Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Freeze Drying

Cargado por

Iranna UdachanDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Freeze Drying

Cargado por

Iranna UdachanCopyright:

Formatos disponibles

Vacuum F R E E Z E - D RY I N G

Industrial Production Plants with Daily Throughputs Ranging from 500 kg to 60 tons of Fresh Product per Unit

Industrial Freeze-Drying

FREEZE DRYING

67

Freeze-drying is used to preserve products containing water or solvents. Good preservation of fragrances, flavorings and ingredients with nutritional value is crucial in the foodstuff industry. With proper packaging and storage, freeze-dried products can be stored for a very long time without any appreciable loss of quality even at room temperature. Weight reduction will be up to 92%. Owing to their extremely large internal surface area, freeze-dried products have an optimal capacity to take up water again (reconstitution, rehydration). ALD industrial freeze-drying systems offer the best capabilities with respect to performance, versatility and product quality and lower heating temperatures by contact heating, hence a lower final temperature of the product and better flavor retention. Further-more they have more sublimation power per m2 of area.

The main application for freeze-drying results from the remarkable advantages of the final product with respect to the conservation of volatile aromatics, heat-sensitive ingredients, color, taste, original shape, texture and nutritional value, as well as quick rehydration before use.

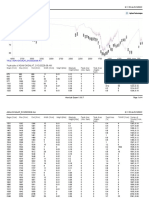

Phase diagram for water Standard freeze-drying tunnel section

Applications of Freeze-Drying: I Instant coffee and tea; I Drying of meat and meat products, poultry, fish and shellfish, fruits and vegetables; I Dairy products such as starter cultures for yogurt and cheese production; I Freeze-drying of coloring pigments; I Production of starting materials having little agglomeration for use in the manufacture of complex sintered ceramic materials.

FREEZE DRYING

68

The Principles of Freeze-Drying

At atmospheric pressure (approx. 1,000 mbar) water can have three physical states I Solid; I Liquid; I Gaseous. Below the triple-point (for pure water: 6.1 mbar at 0C), only the solid and the gaseous states exist. The principle of freeze/sublimation-drying is based on this physical fact. The ice in the product is directly converted into water vapor (without passing through the fluid state) if the ambient partial water vapor pressure is lower than the partial pressure of the ice at its relevant temperature.

The freeze-drying process is divided into two different physical process steps. Step one is the freezing of the material below its solidification temperature and step two removes the ice or solvent crystals at very low temperatures. The Freezing Process The freezing process has a great influence on the quality of the finished product and the time that will be required to dry the material. For continuously operating freeze-drying installations with high throughputs the most familar freezing systems will be continuous blast air freezing belts. In addition, fluidised bed systems, freezing channels or chambers will be used.

Continuous freeze-drying system with up to 60 tons of fresh product per day per unit

FREEZE DRYING

69

For freezing of liquids, especially coffee extract, automatic freezing belts are used. Different temperature zones, variable velocity of the belt and adjustable thickness of the product layer permit optimized freezing conditions adapted to the requirements of the different products. Granulation Frozen liquids, especially coffee extract, are granulated and classified to the desired granule sizes in a cold room at very low ambient temperatures. The frozen granules are collected in a buffer store and then fed into special drying trays by an automatic filling device. Freeze-Drying The drying process is carried out in a vacuum chamber at pressures that are lower than the water vapour pressure of the frozen products at their solidification temperature. The necessary heat to effect and accelerate sublimation is supplied from an external source. The ALD delivery program comprises large industrial production plants with throughputs ranging from 500 kg to 60 tons of fresh product per day and plants in continuous and discontinuous operation. In static freeze-drying, carriers with the filled drying trays are transported into the freeze-drying tunnel. During the drying process, the carriers with the drying trays move automatically through different temperature

zones. The entry and exit operation is realized by vacuum lock systems enabling the continuous operation of freeze-drying. In addition to the known freeze-drying method with trays (static freeze-drying) ALD offers so-called Dynamic Freeze-Drying Installations. This drying method is used for fluid/free-flowing products. In this trayless systems, the products are in direct contact with the heating surface. The frozen and granulated product is brought into the sublimation/drying tunnel by a special lock device. Inside the drying tunnel, the product is uniformly distributed by a special distribution device to the first belt of the belt transport system. A thin product layer and some intermix/turn-around of the product permits

Schematic of the belt system for dynamic freeze-drying

FREEZE DRYING

70

a very short drying time and thereby an excellent quality of the dried product (flavor retention) is attainable. The necessary heat for the sublimation of water is conveyed through direct contact between the synthetic belts and the heating plates mounted below. Different adjustable temperature zones allow an optimized temperature profile in order to perform the different requirements of the pre-drying, main drying and after-drying sections. At the end of the belt transport system, the freeze-dried product passes an outlet vacuum lock and is filled into storage containers.

Condenser Vacuum System The most efficient water vapour pump is a surface at low temperature, if the temperature is lower than the freezing temperature corresponding to the particular pressure. The size of the condenser surface and the area of the connecting tube to the sublimation tunnel determine the maximum suction capacity (load of water vapor) as well as the acceptable ice capacity. The temperature at the surface of the condenser determines the pressure of the condensable vapours during freeze-drying in the chamber. All condenser systems are equipped with automatic defrosting systems whereby defrosting will be realized under vacuum conditions for efficient and quick defrosting. In order to maintain a continuous operation process various condensers are con-

Condenser coil for automatic defrosting

nected to the individual tunnel sections. The ice condenser system collects most of the condensable vapours (mainly water vapour). For removal of non-condensables i.e., inert gases, however, vacuum pump sets are installed. Process Control Regardless of whether the system works continuously or non-continuously, the entire process is controlled and monitored by the PLC according to the production process requirements.

FREEZE DRYING

71

Refrigeration Plant In industrial freeze-drying installations, great refrigeration capacities must be achieved at low evaporation temperatures of less than minus 40 C down to minus 60 C. Ammonia absorption installations and compressor-type installations may be used for the generation of the necessary refrigeration capacity. The final/adequate choice of the refrigeration system depends on various factors such as cost of electrical energy and heavy oil, process, operation and product parameters. Processing Lines ALD Vacuum Technologies AG can also design, engineer and construct complete processing lines for pre- and post-process treatment of products like freeze-dried coffee, fruits and vegetables, etc.

Installation of an ALD industrial freeze-drying unit Vacuum pump system of a continuous freezedrying plant

También podría gustarte

- Sunday, September 04, 2005 1:40:00 AMDocumento2 páginasSunday, September 04, 2005 1:40:00 AMIranna UdachanAún no hay calificaciones

- Ajinath Abde PDFDocumento4 páginasAjinath Abde PDFIranna UdachanAún no hay calificaciones

- Annual Self Assessment For The Performance Based Appraisal System FormatDocumento23 páginasAnnual Self Assessment For The Performance Based Appraisal System FormatIranna UdachanAún no hay calificaciones

- 26 Icfost: Food and Nutrition Challenges: Role of Food Science and TechnologyDocumento8 páginas26 Icfost: Food and Nutrition Challenges: Role of Food Science and TechnologyIranna UdachanAún no hay calificaciones

- M. Tech. (Food Technology) Course Structure Semester I Contact Hours Sr. No. Subject Code Subject Title L T P Credi TsDocumento2 páginasM. Tech. (Food Technology) Course Structure Semester I Contact Hours Sr. No. Subject Code Subject Title L T P Credi TsIranna UdachanAún no hay calificaciones

- IFCON Second CircularDocumento6 páginasIFCON Second CircularIranna UdachanAún no hay calificaciones

- Irann UdachanDocumento3 páginasIrann UdachanIranna UdachanAún no hay calificaciones

- World Food Day NewsDocumento5 páginasWorld Food Day NewsIranna UdachanAún no hay calificaciones

- Dietary FoodsDocumento3 páginasDietary FoodsIranna UdachanAún no hay calificaciones

- Lecture CetrifugationDocumento27 páginasLecture CetrifugationIranna UdachanAún no hay calificaciones

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Dynisco LMI 5500 IV Test ProcedureDocumento5 páginasDynisco LMI 5500 IV Test ProcedureJaimeAún no hay calificaciones

- Termodinâmica Química: Edmundo Gomes de AzevedoDocumento38 páginasTermodinâmica Química: Edmundo Gomes de AzevedoSabinoNetoAún no hay calificaciones

- Kval Hu SteelDocumento2 páginasKval Hu Steelgorane11Aún no hay calificaciones

- Abrasive Water Jet Machining PDFDocumento3 páginasAbrasive Water Jet Machining PDFbvnareshAún no hay calificaciones

- Drilling Fluid: Lodo de PerforaciónDocumento21 páginasDrilling Fluid: Lodo de PerforaciónBelén Ramos100% (1)

- Cambridge English For Engineering PDFDocumento110 páginasCambridge English For Engineering PDFAngee Angelica RomeroAún no hay calificaciones

- TeflonDocumento19 páginasTeflonPappuRamaSubramaniamAún no hay calificaciones

- GradeSlabsDesignandConstruction PresentationDocumento34 páginasGradeSlabsDesignandConstruction PresentationgemotorresAún no hay calificaciones

- NMR 1Documento49 páginasNMR 1Jyoti ChaturvediAún no hay calificaciones

- Asam Oksalat PDFDocumento4 páginasAsam Oksalat PDFfadhilAún no hay calificaciones

- Buckstay 1Documento13 páginasBuckstay 1Siva KumarAún no hay calificaciones

- Advent Technologies Presentation 6 August 2015Documento15 páginasAdvent Technologies Presentation 6 August 2015Chatzianagnostou GeorgeAún no hay calificaciones

- Concentration & Purification of Target Product by PrecipitationDocumento69 páginasConcentration & Purification of Target Product by PrecipitationRoshan jaiswalAún no hay calificaciones

- Q62705 K163 PDFDocumento2 páginasQ62705 K163 PDFArie DinataAún no hay calificaciones

- Inorganic PhosphorusDocumento14 páginasInorganic Phosphorusbnkjaya-1Aún no hay calificaciones

- James B. Anderson - Quantum Chemistry by Random Walk: Higher Accuracy For H +-3Documento5 páginasJames B. Anderson - Quantum Chemistry by Random Walk: Higher Accuracy For H +-3Electro_LiteAún no hay calificaciones

- Loss of Seal by MomentumDocumento4 páginasLoss of Seal by MomentumderekAún no hay calificaciones

- Design of A Pulse Oximeter For Use in MiceDocumento27 páginasDesign of A Pulse Oximeter For Use in MiceIvoan VorchalasAún no hay calificaciones

- YaourtFoodandHealth2016 PDFDocumento10 páginasYaourtFoodandHealth2016 PDFBilsiAún no hay calificaciones

- Anomeric Effect, Hyperconjugation andDocumento41 páginasAnomeric Effect, Hyperconjugation anddanielsad100Aún no hay calificaciones

- Nutrition & Bio-Chemistry PDFDocumento10 páginasNutrition & Bio-Chemistry PDFRãj Pôtti ÑâîkAún no hay calificaciones

- Radiograph InterpretationDocumento12 páginasRadiograph InterpretationnithingrmeAún no hay calificaciones

- NP PsqcaDocumento12 páginasNP Psqcafahim khattak100% (1)

- 05-17 QCS 2014Documento8 páginas05-17 QCS 2014Raja Ahmed Hassan100% (2)

- 06 - Measurement of Calcium in Soil Hi-Res PDFDocumento2 páginas06 - Measurement of Calcium in Soil Hi-Res PDFmac neroAún no hay calificaciones

- HT14-IM2655 - Lecture 1 PDFDocumento33 páginasHT14-IM2655 - Lecture 1 PDFDiego Manuel Hernández AcostaAún no hay calificaciones

- Art-Método Tergotómetro PDFDocumento4 páginasArt-Método Tergotómetro PDFEdinsonMuñozAún no hay calificaciones

- Accurate Rapid Analysis of Alkali Contents in Portland CementDocumento4 páginasAccurate Rapid Analysis of Alkali Contents in Portland CementyinglvAún no hay calificaciones

- Hydraulic Power UnitDocumento44 páginasHydraulic Power UnitDustin WhiteAún no hay calificaciones