Documentos de Académico

Documentos de Profesional

Documentos de Cultura

PEW 404 Inspect Columns 01

Cargado por

Reshmi Vinu0 calificaciones0% encontró este documento útil (0 votos)

28 vistas32 páginasPEW 404 Inspect Columns 01

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoPEW 404 Inspect Columns 01

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

28 vistas32 páginasPEW 404 Inspect Columns 01

Cargado por

Reshmi VinuPEW 404 Inspect Columns 01

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 32

PEW-404

PARTICIPANT

ADDENDA

TABLE 1.

Portable lights, Including a flashlight

Thin-bladed knife or scraper

Broad chisel or scraper

Pointed scraper

Inspector's hammer

Inside calipers

Outside calipers

Magnet

Small mirror

Thickness-measuring equipment

TABLE 2.

Surveyor's level

Carpenter's or plumber’s level

Magnetic particle test equipment

Liquid penetrant test kit

Micrometer

TOOLS NEEDED FOR COLUMN INSPECTION

Pocket knife

Steel tape rule, 50 feet (15 meters)

Flange square

Pit depth gauge

Greaseless crayon or washable paint

Notebook and pencil

Magnifying glass

Wire brush

Plumb bob and line

Small mirror

TOOLS THAT MAY BE REQUIRED FOR COLUMN INSPECTION

Ultrasonic test equipment

Sandblasting equipment

Micrometer, large, 0-1 inch

Radiographic inspection equipment

Camera

124

PEW-404 PARTICIPANT

ADDENDA

ADDENDUM A2. SAFETY INSTRUCTION SHEET

12!

PEW-404 PARTICIPANT ADDENDA

FOR ARABIAN AMERICAN OIL COMPANY

i DATaTant/OFa NATING UuiiTs RHTETE=VESEELS

i {| ‘EQUIPMENT DATA —_

< Sewer obuer STR) wo 468: Bos

Nontevn SUMiTDMO — we WERTCAL _Vegsex |

wine eee vow duit PTS

“.

wa

TE REV Fi

Rauioment Wo —____spec'n No ZAMS 4 order No FR¢BB “32-901 =TA__

| Ameroty 0+ (WUO- C= UBB KE TLCle omign Srna XO-7EIOEP

| ssonae coon ond eaion (LE ASME ST-V, DILL sun omen soot KE= 225705 4

a SABIe = 70 was BART To

Gi Boron | MT 7623" lipo] Cone A” Fae

arm. nema — 9

irae

a Lee,

seh Bee ea ieee oe | See teas

pays ibd toe deo tee een |

Stans Trek anmrocnaray | erronncve

Ny g ees Tat Burra 0 Tea | |

Reg |

ves

| S19) 7

SaaS =

ED "| SEN, st Aaa zaaae —

Wb ra/n

Soc sere a somrmanan mento sin ous vawm esi

SE EPS PE SEO Bese DE ae Boe 1S: dac

- ee rae] ae

| D Fues Ren Nearme Rervemee #68) § | XE 72576 ja)

MAS Te ssvor aman er

| D connusroesenn wrertrannon elise rast vue

Sores se tp tor vecm JES.

ee SARA eee REnETS 13 ERE Eiad Oe OE SORT

Pies Sui Vave os BAB 6 SOG sv sain =

Dee TPEBEL TERE.

‘t

eet —

SAFETY PRECAUTIONS 1

126

PEW-404

PARTICIPANT

ADDENDA

ADDENDUM A3.

MANUFACTURER'S DATA REPORT

17

PEW-404 PARTICIPANT ADDENDA

FORM U-IA MANUFACTURERS DATA REPORT FOR PRESSURE VESSELS

(Altemative Form fr Single Chamber, Completely Shop fabricated Vessels Only)

‘As Required bythe Provisions ofthe ASME Code Rules, Section VII, Division 1

Mandated:

/ITOMO HEAVY INDUSTRIES 1501 IMAZAIKE

2wlaavesie, _FLUOR INTERNATIONAL, INC. 4620N. BRAESWOOD BLVD. HOUSTON _

2 tee__VERT. Vani, 488 YNL84 No = vba __1975

4.SHELL: Long SAS16 Gr. Kite 928, aim 8 Sin

0000

ionic Tot

244. pista ome Pre 420 oi

{SAFETY On RELEF VALVE OUTLETS Number 2 ste 6" _tssatn _TOP_HEAD

DRAIN. "i SASI6 Gr. 10 WELDED _

- SAI06 Gr. 8.438":

REBOILER ING s SALO6 Gr. 20.513

10 NSPECTON Wario No 3 Sv BA teeter TOR, “GONE, 4 BOTTOM SIDE

11, supPons: shit YES ogy = = mates BOTTOM WELDED

12, REMARKS (at apleineotea ence mss th UG 120(9))

DRAG

i ne

oe

Hangin 0

Ter

BE =

a eee

Dae AT SEBE” pTS" Sqned ST alabahadbe fy CHIEF OF InspEcTIon SE

of Aahoreaon Ne sone

CERTIFICATE OF STTOP INSPECTION

OSAKA. JAPAN ha gmt anpnetenesn ma Mnsnte

INALLY ON 17 SEPT, 1 evemene

128

PEW-404

PARTICIPANT

ADDENDA

ADDENDUM B

FORMS

129

PEW-404

PARTICIPANT ADDENDA

ADDENDUM B1.

EQUIPMENT INSPECTION RECORD-GENERAL (BLANK)

130

ove

EQUIPMENT INSPECTION RECORD — GENERAL

‘Sau Ararco 2085-ENG (110)

Plant or un

Fauiaren?

SAUDI ARABIAN OIL COMPANY

DATE

REMARKS:

~ e431

PEW-404

PARTICIPANT ADDENDA

ADDENDUM B2.

EQUIPMENT INSPECTION RECORD (NUMBERED ENTRIES)

132

PEW-404 PARTICIPANT ADDENDA

EQUIPMENT INSPECTION RECORD - GENERAL,

Sn Rare 2D ENG (1, _SAUDLARABAN COMPANY

Fico tar

are

133

PEW-404

PARTICIPANT

ADDENDA

ADDENDUM B3.

WORKSHEET (BLANK)

‘SAUDI ARABIAN OIL COMPANY

“ORKSHEET

PREPARED BY 2

‘Save Armen 2649-ENG (11190) ENGINEERING INSPECTION

Sara oan TURNERS SENSED

ae WORK RECOMMENDED BY

nsPECTORS BoRaTURE

[= Work ORDER (ARAMCO 981) ISSUED ON: (OATE)

ACTON | Won priory cowet, oarE aOR

| Operator scate acon taka, sgn and tim ene copy Engrang nsperon, |

SaORTY TEM

DESCRIPTION OF WORK TO BE DONE

PEW-404 PARTICIPANT

ADDENDA.

ADDENDUM B4, — WORKSHEET (NUMBERED ENTRIES)

136

PEW-404 PARTICIPANT ADDENDA

WORKSHEET | 9G? ENGINEERING INSPECTION

Sit arco 243.680 (1150) INSPECTON REPORT

—=@

rex9) Dower wacom anova

ore" | a, monn £9) coun one (4) _ | rororesanrse ~~

‘at aa aden oer ngs onion @

PRORTY| Tew DESCRIPTION OF WORK TO BE DONE

17

PARTICIPANT PEW-404

SAUDI ARAMCO _

INSPECT COLUMNS

PRETEST

WARNING: The training materials contained in this manual are the property of

the Saudi Arabian Oil Company (Saudi Aramco) and are intended for the

exclusive use of Saudi Aramco employees enrolled in advanced inspection

training courses. Any material contained in this manual which is not already in

the public domain, may not be copied, reproduced, sold, given, or disclosed to

third parties, or otherwise used, in whole or in part, for purposes other than for

use in Saudi Aramco’s Professional Engineering and Technical Development

courses without the prior written permission of the Chief Engineer of Saudi

Aramco.

PEW-404 PARTICIPANT REVISION

DATE REVISION DESCRIPTION PAGE (s) AFFECTED

PEW-404 PARTICIPANT PRETEST

Matching:

Match the words in the word lists with its definition. Write your answers in the

blanks provided in front of the definition. Words are only used once but not all

words are used.

Word Uist

A bubble cap G catalyst

B chimney H_ cladding

C concentration cell corrosion | conversion

D crevasse corrosion J distillates

— —downcomer K fractional distillation

F — deformation L reflux

1. A device that provides a liquid seal over the vapor openings

‘on a fractionation tray.

2. The product that has been separated during the distillation

process,

3. A process steam that is cooled and retumed to a column to

control the process temperature in a given section of the

column.

4. The separation of crude oil into hydrocarbon components to

make useful products.

5. A substance used in reactor columns to cause a change in the

molecular structure of a hydrocarbon in the refining process.

6. Apart of the bubble cap assembly that prevents liquid from

flowing into the vapor openings of the fractionation tray.

7 Corrosion that takes places in cracks or crevices.

PEW-404 PARTICIPANT PRETEST

Word List

A cladding. G radial flow

B vortex H product

Cc packing | skirt

D purlins J conversion

E downcomer K sheathing

F weirs L reactor

10.

1.

uF

13,

14,

A part of the tray that allows the excess liquid to flow from

one tray to the tray below.

The bottom supporting structure for a column.

A reinforcing structure for a tray panel

The walls in the tray assembly that maintain the liquid level in

the fractionator column.

Covering for a column.

A corrosion resistant metal applied to the steel plate of the

column at the mill.

type of change using a catalyst to cause a chemical reaction

that changes the hydrocarbon feed product.

PEW-404 PARTICIPANT PRETEST

Multiple Choice:

Circle the letter in front of the most correct answer.

15, The most important purpose of inspecting a column is. =

A. To ensure the that column can perform in a safe manner.

B. To ensure that the column can perform in an efficient manner.

C. To ensure that the column can perform for one more year.

D. To ensure that the column can perform for 10 more years.

16. The Is not one of the main pressure-containing

parts of the column.

A. Thermowell bundle Cc Top head

B. Shell D. Bottom head

17. The__________contains trays that provide disengaging

surfaces.

A. Packed column C__ Fractionater column

B. Flash column. D. Reactor

18. The ______trays are examples of disengaging surfaces.

A. Bubble cap C Ballast

8. Valve D. Rod

PEW-404 PARTICIPANT PRETEST

19. The separation process occurs in the __ _ _ a

because the pressure inside the vessel is much lower than the pressure in

the inlet pipe.

A. Flash column fractionator

B. Packed column D. Reactor

20. ___is used in the stripper column to strip light

fractions from the product stream.

A Air C Steam

B. Nitrogen D. Water

Ab We __tray is used in the stripper column.

A. Bubble cap Cc _ Ballast

B. Valve D. Rod

22, The_ —— is always kept constant in the fractional

distillation process.

A. Pressure Cc Time

8B. Temperature D. Flow rate

23. Inacolumn, the __ _____ allows the excess liquid to overflow to the

next tray.

A. Downcomer Cc Nozzle

B. Drawoff D. Chimney

PEW-404 PARTICIPANT PRETEST

24, Inacolumn, the vapor__ when it rises to a tray that has a

temperature to low to keep It vaporized.

A. Boils condenses

8. Is drawn off D. rises

25. The. _______ determines whether the hydrocarbon

component remains vaporized or condenses into a liquid.

A. Level of the tray C Flow rate

B. Temperature of the tray D. Time the component

remains on the tray

PEW-404 PARTICIPANT RETEST

Fill In the Blank:

From the word lists for each of the next two problems, fil in the blank with the

correct word. The words may be used once, more than once or not at all.

Word List

bolting ellipsoidal manway

nozzle slotted clamps

spheroidal conical solder

welding differential reinforcement

26. ‘The area around a nozzle is strengthened witha___pad.

27, A, a

e is an opening in the column for personnel or

equipment access.

28. The is a pressure-containing part that provides an

opening in the vessel.

29. The most common shape of the head of a column used in Saudi Aramco

is

30. The pressure-containing parts of a pressure vessel are joined by _

PEW-404 PARTICIPANT PRETEST

31. In Figure 1, write the letter of the part indicated by the arrow beside its

name in the list.

___ 1. Saddle 7. Nozzle

_____ 2. Shell _-& Sodes

3. Ends _—— 9% Conical section

4. Heads eee 10) Foundation

____ 5. Sledge __ 11. Nozzle

6. Skirt 12. Anchor bolt

Figure 1, Parts of a column

INSTRUCTOR

PEW-404

SAUDI ARAMCO

INSPECT COLUMNS

PRETEST

WARNING: The training materials contained in this manual are the property of

the Saudi Arabian Oil Company (Saudi Aramco) and are intended for the

exclusive use of Saudi Aramco employees enrolled in advanced inspection

training courses. Any material contained in this manual which is not already in

the public domain, may not be copied, reproduced, sold, given, or disclosed to

third parties, or otherwise used, in whole or in part, for purposes other than for

use in Saudi Aramco’s Professional Engineering and Technical Development

courses without the prior written permission of the Chief Engineer of Saudi

Aramco.

|

|

PEW-404 INSTRUCTOR REVISION

DATE REVISION DESCRIPTION PAGE(S) AFFECTED

PEW-404 INSTRUCTOR PRETEST

Matching:

Match the words in the word lists with its definition. Write your answers in the

blanks provided in front of the definition. Words are only used once but not all

words are used.

Word List

A bubble cap G catalyst

B chimney H_ cladding

C concentration cell corrosion | conversion

D crevasse corrosion } distillates

— downcomer K fractional distillation

F — deformation L reflux

1. A device that provides a liquid seal over the vapor openings

ona fractionation tray.

2. The product that has been separated during the distillation

process

L 3. Approcess steam that is cooled and retumed to a column to

control the process temperature in a given section of the

column,

r

The separation of crude oil into hydrocarbon components to

make useful products

G 5. Asubstance used in reactor columns to cause a change in the

molecular structure of a hydrocarbon in the refining process.

B 6. Apart of the bubble cap assembly that prevents liquid from

flowing into the vapor openings of the fractionation tray.

D 7 Corrosion that takes places in cracks or crevices.

PEW-404 INSTRUCTOR PRETEST

Word List

A cladding G radial flow

B vortex H product

c packing 1 skirt

D purlins J conversion

E downcomer K sheathing

F weirs L reactor

- 8. A part of the tray that allows the excess liquid to flow from

one tray to the tray below.

|__ 9 _ The bottom supporting structure for a column.

_D 10. _Areinforcing structure for a tray panel.

£ 11. The walls in the tray assembly that maintain the liquid level in

the fractionator column.

K-12. Covering fora column.

A 13. A corrosion resistant metal applied to the steel plate of the

column at the mill,

44. A type of change using a catalyst to cause a chemical reaction

that changes the hydrocarbon feed product.

PEW-404 INSTRUCTOR PRETEST

Multiple Choice:

Circle the letter in front of the most correct answer.

15, The most important purpose of inspecting a column is_ :

A__To ensure that the column can perform Ina safe manner,

8. To ensure that the column can perform in an efficient manner.

To ensure that the column can perform for one more year.

D. To ensure that the column can perform for 10 more years.

16. The_______Is not one of the main pressure-containing

parts of the column.

A__Thermowell bundle Cc Top head

B. Shell D. Bottom head

17, The __contains trays that provide disengaging

surfaces.

A. Packed column C.__ Fractionater column

B___Flash column_ D. Reactor

18. The__ ___ trays are examples of disengaging surfaces.

A. Bubble cap C Ballast

B. Valve D.__Rod

PEW-404 INSTRUCTOR PRETEST

ee

20.

ae

22.

23.

The separation process occurs in the __

because the pressure inside the vessel is much lower than the pressure in

the inlet pipe.

A__flash column C_ Fractionator

B. Packed column D, Reactor

is used in the stripper column to strip light

fractions from the product stream.

A Air C__Steam

B. Nitrogen D. Water

The. 7 tray is used in the stripper column,

A___Bubble cap C Ballast

B. Valve D. Rod

The. is always kept constant in the fractional

distillation process.

A_Pressure Cc Time

B. Temperature D. Flow rate

Inacolumn, the allows the excess liquid to overflow to the

next tray.

A___Downcomer Cc Nozzle

B, Drawoff D. Chimney

PEW-404 INSTRUCTOR PRETEST

24, Inacolumn, the vapor when it rises to a tray that has a

temperature to low to keep it vaporized.

A. Boils C__condenses

B. Is drawn off D. rises

25. The, determines whether the hydrocarbon

component remains vaporized or condenses into a liquid.

A. Level of the tray Flow rate

B___Temperature of the tray D. Time the component

remains on the tray

PEW-404 INSTRUCTOR PRETEST

Fill in the Blank:

From the word lists for each of the next two problems, fill in the blank with the

correct word. The words may be used once, more than once or not at all.

Word List

bolting ellipsoidal manway

nozzle slotted clamps

spheroidal conical solder

welding differential reinforcement

26. The area around a nozzle is strengthened with a reinforcement pad.

27. Amanway.is an opening in the column for personnel or equipment

access, -

28. The nozzle is a pressure-containing part that provides an opening in the

vessel.

29. The most common shape of the head of a column used in Saudi Aramco

is ellipsoidal,

30. The pressure-containing parts of a pressure vessel are joined by welding.

PEW-404 INSTRUCTOR PRETEST

31. In Figure 1, write the letter of the part indicated by the arrow beside its

name in the list.

Fes |= saddle Des 7. Nozzle

__B_ 2. Shell 8 Sodes

3. Ends _€_ 9. Conical section

__A 4, Heads _—H_ 10. Foundation

_ 5. Sledge _11._ Nozzle

E_ 6 Skirt G12. Anchor bolt

Figure 1. Parts of a column

También podría gustarte

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5795)

- HardnessDocumento13 páginasHardnessReshmi VinuAún no hay calificaciones

- Materials of Construction For Heat ExchangersDocumento34 páginasMaterials of Construction For Heat ExchangersReshmi Vinu100% (2)

- Operation of Compressor Control and Protection SystemsDocumento58 páginasOperation of Compressor Control and Protection SystemsReshmi Vinu100% (2)

- De 119885 QA QC ProcedureDocumento33 páginasDe 119885 QA QC ProcedureReshmi Vinu100% (1)

- Evaluating Installation of Vibration Monitoring Equipment For CompressorsDocumento56 páginasEvaluating Installation of Vibration Monitoring Equipment For CompressorsReshmi VinuAún no hay calificaciones

- Introduction To Gas Turbines PDFDocumento37 páginasIntroduction To Gas Turbines PDFMBA103003100% (1)

- Evaluating Installation of Vibration Monitoring Equipment For Gas TurbinesDocumento51 páginasEvaluating Installation of Vibration Monitoring Equipment For Gas TurbinesReshmi VinuAún no hay calificaciones

- Mba 2014 Annamali Part5Documento2 páginasMba 2014 Annamali Part5Reshmi VinuAún no hay calificaciones

- Mba Annamali 2014 Part15Documento3 páginasMba Annamali 2014 Part15Reshmi VinuAún no hay calificaciones

- Evaluating Gas Turbine TestingDocumento27 páginasEvaluating Gas Turbine TestingReshmi Vinu100% (2)

- Mba 2010 Annamali Part 3Documento2 páginasMba 2010 Annamali Part 3Reshmi VinuAún no hay calificaciones

- Mba 2014 AnnamaliDocumento2 páginasMba 2014 AnnamaliReshmi VinuAún no hay calificaciones

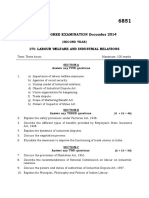

- M.B.A. DEGREE EXAMINATION December 2014: Labour Welfare and Industrial RelationsDocumento2 páginasM.B.A. DEGREE EXAMINATION December 2014: Labour Welfare and Industrial RelationsReshmi VinuAún no hay calificaciones

- Mba 2011 Annamali Part 1Documento5 páginasMba 2011 Annamali Part 1Reshmi VinuAún no hay calificaciones

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)