Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Combustible Dust Poster

Cargado por

Evert W. VanderBergDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Combustible Dust Poster

Cargado por

Evert W. VanderBergCopyright:

Formatos disponibles

Combustible Dust

Does your company or firm

process any of these products or

materials in powdered form?

If your company or firm processes any of these products or

materials, there is potential for a “Combustible Dust” explosion.

Agricultural Products Cottonseed Soybean dust Chemical Dusts Epoxy resin

Egg white Garlic powder Spice dust Adipic acid Melamine resin

Milk, powdered Gluten Spice powder Anthraquinone Melamine, molded

Milk, nonfat, dry Grass dust Sugar (10x) Ascorbic acid (phenol-cellulose)

Soy flour Green coffee Sunflower Calcium acetate Melamine, molded

Starch, corn Hops (malted) Sunflower seed dust Calcium stearate (wood flour and

Starch, rice Lemon peel dust Tea Carboxy-methylcellulose mineral filled phenol-

Starch, wheat Lemon pulp Tobacco blend Dextrin formaldehyde)

Sugar Linseed Tomato Lactose (poly) Methyl acrylate

Sugar, milk Locust bean gum Walnut dust Lead stearate (poly) Methyl acrylate,

Sugar, beet Malt Wheat flour Methyl-cellulose emulsion polymer

Tapioca Oat flour Wheat grain dust Paraformaldehyde Phenolic resin

Whey Oat grain dust Wheat starch Sodium ascorbate (poly) Propylene

Wood flour Olive pellets Xanthan gum Sodium stearate Terpene-phenol resin

Onion powder Sulfur Urea-formaldehyde/

Agricultural Dusts Parsley (dehydrated) Carbonaceous Dusts cellulose, molded

Alfalfa Peach Charcoal, activated Metal Dusts (poly) Vinyl acetate/

Apple Peanut meal and skins Charcoal, wood Aluminum ethylene copolymer

Beet root Peat Coal, bituminous Bronze (poly) Vinyl alcohol

Carrageen Potato Coke, petroleum Iron carbonyl (poly) Vinyl butyral

Carrot Potato flour Lampblack Magnesium (poly) Vinyl chloride/

Cocoa bean dust Potato starch Lignite Zinc ethylene/vinyl

Cocoa powder Raw yucca seed dust Peat, 22%H20 acetylene suspension

Coconut shell dust Rice dust Soot, pine Plastic Dusts copolymer

Coffee dust Rice flour Cellulose (poly) Acrylamide (poly) Vinyl chloride/

Corn meal Rice starch Cellulose pulp (poly) Acrylonitrile vinyl acetylene

Cornstarch Rye flour Cork (poly) Ethylene emulsion

Cotton Semolina Corn (low-pressure process) copolymer

Dust Control Measures The facility selects and uses industrial trucks that are approved for the

combustible dust locations.

The dust-containing systems (ducts and dust collectors) are designed

in a manner (i.e., no leaking) that fugitive dusts are not allowed to Prevention Measures

accumulate in the work area. The facility has separator devices to remove foreign materials

The facility has a housekeeping program with regular cleaning fre- capable of igniting combustible dusts.

quencies established for floors and horizontal surfaces, such as ducts, MSDSs for the chemicals which could become combustible dust under

pipes, hoods, ledges, and beams, to minimize dust accumulations normal operations are available to employees.

within operating areas of the facility.

Employees are trained on the explosion hazards of combustible dusts.

The working surfaces are designed in a manner to minimize dust

accumulation and facilitate cleaning. Protection Measures

Ignition Control Measures The facility has an emergency action plan.

Electrically-powered cleaning devices such as vacuum cleaners, and Dust collectors are not located inside of buildings. (Some exceptions)

electrical equipment are approved for the hazard classification for Rooms, buildings, or other enclosures (dust collectors) have explosion

Class II locations. relief venting distributed over the exterior wall of buildings and

The facility has an ignition control program, such as grounding and enclosures.

bonding and other methods, for dissipating any electrostatic charge that Explosion venting is directed to a safe location away from employees.

could be generated while transporting the dust through the ductwork. The facility has isolation devices to prevent deflagration propagation

The facility has a Hot Work permit program. between pieces of equipment connected by ductwork.

Areas where smoking is prohibited are posted with “No Smoking” signs. The dust collector systems have spark detection and explosion/

Duct systems, dust collectors, and dust-producing machinery are bonded deflagration suppression systems.

and grounded to minimize accumulation of static electrical charge. Emergency exit routes are maintained properly.

www.osha.gov • (800) 321-OSHA • TTY (877) 889-5627

También podría gustarte

- Indusdrial Visit in SSP PVT LTD FaridabadDocumento16 páginasIndusdrial Visit in SSP PVT LTD FaridabadkedarnathvishwakarmaAún no hay calificaciones

- Cleanroom Catalgos 2019 PDFDocumento104 páginasCleanroom Catalgos 2019 PDFleechulmiuAún no hay calificaciones

- Microbiology Clean Room Design SpecificationDocumento2 páginasMicrobiology Clean Room Design SpecificationMHNADAún no hay calificaciones

- Camusat Hazardous Waste Disposal PolicyDocumento8 páginasCamusat Hazardous Waste Disposal PolicyThein Zaw OoAún no hay calificaciones

- The Storage and Handling of Organic Peroxides Guidance Note CS21Documento26 páginasThe Storage and Handling of Organic Peroxides Guidance Note CS21Максим ХилоAún no hay calificaciones

- 093 Paint Booth VentDocumento3 páginas093 Paint Booth VentFajar Hadi CrisnamurtiAún no hay calificaciones

- Gaseous Extinguishing SystemsDocumento45 páginasGaseous Extinguishing SystemsbinsAún no hay calificaciones

- Apparel Considerations For Clean ManufacturingDocumento2 páginasApparel Considerations For Clean ManufacturingGaurav ShakyaAún no hay calificaciones

- Pharmaceutical AAF 1 206Documento20 páginasPharmaceutical AAF 1 206Bader ShrbajiAún no hay calificaciones

- Usp 797GCDocumento61 páginasUsp 797GCAwni1989Aún no hay calificaciones

- Insulation Selection Guide IIG-902Documento2 páginasInsulation Selection Guide IIG-902surawutwijarnAún no hay calificaciones

- Mebs6006 1112 07-VentilationDocumento69 páginasMebs6006 1112 07-VentilationSimoncarter LawAún no hay calificaciones

- 10-Drying of Milk Dairy and Food EngineeringDocumento7 páginas10-Drying of Milk Dairy and Food Engineeringariyani yantoAún no hay calificaciones

- Dust Explosion Protection Using Flameless Venting - FIKE EXEMPLOSDocumento18 páginasDust Explosion Protection Using Flameless Venting - FIKE EXEMPLOSPedro Ceriolli100% (1)

- P-1-10 NFPA 45 - 2015 Edition Changes and Issues Related To Energy ConservationDocumento27 páginasP-1-10 NFPA 45 - 2015 Edition Changes and Issues Related To Energy ConservationAnonymous 7KMe7ER100% (1)

- ACO Industrial DrainageDocumento230 páginasACO Industrial DrainageJohnAún no hay calificaciones

- Flex Head para RociadoresDocumento2 páginasFlex Head para RociadoresjoravicaAún no hay calificaciones

- Xpelair Ventilation Guide - EngDocumento63 páginasXpelair Ventilation Guide - EngMarc MaesAún no hay calificaciones

- What Is A Cleanroom - Cleanroom ClassificationsDocumento2 páginasWhat Is A Cleanroom - Cleanroom ClassificationsMai Phuong Phan TranAún no hay calificaciones

- TheraBond Material Safety Data SheetDocumento6 páginasTheraBond Material Safety Data SheetDougAún no hay calificaciones

- Mechanical Plan Evaluation and Review OutlineDocumento11 páginasMechanical Plan Evaluation and Review OutlineEngelbert CasanovaAún no hay calificaciones

- Le Cappe Waldner En-14175Documento59 páginasLe Cappe Waldner En-14175Yury LorenzAún no hay calificaciones

- Air DyeingDocumento3 páginasAir DyeingMehmood AhmedAún no hay calificaciones

- Calculating Clean Room CleanlinessDocumento3 páginasCalculating Clean Room CleanlinessThanh NhatAún no hay calificaciones

- NBC vs. NFPADocumento12 páginasNBC vs. NFPAMGHIRBI HAYKELAún no hay calificaciones

- iPRODUCT100: Ii 2 GD Ex D Iic T6 GB Ex TD Iiic T100°C DB I M2 Ex D I MBDocumento1 páginaiPRODUCT100: Ii 2 GD Ex D Iic T6 GB Ex TD Iiic T100°C DB I M2 Ex D I MBmlutfimaAún no hay calificaciones

- Iso Propyl Acetate ManufacturersDocumento7 páginasIso Propyl Acetate ManufacturersSomuSolventsAún no hay calificaciones

- VRF InstallationDocumento3 páginasVRF InstallationFanny Tarida TampubolonAún no hay calificaciones

- Final 1 - Hairul - SS 641 Standards Adoption Workshop - 27 Jun 2019 - Chapter 4 5Documento24 páginasFinal 1 - Hairul - SS 641 Standards Adoption Workshop - 27 Jun 2019 - Chapter 4 5Gan Yi ZheAún no hay calificaciones

- TSI PANDA 341 User ManualDocumento38 páginasTSI PANDA 341 User ManualHernan RomeroAún no hay calificaciones

- Dryer DatasheetDocumento2 páginasDryer Datasheetthomas_v501925Aún no hay calificaciones

- Ansul R-102Documento4 páginasAnsul R-102heliopintoAún no hay calificaciones

- Clean RoomDocumento11 páginasClean Roomshamu081Aún no hay calificaciones

- Cleanroom Flow ChartDocumento1 páginaCleanroom Flow Chartjirt2011Aún no hay calificaciones

- Paint Booth GuideDocumento24 páginasPaint Booth GuideAmirul AkmalAún no hay calificaciones

- Cloud and PourDocumento22 páginasCloud and PourAbdulmajid OsmanAún no hay calificaciones

- Sealant - 1st Acrylic A-700 MSDSDocumento6 páginasSealant - 1st Acrylic A-700 MSDSBozow BongAún no hay calificaciones

- 2017-04-03 - Eurovent Air Filters Guidebook - First Edition - English - Web PDFDocumento15 páginas2017-04-03 - Eurovent Air Filters Guidebook - First Edition - English - Web PDFFernando CabreraAún no hay calificaciones

- Feedwater LCA Statement of ComplianceDocumento5 páginasFeedwater LCA Statement of ComplianceTarundeep Singh100% (1)

- Service Manual VD (E1) 12-05 - enDocumento45 páginasService Manual VD (E1) 12-05 - enPhong LeAún no hay calificaciones

- LUNOS Catalogue For Home VentilationDocumento68 páginasLUNOS Catalogue For Home Ventilationing urbanAún no hay calificaciones

- Paracetamol DegradationDocumento9 páginasParacetamol DegradationTruyền Phạm MinhAún no hay calificaciones

- Aultons Pharmaceuticals Drying PDFDocumento18 páginasAultons Pharmaceuticals Drying PDFAdrián L ValladaresAún no hay calificaciones

- Reducing Airborne Exposure of COVID 19 Using Air Filtration Systems WhitePaperDocumento9 páginasReducing Airborne Exposure of COVID 19 Using Air Filtration Systems WhitePaperColectibondiAún no hay calificaciones

- What Is USP Class VI Testing and Why Is It Important - Holland Applied Technologies PDFDocumento2 páginasWhat Is USP Class VI Testing and Why Is It Important - Holland Applied Technologies PDFBiopharmaAún no hay calificaciones

- PublicationoftheANSIZ9 14-2020standardDocumento4 páginasPublicationoftheANSIZ9 14-2020standardDayana SolerAún no hay calificaciones

- CyberCat 2015 FULL PrintoutDocumento430 páginasCyberCat 2015 FULL PrintoutKrishna Kumar100% (1)

- HVAC Design For Pharmaceutical Facilities R1Documento57 páginasHVAC Design For Pharmaceutical Facilities R1sai manojAún no hay calificaciones

- Ateis PavaDocumento4 páginasAteis PavaKannan SreekumarAún no hay calificaciones

- VCPL SDS - Ee133Documento7 páginasVCPL SDS - Ee133Dhia GhoniyyahAún no hay calificaciones

- Pomegranate ProcessingDocumento23 páginasPomegranate ProcessingNaim Khalid0% (1)

- AC Spec Selector EnRetrotec US3212 US 3212 Blower Door Air Leakage Test Systemergy SP500Documento8 páginasAC Spec Selector EnRetrotec US3212 US 3212 Blower Door Air Leakage Test Systemergy SP500nicholaswallacetcgAún no hay calificaciones

- Study of The Degradation of Typical HVAC Materials, Filters and Components Irradiated by UVC Energy - Part I: Literature Search.Documento13 páginasStudy of The Degradation of Typical HVAC Materials, Filters and Components Irradiated by UVC Energy - Part I: Literature Search.1moldAún no hay calificaciones

- Medical and Laboratory Gas Pipeline Design Part 1Documento3 páginasMedical and Laboratory Gas Pipeline Design Part 1karunaAún no hay calificaciones

- HygoodDocumento1 páginaHygoodSachin Darne100% (1)

- Industrial Energy Management Standard RequirementsDe EverandIndustrial Energy Management Standard RequirementsAún no hay calificaciones

- Dust Control and Air Cleaning: International Series of Monographs in Heating, Ventilation and RefrigerationDe EverandDust Control and Air Cleaning: International Series of Monographs in Heating, Ventilation and RefrigerationAún no hay calificaciones

- OSHA Safety MetricsDocumento1 páginaOSHA Safety MetricsEvert W. VanderBergAún no hay calificaciones

- SM - Hoist & Crane BasicsDocumento22 páginasSM - Hoist & Crane BasicsEvert W. VanderBergAún no hay calificaciones

- Thermal HazardsDocumento19 páginasThermal HazardsEvert W. VanderBerg100% (1)

- Thermal Hazards PDFDocumento19 páginasThermal Hazards PDFEvert W. VanderBergAún no hay calificaciones

- SM Fire ExtinguisherDocumento2 páginasSM Fire ExtinguisherEvert W. VanderBergAún no hay calificaciones

- SM - Confined Space For Entrants & AttendantsDocumento16 páginasSM - Confined Space For Entrants & AttendantsEvert W. VanderBergAún no hay calificaciones

- SM Worst HappensDocumento1 páginaSM Worst HappensEvert W. VanderBergAún no hay calificaciones

- General Work Environment Self Inspection ChecklistDocumento1 páginaGeneral Work Environment Self Inspection ChecklistEvert W. VanderBergAún no hay calificaciones

- Electrical General Requirements AuditDocumento4 páginasElectrical General Requirements AuditEvert W. VanderBergAún no hay calificaciones

- Controlling Silica Exposures in ConstructionDocumento72 páginasControlling Silica Exposures in ConstructionEvert W. VanderBergAún no hay calificaciones

- Employee Health and Personal HygieneDocumento68 páginasEmployee Health and Personal HygieneJay Diano AbieraAún no hay calificaciones

- Safety Moment Personal Protective EquipmentDocumento1 páginaSafety Moment Personal Protective EquipmentEvert W. VanderBerg100% (1)

- Employee Safety Inspection ChecklistDocumento2 páginasEmployee Safety Inspection ChecklistEvert W. VanderBerg100% (1)

- OSHA Combustible DustDocumento13 páginasOSHA Combustible Dustdannymay95Aún no hay calificaciones

- Safety Moment Hand ExerciseDocumento1 páginaSafety Moment Hand ExerciseEvert W. VanderBergAún no hay calificaciones

- Lifting Awkward PosterDocumento1 páginaLifting Awkward PosterEvert W. VanderBergAún no hay calificaciones

- Ergonomic Awareness CourseDocumento46 páginasErgonomic Awareness CourseEvert W. VanderBerg100% (1)

- Safety Moment House KeepingDocumento1 páginaSafety Moment House KeepingEvert W. VanderBergAún no hay calificaciones

- Machine SafeguardingDocumento72 páginasMachine SafeguardingEvert W. VanderBergAún no hay calificaciones

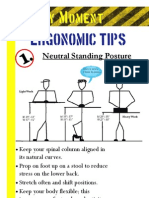

- Neutral Standing PosterDocumento1 páginaNeutral Standing PosterEvert W. VanderBergAún no hay calificaciones

- Safety Moment Use Machine GuardingDocumento1 páginaSafety Moment Use Machine GuardingEvert W. VanderBergAún no hay calificaciones

- Safety Moment Slips & FallsDocumento1 páginaSafety Moment Slips & FallsEvert W. VanderBergAún no hay calificaciones

- Safety Moment Hand ProtectionDocumento1 páginaSafety Moment Hand ProtectionEvert W. VanderBerg100% (1)

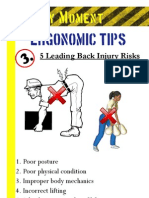

- 5 Leading PosterDocumento1 página5 Leading PosterEvert W. VanderBergAún no hay calificaciones

- Safety Moment Hard HatsDocumento1 páginaSafety Moment Hard HatsEvert W. VanderBergAún no hay calificaciones

- Safety Moment Manual LiftingDocumento1 páginaSafety Moment Manual LiftingEvert W. VanderBerg100% (1)

- Esd Toolkit v2Documento142 páginasEsd Toolkit v2Evert W. VanderBergAún no hay calificaciones

- Flammable and Combustible LiquidsDocumento4 páginasFlammable and Combustible LiquidsEvert W. VanderBerg100% (2)

- Understanding Flammables and CombustiblesDocumento29 páginasUnderstanding Flammables and CombustiblesEvert W. VanderBerg100% (1)

- Angew Chem Int Ed - 2020 - Sarkar - A Neutral Three Membered 2 Aromatic Disilaborirane and The Unique Conversion Into ADocumento5 páginasAngew Chem Int Ed - 2020 - Sarkar - A Neutral Three Membered 2 Aromatic Disilaborirane and The Unique Conversion Into ATutu CaiAún no hay calificaciones

- 15 Enzymescornell NotesDocumento2 páginas15 Enzymescornell NotesRusselAún no hay calificaciones

- Installation Procedure EQOBRUSH For Heat Exchangers and CondensersDocumento16 páginasInstallation Procedure EQOBRUSH For Heat Exchangers and CondensersWatco GroupAún no hay calificaciones

- Sustainability 14 08783 v2Documento27 páginasSustainability 14 08783 v2Shaker QaidiAún no hay calificaciones

- Hydroprocessing: Hydrocracking & HydrotreatingDocumento45 páginasHydroprocessing: Hydrocracking & HydrotreatingRobin ZwartAún no hay calificaciones

- Prof. K.K.Pant Department of Chemical Engineering IIT DelhiDocumento17 páginasProf. K.K.Pant Department of Chemical Engineering IIT DelhiMehul VarshneyAún no hay calificaciones

- Aldehydes Ketones Acid CompressedDocumento23 páginasAldehydes Ketones Acid Compressedmanmohtiwari001Aún no hay calificaciones

- Aldehydes and Ketones-02 Solved ProblemsDocumento13 páginasAldehydes and Ketones-02 Solved ProblemsRaju SinghAún no hay calificaciones

- Bisulfite Liquor Production: Daradal Edorot Pajela CadalsoDocumento8 páginasBisulfite Liquor Production: Daradal Edorot Pajela CadalsoJudy Marl Bingcolado ElarmoAún no hay calificaciones

- Etching Titanium With HF and Nitric Acid SolutionsDocumento13 páginasEtching Titanium With HF and Nitric Acid SolutionsKazuoAún no hay calificaciones

- Colorants and Auxiliaries Vol 2Documento455 páginasColorants and Auxiliaries Vol 2Putri Mayangsari100% (11)

- Sulfur Handbook PDFDocumento24 páginasSulfur Handbook PDFselvaraj5natesanAún no hay calificaciones

- Fluorinated Polymeric Materials: PTFE, FEP, PFA, ETFE: CharacteristicsDocumento1 páginaFluorinated Polymeric Materials: PTFE, FEP, PFA, ETFE: CharacteristicsrocketvtAún no hay calificaciones

- 370 HW 1 SDocumento9 páginas370 HW 1 SNikka LopezAún no hay calificaciones

- KimiaDocumento28 páginasKimiazannubaqotrunnadhaAún no hay calificaciones

- Q2 Lesson Plan 5Documento21 páginasQ2 Lesson Plan 5NOVA LESLIE AGAPAYAún no hay calificaciones

- Periyanayaga Kristy.A M.Tech - Nanotechnology SRM UniversityDocumento50 páginasPeriyanayaga Kristy.A M.Tech - Nanotechnology SRM University05 - JANVI BHATANKARAún no hay calificaciones

- Chemestry Project - Foaming-Capacity-Of-Soap Project 1Documento8 páginasChemestry Project - Foaming-Capacity-Of-Soap Project 1Shubham ChauhanAún no hay calificaciones

- Fakhreddine Exam2Documento10 páginasFakhreddine Exam2Jihye Jennifer HaAún no hay calificaciones

- Bresle Kit Chloride Test Kit Sp7310 m44Documento6 páginasBresle Kit Chloride Test Kit Sp7310 m44nnuekAún no hay calificaciones

- CHAPTER 1 Importance of PetrochemicalDocumento40 páginasCHAPTER 1 Importance of PetrochemicalSyahmiAún no hay calificaciones

- JETIR1804332Documento4 páginasJETIR1804332MAYANK SHARMAAún no hay calificaciones

- 2016 Book NewApproachesToBuildingPatholo PDFDocumento214 páginas2016 Book NewApproachesToBuildingPatholo PDFCarlos Augusto Sanchez RondonAún no hay calificaciones

- Biological Molecules and Spectrophotometry: Bio 171 Week 2Documento31 páginasBiological Molecules and Spectrophotometry: Bio 171 Week 2Victor ZiyechAún no hay calificaciones

- Applied Sciences: Gold Nanoparticles For Drug Delivery and Cancer TherapyDocumento21 páginasApplied Sciences: Gold Nanoparticles For Drug Delivery and Cancer TherapyGénesis OsorioAún no hay calificaciones

- Formula Writing and Naming of CompoundsDocumento24 páginasFormula Writing and Naming of CompoundsKentCastro100% (2)

- Waste Water TreatmentDocumento35 páginasWaste Water TreatmentNaveen Meena100% (1)

- Types of Animal-Based On Excretion of Nitrogenous Waste: Aminotelic AnimalsDocumento5 páginasTypes of Animal-Based On Excretion of Nitrogenous Waste: Aminotelic AnimalsRica NorcioAún no hay calificaciones

- Concrete Technology 100 Objective QuestionsDocumento8 páginasConcrete Technology 100 Objective Questionsanbumani100% (1)

- 02-General Principals of Metallurgical operations-Ques.-Final-EDocumento11 páginas02-General Principals of Metallurgical operations-Ques.-Final-EAbhishek RavirajAún no hay calificaciones