Documentos de Académico

Documentos de Profesional

Documentos de Cultura

4.2 - Risk Assessment Project - SAMPLE

Cargado por

Dhana SekarTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

4.2 - Risk Assessment Project - SAMPLE

Cargado por

Dhana SekarCopyright:

Formatos disponibles

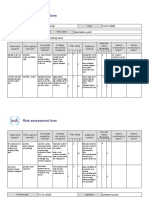

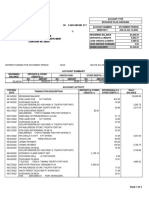

Name

End-of-course date

Training provider

Green World Group

Total

marks

Risk assessment form

Marks

Assessors name

Date

Description of process, activity or task to be risk assessed

The assessment has been done on our welding shop in our company Lamprell Energy. In our Company we have 3 dedicated welding shops in which

Describe the location

where the activities are about 50 people are working in one shift. There are total of 2 shifts. (Day / Night). Our welding shops are located indoor. The total work area size of

our company is about 50,000 sq.feet in total. Our company is into fabrication of offshore / onshore platform structures and pressure vessels. Within

taking place

our welding workshop there are a total of 6 exit / entry points. All the welding workshops are interconnected each other with huge sliding partitions.

The total work strength in our company in total is about 500 people in a shift. 5 dedicated supervisors are available at all times in the welding

workshops to manage the workers in a single shift

Describe the activities

being performed

Within our company the major activities carried out are welding / fabrication / blasting and painting / assembly / commissioning. All together a total

of 500 people are working on the site. Almost all the works are routine till the end of the project. Routine works would include welding, fabrication,

painting, lifting, blasting, daily housekeeping etc. Non routine works would include pressure testing, x-ray etc. X-rays are been conducted only during

the night time and not on a regular basis. 85% of the x-rays are done on the radiography bunker and not inside the workshop.

Describe the

equipment and/or

substances being used

In the welding workshop the main machine's in use are welding machines - Approximate 55 Nos, Grinding machines - 70 Nos, Gas Cutting

equipments - 25 nos, Acetylene / Oxygen cylinder - 30 nos (located outside the welding shops), Hammers & Chisel - 80 nos (Each one per welder),

Buffing machine - 50 nos approximately, Local Exhaust Ventilation machine 10 nos, Fire Extinguishers - 25 nos, Fire hose reels - 10 nos, Fire

blankets - Adequate.

Describe the people

involved in these

activities (and others

who might be affected)

Welders - 50

Supervisor - 5

House keeping personnel - 8

Safety officer - 1

Fire Watcher - 4

Visitors - 2 - 3 sometimes. (This happens during Client Visits or material suppliers)

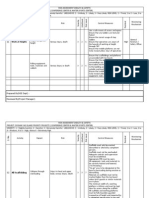

Risk assessment form

Equipment and

substances

Activities

Location

Description of hazard

and hazardous event

Who might be

harmed?

Current risk

rating*

What risk controls

are currently in

place?

Presence of welding fumes

which can cause

respiratory disease,

Chances of contact with

molten materials causing

burns. Chance of fire /

explosion

Welders, Fire

watchers, and other

personnel who are

present in the

workshop.

Local Exhaust

Ventilation is provided

within the workshop.

Fire blankets provided

and made it mandatory

to use it. Fire watcher

present in all locations

During lifting chances of

collision which could lead

to injury, inhalation of

paint fumes to those

involved in painting, Slip

Trip hazards while doing

housekeeping activities

House keeping

personnel, and those

employees who are

involved in lifting

activities.

Risk assessment is done

for the lifting.

Proper PPE is given to

all staffs.

All employees to ensure 3

that there are no trailing

exposed hazardously in

the work floor.

Oxygen / Acetylene

cylinders are stored in

open area which could lead

to explosion due to high

temperature in UAE

Workers working in

the workshop and

anybody near the

storage area

Currently the area is

barricaded to prevent

any unauthorized entry

*Likelihood x Consequence = Risk

Are further

controls needed?

Date to be

completed by

Residual risk

rating*

12

L

Ensure that the LEV is

On going / Daily

working at all times and

no unauthorized

modifications are done.

Regular inspection of

site and proper

housekeeping with PPE

Ensure that a safety

Ongoing / Daily

personnel is present

during the lifting.

Ensure that appropriate

and adequate respiratory

protection is given to

painters.

Permanent roof to be

2 weeks

provided for the cylinder

storages area.

3

12

Marks

Risk Rating Calculator

Likelihood that hazardous event will occur

Consequence of hazardous event

very unlikely

insignificant no injury

unlikely

minor minor injuries needing first aid

fairly likely

moderate up to three days absence

likely

major more than seven days absence

very likely

catastrophic death

Action Level Table

Risk rating

Action

2025

Stop stop activity and take immediate action

1516

Urgent action take immediate action and stop activity if necessary, maintain existing controls rigorously

812

Action improve within specified timescale

36

Monitor look to improve at next review or if there is a significant change

12

No action no further action but ensure controls are maintained and reviewed

Example risk assessment

Activities

Description of hazard

and hazardous event

Filling car with petrol,

leading to spillage

Who might be

harmed?

Person filling vehicle

and others on

forecourt

What risk controls

are currently in

place?

Auto pump cut off,

signage and plastic

gloves

Current risk

rating*

L

4

C

2

Are further

controls needed?

Date to be

completed by

Residual risk

rating*

R

8

L

Make available

paper towels, sand

and absorbent

material

By next week

C

2

R

6

También podría gustarte

- Risk Assessment Record: 5 4 3 2 1 1 2 3 4 5 SeverityDocumento5 páginasRisk Assessment Record: 5 4 3 2 1 1 2 3 4 5 Severitymakdel68% (22)

- Risk Assessment Project Iosh - MsDocumento2 páginasRisk Assessment Project Iosh - MsSanjeev Kumar75% (32)

- Example Risk Assessment For ExcavationsDocumento3 páginasExample Risk Assessment For ExcavationsYaser A. Al-Bustanji72% (18)

- Iosh Risk AssessmentDocumento3 páginasIosh Risk Assessmentmilan shrestha80% (25)

- Risk Assessment Form: Likelihood X Consequence RiskDocumento1 páginaRisk Assessment Form: Likelihood X Consequence RiskAijaz Ahmed Shaikh80% (5)

- Iosh Risk Assessment PDFDocumento3 páginasIosh Risk Assessment PDFAhmad Brothers75% (8)

- Risk Assessment ConstructionDocumento70 páginasRisk Assessment ConstructionArun Celestin93% (42)

- Working at Height Risk AssessmentDocumento7 páginasWorking at Height Risk AssessmentAshish100% (3)

- Risk Assessment Project v5.0Documento2 páginasRisk Assessment Project v5.0Ahmed Sohail93% (15)

- Legal Appointments ListDocumento19 páginasLegal Appointments ListHeleen86% (7)

- Iosh-Risk-Assessment Form PDFDocumento2 páginasIosh-Risk-Assessment Form PDFEngr Muhammad Shahid100% (1)

- Generic Risk AssessmentDocumento8 páginasGeneric Risk Assessmentmorgojoyo100% (3)

- Iosh Risk Assessment FormDocumento2 páginasIosh Risk Assessment FormDave C. Fernandez67% (6)

- ConfinedSpace RiskAssessmentDocumento9 páginasConfinedSpace RiskAssessmentrashid zaman100% (5)

- Task Specific Risk AssessmentDocumento22 páginasTask Specific Risk Assessmentsimone92% (12)

- Risk Assessment RegisterDocumento8 páginasRisk Assessment RegisterFareeha Waqar100% (10)

- 25-Risk Assessment For Fabrication & NDT During Night ShiftDocumento2 páginas25-Risk Assessment For Fabrication & NDT During Night Shiftgulryz84100% (9)

- MS 5.0 (1) Risk Assessment Project - Hardware Fitting On PoleDocumento2 páginasMS 5.0 (1) Risk Assessment Project - Hardware Fitting On Poleraj86% (7)

- Risk Assessment Project - 3Documento3 páginasRisk Assessment Project - 3Syed Amair67% (15)

- Risk AssessmentDocumento10 páginasRisk AssessmentKyaw Kyaw Aung89% (9)

- Risk Assessment For Working in Confined SpaceDocumento1 páginaRisk Assessment For Working in Confined SpaceRicardo Dalisay100% (1)

- Iosh Risk Assessment PDFDocumento3 páginasIosh Risk Assessment PDFromeo ghouse100% (2)

- Mustafa Adnan - Risk Assessment Project PDFDocumento2 páginasMustafa Adnan - Risk Assessment Project PDFMustafaAdnanAún no hay calificaciones

- Model of Risk AssessmentDocumento12 páginasModel of Risk AssessmentTony Gallacher60% (5)

- Hazard Identification Risk Assessment and Risk ControlDocumento7 páginasHazard Identification Risk Assessment and Risk ControlChowKC03100% (17)

- Shashi Sir Iosh AssessementDocumento3 páginasShashi Sir Iosh AssessementKumar Kush100% (2)

- Safety Risk AssessmentDocumento52 páginasSafety Risk Assessmentmujahid113794% (36)

- SWP 002 - Risk AssessmentDocumento23 páginasSWP 002 - Risk AssessmentAbhinavBanerjee100% (2)

- 125 MVA 400 KV Transformer Overhauling at site.: Risk Assessment And Analysis رطاـــــخملا مــــــييقتDocumento3 páginas125 MVA 400 KV Transformer Overhauling at site.: Risk Assessment And Analysis رطاـــــخملا مــــــييقتeng_hma75% (4)

- Example Risk Assessment For Contract Bricklayers: How Was The Site-Specific Risk Assessment Done? Setting The SceneDocumento16 páginasExample Risk Assessment For Contract Bricklayers: How Was The Site-Specific Risk Assessment Done? Setting The SceneWeei Zhee70Aún no hay calificaciones

- 2 Risk Assessment Rev 00 EHS FormatDocumento45 páginas2 Risk Assessment Rev 00 EHS Formatkumar100% (1)

- Site Activities Risk AssessmentDocumento50 páginasSite Activities Risk Assessmentjamie542393% (41)

- Risk Assessment of Scaffolding Works - Rev. 1Documento20 páginasRisk Assessment of Scaffolding Works - Rev. 1Jayson Escamillan67% (3)

- Risk Assesment Tie-In (Mechanical)Documento5 páginasRisk Assesment Tie-In (Mechanical)Galih SukmaAún no hay calificaciones

- Data Structures and Algorithms in Python SlidesDocumento917 páginasData Structures and Algorithms in Python SlidesSai Varma100% (2)

- Lecture 5. Industry 4.0 Technologies and Enterprise ArchitectureDocumento13 páginasLecture 5. Industry 4.0 Technologies and Enterprise ArchitectureBobo SevenAún no hay calificaciones

- Risk AssessmentDocumento10 páginasRisk Assessmentalamdar321100% (2)

- Mustafa Adnan - Risk Assessment ProjectDocumento2 páginasMustafa Adnan - Risk Assessment ProjectMustafaAdnanAún no hay calificaciones

- Sample Risk AssessmentDocumento12 páginasSample Risk Assessmentpaansaeng82% (17)

- App-16.2 - RISK ASSESSMENT For In-Situ Manhole Construction in Al Wukair RoadDocumento15 páginasApp-16.2 - RISK ASSESSMENT For In-Situ Manhole Construction in Al Wukair Roadloveson709Aún no hay calificaciones

- COVID 19 Risk Assessment High PeakDocumento4 páginasCOVID 19 Risk Assessment High PeakShayan KhanAún no hay calificaciones

- Risk Assessment of Construction ProjectsDocumento15 páginasRisk Assessment of Construction ProjectsShashi RanjanAún no hay calificaciones

- MS 5.0 (1) Risk Assessment Project PDFDocumento2 páginasMS 5.0 (1) Risk Assessment Project PDFKumar Kush50% (2)

- Risk AssessmentDocumento4 páginasRisk AssessmentSyedQamarIqbal50% (2)

- 2.risk Assessment of Working at HeightDocumento7 páginas2.risk Assessment of Working at HeightRisal Sinu50% (2)

- MS 5.0 (1) Risk Assessment ProjectDocumento2 páginasMS 5.0 (1) Risk Assessment ProjectAhmed Alrashid100% (1)

- Risk Assessment HP WashingDocumento5 páginasRisk Assessment HP WashingAhmad BarriehAún no hay calificaciones

- Contractor Risk Assessment FormDocumento5 páginasContractor Risk Assessment FormRoger Simbhoo100% (1)

- Guidance of Risk AssessmentDocumento31 páginasGuidance of Risk AssessmentBagus Chandra KurniawanAún no hay calificaciones

- 2949 HSE Risk Register - 2013-06-16 RevD1-VB FreeDocumento3 páginas2949 HSE Risk Register - 2013-06-16 RevD1-VB Freesalic201388% (8)

- Project Risk Assessment For Design and ConstructionDocumento32 páginasProject Risk Assessment For Design and ConstructionAjas Aju100% (31)

- Task-Based Risk Assessment Painting WorksDocumento6 páginasTask-Based Risk Assessment Painting Worksvinodhyper100% (2)

- Contractor SHE Plan-HANNESDocumento16 páginasContractor SHE Plan-HANNESMominé Ve100% (2)

- Risk Assessment - GeneralDocumento10 páginasRisk Assessment - Generallasenggo100% (2)

- Shashi Sir Iosh Assessement PDFDocumento3 páginasShashi Sir Iosh Assessement PDFKumar KushAún no hay calificaciones

- Risk Assessment Form: Task Being AssessedDocumento3 páginasRisk Assessment Form: Task Being AssessedKumar Kush33% (6)

- Risk Assessment Form-2Documento2 páginasRisk Assessment Form-2Badar AlsiyabiAún no hay calificaciones

- Risk Assessment FormDocumento9 páginasRisk Assessment FormAbu ZahidAún no hay calificaciones

- Risk Assessment For General ActivitiesDocumento25 páginasRisk Assessment For General Activitiesabou bakar67% (3)

- Recruitment Services in RomaniaDocumento3 páginasRecruitment Services in RomaniafrjacobsAún no hay calificaciones

- Scribd Download - Com 4 2 Risk Assessment Project Sample 1Documento3 páginasScribd Download - Com 4 2 Risk Assessment Project Sample 1luxorAún no hay calificaciones

- Risk Assessment - Hot Water BoilersDocumento4 páginasRisk Assessment - Hot Water BoilersUgonnaAún no hay calificaciones

- Form 16 PDFDocumento29 páginasForm 16 PDFDhana SekarAún no hay calificaciones

- Form 16 PDFDocumento29 páginasForm 16 PDFDhana SekarAún no hay calificaciones

- Is.13416.2.1992 - Recommendations For PM Against Hazards at WorkplaceDocumento9 páginasIs.13416.2.1992 - Recommendations For PM Against Hazards at WorkplaceDhana SekarAún no hay calificaciones

- FTO 1 Fire SafetyDocumento44 páginasFTO 1 Fire SafetyDhana SekarAún no hay calificaciones

- Emergency Control and ResponseDocumento30 páginasEmergency Control and ResponseDhana Sekar100% (1)

- Electrical Daily ReportDocumento2 páginasElectrical Daily ReportDhana SekarAún no hay calificaciones

- Global WarmingDocumento16 páginasGlobal WarmingDhana SekarAún no hay calificaciones

- NIELIT Recruitment For Scientist and Technical Assistants 2017 Official NotificationDocumento6 páginasNIELIT Recruitment For Scientist and Technical Assistants 2017 Official NotificationKshitija100% (1)

- ASHRAE Journal - VAV System Duct Main DesignDocumento5 páginasASHRAE Journal - VAV System Duct Main DesignJhoAún no hay calificaciones

- Revision Q (Answer)Documento6 páginasRevision Q (Answer)Johan ZafriAún no hay calificaciones

- Arabic Songs and Arabic MusicDocumento3 páginasArabic Songs and Arabic MusicarabicsongsorgAún no hay calificaciones

- Crystal Test SetDocumento8 páginasCrystal Test Setstanpjames2309Aún no hay calificaciones

- AD-330 AD-320 Parts Manual PN 450239 (Rev-1) 042803Documento46 páginasAD-330 AD-320 Parts Manual PN 450239 (Rev-1) 042803naokito AkemiAún no hay calificaciones

- Research Paper Front CoverDocumento7 páginasResearch Paper Front Coverorotmbbkf100% (1)

- Proses Inspeksi SLO Pembangkit PDFDocumento13 páginasProses Inspeksi SLO Pembangkit PDFAlfian Muhammad RezaAún no hay calificaciones

- ActiveVOS BPM Esper CEP PaperDocumento14 páginasActiveVOS BPM Esper CEP PaperManisha_tAún no hay calificaciones

- Hafiz CVDocumento6 páginasHafiz CVkashi4ashiAún no hay calificaciones

- Warri GlobestarDocumento2 páginasWarri GlobestarNkechi KokoAún no hay calificaciones

- Sales Email Integration SecurityDocumento22 páginasSales Email Integration SecuritySocial SmocialAún no hay calificaciones

- Development of A Business Website For Antonio Manuel Catering Services Final - ManuscriptDocumento152 páginasDevelopment of A Business Website For Antonio Manuel Catering Services Final - ManuscriptLesterSanchezCuevaAún no hay calificaciones

- Appointment Scheduling (DAS) ADMIN GUIDE EWM940Documento19 páginasAppointment Scheduling (DAS) ADMIN GUIDE EWM940raviAún no hay calificaciones

- Solution For Problem Statement 3 - WhatsApp PayDocumento7 páginasSolution For Problem Statement 3 - WhatsApp PayManik ManchandaAún no hay calificaciones

- Manual de Usuario PTZ HiLookDocumento101 páginasManual de Usuario PTZ HiLookIvan Alvarado GAún no hay calificaciones

- HVAC Listing - Addendum #1Documento3 páginasHVAC Listing - Addendum #1Jhonny Velasquez PerezAún no hay calificaciones

- KDDDocumento2 páginasKDDnagendraoraappsAún no hay calificaciones

- 21st Century (Reflection)Documento2 páginas21st Century (Reflection)Larie CanoAún no hay calificaciones

- Test Bank For Speech Science An Integrated Approach To Theory and Clinical Practice 3 e 3rd Edition 0132907119Documento38 páginasTest Bank For Speech Science An Integrated Approach To Theory and Clinical Practice 3 e 3rd Edition 0132907119inhoopnebuloseve9nqt100% (10)

- Jumbo C Saver CatalogueDocumento19 páginasJumbo C Saver CatalogueMuhammad Iqbal AAún no hay calificaciones

- W6!7!304E Skin-Pass Mills ReferencesDocumento36 páginasW6!7!304E Skin-Pass Mills Referencesdorin serbanAún no hay calificaciones

- CBCL1501 SI RegisterDocumento17 páginasCBCL1501 SI Registertuyen nguyen longAún no hay calificaciones

- CTSDG 06516 XDMDocumento2 páginasCTSDG 06516 XDMИван КадигробAún no hay calificaciones

- E Authentication System With QR Code and OTPDocumento3 páginasE Authentication System With QR Code and OTPEditor IJTSRDAún no hay calificaciones

- Fetch Statementand NoticesDocumento4 páginasFetch Statementand NoticesElizabethAún no hay calificaciones

- P121.pdf (En US)Documento142 páginasP121.pdf (En US)Planeador MantenimientoAún no hay calificaciones

- Select USA 2021 VirtualDocumento15 páginasSelect USA 2021 VirtualGaurav TripathiAún no hay calificaciones