Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Msa 2013123114002807 3

Cargado por

Ali MoghiTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Msa 2013123114002807 3

Cargado por

Ali MoghiCopyright:

Formatos disponibles

Materials Sciences and Applications, 2013, 4, 856-862

Published Online December 2013 (http://www.scirp.org/journal/msa)

http://dx.doi.org/10.4236/msa.2013.412109

Distribution of Electromagnetic Force of Square Working

Coil for High-Speed Magnetic Pulse Welding Using FEM

Ji-Yeon Shim, Bong-Yong Kang*

Environmentally Materials & Components Center, KITECH, Jeonju-si, Korea.

Email: shimjy@kitech.re.kr, *kanbo@kitech.re.kr

Received September 10, 2013; revised October 21, 2013; accepted November 18, 2013

Copyright 2013 Ji-Yeon Shim, Bong-Yong Kang. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly

cited.

ABSTRACT

Magnetic pulse welding process, one of high speed welding processes, uses electromagnetic force from discharged current through a working coil which develops a repulsive force between the induced currents flowing parallel and in the

opposite direction in the pipe to be welded. For achieving the successful weldment and using this process, the design of

working coil is the most important factor, because working coil has to generate a high-intensity magnetic field on the

surface of the workpiece during the process. Therefore, the objective of this study is to analyze the distribution of electromagnetic force of square working coil for magnetic pulse welding. For this, FE-model has been developed to analyze

the distribution of electromagnetic force; after that, distribution of electromagnetic force, results of numerical analysis

and experimental results for verifying the developed FE-model were compared. A 3-dimensional electromagnetic

FE-model has been developed using a general commercial computer program, ANSYS/EMAG code. The shape and

material of square working coil were decided through literature surveys. For the experiment, an MPW equipment

W-MPW manufactured by WELDMATE Co., Ltd. was employed; also the materials were the Al 1070, SM45C for Al

and Steel square pipe and rod respectively. After the experiment, leakage test was used to verify the weldability. Also

weld joints were observed on longitudinal cross-section by microscope. The electromagnetic force generated was the

greatest one at the center adjacent to square working coil, decreasing as moving into the edge. As the result of Al/Steel

welding experiment, weldment of square Al pipe was not completed at the corner of weldment. These results are similar

to the output data from developed electromagnetic FE-model where electromagnetic force decreases as moving into the

corners of square working coil.

Keywords: Magnetic Pulse Welding; Working Coil; Electromagnetic FE-Model

1. Introduction

The car industry is currently working to accommodate

the conflicting requirements of both environmental legislation and customer demands for high performance and

safety by developing a light-weight vehicle [1]. So the

light weight materials such as aluminum and magnesium

have been applied in automation. Especially, development of aluminum space frame for automotive body

structure has been carried out in recent years [2]. However, when only light materials are used in automotive

body structure, they cannot satisfy the required intensity

and strong property, and it is imperative to weld light

weight materials with existing used ones. Accordingly, it

*

Corresponding author.

Open Access

has been required to study on welding of dissimilar metals [1] due to the different physical properties between

materials. Welding as existing fusion welding generally

causes not only defects, such as solidification, cracking,

porosity and oxidation, but also transformation and corrosion. For this reason, more attention has been paid to

magnetic pulse welding process as a kind of solid-state

welding these days.

In the magnetic pulse welding process, welding is

achieved by the pressure for outer workpiece that only

uses the electromagnetic force which takes advantage of

Flemings left-hand rule. The electrical energy stored in

the magnetic pulse power source is discharged instantaneously as a high current to the working coil by a trigger

discharge, and thus an induced current is generated at the

MSA

Distribution of Electromagnetic Force of Square Working Coil for High-Speed Magnetic Pulse Welding Using FEM

conductive outer workpiece positioned within the working coil. For successful magnetic pulse welding, it is important to develop a working coil that can gain enough

electromagnetic force for welding.

This process is a complicated research area involving

different aspects including electro-magnetic, mechanics,

thermal, and material science. The extensive knowledge

in this complicated area is not easily obtained, as the variety of experimental setups and the complicated dynamic interaction between different phenomena in the

welding process are extremely difficult to describe in a

closed analytical form. Therefore, computer modeling of

the welding process is a useful approach for better insight

into dynamic deformation mechanics with electro-magnetic field interaction, and further it provides design and

quality control information.

Research on the working coil of the magnetic pulse

welding is concentrated on the foundation of the theoretical analysis of electromagnetic forming [3,4]. Li et al.

[4] presented a numerical simulation of the magnetic

pressure in tubular working coil. Also Zhang [3] analyzed the shape and material of the single and multi turn

solenoid coil with finite element method. Takatsu et al.

[5] formulated a mathematical model to solve the problem of forming of a circular disk interacting with a pancake coil. The assumed axisymmetry of the problem

along with other simplifying assumptions, has been used

to obtain a set of partial differential equations for the

magnetic field, mechanical displacement, and the current

in the coil [6,7]. CALE code was employed by Fenton

and Daehn [8].

As mentioned above, the study on tubular structure

working coil has usually been reported, but the one on

the square working coil has never been reported. Consequently, the objective of this research is to develop FEmodel for square working coil in magnetic pulse welding

which is a basic research for manufacturing the automotive space frame. For this study, first, the shape and material of coil were decided through literature survey.

Second, a 3-dimensional electro-magnetic FE-model for

electromagnetic phenomenon of square working coil by

using the ANSYS/EMAG software has been developed.

The comparison between the calculated and measured

results was finally done to verify the developed electromagnetic FE-model.

857

of magnetic pulse welding is based on the physical phenomena of magnetic fields induced by an electric current

[9]. It is well known that two conductors with their electric currents travelling in opposite direction repels due to

the interaction of their oppositely orientated magnetic

fields induced. Figure 1 shows in the initial coil, the inductor, a current impulse which in turn, generates a current of the opposite direction in the outer workpiece. A

electromagnetic force to the initial coil causes the outer

workpiece to impact at a tremendous force and speed at

the inner workpiece, resembling an explosion taking

about 20 millionths of a second [7].

The magnetic pulse welding system consists of magnetic pulse power source for charging extreme energy

and working coil for discharging it. To generate the

high-current impulse an arrangement of capacitors, an

arrestor-discharge and a working coil has been constituted the core of the magnetic pulse module, as shown in

Figure 2 [10,11]. The capacitors, special high-voltage

capacitors with extremely low self-inductance, can store

charge up to a certain maximum level that is determined

by the arrestor-discharge, which creates a short, highcurrent pulse in the work coil [6].

Working coil

F

Discharged

current

F

I

Outer workpiece

Inner workpiece

Figure 1. The principle of the magnetic pulse welding process [7].

4. Work Coil

(Inductor)

3.

Discharge

Capacitors

Switcher

1. Rectifier 2. Bank of

6. Outer Member

to be Welded

5.

Magnetic

Field

2.1. Magnetic Pulse Welding

The magnetic pulse welding is a solid-state, cold-welding

process that is accomplished when a magnetic pulse

causing a high-velocity impact between two materials,

resulting in a true metallurgical bond [8]. The technology

is principally similar to explosion welding. The principle

Open Access

220/380

2. Development of Square Working Coil

7. Inner Member

to be Welded

(Tubing or Solid)

Figure 2. The system of magnetic pulse welding [11].

MSA

858

Distribution of Electromagnetic Force of Square Working Coil for High-Speed Magnetic Pulse Welding Using FEM

3. Numerical Analysis

320

85

52

52

After shape and material of coil was chosen, electromagnetic force needed to welding should be confirmed.

However, there is a limitation for electromagnetic force

Table 1. Mechanical and electrical properties.

Material

Hardness

(Vickers)

Electrical

Resistivity

(ohm-m)

Permeability

()

Al 6061

75

4.32e-8

Cu1220

50

1.70e-8

Becu17000

2.94e-8

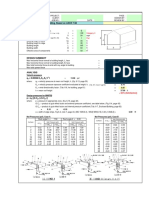

A-A (0.35 : 1)

25

100

85

276

Figure 3. Square working coil for this study.

used for welding to be studied. Because this force is decided by interactions of electromagnetic and workpiece

model development of numerical analysis can be a useful

means. The electromagnetic force P is expressed the following formula (1) [12-13]. B is magnetic flux density, H

is magnetic field intensity and u is permeability.

P

H2

B2

0

2 0

2

(1)

Development of empirical model for a magnetic pulse

welding process is described by the fundamental Maxwell equations [5]. The magnetic field of the workpiece

is expressed from Equations (2) to (5).

B

t

(2)

E 0

(3)

H 0

(4)

H J

(5)

where E is the electric field intensity and J is the electric

current density. To these differential relations, the constitutive relations are included from Equations (6) and (7).

Where is the permeability and is the conductivity.

B H

(6)

J E

3.1. Analysis Method and Procedure

Open Access

15

As I mentioned before, magnetic pulse welding uses the

electromagnetic force from current discharged through

the working coil which develops a repulsive force between the induced currents flowing parallel and in the

opposite direction in the workpice to be welded. However, the theoretical analysis for development of perfected working coils considering various factors hasnt

been established yet. Nevertheless generally the considered factors were classified into a shape and an electric

property [10]. Therefore firstly, the shape considering a

welding direction according to application is decided.

Second, distribution an electromagnetic force by the interaction between working coil and outer pipe should be

investigated after selecting materials that electric resistance is low and that has enough intensity mass possible

to resist electromagnetic force on processing.

The shapes of working coil used in welding are generally classified into a compression coil, an expansion coil

and a plate coil. A compression coil is the solenoid type

surrounding processed materials which is welded from

outside direction to inside. Expansion coil is inserted

inside processed materials and welded from inside to

outside. A plate coil which located on and under the

processed material was employed in plate welding [3].

Therefore, the shape of solenoid-typed compression coil

was chosen between compression coil and expansion one

that are used in joining of pipes because it is located in

the outside of the specimens. In addition it has no size

limit as well as simple connection magnetic pulse power

source.

The material of working coil should allow for an electric feature such as conductivity to prevent the damage of

condenser by duration of magnetic field or sudden discharge. Therefore, copper, aluminum and berylliumcopper, as shown in Table 1 have been considered and

selected the beryllium-copper for this study. Figure 3

shows the developed square working coil.

185

2.2. Shape and Material

(7)

As the workpiece is treated as a single turn square coil,

the boundary conditions can be assumed as follows [5].

To these differential relations, the constitutive relations

are included.

In the Cartesian coordinate system, not only B (magnetic induction intensity) is perpendicular to x axis at y =

0, but also A (vector magnetic potential) is equal to zero

at x = 0.

(8)

where is the permeability of the conductor, is elecMSA

Distribution of Electromagnetic Force of Square Working Coil for High-Speed Magnetic Pulse Welding Using FEM

trical conductivity of the conductor material, and

2 f is angular frequency of the current.

The skin depth effect is an important factor in high

frequency conductors. When a high frequency current

flows through a conductor, the current tends to flow on

the conductor surface. The magnitude of the current is

exponentially decreased with the depth of penetration

into the conductor. The depth at which the value of the

current decreases to 1/e (37%) of the surface current is

defined as skin depth and expressed the following [5]:

The numerical analysis has been done through ANSYS/EMAG that a general electromagnetic mechanics

computer program. Figure 4 shows a schematic diagram

for magnetic pulse welding this study.

The 3D axisymmetirc model for a coil to outer pipe

interaction was chosen numerical calculations for working coil and outer pipe were performed for Beryllium

Copper and Al respectively. Table 2 shows the material

properties for working coil and outer pipe. Current was

inputted into the working coil as a sine wave function.

Not only the magnitude was 500 kA a, but also the frequency was 25 kHz for the experiment. To avoid the

calculation complexity of energy transformation, current

was employed as the excitation in the present analysis.

Eight-node quadrilateral elements of mapped mesh with

219,605 nodes and 139,821 quadrilateral elements in

total were employed.

Al pipe

Working coil

859

3.2. Results and Discussion

Figure 5 shows distributions of the magnetic flux density

of the square working coil. Magnetic flux is increased at

the upper part of a coil and concentrated in adjacent corner of coil.

Figures 6(a)-(b) represent the distributions of the electromagnetic force of the square working coil. Especially,

Figure 6(c) indicates the distribution of the electromagnetic force of inside square coil. The maximum electromagnetic force generated in coil is about 951 N and in

the edge about 503 N was measured. When interaction

between a square coil and Al pipe is being processed, the

collision of Al pipe is caused because the electromagnetic force acts from surface to inside of the Al pipe.

As a result, the magnetic flux density and electromagnetic force generated was the greatest at the center

adjacent to coil, decreasing as moving into the edge.

These phenomena occurred because current is accumulated in the corner of the square coil compared with the

solenoid coil at discharging of current.

4. Experimental Works

4.1. Setup and Procedure

To test for the developed working coil efficiency test, as

show in Figure 7, the experimental employed in this

study is a W-MPW manufactured by WELMATE CO.,

LTD.

Table 3 presents the specification for this equipment

that has the maximum charging energy 36 kJ. Additionally, in order to observe a discharge waveform, Rogowski

coil was installed in working coil. [14-17]

Figure 8 represents the outer workpiece (Al) and inner

workpiece(Steel) within working coil were inserted, and

welding conditions as shown in Table 4. Outer pipes of

2mm in thickness and 110 mm in length were machined

from industrial pure aluminium bars of Al1070. Their

outer diameter was 30 mm for straight. And inner rod

was employed the S45C as shown Table 4.

Air

Table 3. Specifications of MPW equipment.

Dimension (mm)

Figure 4. A schematic diagram for magnetic pulse welding.

1445(W) 1838(D) 1220(H)

Weight (kg)

1800

Power requirement

200 V AC, 13.5 kVA

Condenser

Capacitance 720 F

Rated voltage 10 kV

Table 2. Material properties for analysis.

Material

(WDH)

Electrical

Resistivity

Permeability

()

Poissons

ratio

Coil-BeCu

(37.5 37.5 29)

2.7e-008

0.33

Outer pipe-Al

(17.5 17.5 39)

2.9e-008

0.343

-

Air

(77.5 77.5 59)

Open Access

Table 4. Welding condition.

Charged voltage (kV)

Charged electrical energy (kJ)

23

Outer pipe(mm)

Al 1070/30 30 2 t

Inner rod (mm)

S45C/28 28

The gap between outer pipe and

inner rod (mm)

0.75

MSA

860

Distribution of Electromagnetic Force of Square Working Coil for High-Speed Magnetic Pulse Welding Using FEM

(a)

(a)

(b)

(b)

(c)

(c)

Figure 5. Distributions of the magnetic flux density. (a)

Isometric view; (b) Top view; (c) Graph.

Figure 6. Distributions of the electromagnetic force. (a)

Isometric view; (b) Top view; (c) Graph.

For magnetic pulse welding, the gap between Al pipe

and Steel rod was 0.8 mm. After experimenting, the

specimens were ground using emery paper (#400 ~

#1500) prior to welding to remove machine marks

Open Access

MSA

Distribution of Electromagnetic Force of Square Working Coil for High-Speed Magnetic Pulse Welding Using FEM

861

Ch2

Figure 7. A schematic diagram for magnetic pulse welding.

500.00us

0.00s

500.00us

Figure 9. Discharge current waveform (15v/div, 100us/div).

Figure 10. The section of weldment.

Figure 8. A schematic diagram for experiment.

sustained during machining. In addition, ultrasonic cleansing was carried out for approximately 10 minutes within

acetone in order to remove grease. And then the weldment was observed by microscopic on circumferential

cross section.

4.2. Results and Discussion

Figure 9 shows the measured waveform while discharging the energy charged in working coil. The sin-waveform of decreasing vibration was recorded and it took

about 25 us to peak current needed to welding. The

weldment and section of welded part were presented at

Figure 10. Peak current of about 8 kV was measured as

530 kA. In all sides, wave pattern was observed as Figure 11.

However, the wave pattern in the whole area didnt

measured, because welding was not completed at the

corner of a square working coil. These results are similar

to the output data from electromagnetic model that electromagnetic force decreases as moving into the corners

as shown Figure 6.

5. Conclusions

1. The electromagnetic models for a square working

Open Access

Al

Steel

Figure 11. The macro cross-section of weldment.

coil have been developed to find the distributions of

electromagnetic force. The developed models were verified with the comparison of the result data of the experiments.

2. The maximum electromagnetic force generated in

coil is about 951 N and in the edge about 503 N was

measured. The generated electromagnetic force is the

greatest at the centre adjacent to coil, decreasing as

moving into the edge.

3. The sin-waveform of decreasing vibration was

measured with a period of 25 s while discharging the

energy charged in working coil. The welding at the corners was not completed, so it might be required to study

MSA

862

Distribution of Electromagnetic Force of Square Working Coil for High-Speed Magnetic Pulse Welding Using FEM

the suitable knowledge and technology for a square

working coil.

REFERENCES

[1]

Y. B. Park, Design of Joints for the Automotive Space

frame with Electromagnetic Forming and Adhesive

Bonding, Ph.D. Thesis, Graduate School of the Seoul

National University, Seoul, 2004

[2]

K. Ito and H. Kobayashi, Production and Fabrication

Technology Development of Aluminium Useful for Automobile Lightweights, Advanced Engineering Materials,

Vol. 8, No. 9, 2006, pp. 828-835.

http://dx.doi.org/10.1002/adem.200600072

[3]

P. Zhang, Joining Enabled by High Velocity Deformation, Ph.D. Thesis, Ohio State University, Columbus,

2003.

[4]

C. Li, Z. Zhao, J. Li, Y. Wang, and Y. Yang, Numerical

Simulation of the Magnetic Pressure in tube Electromagnetic Bulging, Journal of Materials Processing Technology, Vol. 123, No. 2, 2002, pp. 225-228.

http://dx.doi.org/10.1016/S0924-0136(02)00063-8

[5]

N. Takatsu, M. Kato and K. Sato, High-Speed Forming

of Metal Sheets by Electromagnetic Force, JSME International Journal, Vol. 31, No., 1988, pp. 142-148.

[6]

A.E. Azab, M. Garnkich and A. Kapoor, Modeling of

the Electromagnetic Forming of Sheet Metals: State of the

Art and Future Need, JSME International Journal, Vol.

142, No. 1, 2003, pp. 744-754.

[7]

D. Dudko, V. Chudakov, L. Kistersky and T. Barber

Magnetic Pulse Welding of Tubing: Exploring the Cold

Welding Process, Fabricator, Vol. 26, No. 8, 1996, pp.

62-66.

[8]

G. K. Fenton and G. S. Daehn, Modeling of Electromagnetically Formed Sheet Metal, Journal of Materials

Processing Technology, Vol. 75, No. 1-3, 1998, pp. 6-16.

[9]

A. Kochan, Magnetic Pulse Welding Shows Potential for

Automotive Applications, Assembly Automation, Vol. 20,

Open Access

No. 2, 2000, pp. 129-132.

http://dx.doi.org/10.1108/01445150010321742

[10] J. S. Lee, Electro-Magnetic Forming, KSME, Vol. 28,

No. 5, 1998, pp. 476-486.

[11] H. Hokari, T. Sato, K. Kawauchi and A. Muto, Magnetic

Impulse Welding of Aluminium Tube and Copper Tube

with Various Core Materials, Journal of Japan welding

Society, Vol. 15, No. 4, 1998, pp. 615-622.

[12] V. Shribman, Y. Livschitz and O. Gafri, The Application

of Magnetic Pulse welding in the Automotive Industry,

Proceedings of the Global Powertrain Congress on Advanced Transmission Design & Performance, Vol. 34,

2005, pp. 21-27.

[13] Y. Haiping, L. Chunfeng and D. Jianghua, Sequential

Coupling Simulation for Electromagnetic-Mechanical

Tube Compression by Finite Element Analysis, Journal

of Materials Processing Technology, Vol. 209, No. 2,

2008, pp. 1-7.

[14] J. Y. Shim, B.Y. Kang, M. J. Kang, I. S. Kim, D. H. Park

and I. J. Kim, A Study on the Development of FE-Model

for Square Working Coil in Mangnetic Pulse Welding,

Proceedings of ICPVT-12, Jeju Island, 20-23 September

2009, p. 187.

[15] J. Y. Shim, B. Y. Kang, I. S. Kim, J. H. Lee and I. J. Kim,

Development of FE-Model for Al 5053 Sheet Plate

Forming Using Electromagnetic Force, Journal of Advanced Materials Research, Vol. 335-336, 2011, pp.

1099-1102.

http://dx.doi.org/10.4028/www.scientific.net/AMR.335-3

36.1099

[16] J. Y. Shim, B. Y. Kang, I. S. Kim and D. H. Park, Magnetic Pulse Forming of Thin-Aluminum Sheet Using Barforming Coil, Journal of Advanced Materials Research,

Vol. 335-336, 2011, pp. 621-624.

http://dx.doi.org/10.4028/www.scientific.net/AMR.337.6

21

[17] H. G. Powers, Bonding of Aluminium by the Capacitor

Discharge Magnetic Forming Processes, Welding Journal, Vol. 46, 1967, pp. 507-510.

MSA

También podría gustarte

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- Methods of DehumidificationDocumento4 páginasMethods of Dehumidificationprashant_mahitkar4532100% (3)

- MSC - Adams TutorialDocumento17 páginasMSC - Adams Tutorialjuandpg0% (1)

- Wind Analysis For Low-Rise Building, Based On ASCE 7-98Documento2 páginasWind Analysis For Low-Rise Building, Based On ASCE 7-98reynoldAún no hay calificaciones

- Ground Fault Protection and Coordination in Industrial and Commercial Power SystemsDocumento46 páginasGround Fault Protection and Coordination in Industrial and Commercial Power Systemsgerrzen64100% (1)

- Non Linear Analysis of RC Column PDFDocumento61 páginasNon Linear Analysis of RC Column PDFLabinotMMorinaAún no hay calificaciones

- Papagiannakis Solutions For Text BookDocumento112 páginasPapagiannakis Solutions For Text BookRishiKaithala100% (2)

- Colless, Matthew - The New CosmologyDocumento249 páginasColless, Matthew - The New CosmologyShade SemjazaAún no hay calificaciones

- ASTM D287 - 12bDocumento5 páginasASTM D287 - 12bmancjaAún no hay calificaciones

- SPDFDocumento119 páginasSPDFAli MoghiAún no hay calificaciones

- Osu 1211986132Documento105 páginasOsu 1211986132Ali MoghiAún no hay calificaciones

- 1 s2.0 S007964250800039X MainDocumento44 páginas1 s2.0 S007964250800039X MainAli MoghiAún no hay calificaciones

- Proposed Welding Procedure Specification FormatDocumento2 páginasProposed Welding Procedure Specification FormatAli MoghiAún no hay calificaciones

- 5Documento9 páginas5Ali MoghiAún no hay calificaciones

- Hahn 2016Documento12 páginasHahn 2016Ali MoghiAún no hay calificaciones

- Kore STWJ 2009Documento5 páginasKore STWJ 2009Ali MoghiAún no hay calificaciones

- 4Documento13 páginas4Ali MoghiAún no hay calificaciones

- Thibaude Au 2013Documento10 páginasThibaude Au 2013Ali MoghiAún no hay calificaciones

- Magnetic Pulse Welding Forms Lightweight Connector CasingsDocumento4 páginasMagnetic Pulse Welding Forms Lightweight Connector CasingsAli MoghiAún no hay calificaciones

- Magnetic Pulse Welding, Crimping and Forming: Cold - Clean - Strong - Cost-EffectiveDocumento12 páginasMagnetic Pulse Welding, Crimping and Forming: Cold - Clean - Strong - Cost-EffectiveAli MoghiAún no hay calificaciones

- An Investigation of Magnetic Pulse Welding of Al/Cu and Interface CharacterizationDocumento11 páginasAn Investigation of Magnetic Pulse Welding of Al/Cu and Interface CharacterizationAli MoghiAún no hay calificaciones

- 10.3233@jae 2010 1062Documento19 páginas10.3233@jae 2010 1062Ali MoghiAún no hay calificaciones

- A 09 V 19 N 1Documento13 páginasA 09 V 19 N 1Ali MoghiAún no hay calificaciones

- EMPW Joins Mixed MaterialsDocumento2 páginasEMPW Joins Mixed MaterialsAli MoghiAún no hay calificaciones

- Microstructure Characterisation of Magnetic Pulse Welded AA6061-T6 by Electron Backscattered DiffractionDocumento5 páginasMicrostructure Characterisation of Magnetic Pulse Welded AA6061-T6 by Electron Backscattered DiffractionAli MoghiAún no hay calificaciones

- Bonding PresentationDocumento20 páginasBonding PresentationAli MoghiAún no hay calificaciones

- File:Rogowsky Coil - PNG: From Wikipedia, The Free EncyclopediaDocumento3 páginasFile:Rogowsky Coil - PNG: From Wikipedia, The Free EncyclopediaAli MoghiAún no hay calificaciones

- Magnetic Pulse Welding Forms Lightweight Connector CasingsDocumento4 páginasMagnetic Pulse Welding Forms Lightweight Connector CasingsAli MoghiAún no hay calificaciones

- How Rogowski Coils Measure ACDocumento1 páginaHow Rogowski Coils Measure ACAli MoghiAún no hay calificaciones

- Bonding PresentationDocumento20 páginasBonding PresentationAli MoghiAún no hay calificaciones

- Numerical Study of Joining Process in Magnetic Pressure Seam WeldingDocumento6 páginasNumerical Study of Joining Process in Magnetic Pressure Seam WeldingAli MoghiAún no hay calificaciones

- Materia Ls and Design: Xu Zhidan, Cui Junjia, Yu Haiping, Li ChunfengDocumento10 páginasMateria Ls and Design: Xu Zhidan, Cui Junjia, Yu Haiping, Li ChunfengAli MoghiAún no hay calificaciones

- Shiven Am EhDocumento4 páginasShiven Am EhAli MoghiAún no hay calificaciones

- Course Handout Rev1Documento69 páginasCourse Handout Rev1Ali MoghiAún no hay calificaciones

- SciencedirectDocumento2 páginasSciencedirectAli MoghiAún no hay calificaciones

- 2009 - 16.5 Asme B 2003 - 16.5 Asme B: NPS 24 NPSDocumento307 páginas2009 - 16.5 Asme B 2003 - 16.5 Asme B: NPS 24 NPSAli MoghiAún no hay calificaciones

- Explosion Welding Between St14 and Ms90 (WeldingWorld)Documento11 páginasExplosion Welding Between St14 and Ms90 (WeldingWorld)Ali MoghiAún no hay calificaciones

- Control Valves PDFDocumento73 páginasControl Valves PDFAli MoghiAún no hay calificaciones

- National Level E-Conference On Innovative Trends in MechanicalDocumento16 páginasNational Level E-Conference On Innovative Trends in MechanicalA BBAún no hay calificaciones

- IEEE 4 Node Test Feeder Revised Sept. 19, 2006Documento9 páginasIEEE 4 Node Test Feeder Revised Sept. 19, 2006Town Obio EteteAún no hay calificaciones

- Str-A6051 52 53 59 61 62 69 79Documento13 páginasStr-A6051 52 53 59 61 62 69 79Александр АндриановAún no hay calificaciones

- Errata FE WasimDocumento4 páginasErrata FE WasimchafobostonAún no hay calificaciones

- Aliasgar Dedanwala - Gizmo Circuits and ResistanceDocumento6 páginasAliasgar Dedanwala - Gizmo Circuits and ResistanceJonan SotoAún no hay calificaciones

- Quantum NumbersDocumento2 páginasQuantum NumbersWong Weng SiongAún no hay calificaciones

- Term 1 - Physics Part 2Documento11 páginasTerm 1 - Physics Part 2Gaming TriadAún no hay calificaciones

- Observer-Based Monitoring of Heat ExchangersDocumento10 páginasObserver-Based Monitoring of Heat ExchangersMiguel LópezAún no hay calificaciones

- Mechanisms Design L 2-1 IntroductionStructural Analysis of MechanismsDocumento24 páginasMechanisms Design L 2-1 IntroductionStructural Analysis of MechanismsaliAún no hay calificaciones

- 2018 Experimental and CFD Analysis of Solar Air Heater With Rectangular ShapedDocumento5 páginas2018 Experimental and CFD Analysis of Solar Air Heater With Rectangular ShapedaliAún no hay calificaciones

- Physics Investigatory ProjectDocumento18 páginasPhysics Investigatory ProjectRΛJIBUL ISLΛMAún no hay calificaciones

- Analysis and Design of Underpass RCC BridgeDocumento7 páginasAnalysis and Design of Underpass RCC Bridgeaaditya chopadeAún no hay calificaciones

- 3-7 Fluids in Rigid-Body Motion: - We ObtainedDocumento6 páginas3-7 Fluids in Rigid-Body Motion: - We ObtainedAsmaa Ali El-AwadyAún no hay calificaciones

- Tut4 OLET1640 Astro Student Answer SheetDocumento4 páginasTut4 OLET1640 Astro Student Answer Sheetdesheng wangAún no hay calificaciones

- Kid-sized humanoid robot design paperDocumento4 páginasKid-sized humanoid robot design paperHimanshu VermaAún no hay calificaciones

- Models - Mph.heat Transient AxiDocumento6 páginasModels - Mph.heat Transient AxiAnonymous sAmJfcVAún no hay calificaciones

- Modern Materials' Atomic StructureDocumento47 páginasModern Materials' Atomic StructureAngelica MartinezAún no hay calificaciones

- 1-Classification of Waves-16-02-2023Documento12 páginas1-Classification of Waves-16-02-2023efewfwedawasAún no hay calificaciones

- Pysical Organic Chapter OneDocumento34 páginasPysical Organic Chapter OneTeferaAún no hay calificaciones

- Test Planner-Repeater Course - 2023-2024 - (Phase-03)Documento2 páginasTest Planner-Repeater Course - 2023-2024 - (Phase-03)SbjAún no hay calificaciones

- Line-Scanning Laser Scattering System For Fast Defect Inspection of A Large Aperture SurfaceDocumento10 páginasLine-Scanning Laser Scattering System For Fast Defect Inspection of A Large Aperture SurfaceAyman IsmailAún no hay calificaciones