no hay calificaciones

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- Solar Power ArticleDocumento3 páginasSolar Power Articleluvisfact7616Aún no hay calificaciones

- KLG SystelDocumento203 páginasKLG Systelluvisfact7616Aún no hay calificaciones

- Grade 11 Geo Scheme Term 2 PDFDocumento5 páginasGrade 11 Geo Scheme Term 2 PDFProf Samuel KashinaAún no hay calificaciones

- Bio Pest CideDocumento7 páginasBio Pest Cidealem010Aún no hay calificaciones

- ClimateDocumento15 páginasClimateaulakhk372Aún no hay calificaciones

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- 1.advanced Landscape Design-Lecture 1,2,3Documento54 páginas1.advanced Landscape Design-Lecture 1,2,3Bhavna MishraAún no hay calificaciones

- Building Sustainability Assessment and BenchmarkingDocumento67 páginasBuilding Sustainability Assessment and Benchmarkingresmi100% (2)

- Agri 32 Study Questions Exer 2Documento3 páginasAgri 32 Study Questions Exer 2ulanrain311100% (1)

- DHYEY-E-INTERNSHIP Weekly ReportDocumento8 páginasDHYEY-E-INTERNSHIP Weekly ReportNikita DubeyAún no hay calificaciones

- BJMC COURSE CONTENTtDocumento24 páginasBJMC COURSE CONTENTtShafaqueAlamAún no hay calificaciones

- Policy Brief: Towards 100% Renewable Energy by 2050 For Uganda (February 2023)Documento4 páginasPolicy Brief: Towards 100% Renewable Energy by 2050 For Uganda (February 2023)Kimbowa RichardAún no hay calificaciones

- Green SkyscrapersDocumento160 páginasGreen SkyscrapersMiti Agarwal100% (2)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- IESWC ISB Green Islamic Financing 12092023Documento16 páginasIESWC ISB Green Islamic Financing 12092023Khairul RijalAún no hay calificaciones

- Eia Unit Iii - EmpDocumento14 páginasEia Unit Iii - EmpBack BenchersAún no hay calificaciones

- Ecosystem ReportDocumento27 páginasEcosystem ReportJay Bianca Abera AlistadoAún no hay calificaciones

- Sediments and ErosionDocumento17 páginasSediments and ErosionRavi UraiyaAún no hay calificaciones

- Environmental EssayDocumento1 páginaEnvironmental EssayEunice B. FadriquelanAún no hay calificaciones

- 100 Facts on Nature's Role in Urban EnvironmentsDocumento8 páginas100 Facts on Nature's Role in Urban EnvironmentslakshmisshajiAún no hay calificaciones

- Leachate and Groundwater Quality in Lagos FinalDocumento12 páginasLeachate and Groundwater Quality in Lagos FinalLasisi Adedoyin K.S100% (2)

- The New Madrid Seismic Zone PaperDocumento12 páginasThe New Madrid Seismic Zone PaperKatelyn Holt0% (1)

- Ajaykumar - Status of MSW Generation in Kerala and Its CharacteristicsDocumento8 páginasAjaykumar - Status of MSW Generation in Kerala and Its CharacteristicsNaveen S NairAún no hay calificaciones

- Case Study: ProblemDocumento2 páginasCase Study: ProblemArashdeep SinghAún no hay calificaciones

- Green Olympiad 2012Documento4 páginasGreen Olympiad 2012Talent4ExamsAún no hay calificaciones

- The Role of Carbon Capture and Storage To Achieve Net-Zero Energy SystemsDocumento10 páginasThe Role of Carbon Capture and Storage To Achieve Net-Zero Energy SystemsMarcelo GuitarrariAún no hay calificaciones

- Environmental Science - EcosystemDocumento27 páginasEnvironmental Science - EcosystemtashAún no hay calificaciones

- Reduce, Recycle, and ReuseDocumento20 páginasReduce, Recycle, and ReuseAbhijit BanikAún no hay calificaciones

- Mediterranean Protected Areas in The Era of Overtourism: Ante Mandić Lidija Petrić EditorsDocumento389 páginasMediterranean Protected Areas in The Era of Overtourism: Ante Mandić Lidija Petrić EditorsberoizapAún no hay calificaciones

- Improving Irrigation Water Use Efficiency in EthiopiaDocumento12 páginasImproving Irrigation Water Use Efficiency in EthiopiaNguyen Van KienAún no hay calificaciones

- LEED - Material and Resources, and Regional PriorityDocumento19 páginasLEED - Material and Resources, and Regional PriorityJoão Pedro GazetoAún no hay calificaciones

- Lahong Proper MPA Sea CucumberDocumento21 páginasLahong Proper MPA Sea Cucumberbeilla swanAún no hay calificaciones

- Bioretention System As Stormwater Quality Improvement MechanismDocumento8 páginasBioretention System As Stormwater Quality Improvement Mechanismrobert0rojer100% (1)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingDe EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingCalificación: 5 de 5 estrellas5/5 (4)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingDe EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingCalificación: 3.5 de 5 estrellas3.5/5 (33)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldDe EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldCalificación: 4.5 de 5 estrellas4.5/5 (18)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsDe EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsCalificación: 4 de 5 estrellas4/5 (221)

- Eels: An Exploration, from New Zealand to the Sargasso, of the World's Most Mysterious FishDe EverandEels: An Exploration, from New Zealand to the Sargasso, of the World's Most Mysterious FishCalificación: 4 de 5 estrellas4/5 (30)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorDe EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorCalificación: 4.5 de 5 estrellas4.5/5 (137)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseDe EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseCalificación: 3.5 de 5 estrellas3.5/5 (69)