Documentos de Académico

Documentos de Profesional

Documentos de Cultura

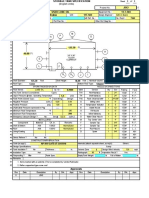

API 650 - Storage Tank Design Calculation

Cargado por

lsgmz100%(1)100% encontró este documento útil (1 voto)

231 vistas12 páginasAPI 650 Design Calculation

Título original

API 650_storage Tank Design Calculation

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoAPI 650 Design Calculation

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

100%(1)100% encontró este documento útil (1 voto)

231 vistas12 páginasAPI 650 - Storage Tank Design Calculation

Cargado por

lsgmzAPI 650 Design Calculation

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 12

TABLE OF CONTEN

TANKTAGNO: —502.28.01

DESCRIPTION

DESIGN DATA

SHELL COURSE THICKNESS

BOTTOM & ANNULAR PLATE, THICKNESS

ROOF PLATE THICK

ROOF TO SHELL JUNCTION CALCULATION

SEISMIC FORCE CALCULATION

‘WEIGHT CALCULATION

ROOF STRENGTHENING CALCULATION

Pegs

502 2801 x

Lo

L

4

STORAGE TANK DESIGN CALCULATION - API 650.

DESIGN CODE & SPECIFICATION

‘DESIGN CODE

TANK

Trem nue

Roof { OpentCiose )

Tank support (Self-supported/Column-supparea)

Type of roof ( Cone-coof ‘Dome-roof)

GEOMETRIC DATA,

Thside diameter ,DiCcomoded )(@ 4000 mm)

‘Nomina diameter, Dn (new ) based on tt shell course)

[Nominal diameter, De-( corroded) hased on 1st shell course )

‘Tank height (tan),

Downe mot radias, Rd USDA = Re |.2De)

Specific eravity of operating Hid 8.

‘Nominal capacity, V

“Maximum esign liquid level, HL

PRESSURE & TEMPERATURE,

‘Design pressure Upper Pa (9880

Lower, PL co

Design temperature: Upper Tu

Lower, TL

MATERIAL & MECHANICAL PROPERTIES

[Componear Wisieral Tene

‘Stress

Sum’

[PLATE

[Shell Pate (Marl Code#1)(bot) $0420.00

(Matt Code#2)(lop)—304—520.00

JArnular Plate - -

Jpotom Plate sot 520,00

Roof Pie 5o4___$20.00,

[STRUCTURE MEMBERS

Roof stucrre(raftecbracingete ) : -

[cotunm Support :

[Top Curb Angle oC)

sum water)

sun water)

ges 3

APT 630 1998

= $0228 01

Close

= SelFsupposted

plitanat

4000 mn

4008 xm,

44008 en

9990 am

4,000 aan

Le

1206 oF

9380 mm

939.80 mbar

0.00 mbarg Vac

325,

“10°C

saab

‘SHELL THICKNESS CALCULATION BY ONE-TOOT METHOD

HELL DESIGN

GEOMETRICDATA

Plate size used 1500 ram

MATERIAL & MECHANICAL PROPERTIES,

No” Material Specified Specified Vieldstrest ‘Max allow” Max, alow Corrosion

‘used min, tensile min. yield reduction fac design hydrastest—allawance

sess stress (App.M) stress stress

St Win) Sy (Nm?) ke Sdn) Sema) 6-2 (mm)

1 308 s20.00 295.00 1.000 13667 153.75 0.00

2 304 $2000 205.00 Lone 13667 © 183.75, 0.00

3 30t 520.00 20500 L000 136.67 15875 9.00

4 304 2000 205.00 100013667 18375, 0.00

5 30H $2000 20500 ono 1368715875 0.00

© 308 520.00 20500 © L000 136.87 15875 0.00

7 308 $2000 20500 = .000 136,67 15875 0.00

8 - - - - : .

9 . . - I

be - - - : : -

2.3 _ SPECIFIED MINIMUM SHELL THICKNESS

‘Specification APT 650 1998

‘Minimum thickness 560 mm

2.4 _ SHELL THICKNESS CALCULATION BY ONE-FOOT METHOD (CLAUSE 36.3)

SIMETRICUNT:=

Design shell thickness, im mm)

4.9De (TH#HI}-0.3).G

js - ———— +a

sa

Hydrostatic test shell thickness, in am )

fo, Mat Material Width Height” “tdesign _uhyaro. cin Be

Code nm) (2mm) (mm) (emmy (eum) (amy

No.

11 3H Iso) 9580 a7 19 5.400 sa ok

2 1 toh 10 OHS 099 3.00 sa Ox

301 Shh Sm 580 40 5.00 Ban OK

401 3 tm) S080 879 961 3.40 S.0 OK

51 Mt su 3580339 oa 00 800. OK

6 1 308 ts) 3000328 034 5.40 so ox

ne ee ee) ous 300 kao ox

ao - - - -

94 . : : : -

oot - : : : :

Nae Taaiae feohepht ant aihashell same,

sana

BOTTOM & ANNULAR PLATE DESIGN

3.0 BOTIOMPLATE ANNULAR LATE DESIGN

“Annular pate used? (yevno)

BOTTOM PLATE

(0 Wntmum thickness asper API 630 198 Clase 3.6.1

‘Minimum thickness required (@ 110 mmea)

‘Therefore, use thickness of 10.50 mam (is

i) Min, sello-borona fille weld size (3.1.5.7)

Min, width of overlapping (@.3.12.5)

(iv) Min. dstagce between 3-plate laps in tank botoms (cl.

(9) Mia. wide of plate (1 3-41)

(i) Min. wide projeste curse of! (el 34.29

54)

ssnistoctry

22601

ROOF PLATE DESIGN page: 6

4.0 ROOFPLATE DESIGN

"Minimum thiekness as per Cleats spexiestion - 680 mam

‘Minimum thickness required (@ 0.00 mm) - 6.00 mm

“Therefore, we thickness of 6.00 mmis——_salislnceny.

4.2 ROOF LOADING

"Root pate lapping evr, a = 1.00

Roof pate weight, @ Roof th 6. mmave(phss lapping) 0.000462 Nim

‘Vacuum pressure. Va = 1000000 nnn?

Ansulrion wet, wi = thiex tho) @ — 6.00 emma) 0.00 = 0.000000 Nima?

Snow weigh, ws = 0000000 Nima

Unifocm live loadel (@ 122.00 kgm’) 9.001187 Naum?

‘Additional Live lead (@ 00 kg) = 0.900000 Nn?

Tooal live load + dead Joads.wld (@ 9.001659. Némm? 160 kPa

. 2.20 kPa

“The compeessionarca shal be increased by the folowing ratio, 108

(Zor SelP Supporting Root design }

CLOSE ROOF TANK

5.0 __ DESIGN OF ROOFTO.SHELL JUNCTION IN ACCORDANCE TO APPENDIX E

TiO. 10x 8

Unit wae (22 pin

Arca 1350 mm?

Leng 100 ma.

1,550 mm?

P= Dome Root nas

B= Dome eof slope

5 At therofine itis

Dena

[ema een

Daten

4008 mm

19580.060 mm of water

6.00 mm

8.000 erm

.0n0 °

sav

aos tava,

Ls

snasorale

69

ran

2

SRISMIC FORCE CALCULATION

“SEISMIC TOADS DESIGN

GEOMETRIC DATA

‘Seismic ane faeton, Z

Importance factor, I max. 1.25)

‘Nominal diameter of tank, De

“Total height of tank shell, Ht

Hit Fom bot shel ta COG of tank,Xs

‘Maxim desig Liquid level,

‘Total weight of tank shell, Ws

‘Total weight of tank ref, We

“Total weight of ank contents, We

770 ke)

664 kg)

220,667 kg)

S88

OVERTURNING MOMENT

EFFECTIVE MASS OF TANK CONTENTS

Ralf of Del

From figure B-2,

wuwe

wr We

‘WL ofthe ef, mass of tank contents that move i unison with the tank shel

wi = Wex WLW)

WE ofthe eff, mass of tank contents that rave inthe frst slashing mode,

wa = Wex WWE)

From figure B-3,

xWH

sort

Ht from shell bottom o centroid of atral seismic force applied to WE,

x =H XU)

“He from shell bottom to cent of lateral seismic farce applied vo W2,

x2 =HxewH)

LATERAL FORCE COEFFICLENTS

Tatcral free eoethivient, CL

‘Natural peti ofthe frst slashing mode,

where

(De304.8)"

= factor obtained from Figure Et

[Wien 48,

[stra foree coefficient,

33758

2 -

Pr

= Site coeficient (Table E-3)

ote

ous

1.00

4008.00 mm

9580.00 mm

4790.00 mi

9580.00 mm

15.24N

SUN

2,165,745 N

oats

oa

08

2,908,793 8

271258

oas

on

3640 mm

7472 mm

46

210s

038

si2280iste

6.23 OVERTURNING MOMENT.

‘Gvertursing woment,

M =Z1(CLWsX8+CLWeHt+CLWLXI+C2W2X2) =

6 3__ RESISTANCE 10 OVERTURNING

pone 8

859046396 Nm

©31 THICKNESS OF THE BOTTOM PLATE UNDER THE SHELL & ITS RADIAL WIDTH

‘Boviony Annular plat Gickaess, 0

“Thiekness of bottom shel course bs

BotomAnmular pate radial width, wha -

‘Since th = greater of bs, ron, therefore itis

6.4 __ SHELL COMPRESSION

WE ofan sl and portion of the fixed roof supperted by the shell, wt

(8) ANCHORED TANKS.

“Maxima longrdinal shell compression,

LM

6 swt

De

Since WI2bs 48 n/m,

83.abs

Pa -

De

‘Therefore, Fa (< O.5Fty )

where

Fey = Min specified yield strength of the bottom shell course

$5. TANK ANCHORAGE

‘SRT GEOMETRIC DATA

‘Naber af bats, N -

Dia. of anchor boll, 2

Dia. of anchor boltdcor (loss 19990 tmm(minsive. 284 mim) =

Bots etele diameter. Da .

‘Root asa of each Kold dowa bolt, Ab -

Spacing between enchor bolts, Sp

6.52__ MATERIAL & MECHANICAL PROPERTIES

“Materia used

Specific minimum yieid sess, Sy -

‘Allowable tensile stent, Stall (1.38 x 0.608y ) (App. E462. )

‘Uplift force due to seismic Hoang,

er

tf dee :

rs

Tena rosy

yan -

Shcec samc sie amcrbo seats ist

4.408 mmm?

165.67 Nn?

97.70 Name

208.00 Summ?

208

203 Nim?

163.59 Winn?

russ

69.92 Nim?

smaz8et se

T.WEIGHT ANALYSIS.

ITEM N

S028

Poxe

7 [GENERAL

[Design [Type of tank suppor = Type of roof

code. ADL 50 1098 Selisupportis pla-roat

Tnside [Fank height [Dome roar hadius, kr (.8DE= Re Tae F

diameter 200 mn 9s) mom \u.o60 ue

Steel density oof plates lapping "Annular/Botom plates lapping

so00 kgm? [factor Loo ff st

7 [SHELL COURSES

lone -FOOT METHOD y

CourseNo, Material Wid Weight :

(um) «2

1 304 1304) 1209

2 34 1s 1209

3 304 is 1209

4 Bn 1K) 1209

8 n se 467

6 wit 1509 1209

7 wa 1500) 1209

8 :

9 . :

10 :

‘Total weight of shell plates ~ 7,720 ky.

3 [ROGER PLATES. ¥

“Material ‘Thickness Area Weight

(um) (eum) (ks)

Mt uo 13828087 664 664 kg

7 [BOTTOM PLATES

“Material "Thickness Outside Dia, Weight

(am) (nm) de)

4 14.00 066 1039 = 1,039 kg.

ro

‘Thickness Mean Di Weight

(um) (mm tke)

kg

© [PoP CURE ANGLE ¥

‘Material ‘Sie Qty Length Unie Weight Weight

dam) (agen) kg)

Ma Labia West 1 aya) an IR = 158 ke

7 [INTERMEDIATE WIND GIRDERS, ¥

[Material Size Qly Length Unit Weight Weight

fem) (kg) (ke)

Ok

sin 2R Ie

[FLAT ROOF WITH RAFTERS

Rafers

ORISA LAO MORTON 4 BIO

(SELI-SUPPORTED ROOF WITH RAFTERS

[Materar Sue Qe) Length

(um)

Unit Weight

e/a)

ose

Weight

)

1536

‘Total weight of roof structures

‘ages

1,536 kg

ROZALES

FTotal weight of nozzles

¥

1,500 kg

70

MISCELLANEOUS

[Assuming 10.00% of otal weight

4.262 kg

mm

STAIRWAY & PERIMETER PLATFORM.

[Assuming “TOO of total weight —

1.202 kg

%

(OPERATING LIQUID WRIGHT.

[Operating liquid height Ter:

0

mm & 5g @=

183)

220,667 bg

i

AYDROSTATIC WATER WEI

[Hydrostatic waterheight——(@— oS

mm)

120,386 kg

ERECTION WEIGHT

JOPERATING WEIGHT

|HYPROSTATIC TEST WEIGHT

T3140 Fe,

235,807 ke,

135,525 kg

sne2aonsty

FLAT ROOF WITH STIFFENER DESIGN page: 11

8.1 GEOMETRIC DATA

Taside diameter, Di - 40000 mm,

Conosion allowance, ¢.a = 0.000 mm

ROOF PLATE THICKNESS CALCULATION

8.2 ROOFLOAD

Value of lap Tor roof plate, a Low

Roof plate weight . @ Roof thk = 6410 —-mm,wr (plus lapping) 0.000462. Nimmé

‘Vacuum pressure , Va 2.000000) Nisam?

Insulation wet, wi(=thkx tho) @ 0.0) (mm) x v.00 0.000000 Nin?

Snow weight, ws 9.000000 Nim?

Uniform live load,w1 (@ 122.00 gin?) 0.001197 Nim

Additional live load,wa (@ 0.00 kein?) 0.000000 Nim

Total live load + dead loads.wld (@ 0.001659. Niram* - 1.66 kPa

< 220 kPa

‘The compression area shail be increased by the following ratio, k 100

502.28¢1.le

erwin

8.3 FLAT ROOF CASK WITH STIFFENER.

33.1 MINIMUM THICKNESS AS PER ROOF LOADING

‘Assume rool plate thickness, ¢

‘Number of stiffener, Ns

Distance between stiffener, Ls

Ratio of DLs

BI

Bending stress at center of long edge,

BLwidLs?

sb —

(Gea)?

Since sb < 0.678y, therefore the roof plate thickness is

page: 12

= 6.00 mm.

= 4

- 1000 mam,

mn

= 4.00

= 0.4974

- 22.92 Nem?

ssuisfuctory.

502.28.01.xls

page: 13

8.3.2 STIFFENER SIZING CALCULATION

“Total oof load, Wer (@ 12) increasing factor) = 25015 N

Roof load exerted per stiffener, W 6254.

Stiffener size + 1730030081015

Sitifener material 2 Q235-A

Unit weight, wst - 96 kg/m

Specified minimum yield strength, Sy - 235 Nim?

Section modulus, Z 1440000) mmm?

Assume simply supported at both end,

WDi

Bending stress, sb =| <——— - 2.17 Némn?

8Z. .

Since sb < _O.6TSy, therefore the size selected is satisfactory.

502.2801.xb8

También podría gustarte

- Storage Tanks CalculationsDocumento21 páginasStorage Tanks Calculationsjimallen21288% (26)

- API 650 Water Storage Tank - Xls 36Documento71 páginasAPI 650 Water Storage Tank - Xls 36rudi 01Aún no hay calificaciones

- Storage Tank CALC Api 650Documento10 páginasStorage Tank CALC Api 650kuselanml100% (3)

- STORAGE TANK DESIGNDocumento7 páginasSTORAGE TANK DESIGNMichael Robert Gatdula SamarAún no hay calificaciones

- Mechanical Calculation Sheet Drafting Procedure PDFDocumento50 páginasMechanical Calculation Sheet Drafting Procedure PDFlongnhar100% (10)

- API MPMS ListDocumento6 páginasAPI MPMS ListhtutsweAún no hay calificaciones

- API MPMS ListDocumento6 páginasAPI MPMS ListhtutsweAún no hay calificaciones

- B ABJ 5000 2 API 650 Calculation ReportDocumento46 páginasB ABJ 5000 2 API 650 Calculation ReportSalamaAún no hay calificaciones

- Example Tank Calculation PDFDocumento108 páginasExample Tank Calculation PDFPricop Cosmin100% (2)

- Tank Design Sample As Per API 650Documento6 páginasTank Design Sample As Per API 650Gutaiba Almasri100% (1)

- API 650 Design TanksDocumento39 páginasAPI 650 Design TanksAhmedAli25% (4)

- Storage Tank Design Calculations - Seismic Design & Overturning Moment - by Abdel Halim GalalaDocumento10 páginasStorage Tank Design Calculations - Seismic Design & Overturning Moment - by Abdel Halim Galalamarkfgt57% (7)

- AMETank PDFDocumento6 páginasAMETank PDFMadan Yadav50% (2)

- API MPMS ListDocumento5 páginasAPI MPMS Listhtutswe0% (1)

- API Standard 650 Storage Tank Data SheetDocumento3 páginasAPI Standard 650 Storage Tank Data SheetLuis JaraAún no hay calificaciones

- API 650 Tank Design 1Documento5 páginasAPI 650 Tank Design 1robertantoreni100% (9)

- Myanmar Energy ReportDocumento11 páginasMyanmar Energy ReportarakanoilwatchAún no hay calificaciones

- Myanmar Energy ReportDocumento11 páginasMyanmar Energy ReportarakanoilwatchAún no hay calificaciones

- Myanmar Energy ReportDocumento11 páginasMyanmar Energy ReportarakanoilwatchAún no hay calificaciones

- StandardsDocumento24 páginasStandardshtutswe0% (1)

- Amp RevaDocumento6 páginasAmp RevajavilapiedraAún no hay calificaciones

- Moge Web OffshoreDocumento27 páginasMoge Web OffshoremmpetroengAún no hay calificaciones

- ASME - Sample .Questions - 1Documento22 páginasASME - Sample .Questions - 1htutsweAún no hay calificaciones

- Required File Name Reaffirmed Title EquivalentDocumento22 páginasRequired File Name Reaffirmed Title Equivalenthtutswe100% (1)

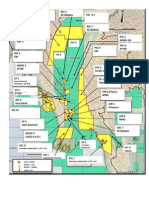

- Offshore MapDocumento1 páginaOffshore MaphtutsweAún no hay calificaciones

- Developments in Myanmar Energy SectorDocumento44 páginasDevelopments in Myanmar Energy SectorBhamotharAún no hay calificaciones

- Moge Web OffshoreDocumento27 páginasMoge Web OffshoremmpetroengAún no hay calificaciones

- Myanmar PDFDocumento18 páginasMyanmar PDFhtutsweAún no hay calificaciones

- Onshore MapDocumento2 páginasOnshore MaphtutsweAún no hay calificaciones

- Overview of Myanma Petrochemical EnterpriseDocumento26 páginasOverview of Myanma Petrochemical EnterprisehtutsweAún no hay calificaciones

- Moge Web OffshoreDocumento27 páginasMoge Web OffshoremmpetroengAún no hay calificaciones

- Developments in Myanmar Energy SectorDocumento44 páginasDevelopments in Myanmar Energy SectorBhamotharAún no hay calificaciones

- Onshore MapDocumento2 páginasOnshore MaphtutsweAún no hay calificaciones

- Onshore MapDocumento2 páginasOnshore MaphtutsweAún no hay calificaciones

- Offshore MapDocumento1 páginaOffshore MaphtutsweAún no hay calificaciones

- Offshore MapDocumento1 páginaOffshore MaphtutsweAún no hay calificaciones

- Offshore MapDocumento1 páginaOffshore MaphtutsweAún no hay calificaciones

- Offshore MapDocumento1 páginaOffshore MaphtutsweAún no hay calificaciones

- Onshore MapDocumento2 páginasOnshore MaphtutsweAún no hay calificaciones

- Offshore MapDocumento1 páginaOffshore MaphtutsweAún no hay calificaciones

- Offshore MapDocumento1 páginaOffshore MaphtutsweAún no hay calificaciones

- Onshore MapDocumento2 páginasOnshore MaphtutsweAún no hay calificaciones

- Offshore MapDocumento1 páginaOffshore MaphtutsweAún no hay calificaciones

- Developments in Myanmar Energy SectorDocumento44 páginasDevelopments in Myanmar Energy SectorBhamotharAún no hay calificaciones