Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Ensayos Dinámicos en Pilotes in Stu

Cargado por

Enrique Lujan0 calificaciones0% encontró este documento útil (0 votos)

18 vistas3 páginaspilotes

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentopilotes

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

18 vistas3 páginasEnsayos Dinámicos en Pilotes in Stu

Cargado por

Enrique Lujanpilotes

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 3

Drilled Shaft Load

Testing: Made Easy

and Inexpensive

by Rob Conroy, American Bridge, and

Brian Mondello, RE., Mohamad Hussein, PE.,

Ryan Gissal, E.1. - GRL Engineers, Inc.

Earlier this year, the American Bridge Company

was awarded the contract for the construction of

Phase 2B extension of the existing Berth 211/210

Crane Rail foundations at the Tampa Port Author-

ity’s Container Terminal in Tampa, Florida. The

foundations included 32-inch diameter rock-sock-

ted drilled shafts constructed with permanent steel

casings. Load testing was required to verify the

foundation design parameters and installation

‘method. The contractor proposed, and the engineer

agreed, to perform Dynamic Load Testing on four of

the shafts utilizing the PDA field instrumentation

system and related CAPWAP® data analysis to ver-

ify a load bearing capacity of 1820 kips per shaft.

This article highlights the testing program, which

was made easy and inexpensive utilizing dynamic

‘methods.

FOUNDATION DRILLING June/July 2010

FEATURE

euws 06222

g] mete

2 | Hemet 1100 ps

|

También podría gustarte

- DimezConc - Sahagun DemoDocumento3 páginasDimezConc - Sahagun DemoEnrique LujanAún no hay calificaciones

- Tratamiento Psicológico de Las Víctimas de AbusoDocumento19 páginasTratamiento Psicológico de Las Víctimas de AbusoCarlos Condori AvilaAún no hay calificaciones

- Formato Granulometria Sub Base Excell 2003Documento41 páginasFormato Granulometria Sub Base Excell 2003Enrique Lujan0% (1)

- Tabla de Dosificaciones y EquivalenciasDocumento13 páginasTabla de Dosificaciones y EquivalenciasCarlos Cuevas Saenz100% (2)

- Metrado ConcretoDocumento3 páginasMetrado ConcretoEdilberto GamarraAún no hay calificaciones

- Arcillas ExpansivasDocumento15 páginasArcillas Expansivasyomac1Aún no hay calificaciones

- Lazaresacelerogramasica 121010210153 Phpapp01Documento14 páginasLazaresacelerogramasica 121010210153 Phpapp01Enrique LujanAún no hay calificaciones

- AF Tabla DosificacionDocumento12 páginasAF Tabla DosificacionSegundo Daniel Fernandez GutierrezAún no hay calificaciones

- DimezConc - Sahagun DemoDocumento3 páginasDimezConc - Sahagun DemoEnrique LujanAún no hay calificaciones

- DISEÑO CIMENTACIONES ARENADocumento46 páginasDISEÑO CIMENTACIONES ARENAJorge Ricardo Malqui MegoAún no hay calificaciones

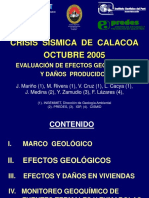

- Crisisssmicadecalacoa Evaluacindeefectosgeolgicosydaosproducidos 120411085714 Phpapp02Documento27 páginasCrisisssmicadecalacoa Evaluacindeefectosgeolgicosydaosproducidos 120411085714 Phpapp02Enrique LujanAún no hay calificaciones

- Procedimiento Guia Excavacion Zanjas Construccion CivilDocumento4 páginasProcedimiento Guia Excavacion Zanjas Construccion CivilLuisabel GarciaAún no hay calificaciones

- Redacis09p 130728210141 Phpapp02Documento62 páginasRedacis09p 130728210141 Phpapp02Enrique LujanAún no hay calificaciones

- Dinámica de suelos en ingeniería civilDocumento220 páginasDinámica de suelos en ingeniería civilnestcop2005Aún no hay calificaciones

- Ar 19Documento42 páginasAr 19Enrique LujanAún no hay calificaciones

- Esfuerzo en Una Masa de SueloDocumento45 páginasEsfuerzo en Una Masa de SueloYerson MendozaAún no hay calificaciones

- Guía Comparativa de Tarot Escuela LeMatDocumento46 páginasGuía Comparativa de Tarot Escuela LeMatnavegante20002003100% (1)

- Doc13394 ContenidoDocumento26 páginasDoc13394 ContenidoEnrique LujanAún no hay calificaciones

- Presas de TierraDocumento84 páginasPresas de Tierrajcrojasm100% (5)

- Diseño Emulsion AsfalticaDocumento5 páginasDiseño Emulsion AsfalticaEnrique LujanAún no hay calificaciones

- Geología Aplicada A Carreteras PDFDocumento59 páginasGeología Aplicada A Carreteras PDFJuan Pablo RH0% (1)

- CimentacionesDocumento21 páginasCimentacionesRDG0131Aún no hay calificaciones

- 1 130 181 83 1181Documento22 páginas1 130 181 83 1181Segundo Ildauro Vásquez SeguraAún no hay calificaciones

- Analisis Vivienda UnifamiliarDocumento5 páginasAnalisis Vivienda UnifamiliarAnonymous 8t4JBPAún no hay calificaciones

- Expansivas 1Documento28 páginasExpansivas 1arturo612Aún no hay calificaciones

- Cant. 13+500 - AbrasiónDocumento1 páginaCant. 13+500 - AbrasiónEnrique LujanAún no hay calificaciones

- Examen Final de Geologi1-2 en UnoDocumento1 páginaExamen Final de Geologi1-2 en UnoEnrique LujanAún no hay calificaciones

- Aashto FlexibleDocumento6 páginasAashto Flexiblejuanma7102Aún no hay calificaciones

- Compactación SuelosDocumento31 páginasCompactación SuelosErika WilkersonAún no hay calificaciones