Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Tabla2 1 4

Cargado por

Rocio VallejosTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Tabla2 1 4

Cargado por

Rocio VallejosCopyright:

Formatos disponibles

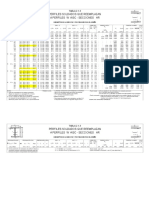

TABLA 2.1.

PERFILES SOLDADOS

SECCIONES T

GEOMETRA DE LA SECCIN Y PROPIEDADES PARA EL DISEO

DESIGNACIN

d

mm

DIMENSIONES

bf

x Peso

tf

tw

x mm

x kgf/m

mm

mm

bf

REA

h ALMA

EJE X - X

TOTAL

IX/106

SX/103

rX

EJE Y - Y

y

ZX/103

yp

IY/106

PANDEO LOCAL*

Qs

SY/103

rY

ZY/103

d

tw

bf

2tf

PROP. FLEXO-TORSION

J/104

Fy , MPa

mm

mm2

mm2

mm4

mm3

mm

mm

mm3

mm

mm4

mm3

mm

mm3

235

248

265

345

mm4

400

500

264.9s

227.7

y, yp

197.8

174.1

50

40

32

x

28

25

25

25

22

350

360

368 x

372

8750tf

9000

9200

8184

h

33750

29000

25200

22184

d

354

348

339

302

1095

1095

1090

967

102

110

116

117

76.9

82.1

89.0

87.8

2024

1960

1926

1701

33.8

29.0

25.2

22.2

521

417

334

292

2085

1669

1335

1168

124

120

115

115

3180

2556

2058

1795

16.0

16.0

16.0

18.2

5.0

6.3

7.8

8.9

0.987

2279

1265

746

503

400

450

203.5

176.6

163.2

147.2

40

32

28

25

22

22

22y

20

360

368

372

375

7920

8096

8184

7500

25920

22496

20784

18750

308

300

294

268

966

961

956

873

109

115

119

120

81.1

88.0

92.8

92.5

1729

1698

1688

1539

28.8

25.0

23.1

20.8

304

243

213

190

1351

1081

946

845

108

104

101

101

2069

1665

1463

1303

18.2

18.2

18.2

20.0

5.6

7.0

8.0

9.0

0.987

0.987

0.987

0.895

1095

628

466

338

400

400

158.3

146.3

137.4

122.5

32

28

25

22

20

20

20

18

368

372

375

378

7360

7440

7500

6804

20160

18640

17500

15604

271

265

260

235

872

867

861

778

116

119

122

123

89.0

93.8

98.2

98.2

1541

1532

1527

1380

25.2

23.3

21.9

19.5

171

150

134

118

855

748

668

588

92.1

89.6

87.4

86.8

1317

1157

1038

911

20.0

20.0

20.0

22.2

6.3

7.1

8.0

9.1

0.979

0.953

0.921

0.895

0.895

0.895

0.782

539

396

312

218

350

450

194.8

168.0

154.5

139.3

40

32

28

25

22

22

22

20

310

318

322

325

6820

6996

7084

6500

24820

21396

19684

17750

208

204

201

184

740

738

736

673

91.7

97.7

101

102

68.1

73.2

77.0

76.6

1348

1312

1300

1184

27.6

23.8

21.9

19.7

304

243

213

190

1351

1081

946

845

111

107

104

103

2063

1658

1456

1298

15.9

15.9

15.9

17.5

5.6

7.0

8.0

9.0

1077

610

449

324

350

400

150.4

138.5

129.5

115.4

32

28

25

22

20

20

20

18

318

322

325

328

6360

6440

6500

5904

19160

17640

16500

14704

185

182

178

161

670

667

664

601

98.2

101

104

105

74.1

77.9

81.4

81.3

1190

1179

1174

1060

24.0

22.1

20.6

18.4

171

150

134

117

854

748

668

587

94.4

92.1

90.0

89.4

1312

1152

1033

907

17.5

17.5

17.5

19.4

6.3

7.1

8.0

9.1

0.923

526

382

298

208

350

350

122.4

114.6

106.8

96.4

28

25

22

20

18

18

18

16

322

325

328

330

5796

5850

5904

5280

15596

14600

13604

12280

162

159

156

140

599

596

591

530

102

104

107

107

79.0

82.6

86.9

85.2

1059

1054

1051

939

22.3

20.9

19.4

17.5

100

89.5

78.8

71.6

573

511

450

409

80.2

78.3

76.1

76.3

884

792

700

634

19.4

19.4

19.4

21.9

6.3

7.0

8.0

8.8

0.968

0.937

0.923

0.923

0.923

0.800

321

248

190

140

300

400

142.6

130.6

121.7

108.4

32

28

25

22

20

20

20

18

268

272

275

278

5360

5440

5500

5004

18160

16640

15500

13804

118

117

115

104

493

492

491

445

80.7

83.7

86.1

86.9

60.3

63.0

65.7

65.4

888

876

869

783

22.7

20.8

19.4

17.3

171

150

134

117

854

748

668

587

97.0

94.8

92.8

92.2

1307

1147

1028

903

15.0

15.0

15.0

16.7

6.3

7.1

8.0

9.1

513

369

285

198

* PANDEO LOCAL

tw

- Qs tabulado corresponde a perfil trabajando en compresin.

- Valor de Qs no indicado, significa valor unitario.

- Valor de Qs est determinado por esbeltez del alma.

- Ningn ala de perfil de la tabla clasifica como esbelta.

- Flexin y flexin compuesta : conservadoramente, usar Qs tabulado para compresin.

TABLA 2.1.4

PERFILES SOLDADOS

SECCIONES T

GEOMETRA DE LA SECCIN Y PROPIEDADES PARA EL DISEO

DESIGNACIN

d

mm

DIMENSIONES

REA

bf

x Peso

tf

tw

x mm

x kgf/m

mm

mm

mm

mm2

28

25

22

x

20

18

18

18

16

272

275

278 x

280

4896tf

4950

5004

4480

h

IX/106

SX/103

mm2

mm4

mm3

14696

13700

12704

11480

d

104

103

101

91.0

442

441

438

393

TOTAL

rX

EJE Y - Y

y

ZX/103

mm

mm

84.2

86.6

89.1

89.0

64.0

66.7

70.1

68.5

PANDEO LOCAL*

Qs

rY

ZY/103

yp

IY/106

SY/103

mm3

mm

mm4

mm3

mm

mm3

235

248

265

345

mm4

786

780

775

693

21.0

19.6

18.1

16.4

100

89.5

78.7

71.6

572

511

450

409

82.6

80.8

78.7

78.9

880

788

696

630

16.7

16.7

16.7

18.8

6.3

7.0

8.0

8.8

0.958

312

238

180

133

d

tw

-

bf

2tf

PROP. FLEXO-TORSION

J/104

Fy , MPa

-

300

350

300

300

93.4

86.7

82.3

73.4

25

22

20

18

16

16

16y

14

275

278

280

282

4400

4448

4480

3948

11900

11048

10480

9348

90.5

88.7

87.2

77.6

390

388

386

341

87.2

89.6

91.2

91.1

68.0

71.4

74.1

72.4

691

687

685

604

19.8

18.4

17.5

15.6

56.3

49.6

45.1

40.6

376

331

301

270

68.8

67.0

65.6

65.9

580

513

468

419

18.8

18.8

18.8

21.4

6.0

6.8

7.5

8.3

0.987

0.956

0.958

0.958

0.958

0.822

196

146

120

84.9

250

350

108.3

100.5

92.7

83.8

28

25

22

20

18

18

18

16

222

225

228

230

3996

4050

4104

3680

13796

12800

11804

10680

61.4

60.8

59.9

54.1

307

307

306

275

66.7

68.9

71.2

71.2

50.2

52.1

54.5

53.1

557

549

543

485

19.7

18.3

16.9

15.3

100

89.4

78.7

71.5

572

511

450

409

85.2

83.6

81.7

81.8

875

784

692

627

13.9

13.9

13.9

15.6

6.3

7.0

8.0

8.8

302

228

171

126

250

300

87.1

80.4

76.0

67.9

25

22

20

18

16

16

16

14

225

228

230

232

3600

3648

3680

3248

11100

10248

9680

8648

53.6

52.8

52.1

46.4

272

271

270

239

69.5

71.8

73.3

73.3

53.0

55.5

57.5

55.9

486

481

479

422

18.5

17.1

16.1

14.4

56.3

49.6

45.1

40.6

376

331

301

270

71.2

69.6

68.2

68.5

577

510

465

416

15.6

15.6

15.6

17.9

6.0

6.8

7.5

8.3

189

139

113

80.4

250

250

68.2

64.5

60.8

53.4

22

20

18

16

14

14

14

12

228

230

232

234

3192

3220

3248

2808

8692

8220

7748

6808

45.6

45.0

44.2

38.7

236

235

234

203

72.4

74.0

75.5

75.4

56.9

59.0

61.4

59.6

419

417

416

359

17.4

16.4

15.5

13.6

28.7

26.1

23.5

20.9

230

209

188

167

57.5

56.3

55.1

55.4

355

324

293

258

17.9

17.9

17.9

20.8

5.7

6.3

6.9

7.8

0.983

0.852

111

88.6

70.6

48.1

200

300

80.9

74.2

69.7

62.4

25

22

20

18

16

16

16

14

175

178

180

182

2800

2848

2880

2548

10300

9448

8880

7948

27.9

27.7

27.4

24.5

174

174

174

154

52.1

54.1

55.6

55.5

39.7

41.1

42.4

41.1

320

314

311

274

17.2

15.7

14.8

13.2

56.3

49.6

45.1

40.5

375

330

300

270

73.9

72.4

71.2

71.4

574

506

462

414

12.5

12.5

12.5

14.3

6.0

6.8

7.5

8.3

182

132

106

75.8

200

250

62.7

59.0

55.3

48.7

22

20

18

16

14

14

14

12

178

180

182

184

2492

2520

2548

2208

7992

7520

7048

6208

24.0

23.7

23.4

20.5

152

152

151

131

54.7

56.2

57.6

57.5

42.2

43.5

45.2

43.6

273

271

269

232

16.0

15.0

14.1

12.4

28.7

26.1

23.5

20.9

229

209

188

167

59.9

58.9

57.7

58.0

352

321

290

257

14.3

14.3

14.3

16.7

5.7

6.3

6.9

7.8

106

84.0

66.1

45.2

* PANDEO LOCAL

115.4s

107.5

y, yp

99.7

90.1

bf

h ALMA

EJE X - X

tw

- Qs tabulado corresponde a perfil trabajando en compresin.

- Valor de Qs no indicado, significa valor unitario.

- Valor de Qs est determinado por esbeltez del alma.

- Ningn ala de perfil de la tabla clasifica como esbelta.

- Flexin y flexin compuesta : conservadoramente, usar Qs tabulado para compresin.

TABLA 2.1.4

PERFILES SOLDADOS

SECCIONES T

GEOMETRA DE LA SECCIN Y PROPIEDADES PARA EL DISEO

DESIGNACIN

d

mm

DIMENSIONES

REA

bf

x Peso

tf

tw

x mm

x kgf/m

mm

mm

mm

mm2

20

18

16

x

14

12

12

12

10

180

182

184 x

186

2160tf

2184

2208

1860

h

IX/106

SX/103

mm2

mm4

mm3

6160

5784

5408

d4660

20.0

19.7

19.4

16.6

129

129

128

108

TOTAL

rX

EJE Y - Y

y

ZX/103

mm

mm

57.0

58.4

59.8

59.7

45.1

46.8

48.8

46.9

PANDEO LOCAL*

Qs

rY

ZY/103

yp

IY/106

SY/103

mm3

mm

mm4

mm3

mm

mm3

235

248

265

345

mm4

230

229

228

191

15.4

14.5

13.5

11.7

13.4

12.0

10.7

9.35

134

120

107

93.5

46.6

45.6

44.5

44.8

206

187

167

145

16.7

16.7

16.7

20.0

5.0

5.6

6.3

7.1

0.895

64.3

49.9

38.4

24.7

d

tw

-

bf

2tf

PROP. FLEXO-TORSION

J/104

Fy , MPa

-

200

200

175

250

60.0

56.3

52.6

46.4

22

20

18

16

14

14

14y

12

153

155

157

159

2142

2170

2198

1908

7642

7170

6698

5908

16.2

16.1

15.9

14.0

116

116

116

101

46.0

47.4

48.8

48.7

35.5

36.5

37.7

36.3

213

210

208

179

15.3

14.3

13.4

11.8

28.7

26.1

23.5

20.9

229

209

188

167

61.3

60.3

59.2

59.4

351

320

289

256

12.5

12.5

12.5

14.6

5.7

6.3

6.9

7.8

104

81.8

63.8

43.8

175

225

49.9

46.6

43.2

37.4

20

18

16

14

12

12

12

10

155

157

159

161

1860

1884

1908

1610

6360

5934

5508

4760

13.9

13.8

13.6

11.7

100

100

99.8

84.4

46.8

48.3

49.8

49.5

35.6

36.8

38.3

36.6

181

179

177

149

14.1

13.2

12.2

10.6

19.0

17.1

15.2

13.3

169

152

135

118

54.7

53.7

52.6

52.9

259

233

208

181

14.6

14.6

14.6

17.5

5.6

6.3

7.0

8.0

69.5

53.3

40.3

26.2

175

200

40.6

37.6

34.6

29.1

18

16

14

12

10

10

10

8

157

159

161

163

1570

1590

1610

1304

5170

4790

4410

3704

11.7

11.6

11.3

9.38

83.9

83.7

83.4

67.9

47.6

49.1

50.7

50.3

35.6

37.0

38.9

36.8

150

149

147

119

12.9

12.0

11.0

9.26

12.0

10.7

9.35

8.01

120

107

93.5

80.1

48.2

47.2

46.0

46.5

184

164

144

123

17.5

17.5

17.5

21.9

5.6

6.3

7.1

8.3

0.968

0.937

0.800

44.4

32.9

23.9

14.4

175

175

32.0

29.3

26.7

16

14

12

8

8

8

159

161

163

1272

1288

1304

4072

3738

3404

9.44

9.29

9.07

67.6

67.4

67.0

48.1

49.8

51.6

35.3

37.1

39.5

120

119

118

11.6

10.7

9.73

7.15

6.26

5.37

81.7

71.5

61.3

41.9

40.9

39.7

125

110

94.5

21.9

21.9

21.9

5.5

6.3

7.3

0.968

0.968

0.968

0.937

0.937

0.937

0.800

0.800

0.800

26.7

18.9

13.0

150

225

47.6

44.2

40.9

35.4

20

18

16

14

12

12

12

10

130

132

134

136

1560

1584

1608

1360

6060

5634

5208

4510

8.86

8.81

8.74

7.49

73.4

73.5

73.5

62.2

38.2

39.6

41.0

40.8

29.3

30.1

31.2

29.6

137

134

132

111

13.5

12.5

11.6

10.0

19.0

17.1

15.2

13.3

169

152

135

118

56.0

55.1

54.0

54.3

258

233

207

181

12.5

12.5

12.5

15.0

5.6

6.3

7.0

8.0

68.1

51.9

38.9

25.3

150

200

38.6

35.6

32.7

27.5

18

16

14

12

10

10

10

8

132

134

136

138

1320

1340

1360

1104

4920

4540

4160

3504

7.45

7.39

7.29

6.03

61.6

61.6

61.5

50.1

38.9

40.3

41.9

41.5

29.1

30.1

31.5

29.6

113

111

109

88.5

12.3

11.4

10.4

8.76

12.0

10.7

9.34

8.01

120

107

93.4

80.1

49.4

48.5

47.4

47.8

183

163

143

122

15.0

15.0

15.0

18.8

5.6

6.3

7.1

8.3

0.958

43.6

32.0

23.1

14.0

* PANDEO LOCAL

48.4s

45.4

y, yp

42.5

36.6

bf

h ALMA

EJE X - X

tw

- Qs tabulado corresponde a perfil trabajando en compresin.

- Valor de Qs no indicado, significa valor unitario.

- Valor de Qs est determinado por esbeltez del alma.

- Ningn ala de perfil de la tabla clasifica como esbelta.

- Flexin y flexin compuesta : conservadoramente, usar Qs tabulado para compresin.

TABLA 2.1.4

PERFILES SOLDADOS

SECCIONES T

GEOMETRA DE LA SECCIN Y PROPIEDADES PARA EL DISEO

DESIGNACIN

d

mm

DIMENSIONES

REA

bf

x Peso

tf

tw

x mm

x kgf/m

mm

mm

mm2

16

14

12

x

10

8

8

8

8

134

1072tf

136

1088

138 x 1104

140

1120

h

8

8

8y

8

136

138

140

142

1088

1104

1120

1136

mm

IX/106

SX/103

mm2

mm4

mm3

3872

3538

3204

d2870

6.02

5.95

5.85

5.69

49.7

49.7

49.5

49.1

3188

2904

2620

2336

5.74

5.62

5.45

5.20

48.9

48.7

48.2

47.5

TOTAL

rX

EJE Y - Y

y

ZX/103

mm

mm

39.4

41.0

42.7

44.5

28.8

30.1

31.8

34.3

42.4

44.0

45.6

47.2

PANDEO LOCAL*

Qs

rY

ZY/103

yp

IY/106

SY/103

mm3

mm

mm4

mm3

mm

mm3

235

248

265

345

mm4

90.0

88.5

87.4

86.6

11.1

10.1

9.15

8.20

7.15

6.26

5.37

4.47

81.7

71.5

61.3

51.1

43.0

42.1

40.9

39.5

125

109

94.1

78.8

18.8

18.8

18.8

18.8

5.5

6.3

7.3

8.8

0.958

0.958

0.958

0.958

26.3

18.4

12.5

8.31

32.6

34.5

37.1

40.5

87.0

86.2

85.7

85.4

10.6

9.68

8.73

7.79

3.94

3.38

2.82

2.26

52.6

45.1

37.6

30.1

35.2

34.1

32.8

31.1

80.9

69.7

58.5

47.3

18.8

18.8

18.8

18.8

5.4

6.3

7.5

9.4

0.958

0.958

0.958

0.958

16.2

11.1

7.47

5.05

d

tw

bf

2tf

PROP. FLEXO-TORSION

J/104

Fy , MPa

-

150

175

150

150

25.0

22.8

20.6

18.3

14

12

10

8

125

175

33.1

30.5

27.9

23.6

18

16

14

12

10

10

10

8

107

109

111

113

1070

1090

1110

904

4220

3890

3560

3004

4.23

4.20

4.16

3.46

42.2

42.3

42.3

34.5

31.6

32.9

34.2

33.9

24.8

25.5

26.5

24.8

79.4

77.6

76.2

61.6

12.1

11.1

10.2

8.58

8.05

7.15

6.26

5.36

92.0

81.8

71.6

61.3

43.7

42.9

41.9

42.3

140

125

110

93.7

12.5

12.5

12.5

15.6

4.9

5.5

6.3

7.3

37.9

27.8

19.9

12.1

125

150

25.7

23.5

21.2

19.0

16

14

12

10

8

8

8

8

109

111

113

115

872

888

904

920

3272

2988

2704

2420

3.41

3.38

3.33

3.25

34.0

34.0

34.0

33.8

32.3

33.7

35.1

36.7

24.7

25.6

26.9

28.8

62.8

61.5

60.5

59.8

10.9

9.96

9.01

8.07

4.50

3.94

3.38

2.82

60.1

52.6

45.1

37.6

37.1

36.3

35.4

34.1

91.7

80.5

69.3

58.1

15.6

15.6

15.6

15.6

4.7

5.4

6.3

7.5

22.5

15.7

10.7

7.05

125

125

20.7

18.9

17.0

15.2

14

12

10

8

8

8

8

8

111

113

115

117

888

904

920

936

2638

2404

2170

1936

3.24

3.18

3.09

2.96

33.4

33.3

33.1

32.6

35.1

36.4

37.8

39.1

28.0

29.5

31.5

34.2

60.0

59.4

58.9

58.7

10.6

9.62

8.68

7.74

2.28

1.96

1.63

1.31

36.5

31.3

26.1

20.9

29.4

28.5

27.4

26.0

56.5

48.7

40.9

33.1

15.6

15.6

15.6

15.6

4.5

5.2

6.3

7.8

13.4

9.23

6.21

4.20

100

150

19.7

17.4

15.2

12

10

8

8

8

8

88

90

92

704

720

736

2504

2220

1936

1.74

1.71

1.67

21.8

21.8

21.6

26.4

27.8

29.3

20.1

21.2

23.0

39.8

38.9

38.3

8.35

7.40

6.45

3.38

2.82

2.25

45.1

37.6

30.1

36.7

35.6

34.1

68.9

57.7

46.5

12.5

12.5

12.5

6.3

7.5

9.4

10.2

6.62

4.20

100

125

17.3

15.5

13.6

12

10

8

8

8

8

88

90

92

704

720

736

2204

1970

1736

1.67

1.64

1.58

21.4

21.4

21.2

27.5

28.8

30.2

22.0

23.3

25.2

38.7

38.1

37.7

8.82

7.88

6.94

1.96

1.63

1.31

31.3

26.1

20.9

29.8

28.8

27.4

48.3

40.5

32.7

12.5

12.5

12.5

5.2

6.3

7.8

8.80

5.79

3.77

100

100

13.5

12.1

10

8

90

720

1720

1.54

20.8

8

8

92

736

1536

1.48

20.6

- Qs tabulado corresponde a perfil trabajando en compresin.

- Valor de Qs no indicado, significa valor unitario.

- Valor de Qs est determinado por esbeltez del alma.

29.9

31.1

25.9

28.0

37.2

8.60

0.84

16.7 22.1

26.4 12.5

5.0

37.0

7.68

0.67

13.4 20.9

21.5 12.5

6.3

- Flexin y flexin compuesta : conservadoramente, usar Qs tabulado para compresin.

4.95

3.35

* PANDEO LOCAL

30.4s

27.8

y, yp

25.2

22.5

bf

h ALMA

EJE X - X

tw

- Ningn ala de perfil de la tabla clasifica como esbelta.

bf

ABLA 2.1.4

ES SOLDADOS

CIONES T

k

x

tw

N Y PROPIEDADES PARA EL DISEO

PROP. FLEXO-TORSIONALES

Cw/1012

mm6

j

mm

ro

SOLD.

AUTO.

H=

mm

mm

0.1313951

0.0793715

0.0530204

0.0360665

105

110

114

115

169

174

179

179

0.906

0.873

0.834

0.831

14

14

14

12

0.0567299

0.0374839

0.0309024

0.0228178

117

121

123

124

165

171

175

176

0.863

0.823

0.797

0.793

12

12

12

12

0.0271465

0.0225370

0.0198746

0.0142684

127

129

131

132

165

169

173

174

0.804

0.777

0.754

0.748

12

12

12

10

0.0511294

0.0317566

0.0251113

0.0184307

91.5

95.4

97.7

98.7

152

156

158

159

0.899

0.865

0.841

0.837

12

12

12

12

0.0228435

0.0181860

0.0154874

0.0110437

103

105

107

108

148

151

154

155

0.846

0.821

0.799

0.794

12

12

12

10

0.0126812

0.0108801

0.0094816

0.0068539

111

113

115

115

145

148

152

151

0.799

0.776

0.749

0.753

10

10

10

8

0.0196538

0.0149550

0.0122253

0.0086427

77.4

79.4

81.1

82.2

134

136

137

138

0.890

0.869

0.850

0.845

12

12

12

10

bf

ABLA 2.1.4

ES SOLDADOS

CIONES T

k

x

tw

N Y PROPIEDADES PARA EL DISEO

PROP. FLEXO-TORSIONALES

Cw/1012

mm6

j

mm

ro

SOLD.

AUTO.

H=

mm

mm

0.0103258

0.0085020

0.0070807

0.0051569

87.0

88.5

90.3

90.7

128

130

133

133

0.848

0.827

0.802

0.805

10

10

10

8

0.0056335

0.0047428

0.0042749

0.0029718

95.0

96.6

97.8

98.2

124

127

129

129

0.800

0.774

0.754

0.759

8

8

8

8

0.0086654

0.0068225

0.0053820

0.0039548

61.2

62.8

64.4

64.9

114

115

117

117

0.899

0.882

0.861

0.864

10

10

10

8

0.0044539

0.0035498

0.0030729

0.0021604

70.7

72.2

73.3

73.7

107

109

111

111

0.858

0.835

0.816

0.820

8

8

8

8

0.0021960

0.0019218

0.0016997

0.0011247

78.8

79.9

81.0

81.3

103

105

107

107

0.802

0.783

0.761

0.767

8

8

8

6

0.0036797

0.0027646

0.0022804

0.0016246

44.4

45.9

47.0

47.4

94.4

95.3

96.0

96.0

0.917

0.900

0.886

0.888

8

8

8

8

0.0016700

0.0013909

0.0011639

0.0007842

54.3

55.3

56.4

56.8

86.9

88.0

89.2

89.1

0.871

0.855

0.836

0.841

8

8

8

6

bf

ABLA 2.1.4

ES SOLDADOS

CIONES T

k

x

tw

N Y PROPIEDADES PARA EL DISEO

PROP. FLEXO-TORSIONALES

Cw/1012

mm6

j

mm

ro

SOLD.

AUTO.

H=

mm

mm

0.0007737

0.0006585

0.0005673

0.0003521

62.2

63.1

64.2

64.5

81.5

83.2

85.0

84.6

0.815

0.794

0.769

0.777

6

6

6

6

0.0014916

0.0012105

0.0009815

0.0006680

41.2

42.1

43.2

43.6

80.5

81.1

81.9

81.8

0.907

0.893

0.877

0.881

8

8

8

6

0.0008484

0.0006809

0.0005476

0.0003488

46.0

47.0

48.1

48.4

76.4

77.4

78.5

78.3

0.888

0.871

0.851

0.857

6

6

6

6

0.0004511

0.0003569

0.0002842

0.0001646

50.4

51.4

52.4

52.7

72.7

74.1

75.6

75.1

0.867

0.846

0.821

0.832

6

6

6

5

0.0002187

0.0001696

0.0001330

54.2

55.2

56.3

69.4

71.2

73.2

0.845

0.821

0.791

5

5

5

0.0007645

0.0005959

0.0004614

0.0002983

32.7

33.6

34.7

35.1

70.5

71.0

71.6

71.6

0.925

0.912

0.896

0.900

6

6

6

6

0.0004019

0.0003071

0.0002337

0.0001385

37.7

38.7

39.7

40.1

66.0

66.8

67.8

67.6

0.907

0.890

0.869

0.878

6

6

6

5

bf

ABLA 2.1.4

ES SOLDADOS

CIONES T

k

x

tw

N Y PROPIEDADES PARA EL DISEO

PROP. FLEXO-TORSIONALES

Cw/1012

mm6

j

mm

ro

SOLD.

AUTO.

H=

mm

mm

0.0001932

0.0001437

0.0001068

0.0000806

42.2

43.1

44.2

45.3

61.9

63.1

64.6

66.3

0.888

0.866

0.840

0.805

5

5

5

5

0.0001059

0.0000830

0.0000668

0.0000563

46.8

47.8

48.9

50.3

60.8

62.6

64.7

67.2

0.823

0.792

0.754

0.706

5

5

5

5

0.0002604

0.0001969

0.0001478

0.0000883

29.0

29.9

30.9

31.3

56.2

56.8

57.5

57.4

0.921

0.905

0.885

0.892

6

6

6

5

0.0001188

0.0000877

0.0000645

0.0000480

33.7

34.6

35.6

36.7

51.9

52.9

54.0

55.4

0.897

0.877

0.850

0.816

5

5

5

5

0.0000606

0.0000474

0.0000381

0.0000321

38.3

39.3

40.3

41.6

50.4

51.9

53.7

55.8

0.826

0.795

0.756

0.707

5

5

5

5

0.0000523

0.0000356

0.0000246

22.4

23.5

24.7

47.4

48.0

48.8

0.912

0.886

0.849

5

5

5

0.0000353

0.0000258

0.0000195

27.0

28.0

29.1

43.6

44.7

46.0

0.866

0.833

0.787

5

5

5

0.0000191

0.0000161

31.7

32.8

42.7

44.4

0.759

0.709

5

5

También podría gustarte

- Vuelve A Casa ACORDESDocumento1 páginaVuelve A Casa ACORDESRocio VallejosAún no hay calificaciones

- Tabla 2-1-3Documento14 páginasTabla 2-1-3Rocio VallejosAún no hay calificaciones

- Manual de Soldadura Electrica Mig y TigDocumento65 páginasManual de Soldadura Electrica Mig y TigJosua Obando98% (57)

- Manual de CaneriasDocumento37 páginasManual de Caneriasprefabmaya3100% (1)

- Secciones HDocumento27 páginasSecciones HRocio VallejosAún no hay calificaciones

- Anclaje Del HormigonDocumento79 páginasAnclaje Del HormigonMaria Cecilia Suarez Rubi100% (2)

- Perfiles IchaDocumento71 páginasPerfiles IchaRocio Vallejos100% (1)

- Anclaje Del HormigonDocumento79 páginasAnclaje Del HormigonMaria Cecilia Suarez Rubi100% (2)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensDe EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensAún no hay calificaciones