Documentos de Académico

Documentos de Profesional

Documentos de Cultura

L2 WPS

Cargado por

Bernardo Leor0 calificaciones0% encontró este documento útil (0 votos)

84 vistas1 páginaANNEX L WELDING PROCEDURE SPECIFICATION (WPS) QUALIFIED by TESTING / PROCEEDURE QUALIFICATION RECORDS (PQR) Yes AASHTO / AWS D1. Qualification Type 5.12. - 5.12. – 5. Contractor / Organization __________________________________ Type: Manual Semiautomatic Machine Automatic Tandem Parallel Identification __________________________ Revision _______ Date __________ by ____________ Authorized

Descripción original:

Título original

L2-WPS

Derechos de autor

© Attribution Non-Commercial (BY-NC)

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoANNEX L WELDING PROCEDURE SPECIFICATION (WPS) QUALIFIED by TESTING / PROCEEDURE QUALIFICATION RECORDS (PQR) Yes AASHTO / AWS D1. Qualification Type 5.12. - 5.12. – 5. Contractor / Organization __________________________________ Type: Manual Semiautomatic Machine Automatic Tandem Parallel Identification __________________________ Revision _______ Date __________ by ____________ Authorized

Copyright:

Attribution Non-Commercial (BY-NC)

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

84 vistas1 páginaL2 WPS

Cargado por

Bernardo LeorANNEX L WELDING PROCEDURE SPECIFICATION (WPS) QUALIFIED by TESTING / PROCEEDURE QUALIFICATION RECORDS (PQR) Yes AASHTO / AWS D1. Qualification Type 5.12. - 5.12. – 5. Contractor / Organization __________________________________ Type: Manual Semiautomatic Machine Automatic Tandem Parallel Identification __________________________ Revision _______ Date __________ by ____________ Authorized

Copyright:

Attribution Non-Commercial (BY-NC)

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 1

AASHTO/AWS D1.5/D1.

5M:2008 ANNEX L

WELDING PROCEDURE SPECIFICATION (WPS)

PREQUALIFIED QUALIFIED BY TESTING

or PROCEDURE QUALIFICATION RECORDS (PQR) Yes

AASHTO/AWS D1.5 Qualification Type 5.12.1 – 5.12.2 – 5.13

Contractor/ Identification ___________________________________

Organization __________________________________ Revision _______ Date __________ By ____________

Welding Process(es) ____________________________ Authorized by __________________ Date __________

Type: Manual Semiautomatic Supporting PQR No.(s) __________________________

Machine Automatic

POSITION

Tandem Parallel

Position of Groove ______________ Fillet __________

Vertical Progression: Up Down

JOINT DESIGN USED ELECTRICAL CHARACTERISTICS

Single Double Weld Transfer Mode (GMAW): Globular Spray

Backing: Yes No Material _______________ Current: AC DCEP DCEN Pulsed

Root Opening ______ Root Face Dimension ________

Electrical Stick Out ______________________________

Groove Angle ___________ Radius (J–U) _________

Other ________________________________________

Backgouging: Yes No Method ____________

Root Treatment ________________________________ TECHNIQUE

Stringer or Weave Bead __________________________

BASE METALS Multi-pass or Single Pass (per side)_________________

Material Spec. _________________________________ Number of Electrodes ___________________________

Type or Grade _________________________________ Electrode Spacing: Longitudinal __________________

Thickness: Groove ____________ Fillet __________ Lateral _______________________ Angle__________

Diameter (Pipe) ________________________________ Interpass Cleaning ______________________________

PREHEAT

FILLER METALS Preheat Temp., Min. _____________________________

AWS Specification______________________________ Interpass Temp., Min. ____________________________

AWS Classification _____________________________ Interpass Temp., Max. ___________________________

Manufacturer Trade Name________________________

POSTWELD HEAT TREATMENT

Temp. _________________ Hold Time_____________

SHIELDING

Heating/Cooling Rate ____________________________

Flux ___________________ Mfg. Trade Name_______

Electrode-Flux (Class)___________________________ HEAT INPUT

Gas Composition ______________________________ Calculated Heat Input Value: kJ/in kJ/mm

Flow Rate ______________ Gas Cup Size _________ Max. Heat Input _________ Min. Heat Input_________

WELDING PROCEDURE

Filler

Pass or Metals Current

Weld Type & Amps or Wire Travel

Layer(s) Process Diam. Polarity Feed Speed Volts Speed Joint Details

Form L-2

Form L-2—Sample Welding Procedure Specification

261

También podría gustarte

- AutoCAD Electrical 2024: A Tutorial Approach, 5th EditionDe EverandAutoCAD Electrical 2024: A Tutorial Approach, 5th EditionAún no hay calificaciones

- Sucker Rod Pump BasicsDocumento76 páginasSucker Rod Pump BasicsDumitrescu GabrielAún no hay calificaciones

- Autodesk Fusion 360 Black Book (V 2.0.10027) - Part 2De EverandAutodesk Fusion 360 Black Book (V 2.0.10027) - Part 2Aún no hay calificaciones

- GRE Physics Review: Comprehensive Review for GRE Physics Subject TestDe EverandGRE Physics Review: Comprehensive Review for GRE Physics Subject TestAún no hay calificaciones

- GRE Chemistry: Inorganic Chemistry Review for GRE Chemistry Subject TestDe EverandGRE Chemistry: Inorganic Chemistry Review for GRE Chemistry Subject TestAún no hay calificaciones

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDe EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsCalificación: 3.5 de 5 estrellas3.5/5 (3)

- Hacking for Beginners: Comprehensive Guide on Hacking Websites, Smartphones, Wireless Networks, Conducting Social Engineering, Performing a Penetration Test, and Securing Your Network (2022)De EverandHacking for Beginners: Comprehensive Guide on Hacking Websites, Smartphones, Wireless Networks, Conducting Social Engineering, Performing a Penetration Test, and Securing Your Network (2022)Aún no hay calificaciones

- B2.1 B2.1M 2014 Amd1 Procedure Qualification Record PQR PDFDocumento2 páginasB2.1 B2.1M 2014 Amd1 Procedure Qualification Record PQR PDFNavanitheeshwaran SivasubramaniyamAún no hay calificaciones

- Autodesk Fusion 360 Black Book (V 2.0.12670) - Part 2: Autodesk Fusion 360 Black Book (V 2.0.12670)De EverandAutodesk Fusion 360 Black Book (V 2.0.12670) - Part 2: Autodesk Fusion 360 Black Book (V 2.0.12670)Aún no hay calificaciones

- MCAT General Chemistry Review: Complete Subject ReviewDe EverandMCAT General Chemistry Review: Complete Subject ReviewAún no hay calificaciones

- WPS D1.6 Annex m1 PDFDocumento1 páginaWPS D1.6 Annex m1 PDFbollascribdAún no hay calificaciones

- 2018 ThermogravimetricAnalysisofPolymersBookChapter PDFDocumento30 páginas2018 ThermogravimetricAnalysisofPolymersBookChapter PDFA1234 AJEFAún no hay calificaciones

- Wps PQR Aws d11 FormDocumento2 páginasWps PQR Aws d11 Formflakosisas100% (1)

- Pip Vesv1003-2014Documento9 páginasPip Vesv1003-2014d-fbuser-93320248Aún no hay calificaciones

- Welding Procedure Specification (WPS) Yes PREQUALIFIED - Qualified by Testing - or Procedure Qualification Records (PQR) YesDocumento4 páginasWelding Procedure Specification (WPS) Yes PREQUALIFIED - Qualified by Testing - or Procedure Qualification Records (PQR) Yesvarun100% (1)

- AHRI 740 1998 Corrected TablesDocumento21 páginasAHRI 740 1998 Corrected TablesBernardo LeorAún no hay calificaciones

- Gas HydrateDocumento57 páginasGas HydrateMahdiAún no hay calificaciones

- F4-WPS PQR Stud WeldingDocumento1 páginaF4-WPS PQR Stud WeldingBernardo LeorAún no hay calificaciones

- F4-WPS PQR Stud WeldingDocumento1 páginaF4-WPS PQR Stud WeldingBernardo LeorAún no hay calificaciones

- Types of Welding in ShipbuildingDocumento30 páginasTypes of Welding in ShipbuildingPranjyoti SaikiaAún no hay calificaciones

- Standards Related To BearingsDocumento6 páginasStandards Related To Bearingswholenumber0% (1)

- WPS SampleDocumento2 páginasWPS Sampleeetua100% (1)

- Requirements For Welding InspectionDocumento43 páginasRequirements For Welding Inspectionhitm357Aún no hay calificaciones

- OAT General Chemistry Review: Complete Subject ReviewDe EverandOAT General Chemistry Review: Complete Subject ReviewAún no hay calificaciones

- AWS D1-1 PQR-WPS Yes Pre QualifiedDocumento2 páginasAWS D1-1 PQR-WPS Yes Pre QualifiedJRodengineerAún no hay calificaciones

- PQRDocumento2 páginasPQRRavi KumaranAún no hay calificaciones

- Form N 2 Sample Welding Procedure SpecificationDocumento1 páginaForm N 2 Sample Welding Procedure SpecificationViswanath SreepadaAún no hay calificaciones

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocumento1 páginaD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1Aún no hay calificaciones

- WPS TemplateDocumento1 páginaWPS TemplateMatt De Hoog100% (1)

- Wps Short FormDocumento2 páginasWps Short FormsrinivasanAún no hay calificaciones

- WPS VarillaDocumento2 páginasWPS Varillalabingles89Aún no hay calificaciones

- Aws N-1 WPS-PQR FormDocumento2 páginasAws N-1 WPS-PQR FormEdwin MariacaAún no hay calificaciones

- WPS - Sample - Form D17.1 D17.1M 2010Documento1 páginaWPS - Sample - Form D17.1 D17.1M 2010Mohammed AzizAún no hay calificaciones

- JushDocumento2 páginasJushg6vhdytsyzAún no hay calificaciones

- AslnDocumento2 páginasAslng6vhdytsyzAún no hay calificaciones

- Welding Procedure Specification (WPS) : BackingDocumento1 páginaWelding Procedure Specification (WPS) : BackingtimkemperAún no hay calificaciones

- CS-1 6/1/2015 6/1/2015 R1 Gtaw / Smaw Manual / Manual: Type(s)Documento2 páginasCS-1 6/1/2015 6/1/2015 R1 Gtaw / Smaw Manual / Manual: Type(s)Nazar Abdul KareemAún no hay calificaciones

- WPS - Pre-Insulated PipesDocumento4 páginasWPS - Pre-Insulated Pipesharis bhuttoAún no hay calificaciones

- Uail - Pin Li-Cqa-213-F-01 WPS FormatDocumento2 páginasUail - Pin Li-Cqa-213-F-01 WPS FormatKarthikAún no hay calificaciones

- 2G Rev-0-D1 - 2 - AL - PQRDocumento2 páginas2G Rev-0-D1 - 2 - AL - PQRAhmed GomaaAún no hay calificaciones

- 3G Rev-0-D1 - 2 - AL-PQRDocumento2 páginas3G Rev-0-D1 - 2 - AL-PQRAhmed GomaaAún no hay calificaciones

- Sample Format: Sensitivity: LNT Construction Internal UseDocumento2 páginasSample Format: Sensitivity: LNT Construction Internal UseKarthikAún no hay calificaciones

- Sample Welding Procedure Specification (WPS) : Joints (See 4.13.1)Documento2 páginasSample Welding Procedure Specification (WPS) : Joints (See 4.13.1)muadzAún no hay calificaciones

- Suggested Weldin Lr. VijDocumento4 páginasSuggested Weldin Lr. Vijmallik017100% (2)

- Performance Qualification Test Record: Test Weldment Position Tested Weldment Thickness (T)Documento1 páginaPerformance Qualification Test Record: Test Weldment Position Tested Weldment Thickness (T)Navanitheeshwaran SivasubramaniyamAún no hay calificaciones

- Welding Procedure Specification (WPS) : JointsDocumento2 páginasWelding Procedure Specification (WPS) : JointsNavanitheeshwaran SivasubramaniyamAún no hay calificaciones

- Joint (QW-402)Documento3 páginasJoint (QW-402)MuhammadNajibAún no hay calificaciones

- B2.1 B2.1M 2014 AMD1 Stud Welding WPS PQR or WQR FormDocumento1 páginaB2.1 B2.1M 2014 AMD1 Stud Welding WPS PQR or WQR FormtuanAún no hay calificaciones

- QW-482 WPS BlankDocumento2 páginasQW-482 WPS Blankj29mahonAún no hay calificaciones

- D1.3 D1.3M 2018 Annexb1 PQR FormDocumento1 páginaD1.3 D1.3M 2018 Annexb1 PQR FormAkihiko TakagiAún no hay calificaciones

- FM-87 Welding Procedure Specification WPS (MEC ENERGY's Conflicted Copy 2018-07-10)Documento2 páginasFM-87 Welding Procedure Specification WPS (MEC ENERGY's Conflicted Copy 2018-07-10)tayyabAún no hay calificaciones

- Annex Form J3 D1.1 D1.1M 2020Documento1 páginaAnnex Form J3 D1.1 D1.1M 2020Donaldo CausilAún no hay calificaciones

- M 3 D1.1 2015 FormDocumento1 páginaM 3 D1.1 2015 FormĐỗ Văn ChinhAún no hay calificaciones

- Aws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFDocumento1 páginaAws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFrajAún no hay calificaciones

- Form L-4-Procedure Qualification Record (PQR) WorksheetDocumento1 páginaForm L-4-Procedure Qualification Record (PQR) WorksheetCemal NergizAún no hay calificaciones

- L3 PQRforQualificationDocumento1 páginaL3 PQRforQualificationBernardo LeorAún no hay calificaciones

- Tata Consulting Engineers Limited: P Q T R (PQR)Documento2 páginasTata Consulting Engineers Limited: P Q T R (PQR)Rajat KoleyAún no hay calificaciones

- 003PQR P1&2 May 17 2018Documento3 páginas003PQR P1&2 May 17 2018Oliver CastroAún no hay calificaciones

- Welding Procedure Qualification Log - Rev2Documento8 páginasWelding Procedure Qualification Log - Rev2HoangAún no hay calificaciones

- D1.5M D1.5 2015 AMD1 Form O 3 FillableDocumento1 páginaD1.5M D1.5 2015 AMD1 Form O 3 FillableNavanitheeshwaran SivasubramaniyamAún no hay calificaciones

- Power Systems-On-Chip: Practical Aspects of DesignDe EverandPower Systems-On-Chip: Practical Aspects of DesignBruno AllardAún no hay calificaciones

- AutoCAD Electrical 2024 for Electrical Control Designers, 15th EditionDe EverandAutoCAD Electrical 2024 for Electrical Control Designers, 15th EditionAún no hay calificaciones

- AutoCAD Electrical 2024 for Electrical Control Designers, 15th EditionDe EverandAutoCAD Electrical 2024 for Electrical Control Designers, 15th EditionAún no hay calificaciones

- Astm A403 Welded Fittings Index: Ta Chen International, Inc.Documento23 páginasAstm A403 Welded Fittings Index: Ta Chen International, Inc.Bernardo LeorAún no hay calificaciones

- Solderer Performance Qualification (SPQ) - Sample Form: Qualification, AWS B2.3/B2.3MDocumento1 páginaSolderer Performance Qualification (SPQ) - Sample Form: Qualification, AWS B2.3/B2.3MBernardo LeorAún no hay calificaciones

- Soldering Procedure Specification (SPS) - Sample FormDocumento1 páginaSoldering Procedure Specification (SPS) - Sample FormBernardo LeorAún no hay calificaciones

- Soldering Procedure Qualification Record (SPQR) - Sample FormDocumento2 páginasSoldering Procedure Qualification Record (SPQR) - Sample FormBernardo LeorAún no hay calificaciones

- L3 PQRforQualificationDocumento1 páginaL3 PQRforQualificationBernardo LeorAún no hay calificaciones

- L1 CertificateOfConformanceDocumento1 páginaL1 CertificateOfConformanceBernardo LeorAún no hay calificaciones

- Form L-5-Welder and Welding Operator Qualification RecordDocumento1 páginaForm L-5-Welder and Welding Operator Qualification RecordBernardo LeorAún no hay calificaciones

- ReportttttttttttDocumento42 páginasReportttttttttttpradeep rAún no hay calificaciones

- Chem AssignmentsDocumento3 páginasChem AssignmentsDarshan H. GodhiaAún no hay calificaciones

- Compositional Changes of Crude Oil SARA Fractions Due To Biodegradation and Adsorption Supported On Colloidal Support Such As Clay Susing IatroscanDocumento13 páginasCompositional Changes of Crude Oil SARA Fractions Due To Biodegradation and Adsorption Supported On Colloidal Support Such As Clay Susing IatroscanNatalia KovalovaAún no hay calificaciones

- Add AcidDocumento4 páginasAdd AcidKathir KiranAún no hay calificaciones

- Brusseau, M. L., & Artiola, J. F. (2019) - Chemical Contaminants. in Environmental and Pollution Science (Pp. 175-190) - Academic Press.Documento16 páginasBrusseau, M. L., & Artiola, J. F. (2019) - Chemical Contaminants. in Environmental and Pollution Science (Pp. 175-190) - Academic Press.Jimena ValeriaAún no hay calificaciones

- Analytical Study On The Dynamic Properties of Viscoelastically Coupled Shear Walls in High-Rise BuildingsDocumento11 páginasAnalytical Study On The Dynamic Properties of Viscoelastically Coupled Shear Walls in High-Rise BuildingsKrishnakumar ThanirosanAún no hay calificaciones

- Structural AnalysissssssDocumento43 páginasStructural AnalysissssssNobiel MellomidaAún no hay calificaciones

- Manufacturing Technology II - Notes PDFDocumento17 páginasManufacturing Technology II - Notes PDFSenthil Kumar Subramanian100% (1)

- Mono87 6Documento145 páginasMono87 6rizky dwi anandaAún no hay calificaciones

- Catalogo Tecnico ENGDocumento52 páginasCatalogo Tecnico ENGAdvokat HadziTonicAún no hay calificaciones

- 15 - Mangla Joshi PDFDocumento22 páginas15 - Mangla Joshi PDFSHIKHA SINGHAún no hay calificaciones

- Mineralogy 100A Syllabus 2016-EditDocumento4 páginasMineralogy 100A Syllabus 2016-Editnot realAún no hay calificaciones

- Nuratherm PIR TDSDocumento2 páginasNuratherm PIR TDSNathan BlythAún no hay calificaciones

- The Accuracyof Pvt-Paraywem Calculated From Computerflash Separationat Prxssures Less Than 1000 PsiDocumento26 páginasThe Accuracyof Pvt-Paraywem Calculated From Computerflash Separationat Prxssures Less Than 1000 PsiEduardo MejoradoAún no hay calificaciones

- Compressive Strength Modelling of Concrete Mixed With Fly Ash and Waste Ceramics Using K-Nearest Neighbor AlgorithmDocumento6 páginasCompressive Strength Modelling of Concrete Mixed With Fly Ash and Waste Ceramics Using K-Nearest Neighbor AlgorithmNewton GalileoAún no hay calificaciones

- 2020 Flow Control Choke Valve: SeriesDocumento4 páginas2020 Flow Control Choke Valve: SeriesDaniel AcostaAún no hay calificaciones

- Improving Mechanical Properties of Alsi10Mg Aluminum Alloy Using Ultrasonic Melt Treatment Combined With T6 Heat TreatmentDocumento11 páginasImproving Mechanical Properties of Alsi10Mg Aluminum Alloy Using Ultrasonic Melt Treatment Combined With T6 Heat Treatmentפּואַ פּוגאַAún no hay calificaciones

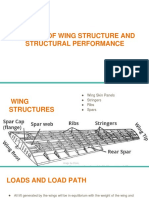

- Bending of Wing Structure and Structural PerformanceDocumento21 páginasBending of Wing Structure and Structural Performancemrajadurai700Aún no hay calificaciones

- Using Electronic Detonators To Improve All-Round Blasting PerformancesDocumento8 páginasUsing Electronic Detonators To Improve All-Round Blasting Performancesangel baez contrerasAún no hay calificaciones

- Metalworking Woodworking Tool Cut Hand Tool Steel Case Hardened Tang RaspDocumento1 páginaMetalworking Woodworking Tool Cut Hand Tool Steel Case Hardened Tang RaspQamar ZamansAún no hay calificaciones

- GB 8163-2008Documento14 páginasGB 8163-2008hungAún no hay calificaciones

- Product Data Sheet 3900 3900vp General Purpose PH Orp Sensors Rosemount en 70722Documento20 páginasProduct Data Sheet 3900 3900vp General Purpose PH Orp Sensors Rosemount en 70722KishorAún no hay calificaciones

- 110411020Documento6 páginas110411020nishantk93Aún no hay calificaciones