Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Pages From Centrifugal Pumps Handbook

Cargado por

salamrefighTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Pages From Centrifugal Pumps Handbook

Cargado por

salamrefighCopyright:

Formatos disponibles

CENTRIFUGAL PUMPS

HANDBOOK

Suction Side Problems Gas Entrainment

BY: JAMES H. INGRAM

ENTRAINMENT VERSUS CAVITATION

The audible pump noise from

noncondensable entrained gas will

produce a crackling similar to cavitation or impeller recirculation.

However, cavitation is produced by a

vapor phase of the liquid which is

condensable, while noncondensable

entrained gas must enter and exit the

pump with the liquid stream.

To test for gas entrainment over

mild cavitation, run the pump back

upon the curve by slowly closing the

discharge valve. The noise will diminish if it originated from cavitation and

the pump is not prone to suction recirculation. In contrast, with entrained

gas, continued performance at this

portion of the curve will choke off or

gas-bind the pump, causing unusually

quiet operation or low flow.

A pump in this gas bound state,

will not re-prime itself, and the gas,

with some portion of the liquid, must

be vented for a restart against a discharge head. The effort to restart a

gas bound impeller depends on

GAS BOUND IMPELLERS

As a process stream containing

entrained gas nears the impeller, the

liquid pre-rotating from the impeller

tends to centrifuge the gas from the

process stream. Gas not passing into

the impeller accumulates near the impeller

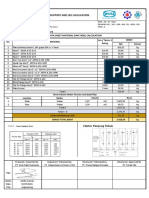

FIGURE 1. ENCLOSED IMPELLER-ENTRAINED

eye. As entrained gas

GAS HANDLING PERFORMANCE

flow continues to increase, the accumulatThe LaBour Company, Inc. Effect on head and capacity of

ing groups of bubbles

varying quantities of air with water being pumped.

are pulled through the

impeller into the dis160

charge vane area where

NO AIR

HEAD

they initiate a fall in

2%

140

flow performance. The

bubble choking effect at

the impeller eye pro5%

120

duces a further reduction of Net Positive

8%

100

Suction Head Available

(NPSHA). At this stage

long term damage to the

80

10%

pump from handling

12%

entrained gases is gener60

ally negligible when

15%

compared with the

50

damage due to cavita0

200 400 600 800 1000 1200

tion. If the process

Capacity

in U.S. Gallons per Minute

stream gas volume

increases, however, furSize: no. 55; Type: SQ. Speed: 1750

ther bubble build-up

Impeller Diameter: 11

will occur, blocking off

Air quantities given are in terms of free air at atmospheric

the impeller eye and

pressure referred to % of total volume of fluid being handled.

stopping flow (Ref. 1).

Head in Feet

ultiple symptoms associated

with noncondensable suction side gas entrainment,

such as loss of pump head,

noisy operation, and erratic performance, often mislead the pump operator. As a result, entrained gas is

generally diagnosed by eliminating

other possible sources of performance

problems. To adequately control gas

entrainment a user should first be

aware of systems most likely to produce gas, and then employ methods

or designs to eliminate entrainment

into these pumping systems.

The Pump Handbook Series

87

discusses open impeller pump modifications.)

FIGURE 2. OPEN IMPELLER-ENTRAINED GAS HANDLING PERFORMANCE

Goulds Pumps, Inc. Approximate Characteristic Curves of Centrifugal Pump

SYSTEMS PRODUCING

ENTRAINED GAS

350

The most common conditions or

mechanisms for introducing gas into

the suction line are:

1. Vortexing

200

150

250

Efficiency %

250

Brake Horse Power (Bhp)

Head in Feet

300

80

70

60

50

Bhp@ sp gr=1.0

200

0%

2%

4%

6%

0%

2%

4%

6%

0%

6%

Previously flashed process

liquid conveying flashed gas

into the suction piping.

3.

Injection of gas, which does not

go into solution, into the

pumpage.

4.

Vacuum systems, valves, seals,

flanges, or other equipment in a

suction lift application allowing

air to leak into the pumpage

stream.

5.

Gas evolution from an incomplete or gas producing chemical

reaction.

150

500

1000 1500 2000 2500

Gallons per Minute

3000

If a particular application produces entrained gas or has the potential to do so, the best solution is to

eliminate as much entrainment as

possible by applying corrective pump

system design and/or a gas handling

pump. If liquid gas mixing is desired,

employ a static mixer on the dis-

Size: 6x8-18 Speed: 1780 rpm Impeller Diameter: 17 1/4

impeller position, type and valving

arrangement, among other variables.

Degassing is easier to accomplish

with a variable speed driver, such as

a steam turbine, than with a constant

speed electric motor drive. In addition, a recycle line to the suction vessel vapor space is often an effective

method for degassing an impeller,

since with this arrangement the

pump is not required to work against

a discharge head. (Ref. 1 describes

methods for venting gas on modified

pumps that are gas bound.)

As a rule, if the probability of

entrained gas exists from a chemical

reaction, the inlet piping design

should incorporate a means to vent

the vapor back to the suction vessels

vapor space or to some other source.

EFFECTS OF ENTRAINED GAS ON

PUMP PERFORMANCE

Figures 1 and 2 illustrate the

effect of entrained gas on a LaBour

enclosed impeller and a Goulds

paper stock open impeller. As illustrated by the figures, 2% entrained

gas does not produce a significant

head curve drop. Note that while the

LaBour impeller experiences a 22%

88

2.

head loss at 5% gas volume, the

Goulds open impeller experiences a

12% head loss at this volume. Some

open impeller paper stock designs

can actually handle

up to 10% entrained

FIGURE 3. DEVELOPMENT OF A VORTEX

gas because clearance between the

case and impeller

vanes allows more

turbulence in the

(a)

process fluid, which

tends to break up

gas accumulation

more efficiently

than an enclosed

impeller with wear

rings. In addition,

other designs, such

(d)

as a recessed im(b)

peller pump, may

A. Incoherent surface swirl

handle up to 18%

entrained gas. In

B. Surface dimple with coherent

fact, most standard

surface swirl

centrifugal pumps

handle up to 3%

C. Vortex pulling air bubbles to

entrained gas volintake

ume at suction conditions

without

D. Fully developed vortex with air

AIR

difficulty. (Ref. 2

core to nozzle outlet

(c)

The Pump Handbook Series

FIGURE 4. HAT TYPE VORTEX BREAKER

charge of the pump. In addition, an

anticipated drop in pump head due to

an entrained gas situation may be offset by oversizing the impeller.

Of the five aforementioned

mechanisms, vortexing is the most

common source of entrained gas.

Therefore, a user should be especially

cautious employing mechanical

equipment, such as tangential flash

gas separators and column bottoms

re-boilers, likely to produce a strong

vortex.

VORTEX BREAKER DESIGN

The extent of gas entrainment in

the pumped fluid as the result of

vortex formation depends on the

strength of the vortex, the submergence to pump suction outlet, and

the liquid velocity in the pump suction nozzle outlet. Vortices form not

only through gravity draining vessel

applications, but also in steady state

draining vessels, and in vessels

under pressure or with submerged

pump suction inlets. Vortex formation follows conservation of angular

momentum. As fluid moves toward

the vessel outlet, the tangential

velocity component in the fluid

increases as the radius from the outlet decreases. Figure 3 shows various

stages of vortex development. The

first phase is a surface dimple. This

dimple must sense a high enough

exit velocity to extend from the surface and form a vortex. (For experimental observations regarding

vortex formation see Refs. 3, 4.)

The most effective method to

FIGURE 5. CROSS TYPE VORTEX BREAKER

eliminate entrained gas in pump

suction piping is to prevent vortex

formation either by avoiding vortex

introducing mechanisms or by employing an appropriate vortex breaker at the vessel outlet. A hat type

vortex breaker, illustrated in Figure

4, covers the vessel outlet nozzle to

reduce the effective outlet velocity.

This design doesnt allow a vortex to

stabilize because the fluid surface

senses only the annular velocity at

the hat outside diameter (OD). In

addition, the vanes supporting the

hat introduce a shear in the vicinity

of the outlet to further inhibit vortex

formation. An annular velocity of

1/2 ft/sec at the hat OD produces a

viable solution. Variations in hat

diameters from 4d to 5d and hat

annular openings of d/2 to d/3 are

acceptable when annular velocity criteria are met. Annular design velocities of more than 1 ft/sec are not

recommended.

Cross type breakers, installed

above or inserted in vessel nozzle outlets as shown in Figure 5, work for

some applications by providing additional shear to inhibit a mild vortex

from feeding gas into a nozzle outlet

(providing enough submergence is

available). However, this design will

not stop a strong vortex and will

decrease NPSHA. A user should be

aware of these limitations.

COLUMN VORTEXING

If a column draw-off pump is

erratic and/or nearly uncontrollable, a

vortex may be feeding gas into the

The Pump Handbook Series

draw-off nozzle of the pump as illustrated by Figure 6a.

It may be difficult to understand

how a pump with 60 ft of vertical

suction could be affected by entrained gas, but in this real case

example Murphys law applied twice.

First, since the pump system in question has a NPSHA greater than 50 ft,

the piping designer employed a smaller suction pipe with a liquid velocity

of 10 ft/sec. Second, the column

draw-off nozzle was sized according

to normal fluid velocity practice. As a

result, the tray liquid had an exit

velocity of 5 ft/sec with a liquid level

6-in. above the top of the draw-off

nozzle and a vortex formed, feeding

gas into the draw-off nozzle.

As in the above example, due to a

lack of proper submergence, gas is carried into the pump suction piping as a

high liquid downward velocity exceeds

the upward velocity of a gas bubble.

Many draw-off vortexing problems may be eliminated by proper

pump system design or by one of two

vortex breaker designs illustrated by

Figures 6b and c. The selection of the

breaker design may depend on the

downcomer arrangement and space

limitations. The most effective vortex

breaker is the slotted pipe design

shown in Figure 6c.

Application of these corrective

pump systems designs or installation of an appropriate gas handling

pump can solve suction side gas

entrainment problems, resulting in a

smoother process operation.

89

FIGURE 6. DESIGN MODIFICATIONS FOR A SYSTEM EXHIBITING A LACK OF

ADEQUATE SUBMERGENCE AND PROHIBITIVELY HIGH EXIT VELOCITY

DOWNSPOUT OR

DOWNCOMER FROM

TRAY ABOVE

BUBBLE CAP

REFERENCES

1.

Doolin, John H., Centrifugal

Pumps and Entrained-Air Problem,

Chemical Engineering, pp.103-106

(1963)

2.

Cappellino, C.A., Roll, R. and

Wilson, George, Centrifugal

Pump Design Considerations and

Application Guidelines for

Pumping Liquids with Entrained

Gas, 9th Texas A&M Pump

Symposium 1992

3.

Patterson, F.M., Vortexing can

be Prevented in Process Vessels

and Tanks, Oil and Gas Journal,

pp. 118-120 (1969)

4.

Patterson, F.M., and Springer, E.K.,

Experimental Investigation of

Critical Submergence for Vortexing

in a Vertical Cylinder Tank,

ASME Paper 69-FE-49 (1969)

5.

Kern, Robert, How to Design

Piping for Pump Suction Conditions, Chemical Engineering,

pp.119-126 (1975)

10

10/sec.

Figure 6a. Tray take off nozzle with vortex from lack of correct

submergence and too high exit velocity.

EXTEND PLATE FROM

VESSEL WALL.

CHECK VELOCITY

AT PLATE

EDGE 1/2/sec.

James H. Ingram is an Engineering

Technologist with Sterling Chemicals in

Texas City.

1/2/sec.

Figure 6b. Plate extension over outlet nozzle lowers high outlet

velocity.

AREA OF SLOTS3X

PIPE CROSS SECTION

AREA. CHECK

VELOCITY INTO SLOT

AREA 1/sec.

Figure 6c. Slotted pipe vortex breaker.

90

The Pump Handbook Series

También podría gustarte

- CAEPIPE Users ManualDocumento257 páginasCAEPIPE Users ManualFATIMA TORRADO CASASAún no hay calificaciones

- Caesar Ii: General OverviewDocumento38 páginasCaesar Ii: General OverviewLeandro VargasAún no hay calificaciones

- Calculo de SilletasDocumento5 páginasCalculo de SilletasOmar muñozAún no hay calificaciones

- Coupling UW16.2 KL Ver 1.1Documento4 páginasCoupling UW16.2 KL Ver 1.1gopaltryAún no hay calificaciones

- C890 Ceramic Fiber PDFDocumento6 páginasC890 Ceramic Fiber PDFKf LiauAún no hay calificaciones

- Practical Design Approaches for Pressure Vessels and Heat ExchangersDocumento10 páginasPractical Design Approaches for Pressure Vessels and Heat ExchangersballisnothingAún no hay calificaciones

- Mercer Valve Pilot Sizing v6.4CUSTDocumento5 páginasMercer Valve Pilot Sizing v6.4CUSTFaizan AhmedAún no hay calificaciones

- Tutorial Pressure Relief Valve AnalysisDocumento1 páginaTutorial Pressure Relief Valve Analysissanthosh_yash1Aún no hay calificaciones

- Cooling System Surge Analysis With AFT ImpulseDocumento2 páginasCooling System Surge Analysis With AFT ImpulsektejankarAún no hay calificaciones

- Platform Calculation (Jan 22-2012)Documento28 páginasPlatform Calculation (Jan 22-2012)SAMER OSMANAún no hay calificaciones

- WRC 107 WRC 297 Co MP PDFDocumento11 páginasWRC 107 WRC 297 Co MP PDFIqbal Muhammad100% (1)

- Datasheet For Pig Signaler: DSH Serial 05 Project Pro. Part Scope Dis. 0002 Igat6 D PL IN Doc. RevDocumento22 páginasDatasheet For Pig Signaler: DSH Serial 05 Project Pro. Part Scope Dis. 0002 Igat6 D PL IN Doc. Revamini_mohiAún no hay calificaciones

- Modeling Spring Cans With FrictionDocumento1 páginaModeling Spring Cans With FrictionKirana SbAún no hay calificaciones

- FE107 Experimental ResultsDocumento11 páginasFE107 Experimental ResultsEsapermana RiyanAún no hay calificaciones

- DC S3-1301 REV.0 OriginalDocumento93 páginasDC S3-1301 REV.0 OriginalPeja JusohAún no hay calificaciones

- Support and Leg Calculation: Data Sheet Material Dan Tabel CalculationDocumento3 páginasSupport and Leg Calculation: Data Sheet Material Dan Tabel CalculationliusAún no hay calificaciones

- Jun 97Documento349 páginasJun 97homer hullezaAún no hay calificaciones

- Caesar II Soil Modeler - American Lifelines Alliance - Intergraph CADWorx - Analysis PDFDocumento4 páginasCaesar II Soil Modeler - American Lifelines Alliance - Intergraph CADWorx - Analysis PDFSharun SureshAún no hay calificaciones

- Analisis of Stress in BellowsDocumento101 páginasAnalisis of Stress in BellowsOswaldo GuerraAún no hay calificaciones

- Pipe Flow Expert Guide - System Calculation TolerancesDocumento13 páginasPipe Flow Expert Guide - System Calculation TolerancesradiopascalgeAún no hay calificaciones

- Design by AnalysisDocumento22 páginasDesign by AnalysisJEELE77Aún no hay calificaciones

- Case Study To Find Tank Nozzle Stiffness, Flexibility and Allowable Loads by API650 Using PASS START PROFDocumento15 páginasCase Study To Find Tank Nozzle Stiffness, Flexibility and Allowable Loads by API650 Using PASS START PROFJafer SayedAún no hay calificaciones

- Process Industry Basket StrainersDocumento27 páginasProcess Industry Basket StrainersmartinnovelAún no hay calificaciones

- Astm A 48-2016Documento6 páginasAstm A 48-2016Mohammed AliAún no hay calificaciones

- API 617 Centrifugal Compressors 6th Ed - Nozzle LoadingDocumento5 páginasAPI 617 Centrifugal Compressors 6th Ed - Nozzle Loadingreach_arindomAún no hay calificaciones

- Pip Resp003s 1997Documento33 páginasPip Resp003s 1997zufriateguiAún no hay calificaciones

- Flange Mawp Reduction PV Elite PDFDocumento8 páginasFlange Mawp Reduction PV Elite PDFDarshan PanchalAún no hay calificaciones

- In Line MixingDocumento4 páginasIn Line MixingKemas Ganesha MahendraAún no hay calificaciones

- PSV Reaction Force Calculation: For Any Gas, Vapor, or SteamDocumento1 páginaPSV Reaction Force Calculation: For Any Gas, Vapor, or Steam20jose12luisAún no hay calificaciones

- Piping Engineering - Tank Nozzle Loads 1Documento1 páginaPiping Engineering - Tank Nozzle Loads 1Nasrul AdliAún no hay calificaciones

- CAESAR II NonconvergenceDocumento11 páginasCAESAR II NonconvergenceJohn BrindleyAún no hay calificaciones

- Estudo de Caso - Asme 2398Documento6 páginasEstudo de Caso - Asme 2398biancogallazziAún no hay calificaciones

- Sampling Cylinder Thickness Calculation As Per B31.8Documento4 páginasSampling Cylinder Thickness Calculation As Per B31.8SathiyaseelanAún no hay calificaciones

- Flush Bottom ValvesDocumento3 páginasFlush Bottom ValvesErkan TakAún no hay calificaciones

- Caepipe-To-Caesar-Ii: User's ManualDocumento95 páginasCaepipe-To-Caesar-Ii: User's ManualSnehasish Mukherjee100% (1)

- 3T Oil Refining Processing LineDocumento2 páginas3T Oil Refining Processing LineWanda OilpressAún no hay calificaciones

- Nozzle Loads - Part 1 - Piping-EngineeringDocumento5 páginasNozzle Loads - Part 1 - Piping-EngineeringShaikh AftabAún no hay calificaciones

- PSV Reaction Force CalculationDocumento2 páginasPSV Reaction Force CalculationSuthanAún no hay calificaciones

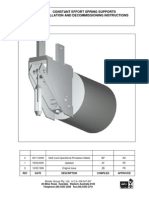

- Installation Manual - Constant Spring Supports - Rev 2Documento17 páginasInstallation Manual - Constant Spring Supports - Rev 2Tonthat QuangAún no hay calificaciones

- Memoria de Cálculo de Enterrados de Tubería de PolietilenoDocumento1 páginaMemoria de Cálculo de Enterrados de Tubería de Polietilenopike86Aún no hay calificaciones

- Modeling For Caesar Ii Piping Stress AnalysisDocumento37 páginasModeling For Caesar Ii Piping Stress Analysisrajeevfa100% (1)

- Examples Applying Fea Results With Caesar II Models Webinar PDFDocumento36 páginasExamples Applying Fea Results With Caesar II Models Webinar PDFkorbelAún no hay calificaciones

- Calculo Brida Ejemplo PV - EliteDocumento8 páginasCalculo Brida Ejemplo PV - ElitePedro Montes MarinAún no hay calificaciones

- Hot Tapping Split Tee SpecificationDocumento19 páginasHot Tapping Split Tee SpecificationAli ClubistAún no hay calificaciones

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocumento5 páginasASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaAún no hay calificaciones

- Cross Country Piping Stress AnalysisDocumento8 páginasCross Country Piping Stress Analysisprabu2001Aún no hay calificaciones

- Acceptable External Nozzle Loads Calculation For Pressure VesseDocumento7 páginasAcceptable External Nozzle Loads Calculation For Pressure Vesset_rajith1179Aún no hay calificaciones

- 01 E02STB007-W146693-03-0 - BC - Stress UpdateDocumento1 página01 E02STB007-W146693-03-0 - BC - Stress Update86tejasAún no hay calificaciones

- Design and Analysis of Piping System With Supports Using CAESAR-IIDocumento5 páginasDesign and Analysis of Piping System With Supports Using CAESAR-IIincaurcoAún no hay calificaciones

- Test Report Long-Term Ring Bending Strain (SB)Documento4 páginasTest Report Long-Term Ring Bending Strain (SB)Diana QuinteroAún no hay calificaciones

- PC-01 - Process Column Design Calculations Using CademPVD SoftwareDocumento127 páginasPC-01 - Process Column Design Calculations Using CademPVD SoftwareCADEM SoftwaresAún no hay calificaciones

- 9.line Size & Wall ThicknessDocumento48 páginas9.line Size & Wall ThicknessClark PlúaAún no hay calificaciones

- Pipe Thickness & RF Pad Calculations As Per Asme b313Documento3 páginasPipe Thickness & RF Pad Calculations As Per Asme b313Gaurav BhendeAún no hay calificaciones

- Dynamic Analysis of Slug by Advance Input MethodDocumento53 páginasDynamic Analysis of Slug by Advance Input MethodYogesh PangareAún no hay calificaciones

- Piping Wind LoadsDocumento2 páginasPiping Wind LoadsAbhishek GorkarAún no hay calificaciones

- Calculations For: Calculations No. Asme Viii Div 1 Ed 2019Documento21 páginasCalculations For: Calculations No. Asme Viii Div 1 Ed 2019David Vanegas100% (1)

- Loadings and Sign Convention SummaryDocumento9 páginasLoadings and Sign Convention SummaryGovindan KrishnamoorthybashyamAún no hay calificaciones

- PSV CatalogDocumento60 páginasPSV Catalogbuler empatsatuduaAún no hay calificaciones

- Sample Calculation ReportDocumento9 páginasSample Calculation ReportmikimecAún no hay calificaciones

- Paper NRTB 2005 02 Sec Refrig ConferenceDocumento17 páginasPaper NRTB 2005 02 Sec Refrig ConferencesalamrefighAún no hay calificaciones

- Heat RecoveryDocumento8 páginasHeat RecoveryPrashantAún no hay calificaciones

- Cold Weather ProductDocumento2 páginasCold Weather ProductsalamrefighAún no hay calificaciones

- Anfragedatenblatt BehaelterDocumento4 páginasAnfragedatenblatt BehaeltersalamrefighAún no hay calificaciones

- AS1548-PT49ON August2009bDocumento3 páginasAS1548-PT49ON August2009bsalamrefighAún no hay calificaciones

- 10 Tips Refrigerant PipingDocumento3 páginas10 Tips Refrigerant PipingAndres CarrascoAún no hay calificaciones

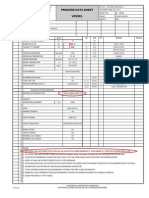

- Inspection and Tests: Instrument Air Receiver TWO Code Stamp: Not RequiredDocumento2 páginasInspection and Tests: Instrument Air Receiver TWO Code Stamp: Not RequiredSean DavisAún no hay calificaciones

- Vessel Data Sheet DetailsDocumento1 páginaVessel Data Sheet DetailsunitedmanticoreAún no hay calificaciones

- Https - WWW - Johncrane.com - Media - J - Johncrane - Com - Files - Products - Specification Sheets - S-28SCDocumento4 páginasHttps - WWW - Johncrane.com - Media - J - Johncrane - Com - Files - Products - Specification Sheets - S-28SCsalamrefighAún no hay calificaciones

- Mechanical Data Sheet - VesselDocumento1 páginaMechanical Data Sheet - VesselsalamrefighAún no hay calificaciones

- MS 803Documento2 páginasMS 803salamrefighAún no hay calificaciones

- General SpecificationsDocumento2 páginasGeneral SpecificationssalamrefighAún no hay calificaciones

- Midstream Solution ASPEN ONEDocumento4 páginasMidstream Solution ASPEN ONEAndrés PeñaAún no hay calificaciones

- Mechanical Data Sheet - VesselDocumento1 páginaMechanical Data Sheet - VesselsalamrefighAún no hay calificaciones

- 11 08 23 (Illawarra Manufacturing Expo All The More Important)Documento2 páginas11 08 23 (Illawarra Manufacturing Expo All The More Important)salamrefighAún no hay calificaciones

- RPGT Full en UsDocumento2 páginasRPGT Full en UssalamrefighAún no hay calificaciones

- Design and Operation: Star-Pleated Element (5) Candle Elements For Automatic FiltersDocumento1 páginaDesign and Operation: Star-Pleated Element (5) Candle Elements For Automatic FilterssalamrefighAún no hay calificaciones

- Working Safely With HCsDocumento2 páginasWorking Safely With HCssalamrefighAún no hay calificaciones

- Model: S100 Series: See Through Type Sight GlassDocumento2 páginasModel: S100 Series: See Through Type Sight GlasssalamrefighAún no hay calificaciones

- High Speed GearboxesDocumento6 páginasHigh Speed Gearboxeskh_chu_1100% (1)

- Ug Call Back 0Documento1 páginaUg Call Back 0salamrefighAún no hay calificaciones

- Thermowell Calculation Guide V1.3Documento19 páginasThermowell Calculation Guide V1.3AymanelorbanyAún no hay calificaciones

- EngineeringDocumento7 páginasEngineeringsalamrefighAún no hay calificaciones

- 3618Documento6 páginas3618salamrefighAún no hay calificaciones

- Throttle (And Check) Valve: FeaturesDocumento3 páginasThrottle (And Check) Valve: FeaturessalamrefighAún no hay calificaciones

- Of-Pla NF00074 1001D PDFDocumento8 páginasOf-Pla NF00074 1001D PDFNigin ParambathAún no hay calificaciones

- Refrigerant Recovery System ManualDocumento19 páginasRefrigerant Recovery System ManualsalamrefighAún no hay calificaciones

- Detailed Equipment Design: Attention To DetailsDocumento13 páginasDetailed Equipment Design: Attention To DetailssalamrefighAún no hay calificaciones