Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Trunnion N392-3 R0

Cargado por

Sergio SmithTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Trunnion N392-3 R0

Cargado por

Sergio SmithCopyright:

Formatos disponibles

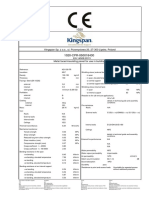

TRUNNION QUALIFICATION SHEET

Procedure for Evaluation of the Design of Hollow Circular Cross Section

Welded Attachments on Classes 2 and 3 Piping

ASME Code Case N-392-3 (Section III, Div 1 Nonmandatory Appendix Y-5000)

For trunnions perpendicular to the axis of the run pipe; modified for elbow-mounted trunnions per EPRI TR-107453 (

Yellow cells: User input; Gray cells: automated

ENTER STRESS PROGRAM OUTPUT ON NEXT TAB. (Stress Model must include Reaction Node at pipe O.D. See Gener

JOB NO.:

Upgrade Steam System

PIPE SUPPORT NO.:

NODE 4000

LINE NUMBER:

Attachment location =

Run Pipe OD =

Run Pipe Wall thk =

14" STEAM LINE

Attachment Pipe OD =

POPER (PSIG)

PMAX (PSIG)

TOPER (F)

TMAX (F)

Attachment Pipe Wall thk =

450

525

600

750

Fillet Weld Size =

DESIGN CONDITIONS:

Run Pipe material | Sy at TOPER :

A53B Seamless

Run pipe welding factor f:

Attachment material | Sy at TOPER :

22200 psi; Sec. II, Pt.D, Table Y-1

1.00

A53B Seamless

22200 psi; Sec. II, Pt.D, Table Y-1

Support Service Limit (Level A, B, C, D):

SELECT

2.0 NOMENCLATURE AND DEFINITIONS (See Fig. 1); ASME Code Case N-392-3 included with EPRI TR-107453, Ap

Ro

Ro

= run pipe outside radius, in.

RI

= run pipe inside radius, in.

RI

ro

= attachment pipe outside radius, in.

ro

ri

= attachment pipe inside radius, in.

ri

= nominal run pipe wall thickness, in.

t

Do

= nominal attachment wall thickness, in.

= outside diameter of the run pipe, in.

t

Do

do

= outside diameter of the attachment, in.

do

ZT

= mean radius of run pipe, in.

= ( ro

= IT/ro

ri )

area of trunnion, in.

4

4

I T ( ro ri )

4

2

2

A (ro ri )

2

ro T

2

Ro / T

IT

or ZT

[where 4.0 50.0]

t /T

[where 0.2 1.0]

d o / Do

Ao ( 2 )

ZT

section modulus of trunnion, in.3

= lesser of

AT

Range for

ells per TR107453

R

AT

[where 0.3 1.0]

[but not less than 1.0]

[10 30]

[0.2 2.0]

[0.3 0.8]

CW

CL

The equation for C shall be used to determine Cw, CL, and CN, based on

CN

the following table (modified for elbow-mounted trunnions per EPRI

Parameters , and in

range for ells per EPRI?

TR-107453). Select the max. value of pipe and attachment equations.

Index

Cw

Part

Range

Ao

n1

Pipe

0.3 - 1.0

1.40

0.81

Trunnion Qualification Sheet - ASME Code Case N-392-3

n2

(a)

n3

1.33

NOTES:

(a) replace

Page 1 of 30

TRUNNION QUALIFICATION SHEET

Procedure for Evaluation of the Design of Hollow Circular Cross Section

Welded Attachments on Classes 2 and 3 Piping

ASME Code Case N-392-3 (Section III, Div 1 Nonmandatory Appendix Y-5000)

For trunnions perpendicular to the axis of the run pipe; modified for elbow-mounted trunnions per EPRI TR-107453 (

attachment

Cw

0.3 - 1.0

For elbow-mounted trunnions

Trunnion Qualification Sheet - ASME Code Case N-392-3

4.00

0.55

0.75

0.229

(b)

-0.42

1.00

0.85

(b) replace

(EPRI TR-107453, Eq. 5-4)

Page 2 of 30

TRUNNION QUALIFICATION SHEET

Procedure for Evaluation of the Design of Hollow Circular Cross Section

Welded Attachments on Classes 2 and 3 Piping

ASME Code Case N-392-3 (Section III, Div 1 Nonmandatory Appendix Y-5000)

For trunnions perpendicular to the axis of the run pipe; modified for elbow-mounted trunnions per EPRI TR-107453 (

Index

CL

Part

Range

Ao

n1

n2

n3

Pipe

0.3 - 1.0

0.46

0.60

-0.04

0.86

attachment

0.3 - 1.0

1.10

0.23

-0.38

0.38

CL

For elbow-mounted trunnions

1.68

0.0734

-0.01

0.769

CN

Pipe

0.3 - 0.55

0.51

1.01

0.79

0.89

attachment

0.3 - 0.55

0.84

0.85

0.80

0.54

Pipe

> 0.55 - 1.0

0.23

1.01

-0.62

0.89

attachment

> 0.55 - 1.0

0.44

0.85

-0.28

0.54

(EPRI TR-107453, Eq. 5-1)

<else>

CN

For elbow-mounted trunnions

0.72

0.210

-0.355

0.84

(EPRI TR-107453, Eq. 5-2)

CT

For elbow-mounted trunnions

1.25

0.158

-0.06

0.717

(EPRI TR-107453, Eq. 5-3)

<else>

CT

= 1.0 for 0.55

CT

= CN for = 1.0, but not less than 1.0; CT

should be linearly interplated for 0.55 1.0,

CT

Except as modified for elbow

trunnions per EPRI

BW

but not less than 1.0

= 0.5 (CW), but not less than 1.0

BW

BL

= 0.5 (CL), but not less than 1.0

BL

BN

= 0.5 (CN), but not less than 1.0

BN

BT

= 0.5 (CT), but not less than 1.0

BT

KT

= 2.0 for fillet or partial welds

KT

= 1.8 for full penetration welds

Sh

= basic material allowable stress at maximum

Sec. II, Pt. D, Table 1

Sh

Sec. II, Pt. D, Table 1

Sc

(hot) temperature, psi (lesser of attachment

or pipe material allowable)

Sc

= basic material allowable stress at ambient

temperature, psi (lesser of attachment or

SA

or pipe material allowable)

= f (1.25Sc + 0.25Sh), psi as defined in NC/

SA

ND-3611.2 (lesser of attachment or pipe

material allowable)

Sy

Sy

= yield stress at temperature, psi (lesser of

attachment or pipe material yield stress)

Zwn

= section modulus of fillet weld or partial

penetration weld about the neutral axis of

Z wn

t do2

4

Note 6:

t do2

Note 6:

Zwn

t is weld throat thickness: (cos 45 x fi

bending parallel to the run pipe center line, in.3

Zwl

= section modulus of fillet weld or partial

Trunnion Qualification Sheet - ASME Code Case N-392-3

Z wl

Zwl

Page 3 of 30

TRUNNION QUALIFICATION SHEET

Procedure for Evaluation of the Design of Hollow Circular Cross Section

Welded Attachments on Classes 2 and 3 Piping

ASME Code Case N-392-3 (Section III, Div 1 Nonmandatory Appendix Y-5000)

For trunnions perpendicular to the axis of the run pipe; modified for elbow-mounted

trunnions per EPRI TR-107453 (

t do

Z wl

4

penetration weld about the neutral axis

t is weld throat thickness: (cos 45 x fi

2

normal to the run pipe center line, in.3

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 4 of 30

TRUNNION QUALIFICATION SHEET

Procedure for Evaluation of the Design of Hollow Circular Cross Section

Welded Attachments on Classes 2 and 3 Piping

ASME Code Case N-392-3 (Section III, Div 1 Nonmandatory Appendix Y-5000)

For trunnions perpendicular to the axis of the run pipe; modified for elbow-mounted trunnions per EPRI TR-107453 (

Zwt

= torsional section modulus of fillet weld or

partial penetration weld for torsional

loading, in.

Aw

Z wt

= fillet weld or partial penetration weld throat area, in. 2

t d

4

J

ro

Zwt

Note 6:

t is weld throat thickness: (cos 45 x fi

Aw

td = cos 45 x fillet weld size x Mean weld circumference (per AWS D1.1/D1.1M;2006, 2.23.4)

Absolute Value

of loads due to weight

and other sustained loads

See Figs. 1, 2-1 (below) for nomenclature.

From Stress Program Output tab.

ML

= bending moment applied to the attachment

Absolute Values of

loads occurring sim

under all service load

M L=

41714

in-lbs

ML**

M N=

2327

in-lbs

MN**

M T=

in-lbs

MT**

Q1=

101

lbs

Q1**

Q2=

1777

lbs

Q2**

W=

340

lbs

W**

as shown in Fig. 1, in.-lbs

MN

= bending moment applied to the attachment

as shown in Fig. 1, in.-lbs

MT

= torsional moment applied to the attachment

as shown in Fig. 1, in.-lbs

Q1

= shear load applied to the attachment as

shown in Fig. 1, lbs

Q2

= shear load applied to the attachment as

shown in Fig. 1, lbs

= thrust load applied to the attachment as

shown in Fig. 1, lbs

ML, MN, MT, Q1, Q2, and W are determined at the

ML**, MN**, MT**, Q1**, Q2**, and W** are absolute

surface of the pipe. The values of attachment loads

values of maximum loads occurring simultaneously

used in the stress evaluation (Section 3.0) are based

under all service loading conditions. (Select Load Ca

on the loads used in the different Code equations.

from Operating results with maximum resultant Mom

3.1 Analysis of Attachment Welded to Pipe with a Full Penetration Weld

(a)

Calculate stresses

S MT

BW W

B M

B M

Q

Q

B M

N N L L 1 2 T T

AT

ZT

ZT

A

A

J

(1)

S NT

CW W

C M

C M

Q

Q

C M

N N L L 1 2 T T

AT

ZT

ZT

A

A

J

(2)

SPT = KT(SNT)

S NT

**

CW W **

C MN

N

AT

ZT

**

CL M L

ZT

Trunnion Qualification Sheet - ASME Code Case N-392-3

(3)

**

**

**

Q1

Q

2

A

A

CT M T

J

**

(4)

Page 5 of 30

TRUNNION QUALIFICATION SHEET

Procedure for Evaluation of the Design of Hollow Circular Cross Section

Welded Attachments on Classes 2 and 3 Piping

ASME

Code

Case

N-392-3 (Section

III, Div**1 Nonmandatory

Appendix Y-5000)

**

**

**

**

CW W **

CN M N

CL M L

Q1

Q2

CT M T

**

S NT

to the axisof the run pipe;

elbow-mounted trunnions per EPRI TR-107453 (

For trunnions

perpendicular

modified

for

AT

ZT

ZT

A

A

J

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 6 of 30

TRUNNION QUALIFICATION SHEET

Procedure for Evaluation of the Design of Hollow Circular Cross Section

Welded Attachments on Classes 2 and 3 Piping

ASME Code Case N-392-3 (Section III, Div 1 Nonmandatory Appendix Y-5000)

For trunnions perpendicular to the axis of the run pipe; modified for elbow-mounted trunnions per EPRI TR-107453 (

ASME BPVC, Section

Code Case N-39

Fig. 1, Pg. 730

EPRI, TR-107453 (

Figure 2-1, Pg. 2

(b)

The following modified Code equations shall be satisfied:

First, calculate MA, MB, MC, MD

Mj

where

2

xj

M y j M zj

Ref. NC-3653.3

1/ 2

j = A, B, C, or D which are the subscripts of MA, MB, MC, MD

defined in NC-3652, NC-3653.1, and NC-3653.2

MA =

M xA M yA M zA

resultant moment loading on cross section

due to weight and other sustained

loads, in.-lb

MB =

M xB M yB M zB

Ref. NC-3652

moment loading on cross section due to

nonreversing dynamic (Occasional)

loads., in.-lb

(1)

Ref. NC-3653.1

NC-3652 Eq. (8) becomes:

S SL B1

"Left" and "Right" (below) are Eq. values b

PD o

MA

B2

S MT 1.5S h

2t n

Z

Left Side

(NC-8)

10767

where B1 = 0.5 and B2 = 1.0 for straight pipe, tn = run pipe nominal wall thickness (T from Section 2 above),

and Z = IP/Ro is the section modulus of run pipe, in.3

IP

Trunnion Qualification Sheet - ASME Code Case N-392-3

4

4

( Ro Ri )

4

Page 7 of 30

TRUNNION QUALIFICATION SHEET

Procedure for Evaluation of the Design of Hollow Circular Cross Section

Welded Attachments on Classes 2 and 3 Piping

ASME Code Case N-392-3 (Section III, Div 1 Nonmandatory Appendix Y-5000)

For trunnions perpendicular to the axis of the run pipe; modified for elbow-mounted trunnions per EPRI TR-107453 (

IP

Trunnion Qualification Sheet - ASME Code Case N-392-3

4

4

( Ro Ri )

4

IP

Page 8 of 30

TRUNNION QUALIFICATION SHEET

Procedure for Evaluation of the Design of Hollow Circular Cross Section

Welded Attachments on Classes 2 and 3 Piping

ASME Code Case N-392-3 (Section III, Div 1 Nonmandatory Appendix Y-5000)

For trunnions perpendicular to the axis of the run pipe; modified for elbow-mounted trunnions per EPRI TR-107453 (

(2)

1.8Sh but not greater than

NC-3653.1 Eq. (9) becomes:

S OL B1

1.5 Sy for Level A and

Pmax . Do

MA MB

B2

S MT

2t n

Z

Level B loadings

2.25Sh but not greater than

where B1 = 0.5 and B2 = 1.0 for straight pipe, and

1.85 Sy for Level C loading

3.0Sh but not greater than

where terms tn and Z are defined as in Eq. (1) above

2.0 Sy for Level D loading

SOL

(NC-9)

MC =

M xC M yC M zC

12221

range of resultant moments due to thermal

expansion, in.-lb.; also include moment effects

of anchor displacements due to nonreversing

dynamic loads if anchor displacement

effects were omitted from Eq. (9)

MD =

M xD

M yD

M zD

Ref. NC-3653.2

resultant moment due to any single nonrepeated anchor movement (e.g., predicted

building settlement), in.-lb.

Ref. NC-3653.2

Equations 3, 4 and 5 (below) require determining the maximum intensification factor,

where i is the stress intensification factor from NC-3673.2 and Fig. NC-3673.2(b)-1.

i = C2K2/2, but not less than 1.0

where C2 and K2 are stress indices for Class 1 piping products or joints from NB-3681(a)-1.

(C2 and K2 values for trunnions per

C2

EPRI TR-107453 Ch. 3 Test Program.)

(3)

1.0

1.0

NC-3653.2 Eq. (10) becomes:

SE

(4)

K2

i MC

S

PT S A

Z

2

Left Side

(NC-10) 11554

NC-3653.2 Eq. (10a) becomes:

iMD

S

PT 3.0 S C

Z

2

Trunnion Qualification Sheet - ASME Code Case N-392-3

Left Side

(NC-10a) 11119

Page 9 of 30

TRUNNION QUALIFICATION SHEET

Procedure for Evaluation of the Design of Hollow Circular Cross Section

Welded Attachments on Classes 2 and 3 Piping

ASME Code Case N-392-3 (Section III, Div 1 Nonmandatory Appendix Y-5000)

iM

S

For trunnions perpendicular to theDaxis

the

run

of PT

3.pipe;

0 S C modified for elbow-mounted trunnions per EPRI TR-107453 (

Z

2

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 10 of 30

TRUNNION QUALIFICATION SHEET

Procedure for Evaluation of the Design of Hollow Circular Cross Section

Welded Attachments on Classes 2 and 3 Piping

ASME Code Case N-392-3 (Section III, Div 1 Nonmandatory Appendix Y-5000)

For trunnions perpendicular to the axis of the run pipe; modified for elbow-mounted trunnions per EPRI TR-107453 (

(5)

NC-3653.2 Eq. (11) becomes:

ST E

PDo

4 tn

S

MC

MA

S M T P T (S h S A )

i

2

Z

Z

0.7 5 i

Left Side

(NC-11)

22125

where terms tn and Z are defined in Eq. (3, 4, 5) as in Eq. (1) above

(c)

In addition to the Code equations, the following equations shall also be satisfied:

Left Side

S NT

Q1

**

**

Q2

2S y

**

T

J

A

A

(5)

40891

(6)

783

**

Sy

3.2 Analysis of Attachment Welded to Pipe With Fillet Welds or Partial Penetration Welds *

* Verify that value of K

(a)

The requirements of 3.1 shall be met.

(b)

The following additional requirements shall be met:

**

**

M

Q

W ** M L

N 1

Aw

Zwl

Zwn

W **

Aw

** 2

Q2

Aw

Q1** Q2 **

4

Aw

** 2

1/ 2

Left Side

**

MT

2S y

Zwl

**

MT

Z wt

properly to 2.0 on Pa

(7)

8035

1/ 2

Sy

Left Side

(8)

1293

Reaction Node at Point A (EPRI TR-107453)

Construct elbow trunnion with rigid element between

points A and D. Place support w/connecting node at A.

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 11 of 30

TRUNNION QUALIFICATION SHEET

Procedure for Evaluation of the Design of Hollow Circular Cross Section

Welded Attachments on Classes 2 and 3 Piping

ASME

Code

Case N-392-3 (Section III, Div 1 Nonmandatory Appendix Y-5000)

Reaction Node at Point

A (EPRI

TR-107453)

Construct

elbowperpendicular

trunnion with to

rigid

between

For trunnions

theelement

axis of the

run pipe; modified for elbow-mounted trunnions per EPRI TR-107453 (

points A and D. Place support w/connecting node at A.

GENERAL NOTES:

1.

For attachments on straight pipe with nearest attachment weld at a minimum of

discontuinuity, per Code Case N-392-3, para. 1.4.

2.

N-392-3 (1994) was added to Section III, Div 1 Nonmandatory Appendix Y-5000 in 2004. Eq. 6 was simplified in Ybut yields same results as N-392-3. For consistency with EPRI TR-107453, N-392-3 is referenced here.

3.

The Electric Power Research Institute (EPRI) extended the ASME Code Case N-392-3 for welded attachments to co

LR & SR elbow trunnions. Testing and analysis provided a basis for modifying constants A 0, n1, n2

and n3 when applied to 90 trunnion/elbow configurations.

RTany other weld or

from

Download TR-107453 free at EPRI

4.

When compared to FEA data EPRI obtained during TR-107453, the Code Case N-392-3 method is "conservative by

factor of 4.6," dropping to 2.39 when the equation for C is adjusted for the curvature Q at the elbow. (Pg. 4-16) T

reduction in conservatism from N-392-3 for elbow-mounted trunnions is reflected in the modified factors used to

evaluate C in the EPRI method above.

5.

EPRI concluded, "The FEA from this study indicates that the presence of the trunnion decreases the stress in the e

when the loading is on the elbow. This is confirmed by Hankinson [7] in that the value of C2 determined is less tha

that of a plain elbow." (Pg. 4-17) See EPRI link for elbow k-factors, pg. 7-2.

6.

Machine Design - R.S. Khurmi, J.K. Gupta, Chapter-10, pg. 351, Figs. 10.9 & 10.10; Table 10.8, pg. 365

7.

Sections from Code Case N-392-3 from ASME 1995 BPVC, Code Cases, Nuclear Components, reproduced with the

permission of The American Society of Mechanical Engineers.

8.

Sections from Stress Indices for Elbows with Trunnion Attachments (TR-107453) reproduced with the permission o

Electric Power Research Institute.

9.

AWS D1.1/D1.1M;2006, 2.3.2.10 Effective Area of Fillet Welds, reproduced with permission of the American Weldin

Society (AWS), Miami, Florida. (outside spreadsheet print area)

10.

AWS D1.1/D1.1M;2006, 2.23.4 Circular Connection Lengths, reproduced with permission of the American Welding

Society (AWS), Miami, Florida. (outside spreadsheet print area)

11.

Document was prepared as a tool for pipe stress engineers. It is intended to supplement analysis performed with

commercial pipe stress analysis software. All cell programming is visible for review and applicable Code equations

reproduced and referenced so users may verify function accuracy. Proper modeling and load selection is responsib

of the analyst. Spreadsheet is locked to prevent tampering after distribution.

Send comments/corrections to TomMS.pe at gmail dot com.

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 12 of 30

TRUNNION QUALIFICATION SHEET

Procedure for Evaluation of the Design of Hollow Circular Cross Section

Welded Attachments on Classes 2 and 3 Piping

ASME Code Case N-392-3 (Section III, Div 1 Nonmandatory Appendix Y-5000)

For trunnions perpendicular to the axis of the run pipe; modified for elbow-mounted trunnions per EPRI TR-107453 (

While believed to contain correct information, the author makes no warranty, express or implied, or assumes any legal responsibility for the accuracy,

completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned righ

WARRANTY DISCLAIMER. THIS SPREADSHEET IS SUPPLIED "AS IS" WITHOUT WARRANTY OF ANY KIND. THE AUTHOR: (1) DISCLAIMS ANY WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, TITLE OR

INFRINGEMENT, (2) DOES NOT ASSUME ANY LEGAL LIABILITY OR RESPONSIBILITY FOR THE ACCURACY, COMPLETENESS, OR USEFULNESS OF THE SPREADS

(3) DOES NOT REPRESENT THAT USE OF THE SPREADSHEET WOULD NOT INFRINGE PRIVATELY OWNED RIGHTS, (4) DOES NOT WARRANT THAT THE SPREAD

WILL FUNCTION UNINTERRUPTED, THAT IT IS ERROR-FREE OR THAT ANY ERRORS WILL BE CORRECTED.

LIMITATION OF LIABILITY. IN NO EVENT WILL THE AUTHOR BE LIABLE FOR ANY INDIRECT, INCIDENTAL, CONSEQUENTIAL, SPECIAL OR PUNITIVE DAMAGE

ANY KIND OR NATURE, INCLUDING BUT NOT LIMITED TO LOSS OF PROFITS OR LOSS OF DATA, FOR ANY REASON WHATSOEVER.

2012 Thomas M. Sullivan, P.E. Rev. 0, 1-11-2013

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 13 of 30

oss Section

dix Y-5000)

ons per EPRI TR-107453 (1998).

e at pipe O.D. See General Notes.)

tachment location =

Run Pipe OD =

Run

<SELECT

14.000

in.

Run Pipe Wall thk =

0.375

in.

tachment Pipe OD =

8.625

in.

ment Pipe Wall thk =

0.322

in.

Fillet Weld Size =

0.250

in.

Per ASME Section III

Level A - Normal

Level B - Upset

Level C - Emergency

Level D - Faulted

th EPRI TR-107453, Appendix A

=

7.000

in.

6.625

in.

4.313

in.

3.991

in.

0.375

in.

0.322

in.

14.000

in.

8.625

in.

6.813

in.

8.399

in.2

16.809

in.3

72.489

in.4

4.200

in.2

16.809

18.667

0.859

0.616

6.404

3.610

10.497

#VALUE!

#VALUE!

(a) replace n2 with e-1.209

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 14 of 30

oss Section

dix Y-5000)

ons per EPRI TR-107453 (1998).

(b) replace n2 with e-1.3905

RI TR-107453, Eq. 5-4)

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 15 of 30

oss Section

dix Y-5000)

ons per EPRI TR-107453 (1998).

RI TR-107453, Eq. 5-1)

RI TR-107453, Eq. 5-2)

RI TR-107453, Eq. 5-3)

1.394

3.202

1.805

5.249

1.000

2.0 <SELECT

13700

psi

13700

psi

20550

psi

22200

psi

10.33

in.3

throat thickness: (cos 45 x fillet weld size)

10.33

in.3

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 16 of 30

oss Section

dix Y-5000)

ons per EPRI TR-107453 (1998).

throat thickness: (cos 45 x fillet weld size)

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 17 of 30

oss Section

dix Y-5000)

ons per EPRI TR-107453 (1998).

=

20.66

in.3

throat thickness: (cos 45 x fillet weld size)

5.09

in.2

Absolute Values of Maximum

loads occurring simultaneously

under all service loading conditions

20269 in-lbs

56914 in-lbs

0 in-lbs

2444

lbs

845

lbs

278

lbs

d W** are absolute

occurring simultaneously

onditions. (Select Load Case

h maximum resultant Moment.)

SMT =

5783

psi

SNT =

11119

psi

SPT =

22237

psi

SNT**=

40891

psi

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 18 of 30

oss Section

dix Y-5000)

ons per EPRI TR-107453 (1998).

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 19 of 30

oss Section

dix Y-5000)

ons per EPRI TR-107453 (1998).

ASME BPVC, Section XI-1998

Code Case N-392-3

Fig. 1, Pg. 730

EPRI, TR-107453 (1998)

Figure 2-1, Pg. 2-1

Weight and other Sustained

MA =

41779 in-lbs

Occasional loads only

MB =

40132 in-lbs

(below) are Eq. values being compared

Right Side

20550

PASS

m Section 2 above),

=

53.251

in.3

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 20 of 30

oss Section

dix Y-5000)

ons per EPRI TR-107453 (1998).

=

372.760

in.4

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 21 of 30

oss Section

dix Y-5000)

ons per EPRI TR-107453 (1998).

but not greater than

Sy for Level A and

Level B loadings

but not greater than

Sy for Level C loadings

but not greater than

Sy for Level D loadings

1.8Sh

24660

PASS

Expansion and Displacement

MC =

23187 in-lbs

Ref. NC-3653.2

Settlement, if any

MD =

0 in-lbs

Ref. NC-3653.2

i=

1.00

Right Side

20550

PASS

Right Side

41100

PASS

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 22 of 30

oss Section

dix Y-5000)

ons per EPRI TR-107453 (1998).

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 23 of 30

oss Section

dix Y-5000)

ons per EPRI TR-107453 (1998).

Right Side

34250

PASS

Right Side

44400

PASS

22200

PASS

* Verify that value of KT is set

properly to 2.0 on Page 2.

Right Side

44400

PASS

Right Side

22200

PASS

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 24 of 30

oss Section

dix Y-5000)

ons per EPRI TR-107453 (1998).

m any other weld or

Eq. 6 was simplified in Y-5000,

erenced here.

welded attachments to cover

, n1, n2

0

R-107453 free at EPRI.com.

ethod is "conservative by a

t the elbow. (Pg. 4-16) The

modified factors used to

reases the stress in the elbow

C2 determined is less than

10.8, pg. 365

nts, reproduced with the

ed with the permission of the

n of the American Welding

of the American Welding

analysis performed with

pplicable Code equations are

oad selection is responsibility

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 25 of 30

oss Section

dix Y-5000)

ons per EPRI TR-107453 (1998).

onsibility for the accuracy,

not infringe privately owned rights.

DISCLAIMS ANY WARRANTIES,

ARTICULAR PURPOSE, TITLE OR NONR USEFULNESS OF THE SPREADSHEET,

OT WARRANT THAT THE SPREADSHEET

, SPECIAL OR PUNITIVE DAMAGES OF

ER.

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 26 of 30

TRUNNION QUALIFICATION SHEET

ENTER OUTPUT FROM STRESS PROGRAM HERE

Procedure for Evaluation of the Design of Hollow Circular Cross Section

Welded Attachments on Classes 2 and 3 Piping

ASME Code Case N-392-3 (Section III, Div 1 Nonmandatory Appendix Y-5000)

For trunnions perpendicular to the axis of the run pipe; modified for elbow-mounted trunnions per EPRI TR-107453 (199

Yellow cells: User input; Gray cells: automated

FIG. 1, FIGURE 2-1 VECTORS

SELECT STRESS MODEL VECTORS (X, Y, Z) THAT CORRESPOND TO FIGURES

TRUNNION REACTION NODE NO.:

298

STRESS PROGRAM OUTPUT (Based on Example below)

Set up extra Load Cases as required by N-392-3

Q2

Q1

ENTER STRESS PROGRAM OUTPUT FROM TRUNNION REA

Fx

Fy

Fz

Weight and other Sustained

6 (SUS) L6=W+P1+H

-340.0

1777.0

-101.0

Occasional loads only1

18 (OCC) L6=L10-L4

50.0

-149.0

-1708.0

Expansion and Displacement

32 (EXP) L32=L4-L6

11.0

-783.0

-635.0

10 (OPE) L10=W+T1+P1+H+WIN3

-278.0

845.0

-2444.0

PIPE axis corresponding

to Stress Analysis axis

FY

FZ

FX

Settlement, if any

**Max Loading under all conditions2

Loads From Above Assigned to Pipe Axes, Moments

FIG. 1, FIGURE 2-1 VECTORS

ASME Code Case

N-392-3 Input

Q2

Q1

Weight and other Sustained

6 (SUS) L6=W+P1+H

1777.0

-101.0

-340.0

Occasional loads only

18 (OCC) L6=L10-L4

-149.0

-1708.0

50.0

32 (EXP) L32=L4-L6

-783.0

-635.0

11.0

0.0

0.0

0.0

845.0

-2444.0

-278.0

Expansion and Displacement

Settlement, if any

**Max Loading under all conditions

10 (OPE) L10=W+T1+P1+H+WIN3

1. Select Load Case from pure Occasional load results with the maximum Code Stress.

2. Select Load Case from Operating load results with the maximum resultant Moment.

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 27 of 30

TRUNNION QUALIFICATION SHEET

ASME BPVC, Section XI-1998 N-392-3, Pg. 730

Trunnion Qualification Sheet - ASME Code Case N-392-3

EPRI, TR-107453, Pg

Page 28 of 30

TRUNNION QUALIFICATION SHEET

T FROM STRESS PROGRAM HERE

n of the Design of Hollow Circular Cross Section

achments on Classes 2 and 3 Piping

(Section III, Div 1 Nonmandatory Appendix Y-5000)

un pipe; modified for elbow-mounted trunnions per EPRI TR-107453 (1998).

ells: User input; Gray cells: automated

MN

ML

MT

MY

MZ

MX

ENTER STRESS PROGRAM OUTPUT FROM TRUNNION REACTION NODE (LBS, FT-LBS)

Mx

My

Mz

0.0

193.9

3476.2

0.0

3332.1

-286.1

0.0

1216.8

-1501.0

0.0

4742.8

1689.1

MY

MZ

MX

Loads From Above Assigned to Pipe Axes, Moments Converted to in-lbs

MN

ML

MT

2326.8

41714.4

0.0

39985.2

-3433.2

0.0

14601.6

-18012.0

0.0

0.0

0.0

0.0

56913.6

20269.2

0.0

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 29 of 30

TRUNNION QUALIFICATION SHEET

EPRI, TR-107453, Pg. 2-1 (1998)

Trunnion Qualification Sheet - ASME Code Case N-392-3

Page 30 of 30

También podría gustarte

- N-318-5 Lug Local StressDocumento3 páginasN-318-5 Lug Local StresscohenfuAún no hay calificaciones

- Methods For WRC 107 and WRC 297 Checking in Caesar IIDocumento8 páginasMethods For WRC 107 and WRC 297 Checking in Caesar IIRomner CordovaAún no hay calificaciones

- Appendix E.1. Pipe Support Calculation - PS-CP-01Documento10 páginasAppendix E.1. Pipe Support Calculation - PS-CP-01noto.sugiarto50% (2)

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Documento32 páginasPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoAún no hay calificaciones

- Dennis R Moss 4th EditionDocumento5 páginasDennis R Moss 4th Editionsenthil kumarAún no hay calificaciones

- Stress Analysis of Reactor Nozzle To HeadDocumento5 páginasStress Analysis of Reactor Nozzle To HeadKagira Drawing SoltuionAún no hay calificaciones

- HotTap Tie-In Analysis Caesar IIDocumento24 páginasHotTap Tie-In Analysis Caesar IIvarshneydushyantAún no hay calificaciones

- Method For Finding Stress in Cylinders With Radial NozzlesDocumento10 páginasMethod For Finding Stress in Cylinders With Radial NozzlesmatodelanusAún no hay calificaciones

- Jacketed Piping CalculationDocumento9 páginasJacketed Piping CalculationKamran Shaikh0% (1)

- WRC 107 Calculation-Circular Attachment On Cylinder (Without Repad)Documento3 páginasWRC 107 Calculation-Circular Attachment On Cylinder (Without Repad)naim100% (1)

- Nozzle ProDocumento3 páginasNozzle Projojo_323Aún no hay calificaciones

- WRC 107, WRC 297 Co MP PDFDocumento11 páginasWRC 107, WRC 297 Co MP PDFkarthickmectr100% (2)

- NozzlePRO FEA Training ContentDocumento1 páginaNozzlePRO FEA Training Contentmbc_enggAún no hay calificaciones

- Modeling An API 661 Air Cooler - Intergraph CADWorx & AnalysisDocumento2 páginasModeling An API 661 Air Cooler - Intergraph CADWorx & AnalysisdhurjatibhuteshAún no hay calificaciones

- Work Instruction - Expansion Joint Modelling in CAESAR IIDocumento11 páginasWork Instruction - Expansion Joint Modelling in CAESAR IIChanAún no hay calificaciones

- Trunnion Check Calculation (Onsite) : Page No: Contract No: System NoDocumento2 páginasTrunnion Check Calculation (Onsite) : Page No: Contract No: System NoJ A S JAS0% (1)

- B31.3 Case 178Documento11 páginasB31.3 Case 178fileseekerAún no hay calificaciones

- 45 Deg Branch SIFsDocumento1 página45 Deg Branch SIFsayoungaAún no hay calificaciones

- Mech. Design CalculationDocumento182 páginasMech. Design CalculationSajad AbdulAún no hay calificaciones

- Check 18Documento6 páginasCheck 18Anonymous qBwHKusAún no hay calificaciones

- PNC00001 - Pipe Support Criteria For B31.3 Metallic PipingDocumento11 páginasPNC00001 - Pipe Support Criteria For B31.3 Metallic PipingYamini Shinde0% (1)

- NC3658 Flange CheckDocumento2 páginasNC3658 Flange CheckvsvineeshAún no hay calificaciones

- Nozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)Documento17 páginasNozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)SingoAún no hay calificaciones

- Step by Step Methods For WRC 107 and WRC 297 Checking in Caesar IIDocumento4 páginasStep by Step Methods For WRC 107 and WRC 297 Checking in Caesar IIdangminhAún no hay calificaciones

- Asme B 31J SifDocumento6 páginasAsme B 31J SifVineesh Vs100% (1)

- Allowable External Loads On Tank Shell Openings (API 650 APP.P)Documento2 páginasAllowable External Loads On Tank Shell Openings (API 650 APP.P)Geronimo ZamoraAún no hay calificaciones

- SP by CantileverDocumento18 páginasSP by CantileverPaldexAún no hay calificaciones

- Stress Analysis Specification: CONT. NO.: 1032/GC-GN/CON-EP09-00 DOC. NO.: 3607/34-78-ED-PI-SPDocumento23 páginasStress Analysis Specification: CONT. NO.: 1032/GC-GN/CON-EP09-00 DOC. NO.: 3607/34-78-ED-PI-SPhamedpdms100% (1)

- ShoeDocumento1 páginaShoePhornlert Wana100% (1)

- Nozzle Evaluation Sheet: Xxofxx C17058 XXXXXXXX FPSO Carioca MV30Documento1 páginaNozzle Evaluation Sheet: Xxofxx C17058 XXXXXXXX FPSO Carioca MV30J A S JASAún no hay calificaciones

- C17058 XXXXXXXX FPSO Carioca MV30: Lthe Offshore Engineering Nozzle Evaluation SheetDocumento3 páginasC17058 XXXXXXXX FPSO Carioca MV30: Lthe Offshore Engineering Nozzle Evaluation SheetJ A S JASAún no hay calificaciones

- Calculo de Brida Segun ASMEDocumento29 páginasCalculo de Brida Segun ASMEakarcz6731Aún no hay calificaciones

- SIF CalculatorDocumento4 páginasSIF CalculatorKannaphat Wattanaphan100% (1)

- WRC 537 Cige Noz B Op 1Documento1 páginaWRC 537 Cige Noz B Op 1metroroadAún no hay calificaciones

- Trunnion Check - Node 710Documento13 páginasTrunnion Check - Node 710Prashant ChauhanAún no hay calificaciones

- Advantages of Code Case 2695 and Comparison Bet ASME Div 1 and Div 2 PDFDocumento42 páginasAdvantages of Code Case 2695 and Comparison Bet ASME Div 1 and Div 2 PDFPrashant Agrawal100% (1)

- Saddle AnalysisDocumento17 páginasSaddle AnalysisPEJU0007Aún no hay calificaciones

- H H Optimum 0,2: Instructions For Using NomogramDocumento4 páginasH H Optimum 0,2: Instructions For Using NomogrammithunjobsAún no hay calificaciones

- FatigueLife FEA PDFDocumento43 páginasFatigueLife FEA PDFAbigail SommersetAún no hay calificaciones

- 212.nozzle Load Stress Analysis Using WRC 107 and WRC 297Documento4 páginas212.nozzle Load Stress Analysis Using WRC 107 and WRC 297jeronimo113Aún no hay calificaciones

- Stress Sample Calculation On Base EllDocumento1 páginaStress Sample Calculation On Base EllLionel TorradoAún no hay calificaciones

- WRC 107Documento2 páginasWRC 107mit1111chinAún no hay calificaciones

- Nema CalculationsDocumento149 páginasNema CalculationsJ A S JASAún no hay calificaciones

- 04 - Local Coordinate SystemDocumento18 páginas04 - Local Coordinate Systemerikoh100% (2)

- Few Important Points For Stress Analysis Based On ASME B 31Documento4 páginasFew Important Points For Stress Analysis Based On ASME B 31Nilesh GohelAún no hay calificaciones

- Agitator Nozzle Load Data SheetDocumento1 páginaAgitator Nozzle Load Data SheetAnonymous MB5YbaLrBEAún no hay calificaciones

- Lug - On - FlangeDocumento17 páginasLug - On - Flangeshaishav100% (1)

- Analisis de Stress en TuberíasDocumento4 páginasAnalisis de Stress en TuberíasJanneth Herrera FloresAún no hay calificaciones

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocumento5 páginasASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaAún no hay calificaciones

- CHECK-LIST PI-04 Stress Analysis Report - Piping - Fr.enDocumento4 páginasCHECK-LIST PI-04 Stress Analysis Report - Piping - Fr.enYousef SalahAún no hay calificaciones

- Piping Stress Analysis Pipeline System in Offshore PlatformDocumento2 páginasPiping Stress Analysis Pipeline System in Offshore Platformgpskumar22100% (1)

- Dummy Leg & Trunnion Calculation Sheet: Pipe Dia. MM Pipe Nom. THK (Tnom) MMDocumento4 páginasDummy Leg & Trunnion Calculation Sheet: Pipe Dia. MM Pipe Nom. THK (Tnom) MMashish shrivastav50% (2)

- Data Sheet For Allowable Nozzle Load - SP1-110-9850-00-PI-DTDocumento8 páginasData Sheet For Allowable Nozzle Load - SP1-110-9850-00-PI-DTbabak mirAún no hay calificaciones

- ASME Ch38 p001-018 11-8-08Documento18 páginasASME Ch38 p001-018 11-8-08Dan MorganAún no hay calificaciones

- S TN Pun 005Documento5 páginasS TN Pun 005Batepola BacAún no hay calificaciones

- Miter B1 ADocumento55 páginasMiter B1 AFarid TataAún no hay calificaciones

- API 510 PC 05mar05 Summmary of NDT Asme Viii 1Documento1 páginaAPI 510 PC 05mar05 Summmary of NDT Asme Viii 1Sampath KumarAún no hay calificaciones

- 171-178 EurocodeDocumento8 páginas171-178 EurocodeDeana WhiteAún no hay calificaciones

- Area Reinforcement CalculatorDocumento5 páginasArea Reinforcement CalculatorAnonymous Iev5ggSR100% (1)

- LearningDocumento1 páginaLearningSergio SmithAún no hay calificaciones

- Cubic CurveDocumento2 páginasCubic CurveSergio SmithAún no hay calificaciones

- PDILDocumento13 páginasPDILSergio SmithAún no hay calificaciones

- Quqntity: Keyboard 2 600 Mouse 4 800 BBBBBBB BBBB Aaaaaa AaaaaaDocumento1 páginaQuqntity: Keyboard 2 600 Mouse 4 800 BBBBBBB BBBB Aaaaaa AaaaaaSergio SmithAún no hay calificaciones

- Hydraulics: Pressure Transducer With LMS™ Amesim™ Student EditionDocumento5 páginasHydraulics: Pressure Transducer With LMS™ Amesim™ Student EditionSergio SmithAún no hay calificaciones

- Good SummaryDocumento22 páginasGood SummarySergio SmithAún no hay calificaciones

- Quqntity: Keyboard 2 600 Mouse 4 800 BBBBBBB BBBB Aaaaaa AaaaaaDocumento1 páginaQuqntity: Keyboard 2 600 Mouse 4 800 BBBBBBB BBBB Aaaaaa AaaaaaSergio SmithAún no hay calificaciones

- By Edwards Pearson: Differential Equations and Boundary Value Problems: Computing and Modeling, 3/EDocumento1 páginaBy Edwards Pearson: Differential Equations and Boundary Value Problems: Computing and Modeling, 3/ESergio SmithAún no hay calificaciones

- LearningDocumento1 páginaLearningSergio SmithAún no hay calificaciones

- Uses of Magnets: By-Aditi Vi-BDocumento5 páginasUses of Magnets: By-Aditi Vi-BSergio SmithAún no hay calificaciones

- Towards East Towards NorthDocumento3 páginasTowards East Towards NorthSergio SmithAún no hay calificaciones

- Modal ParametersDocumento8 páginasModal ParametersSergio SmithAún no hay calificaciones

- Sif B31 3Documento10 páginasSif B31 3Sergio SmithAún no hay calificaciones

- Books For Collection: 26/5/16: Remarkable Books, Dickson: Constructions in Geometry Dickson: AlgebraDocumento4 páginasBooks For Collection: 26/5/16: Remarkable Books, Dickson: Constructions in Geometry Dickson: AlgebraSergio SmithAún no hay calificaciones

- X F Z F X F Z F X F Z F M M M M y F Z F y F Z F y F Z F M M M MDocumento1 páginaX F Z F X F Z F X F Z F M M M M y F Z F y F Z F y F Z F M M M MSergio SmithAún no hay calificaciones

- Airtel 1Documento1 páginaAirtel 1Sergio SmithAún no hay calificaciones

- W e Byerly Fourier Series DoverDocumento1 páginaW e Byerly Fourier Series DoverSergio SmithAún no hay calificaciones

- 106 - Suggested Answer Scheme Mock PSPM 2 Week 17 Set 2 PDFDocumento10 páginas106 - Suggested Answer Scheme Mock PSPM 2 Week 17 Set 2 PDFSyaza IsmailAún no hay calificaciones

- Overhead Line Design NotesDocumento35 páginasOverhead Line Design NotesiaessackjeeAún no hay calificaciones

- Basic Data Viper40 15066 enDocumento10 páginasBasic Data Viper40 15066 enArmando RiveraAún no hay calificaciones

- ANFODocumento2 páginasANFOYef PumacayoAún no hay calificaciones

- STANDARD TEST METHOD: Thermostable Alpha-AmylasesDocumento5 páginasSTANDARD TEST METHOD: Thermostable Alpha-Amylasesamithg33Aún no hay calificaciones

- Astro Solar Information-EDocumento1 páginaAstro Solar Information-EMutoha ArkanuddinAún no hay calificaciones

- STAD Balancing ValvesDocumento10 páginasSTAD Balancing ValvesNestramiAún no hay calificaciones

- Gree Change 18-24 Technical Manual EngDocumento101 páginasGree Change 18-24 Technical Manual Engstr.maintenance.reAún no hay calificaciones

- Zoncare-Q7: Full Digital Color Doppler Ultrasound Diagnostic SystemDocumento3 páginasZoncare-Q7: Full Digital Color Doppler Ultrasound Diagnostic SystemyeniAún no hay calificaciones

- SPM General CatalogDocumento40 páginasSPM General CatalogNailuth García100% (1)

- IS 3370 (Part 3) 1967 R 1999Documento14 páginasIS 3370 (Part 3) 1967 R 1999Nayag Singh100% (1)

- Digital Signal ProcessingDocumento2 páginasDigital Signal ProcessingAnonymous HyOfbJ60% (1)

- KrishnaDocumento9 páginasKrishnaKrishna KashyapAún no hay calificaciones

- Black SmokerDocumento25 páginasBlack SmokergilangAún no hay calificaciones

- Fixed-Point Signal ProcessingDocumento133 páginasFixed-Point Signal ProcessingRaveendra MoodithayaAún no hay calificaciones

- Understanding BatteriesDocumento258 páginasUnderstanding Batteriesramprabhakarj100% (8)

- LogiComm Pattern ControlDocumento2 páginasLogiComm Pattern ControlNordson Adhesive Dispensing SystemsAún no hay calificaciones

- Borzone Et Al 1996Documento13 páginasBorzone Et Al 1996Daiane Evangelista AvizAún no hay calificaciones

- A Kinetic Model of The Peirce-Smith Converter: Part I. Model Formulation and ValidationDocumento11 páginasA Kinetic Model of The Peirce-Smith Converter: Part I. Model Formulation and ValidationJaime MoralesAún no hay calificaciones

- Lets Rock ItDocumento17 páginasLets Rock Itapi-312503373Aún no hay calificaciones

- 2010 AP Physics Free Response AnswersDocumento9 páginas2010 AP Physics Free Response AnswersAugust ValeraAún no hay calificaciones

- Edge WeldDocumento26 páginasEdge WeldnekroAún no hay calificaciones

- Ce60 Theory of StructuresDocumento2 páginasCe60 Theory of StructuresKhryzzia Maye FelicildaAún no hay calificaciones

- Electrostatics FormulaDocumento2 páginasElectrostatics FormulaAbdul AhadAún no hay calificaciones

- Gulfmaster Manual PDFDocumento15 páginasGulfmaster Manual PDFJoan RosanwoAún no hay calificaciones

- File 00000003Documento303 páginasFile 00000003monica laraAún no hay calificaciones

- R. Angeline Prabha & J.Lavina Mary: Jacsi College of Engg. NazarethDocumento17 páginasR. Angeline Prabha & J.Lavina Mary: Jacsi College of Engg. NazarethRose EdwardAún no hay calificaciones

- Second Grading Grade 9Documento2 páginasSecond Grading Grade 9VINES100% (1)

- 3 V/5 V, 450 A 16-Bit, Sigma Delta ADC AD7715 : Ma Max at 3 V SuppliesDocumento32 páginas3 V/5 V, 450 A 16-Bit, Sigma Delta ADC AD7715 : Ma Max at 3 V SuppliesMichele BacocchiaAún no hay calificaciones

- A.7.a.1CE Mark - KS1150 FR - Panou Perete Rez Foc 180 Min C2Documento1 páginaA.7.a.1CE Mark - KS1150 FR - Panou Perete Rez Foc 180 Min C2Agnes SzaboAún no hay calificaciones