Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Checklist Pms MT

Cargado por

alsitorDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Checklist Pms MT

Cargado por

alsitorCopyright:

Formatos disponibles

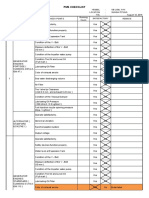

PMS CHECKLIST

VESSEL

LOCATION

PIC

NO.

ITEM

MAIN ENGINE

PORTSIDE

(YANMAR 6AYM

ETE)

GEARBOX PORT

(ADVANCE D300A)

MAIN ENGINE

PORTSIDE

(YANMAR 6AYM

ETE)

GEARBOX PORT

(ADVANCE D300A)

GENERATOR

ENGINES

PORTSIDE

(WEICHAI WD615)

ALTERNATOR

(WEICHAI

GENERATING SET)

GENERATOR

ENGINES

PORTSIDE

(WEICHAI WD615)

ALTERNATOR

(WEICHAI

GENERATING SET)

FIRE SISTEM

FIRE PUMP

CHECK POINTS

Running

hours

:

:

:

SATISFACTORY

Operate satisfactorily.

Safety devices function properly.

Check the alarm lamp operation

Water level at expansion tank

Check condition and level the Engine Oil

Oli filter

Condition of the V- Belt

The primary and secondary of fuel filter

Damper vibration

Color of exhaust smoke

Sea water discharging volume

Tightening torque of bolts

Operate satisfactorily.

Oil pressure

Oil level ( between " Min " and " Max" )

and condition of The Oil

Oil temperature

Leakage

Abnormal running

Abnormal opeating noises

Tightening torque of bolts

Operate satisfactorily.

Safety devices function properly.

Check the alarm lamp operation

Water level at expansion tank

Check condition and level the Engine Oil

Oli filter

Condition of the V- Belt

The primary and secondary of fuel filter

Damper vibration

Color of exhaust smoke

Sea water discharging volume

Tightening torque of bolts

Operate satisfactorily.

Oil pressure

Oil level ( between " Min " and " Max" )

and condition of The Oil

Oil temperature

Leakage

Abnormal running

Abnormal opeating noises

Tightening torque of bolts

Operate satisfactorily.

Safety devices function properly.

Water level at Expansion Tank

Condition of the V - Belt

Condition The Oil and Level Oil

( Full mark )

Lubricating Oil Filter

Color of exhaust smoke

Sea water discharging volume

Lubricating Oil Pressure

Operate satisfactorily.

Abnormal vibration

Output voltage

Operate satisfactorily.

Safety devices function properly.

Water level at Expansion Tank

Condition of the V - Belt

Condition The Oil and Level Oil

( Full mark )

Lubricating Oil Filter

Color of exhaust smoke

Sea water discharging volume

Lubricating Oil Pressure

Operate satisfactorily.

Abnormal vibration

Output voltage

Operate satisfactorily.

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

No

No

No

No

No

No

No

No

Yes

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

Yes

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

No

No

No

Yes

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

No

No

No

No

No

Yes

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

No

No

Check condition and level the Engine Oil

Yes

No

Water level at expansion tank

Condition of the V- Belt

Oil filter element

Fuel filter element

Sea water discharging volume

Abnormal noise and vibrate

Exhaust color of smoke

Operate satisfactorily.

Abnormal noise and vibrate

leakage from the pump casing

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

No

No

No

No

MT FERY XVI

SEI. PITUNG

3 AGUSTUS 2015

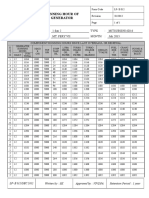

REMAKS

NO.

ITEM

FIRE PUMP

MAIN ENGINE

BALLAST

SYSTEM

PORTSIDE

PORT

& STBD

(YANMAR 6AYM

ETE)

BILGE & GS

SYSTEM

SEA WATER

COOLING SYSTEM

10

FUEL OIL SYSTEM

11

DIRTY OIL SYSTEM

12

OILY WATER

SEPARATOR

13

HYDRAULIC

POWER PACK AND

CONTROL

14

PIPING

15

16

BLOWER E/R

BLOWER P/R

EMERGENCY

STEERING

CONTROL

CONSOL

CLEANLINESS of

E/R

QUICK CLOSING

VALVE

17

18

19

20

21

22

23

24

25

26

27

28

CHECK POINTS

Running

hours

SATISFACTORY

Greasing

All valves operate satisfactorily.

Piping in good order.

Ballast pump Operate satisfactorily.

No heavy corrosion and leakage.

All valves operate satisfactorily.

Piping in good order.

Bilge & GS Pump operate satisfactorily.

No heavy corrosion and leakage.

All valves operate satisfactorily.

Piping in good order.

Sea water cooling Pump operate

satisfactorily.

No heavy corrosion and leakage.

All valves operate satisfactorily.

Piping in good order.

Fuel oil Pump operate satisfactorily.

No heavy corrosion and leakage.

All valves operate satisfactorily.

Piping in good order.

Emergency stop operating satisfactorily

Dirty oil Pump operate satisfactorily.

No heavy corrosion and leakage.

All valves operate satisfactorily.

Piping in good order.

Operate satisfactorily.

Remote and control function properly.

Meters and gauges in good order.

Operate satisfactorily.

Remote and control function properly.

Meters and gauges in good order.

No heavy corrosion and leakage.

All valves operate satisfactorily.

Operate satisfactorily.

Operate satisfactorily.

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

No

No

No

No

No

Yes

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

Operate satisfactorily.

Yes

No

Operate satisfactorily.

Yes

No

Must be clean without rubbish or waste oil.

Yes

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

No

No

No

No

Operate satisfactorily.

All valves operate satisfactorily.

All lights in good order.

Lighting in E/R

Protection covers or guards in good order

All lights in good order.

Lighting in P/R

Protection covers or guards in good order

Lighting in working All lights in good order.

room, steering room

Protection covers or guards in good order

and other spaces

Emergency lights All lights in good order, no broken lights.

Insulating mats

Available on board or insulation cement

around MSB

permanently laid up on the floor.

All gauges and indicating light are

functioning

The surface of panel for excessive

Main Switch Board

warmness

Unusual smell

All cable conncetion and bus

Gas detector at P.R

Fire detector

Alarms operate

Sensor CO2

satisfactorily

Bilges at Engine Room

Bilges at Pump Room

Bilges at Steering Room

Level high / low Daily Oil Tank

alarm operate

Fuel Oil Tank

REMAKS

Good

Sutopo

Abdi Subiantoro

Chief Engineers

Date : 3 Juli 2015

Technical Superintendent

Date : 3 Juli 2015

También podría gustarte

- Draft Form of Record Book of Engine ParametersDocumento6 páginasDraft Form of Record Book of Engine ParametersRomanko100% (1)

- BRD TemplateDocumento4 páginasBRD TemplateTrang Nguyen0% (1)

- Chill - Lease NotesDocumento19 páginasChill - Lease Notesbellinabarrow100% (4)

- C79 Service Kit and Parts List GuideDocumento32 páginasC79 Service Kit and Parts List Guiderobert100% (2)

- Ce Handing OverDocumento10 páginasCe Handing OverAkhilvjohnAún no hay calificaciones

- Maintenance Plan Bg. TaisirDocumento12 páginasMaintenance Plan Bg. TaisiralsitorAún no hay calificaciones

- Waruna Nusa Sentana: Mt. Seaborne Petro O.S.C Kit (Sopep) Inventory STBD Side Mid Ship StoreDocumento2 páginasWaruna Nusa Sentana: Mt. Seaborne Petro O.S.C Kit (Sopep) Inventory STBD Side Mid Ship StoreshandiAún no hay calificaciones

- Marpol Annex I Surveys ChecklistDocumento4 páginasMarpol Annex I Surveys ChecklistvagGS1150Aún no hay calificaciones

- Ods-Record-Book - Latest & ApprovedDocumento10 páginasOds-Record-Book - Latest & ApprovedErsin SaltAún no hay calificaciones

- Guidance For Sox Emissions Reduction and Fo Change Over ProceduresDocumento13 páginasGuidance For Sox Emissions Reduction and Fo Change Over Proceduresnikbatist100% (1)

- CLH Vertical SilipumpDocumento13 páginasCLH Vertical Silipumpriky nurgiantoroAún no hay calificaciones

- Technical CircularsDocumento3 páginasTechnical CircularsAjay SinghAún no hay calificaciones

- Maintenance Plan Bg. TaisirDocumento12 páginasMaintenance Plan Bg. TaisiralsitorAún no hay calificaciones

- Take Private Profit Out of Medicine: Bethune Calls for Socialized HealthcareDocumento5 páginasTake Private Profit Out of Medicine: Bethune Calls for Socialized HealthcareDoroteo Jose Station100% (1)

- 2.8 V6 5V (Aha & Atq)Documento200 páginas2.8 V6 5V (Aha & Atq)Vladimir Socin ShakhbazyanAún no hay calificaciones

- Proposed Delivery For PAU/AHU Method Statement SEC/MS/3-25Documento4 páginasProposed Delivery For PAU/AHU Method Statement SEC/MS/3-25Zin Ko NaingAún no hay calificaciones

- Checklist Pms ObDocumento3 páginasChecklist Pms ObalsitorAún no hay calificaciones

- Checklist Pms ObDocumento3 páginasChecklist Pms ObalsitorAún no hay calificaciones

- Checklist Oil BargeDocumento10 páginasChecklist Oil BargealsitorAún no hay calificaciones

- Checklist Pms TB Tytyan Karimata 02Documento3 páginasChecklist Pms TB Tytyan Karimata 02alsitorAún no hay calificaciones

- Checklist PMS TBDocumento3 páginasChecklist PMS TBalsitorAún no hay calificaciones

- Checklist Pms ObDocumento3 páginasChecklist Pms ObalsitorAún no hay calificaciones

- Engine Room Critical TestDocumento13 páginasEngine Room Critical TestalsitorAún no hay calificaciones

- Vessel Name: TB SADP XXX Date Position Description Tested by Sensor AlarmDocumento4 páginasVessel Name: TB SADP XXX Date Position Description Tested by Sensor AlarmalsitorAún no hay calificaciones

- E-021 Auxiliary Engine Performance.04Documento2 páginasE-021 Auxiliary Engine Performance.04Rizky Sapugungdo100% (1)

- SBS-417 Bunker PlanDocumento2 páginasSBS-417 Bunker PlanalberioAún no hay calificaciones

- Main engine running hours reportDocumento1 páginaMain engine running hours reportalsitorAún no hay calificaciones

- MAIN PROPULSION STARBOARD CHECKLISTDocumento27 páginasMAIN PROPULSION STARBOARD CHECKLISTalsitorAún no hay calificaciones

- July-Running Hour Ps Main EngineDocumento1 páginaJuly-Running Hour Ps Main EnginealsitorAún no hay calificaciones

- Yanmar Auxiliary Engine Overhaul PDFDocumento7 páginasYanmar Auxiliary Engine Overhaul PDFRani NoumanAún no hay calificaciones

- DECK MAINTENANCE SCHEDULE"MaxIntervalJanFebMarAprMayJunJulAugSepOctNovDec1mth1mth1mth3mths1mth6mthsas reqd1mth1mth1mth3mths1mth6mthsas reqd1mth3mths1yrDocumento12 páginasDECK MAINTENANCE SCHEDULE"MaxIntervalJanFebMarAprMayJunJulAugSepOctNovDec1mth1mth1mth3mths1mth6mthsas reqd1mth1mth1mth3mths1mth6mthsas reqd1mth3mths1yralsitorAún no hay calificaciones

- Tec-B 028 Engine Room Critical Test B.indoDocumento13 páginasTec-B 028 Engine Room Critical Test B.indoalsitorAún no hay calificaciones

- ENV-09A - Fuel Change-Over Procedure Rev 0Documento15 páginasENV-09A - Fuel Change-Over Procedure Rev 0Filip NikolevskiAún no hay calificaciones

- What Is Cappuccino Bunker Effect On ShipsDocumento7 páginasWhat Is Cappuccino Bunker Effect On ShipsshubhamAún no hay calificaciones

- How To Conduct Bunker Survey - Marine Surveyor InformationDocumento1 páginaHow To Conduct Bunker Survey - Marine Surveyor InformationgustavoseseAún no hay calificaciones

- 18-010E - Rev1 - 6EY17 Intercooler Case CorrosionDocumento2 páginas18-010E - Rev1 - 6EY17 Intercooler Case CorrosionG_ARVALIS8470Aún no hay calificaciones

- Why Captain's Cabin Is Always On Starboard SideDocumento2 páginasWhy Captain's Cabin Is Always On Starboard SideKunal SinghAún no hay calificaciones

- Sample SOPEPDocumento47 páginasSample SOPEPaifa22Aún no hay calificaciones

- Form Open Closed Vetting Pertamina Spob Elisabeth 03Documento10 páginasForm Open Closed Vetting Pertamina Spob Elisabeth 03Deni PurnamaAún no hay calificaciones

- Vessel Inspection Report Highlights Cargo Tank Crack RepairDocumento106 páginasVessel Inspection Report Highlights Cargo Tank Crack RepairPrinceSadhotraAún no hay calificaciones

- Major Shipping Document with Location and Date DetailsDocumento30 páginasMajor Shipping Document with Location and Date DetailsBrian Dsilva60% (5)

- Engine Room Departure ChecklistDocumento1 páginaEngine Room Departure ChecklistopytnymoryakAún no hay calificaciones

- DKT0/2020/J5110: Ships in Service Survey ReportDocumento26 páginasDKT0/2020/J5110: Ships in Service Survey ReportLeonidas Galanis100% (1)

- WORKBOAT INTERNATIONAL DMCCO EMERGENCY REPORTING FORMATDocumento3 páginasWORKBOAT INTERNATIONAL DMCCO EMERGENCY REPORTING FORMATKunal SinghAún no hay calificaciones

- Ef0ebd61 Yanmar-12AYM-WET Datasheet ENGINE DataDocumento2 páginasEf0ebd61 Yanmar-12AYM-WET Datasheet ENGINE Datapd wiradisuriaAún no hay calificaciones

- Preparing The Ship For Dry DockDocumento2 páginasPreparing The Ship For Dry DockSwarg VibhaAún no hay calificaciones

- Seaquest Shipmanagement Engine Manual Engine Instructions: Engine Filing System File No. File NameDocumento1 páginaSeaquest Shipmanagement Engine Manual Engine Instructions: Engine Filing System File No. File NameFilip NikolevskiAún no hay calificaciones

- G138 Shipboard WorkingDocumento3 páginasG138 Shipboard WorkingJeet SinghAún no hay calificaciones

- Pms Engine Nasyda LinsoDocumento12 páginasPms Engine Nasyda LinsoalsitorAún no hay calificaciones

- Second marine engineer duties upon joiningDocumento2 páginasSecond marine engineer duties upon joiningSARATKUMAR RATNALAAún no hay calificaciones

- Departure CHECKLISTDocumento1 páginaDeparture CHECKLISTFahreza MawlanaAún no hay calificaciones

- Main Engine Running Hours ReportDocumento1 páginaMain Engine Running Hours ReportIhwan AsrulAún no hay calificaciones

- Every Day Checks in Engine Room Rounds From Funnel To Tunnel On ShipDocumento5 páginasEvery Day Checks in Engine Room Rounds From Funnel To Tunnel On ShipjoyceAún no hay calificaciones

- LF - e 000 Chief Engineers Standing OrdersDocumento1 páginaLF - e 000 Chief Engineers Standing Ordersmiswanto antoAún no hay calificaciones

- Shipboard Safety MeetingDocumento2 páginasShipboard Safety MeetingKunal SinghAún no hay calificaciones

- Chief Engineer pre-vetting checklistDocumento6 páginasChief Engineer pre-vetting checklistDrs EsmAún no hay calificaciones

- List of Ship's Certificates for Tanker ClearanceDocumento3 páginasList of Ship's Certificates for Tanker ClearanceBrian PhamAún no hay calificaciones

- ESP CodeDocumento7 páginasESP CodeAkash KandwalAún no hay calificaciones

- VGP Manual PDFDocumento58 páginasVGP Manual PDFGenghu YeAún no hay calificaciones

- UMS Checklist Ensures Ship Systems Are Functioning ProperlyDocumento1 páginaUMS Checklist Ensures Ship Systems Are Functioning Properlyshabirhaider_7629841100% (2)

- Recent MMD QuestionsDocumento49 páginasRecent MMD QuestionsAkash Nair100% (1)

- Speck Dock Is MT Kasim (After Aanwijzing)Documento127 páginasSpeck Dock Is MT Kasim (After Aanwijzing)nugroho sulistiyadiAún no hay calificaciones

- Tec-B 014 Running Hour Ae 1Documento2 páginasTec-B 014 Running Hour Ae 1alsitorAún no hay calificaciones

- US Oil Record Book Falsification Cases and PenaltiesDocumento27 páginasUS Oil Record Book Falsification Cases and Penaltiesvivek100% (1)

- Kseasmachinery: Surveyors and Engineers KnowledgeDocumento36 páginasKseasmachinery: Surveyors and Engineers KnowledgeMr Lee100% (1)

- PMS Checklist for OB LSBL XVIIIDocumento5 páginasPMS Checklist for OB LSBL XVIIIalsitorAún no hay calificaciones

- Pms Deck Nasyda LinsoDocumento21 páginasPms Deck Nasyda Linsoalsitor100% (1)

- Tec-B 014 Running Hour Ae 1Documento2 páginasTec-B 014 Running Hour Ae 1alsitorAún no hay calificaciones

- (782982478) Monthly Fuel, Lo Consumption Report - February 2016Documento1 página(782982478) Monthly Fuel, Lo Consumption Report - February 2016alsitorAún no hay calificaciones

- 2016.04.13 S30 - Monitoring ROB (Dumai-Merak)Documento2 páginas2016.04.13 S30 - Monitoring ROB (Dumai-Merak)alsitorAún no hay calificaciones

- TB SADP XXX Exhaust Vent Emergency Stop Test RecordsDocumento4 páginasTB SADP XXX Exhaust Vent Emergency Stop Test RecordsalsitorAún no hay calificaciones

- Croscheck PMS LSBL XIX Agustus 2015Documento7 páginasCroscheck PMS LSBL XIX Agustus 2015alsitorAún no hay calificaciones

- Pms Engine Lintas Ix LinsoDocumento27 páginasPms Engine Lintas Ix LinsoalsitorAún no hay calificaciones

- Pms Deck Nasyda LinsoDocumento21 páginasPms Deck Nasyda Linsoalsitor100% (1)

- Pms Deck TB Fery 03 LinsoDocumento15 páginasPms Deck TB Fery 03 LinsoalsitorAún no hay calificaciones

- PMS Checklist for OB LSBL XVIIIDocumento5 páginasPMS Checklist for OB LSBL XVIIIalsitorAún no hay calificaciones

- Pms Engine TB Fery 03 LinsoDocumento15 páginasPms Engine TB Fery 03 LinsoalsitorAún no hay calificaciones

- Vessel Name: TB SADP XXX Date Position Description Tested by Sensor AlarmDocumento4 páginasVessel Name: TB SADP XXX Date Position Description Tested by Sensor AlarmalsitorAún no hay calificaciones

- Pms Engine Nasyda LinsoDocumento12 páginasPms Engine Nasyda LinsoalsitorAún no hay calificaciones

- Monthly work reportDocumento11 páginasMonthly work reportalsitor100% (2)

- Pms June @LSBL XviiiDocumento32 páginasPms June @LSBL XviiialsitorAún no hay calificaciones

- DECK MAINTENANCE SCHEDULE"MaxIntervalJanFebMarAprMayJunJulAugSepOctNovDec1mth1mth1mth3mths1mth6mthsas reqd1mth1mth1mth3mths1mth6mthsas reqd1mth3mths1yrDocumento12 páginasDECK MAINTENANCE SCHEDULE"MaxIntervalJanFebMarAprMayJunJulAugSepOctNovDec1mth1mth1mth3mths1mth6mthsas reqd1mth1mth1mth3mths1mth6mthsas reqd1mth3mths1yralsitorAún no hay calificaciones

- Technical Superintendent Visit: Superintendent'S Detailed ReportDocumento8 páginasTechnical Superintendent Visit: Superintendent'S Detailed ReportalsitorAún no hay calificaciones

- LF - e 011 Inventory Spare Parts JuliDocumento1 páginaLF - e 011 Inventory Spare Parts JulialsitorAún no hay calificaciones

- Tec-B 028 Engine Room Critical Test B.indoDocumento13 páginasTec-B 028 Engine Room Critical Test B.indoalsitorAún no hay calificaciones

- Technical Superintendent Visit: Superintendent'S Detailed ReportDocumento8 páginasTechnical Superintendent Visit: Superintendent'S Detailed ReportalsitorAún no hay calificaciones

- Technical Superintendent Visit: Superintendent'S Detailed ReportDocumento8 páginasTechnical Superintendent Visit: Superintendent'S Detailed ReportalsitorAún no hay calificaciones

- LF - e 011 Inventory Spare Parts JuliDocumento1 páginaLF - e 011 Inventory Spare Parts JulialsitorAún no hay calificaciones

- Standarisasi: Perawatan Generator AE (Cleaning) MT - Fery XVIDocumento2 páginasStandarisasi: Perawatan Generator AE (Cleaning) MT - Fery XVIalsitorAún no hay calificaciones

- MT FERY VII MAINTENANCE REPAIR REPORTDocumento1 páginaMT FERY VII MAINTENANCE REPAIR REPORTalsitorAún no hay calificaciones

- Damage report formDocumento1 páginaDamage report formalsitor0% (1)

- LF - e 012 Running Hour of GeneratorDocumento2 páginasLF - e 012 Running Hour of GeneratoralsitorAún no hay calificaciones

- Tata Cara PengisiDocumento327 páginasTata Cara PengisialsitorAún no hay calificaciones

- Monthly fuel and lube reportDocumento1 páginaMonthly fuel and lube reportalsitorAún no hay calificaciones

- Elaspeed Cold Shrink Splices 2010Documento3 páginasElaspeed Cold Shrink Splices 2010moisesramosAún no hay calificaciones

- Discretionary Lending Power Updated Sep 2012Documento28 páginasDiscretionary Lending Power Updated Sep 2012akranjan888Aún no hay calificaciones

- As 1769-1975 Welded Stainless Steel Tubes For Plumbing ApplicationsDocumento6 páginasAs 1769-1975 Welded Stainless Steel Tubes For Plumbing ApplicationsSAI Global - APACAún no hay calificaciones

- Fabric Bursting StrengthDocumento14 páginasFabric Bursting StrengthQaiseriqball100% (5)

- Software EngineeringDocumento3 páginasSoftware EngineeringImtiyaz BashaAún no hay calificaciones

- 2022 Product Catalog WebDocumento100 páginas2022 Product Catalog WebEdinson Reyes ValderramaAún no hay calificaciones

- Cib DC22692Documento16 páginasCib DC22692Ashutosh SharmaAún no hay calificaciones

- Overall Dimensions and Mounting: Solar Water Pump Controller Mu - G3 Solar Mu - G5 Solar Mu - G7.5 Solar Mu - G10 SolarDocumento2 páginasOverall Dimensions and Mounting: Solar Water Pump Controller Mu - G3 Solar Mu - G5 Solar Mu - G7.5 Solar Mu - G10 SolarVishak ThebossAún no hay calificaciones

- 13-07-01 Declaration in Support of Skyhook Motion To CompelDocumento217 páginas13-07-01 Declaration in Support of Skyhook Motion To CompelFlorian MuellerAún no hay calificaciones

- EWAIRDocumento1 páginaEWAIRKissy AndarzaAún no hay calificaciones

- 5.0 A Throttle Control H-BridgeDocumento26 páginas5.0 A Throttle Control H-Bridgerumellemur59Aún no hay calificaciones

- CSEC IT Fundamentals of Hardware and SoftwareDocumento2 páginasCSEC IT Fundamentals of Hardware and SoftwareR.D. Khan100% (1)

- UKIERI Result Announcement-1Documento2 páginasUKIERI Result Announcement-1kozhiiiAún no hay calificaciones

- Top 35 Brokerage Firms in PakistanDocumento11 páginasTop 35 Brokerage Firms in PakistannasiralisauAún no hay calificaciones

- Programme Report Light The SparkDocumento17 páginasProgramme Report Light The SparkAbhishek Mishra100% (1)

- FEM Lecture Notes-2Documento18 páginasFEM Lecture Notes-2macynthia26Aún no hay calificaciones

- Comparing Time Series Models to Predict Future COVID-19 CasesDocumento31 páginasComparing Time Series Models to Predict Future COVID-19 CasesManoj KumarAún no hay calificaciones

- Chapter 2a Non Structured DataRozianiwatiDocumento43 páginasChapter 2a Non Structured DataRozianiwatiNur AnisaAún no hay calificaciones

- Simplex Addressable Breakglass PDFDocumento12 páginasSimplex Addressable Breakglass PDFNurrul Ahmad Hidayat100% (1)

- Sav 5446Documento21 páginasSav 5446Michael100% (2)

- SyllabusDocumento4 páginasSyllabusapi-105955784Aún no hay calificaciones

- Proposal Semister ProjectDocumento7 páginasProposal Semister ProjectMuket AgmasAún no hay calificaciones

- Khadi Natural Company ProfileDocumento18 páginasKhadi Natural Company ProfileKleiton FontesAún no hay calificaciones

- PRE EmtionDocumento10 páginasPRE EmtionYahya JanAún no hay calificaciones