Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Britt Lit Review

Cargado por

api-258119727Descripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Britt Lit Review

Cargado por

api-258119727Copyright:

Formatos disponibles

VARIABILITY TESTING OF BIVO4 PHOTOVOLTAIC CELLS

Testing Variables of BiVO4 Photovoltaic Cells and their Efficiency to Split Water and Produce

Hydrogen as a Renewable Energy Source

Kylie M. Britt

Massanutten Regional Governors School

12 December 2014

VARIABILITY TESTING OF BIVO4 PHOTOVOLTAIC CELLS

Literature Review

Using photovoltaic cells is one method of harnessing solar energy and converting it to

electricity. This can be done with the intent to eventually use that energy to split water and

produce hydrogen. These cells have been improved upon by adding a solution called bismuth

vanadate (shortened as BiVO4), and the current output (in mA) has been boosted even with the

addition of a solution known as CoPi (a cobalt and phosphate solution). However, it is unknown

how to optimize the amount of these solutions, and what concentration of each element in those

solutions is more beneficial to the efficiency of the photovoltaic thin-films.

Hydrogen is produced mainly through splitting water into its two components, hydrogen

and oxygen. Photoelectrochemical water splitting is a combination of two processes,

photovoltaic energy production and electrolysis to produce hydrogen. When both processes are

used, but do not occur in the single device, it is called the PV (photovoltaic)/electrolysis system.

Photoelectrolysis, a way to separate water, is a method of using solar energy to conduct an

otherwise non-spontaneous reaction through a direct electric current. (Photoelectrochemical

Water Splitting). By using photoelectrolysis to split water, the efficiency is 30% higher than if a

standard, PV/electrolysis water splitting system were used (MacQueen). The photoelectrolysis

method requires the catalysts be submerged in an aqueous solution.

A study involving carbon-doped tungsten PV films was performed, evaluating the method

of spray pyrolysis for deposition. (Photoelectrochemical and structural characterization of

carbon-doped WO films prepared via spray pyrolysis). The topography and variables of the

3

films were then measured using scanning electron microscopy, spectroscopy, and resonance. The

difference in doped and undoped films results from the variability in glucose levels. When used

VARIABILITY TESTING OF BIVO4 PHOTOVOLTAIC CELLS

to produce electricity, these films exhibited a 50% growth in current. The researchers then found

the optimal depth and concentration of the solution that was deposited on the carbon-tungsten

films.

This research team, the one I am now partnering with at JMU, hoped to improve the

electric output of photovoltaic thin films by adding a chemical known as bismuth vanadate. The

coating is done through a process known as ultra-spray pyrolysis, in a cost-efficient method

devised by Dr. Lawrence himself. Tungsten was added to the films as well to act as a hole

scavenger and electrical conductor. Turns out, tungsten was reducing the energy produced, but it

was found that ultra-spray pyrolysis is very effective in fully coating the photovoltaic thin films.

(Photoelectrochemical performance of W-doped BiVO4 thin films deposited by spray pyrolysis.)

The use of spray pyrolysis as a solution depositor, especially on photovoltaic thin films,

is incredibly applicable to using photoanodes in solar-hydrogen research. This spray pyrolysis,

pioneered by Dr. David J. Lawrence and Dr. Keith Holland, is a cost-effective method of

depositing solution onto the PV cells. It is homemade, with materials including a gift-store fog

machine and PVC pipe. Finding an optimal level of solution (in my case, cobalt phosphate), and

concentration of either bismuth or vanadate in the BiVO4 is the next step. Using electron

microscopy images, surface profiling depicting depth and photoelectrochemical (PEC) testing,

the efficiency of these variables can be compared. (Photoelectrochemical and structural

characterization of carbon-doped WO films prepared via spray pyrolysis).

3

This research, founded by Drs. Holland and Lawrence, will focus on such solutions as

cobalt phosphate (CoPi) and upping the potency of the BiVO . Some of the variables that stand to

4

be tested include the depth of the CoPi and BiVO4, films with an excess of bismuth, and some

VARIABILITY TESTING OF BIVO4 PHOTOVOLTAIC CELLS

with a copious amount of vanadate. As the year progresses and data is produced from these

original tests, the variables will be reevaluated and there may be a new list of factors to test.

Analyzing these variables will have invaluable effects for the overall process of solarhydrogen electrolysis. This year the research will follow the process of variability testing from

start to finishfrom deposition and the fabrication of the BiVO4 PV cells to the electron

microscopy and finally photoelectrochemical testing. Many different methods will be used to test

the productivity of variables that could cheaply improve the process of using solar-hydrogen as a

renewable resource.

VARIABILITY TESTING OF BIVO4 PHOTOVOLTAIC CELLS

References

Currao, A. (2007). Photoelectrochemical Water Splitting. CHIMIA, 61 (12), pages 815-819.

Holland, S., Dutter, M., Lawrence, D., Reisner, B., and DeVore, C. (2013). Photoelectrochemical

performance of W-doped BiVO4 thin films deposited by spray pyrolysis. SPIE, 8822, 514.

MacQueen, D. B. (n.d.). Photoelectrochemical water splitting. Retrieved from

http://gcep.stanford.edu/pdfs/hydrogen_workshop/MacQueen.pdf

Sun, Y., Murphy, C., Reyes-Gil, K., Reyes-Garcia, E., Thornton, J., Morris, N., & Raftery, D.

(2009). Photoelectrochemical and structural characterization of carbon-doped WO3 films

prepared via spray pyrolysis. International Journal of Hydrogen Energy, 34, 8476- 8484.

También podría gustarte

- Britt Research ProposalDocumento4 páginasBritt Research Proposalapi-258119727Aún no hay calificaciones

- IHS Markit HydrogeDocumento19 páginasIHS Markit HydrogeXkeiPIngAún no hay calificaciones

- BS5440 Quick GuideDocumento4 páginasBS5440 Quick Guidenyj martin100% (2)

- Exhaust Brake FunctionalityDocumento3 páginasExhaust Brake FunctionalityDragan100% (2)

- Cat Serial Number PrefixesDocumento14 páginasCat Serial Number PrefixesWill ?Aún no hay calificaciones

- Macroporous V2O5-BiVO4 Composites Effect of Heterojunction On The Behavior of Photogenerated ChargesDocumento9 páginasMacroporous V2O5-BiVO4 Composites Effect of Heterojunction On The Behavior of Photogenerated ChargesAnonymous IZdXRyvsxAún no hay calificaciones

- Bivo VariabilityDocumento17 páginasBivo Variabilityapi-258119727Aún no hay calificaciones

- Chemical Engineering Journal: Jin Zhang, Hao Cui, Bing Wang, Chuang Li, Jianping Zhai, Qin LiDocumento10 páginasChemical Engineering Journal: Jin Zhang, Hao Cui, Bing Wang, Chuang Li, Jianping Zhai, Qin LiManuel RiegaAún no hay calificaciones

- Enhancing Photoelectrochemical Water Splitting by Combining Work Function Tuning and Heterojunction EngineeringDocumento9 páginasEnhancing Photoelectrochemical Water Splitting by Combining Work Function Tuning and Heterojunction EngineeringSyeda Ammara AnwarAún no hay calificaciones

- N-Doped BiVO4Documento7 páginasN-Doped BiVO4gta gtaAún no hay calificaciones

- Electrochemical DepositionDocumento11 páginasElectrochemical DepositionmuhammadAún no hay calificaciones

- Al Mayouf, Abdullah M., Catalysts, 9 (2019)Documento16 páginasAl Mayouf, Abdullah M., Catalysts, 9 (2019)pramodmaheshwari777Aún no hay calificaciones

- Applied Catalysis B: Environmental: SciencedirectDocumento10 páginasApplied Catalysis B: Environmental: Sciencedirectmalka ShahidAún no hay calificaciones

- MP Review PaperDocumento10 páginasMP Review PaperMUHAMMAD USMAN Mechanical Pesh.-Batch 20Aún no hay calificaciones

- Synthesis and Characterization of Cufe2O4 Nano/Submicron Wire-Carbon Nanotube Composites As Binder-Free Anodes For Li-Ion BatteriesDocumento51 páginasSynthesis and Characterization of Cufe2O4 Nano/Submicron Wire-Carbon Nanotube Composites As Binder-Free Anodes For Li-Ion BatteriesKepoin yukAún no hay calificaciones

- 1 s2.0 S0926337323004186 MainDocumento13 páginas1 s2.0 S0926337323004186 MainHanane Mohammed BirkudarAún no hay calificaciones

- Wang 2022 J. Electrochem. Soc. 169 066508Documento8 páginasWang 2022 J. Electrochem. Soc. 169 066508ShrabaniPaulAún no hay calificaciones

- Author's Accepted Manuscript: Journal of Membrane ScienceDocumento33 páginasAuthor's Accepted Manuscript: Journal of Membrane ScienceMuhammed AfnazAún no hay calificaciones

- Molecular Level Artificial Photosynthetic MaterialsDe EverandMolecular Level Artificial Photosynthetic MaterialsGerald J. MeyerAún no hay calificaciones

- 15 Chapter4Documento28 páginas15 Chapter4sanaul haqueAún no hay calificaciones

- IMproved Electrolyte for VRB - jing2016Documento9 páginasIMproved Electrolyte for VRB - jing2016SureshBharadwajAún no hay calificaciones

- MarschallDocumento20 páginasMarschallgasweb19Aún no hay calificaciones

- Slimming World, Feb 2011Documento5 páginasSlimming World, Feb 2011emediageAún no hay calificaciones

- Baumann 2020Documento13 páginasBaumann 2020Ali TunaAún no hay calificaciones

- 1 s2.0 S0143720823005831 MainDocumento7 páginas1 s2.0 S0143720823005831 MainMatias AlonsoAún no hay calificaciones

- Co3O4 Thin FilmsDocumento46 páginasCo3O4 Thin FilmsEddy MaroAún no hay calificaciones

- 1 s2.0 S0254058423011380 MainDocumento15 páginas1 s2.0 S0254058423011380 Mainmy.local.address.infoAún no hay calificaciones

- A Modified Two-Step Sequential Spin-Coating Method For Perovskite Solar Cells Using CsI Containing Organic Salts in Mixed Ethanol Methanol SolventDocumento7 páginasA Modified Two-Step Sequential Spin-Coating Method For Perovskite Solar Cells Using CsI Containing Organic Salts in Mixed Ethanol Methanol Solvent北科大-洪珮倫Aún no hay calificaciones

- Licoo and Limn O Thin-Film Electrodes For Rechargeable Lithium BatteriesDocumento5 páginasLicoo and Limn O Thin-Film Electrodes For Rechargeable Lithium Batteriesمصطفى محمودAún no hay calificaciones

- Accepted Article: Title: Bi5+, Bi (3-X) +, and Oxygen Vacancy Induced Bioclxi1-X SolidDocumento14 páginasAccepted Article: Title: Bi5+, Bi (3-X) +, and Oxygen Vacancy Induced Bioclxi1-X SolidMys GenieAún no hay calificaciones

- 19 PDFDocumento9 páginas19 PDFSumairaAún no hay calificaciones

- Molecules 27 06949Documento17 páginasMolecules 27 06949exact medicalAún no hay calificaciones

- Review On Bivo Based Photoanodes For Photoelectrochemical Water Oxidation: The Main Influencing FactorsDocumento18 páginasReview On Bivo Based Photoanodes For Photoelectrochemical Water Oxidation: The Main Influencing Factorsgta gtaAún no hay calificaciones

- Materials Science in Semiconductor ProcessingDocumento9 páginasMaterials Science in Semiconductor ProcessingManuel RiegaAún no hay calificaciones

- Carbon Dots/Biocl Films With Enhanced Visible Light Photocatalytic PerformanceDocumento11 páginasCarbon Dots/Biocl Films With Enhanced Visible Light Photocatalytic PerformanceAde SazalianaAún no hay calificaciones

- Wang 2017Documento10 páginasWang 2017nisrina amaliaAún no hay calificaciones

- Liquid Crystal UGM 1Documento8 páginasLiquid Crystal UGM 1YusrilAún no hay calificaciones

- Renewable and Sustainable Energy Reviews: SciencedirectDocumento12 páginasRenewable and Sustainable Energy Reviews: SciencedirectManifa NoorAún no hay calificaciones

- Visibly Transparent Polymer Solar Cells Produced by Solution ProcessingDocumento6 páginasVisibly Transparent Polymer Solar Cells Produced by Solution ProcessingHendrawan LDAún no hay calificaciones

- Photoelectrodeposition of Ag3PO4 Nanoparticles On BiVO4 Photoanode For Enhancing Its Photoelectrochemical Water Oxidation PerformanceDocumento10 páginasPhotoelectrodeposition of Ag3PO4 Nanoparticles On BiVO4 Photoanode For Enhancing Its Photoelectrochemical Water Oxidation Performancelevanhoang.tnAún no hay calificaciones

- Design of Potassium Ion Conducting PVA Basedpolymer Electrolyte For EDLC Device Application - Aziz 2021Documento14 páginasDesign of Potassium Ion Conducting PVA Basedpolymer Electrolyte For EDLC Device Application - Aziz 2021I.T.S EnggAún no hay calificaciones

- Research Paper On Lithium Ion BatteryDocumento9 páginasResearch Paper On Lithium Ion Batterymajvbwund100% (1)

- PF6-Halide Perovskite Based On Hydrophobic Ionic Liquid For StabilityDocumento7 páginasPF6-Halide Perovskite Based On Hydrophobic Ionic Liquid For StabilityDanila SaraninAún no hay calificaciones

- tmpF24A TMPDocumento7 páginastmpF24A TMPFrontiersAún no hay calificaciones

- Applied Surface Science: Jiapeng Fu, Zengyuan Pang, Jie Yang, Fenglin Huang, Yibing Cai, Qufu WeiDocumento8 páginasApplied Surface Science: Jiapeng Fu, Zengyuan Pang, Jie Yang, Fenglin Huang, Yibing Cai, Qufu WeibelkhamasAún no hay calificaciones

- Fabrication and Photocatalytic Property of Novel SDocumento9 páginasFabrication and Photocatalytic Property of Novel SMys GenieAún no hay calificaciones

- Electrospinning Preparation of Atactic Poly(vinyl alcohol)/Sodium Alginate Blend NanowebsDocumento6 páginasElectrospinning Preparation of Atactic Poly(vinyl alcohol)/Sodium Alginate Blend NanowebsEka LutfiAún no hay calificaciones

- PV PV Third GenerationDocumento244 páginasPV PV Third GenerationJP GUPTAAún no hay calificaciones

- Greatly Enhanced Photocurrent In Inorganic Perovskite (Knbo3) 0.9 (Bani0.5Nb0.5O3‐Σ) 0.1 Ferroelectric Thin‐Film Solar CellDocumento18 páginasGreatly Enhanced Photocurrent In Inorganic Perovskite (Knbo3) 0.9 (Bani0.5Nb0.5O3‐Σ) 0.1 Ferroelectric Thin‐Film Solar Cellcbs78Aún no hay calificaciones

- Navarro Et Al 2020Documento9 páginasNavarro Et Al 2020Rosmery Naupari AlvarezAún no hay calificaciones

- 1B EngbergDocumento12 páginas1B EngbergPeter LichterveldAún no hay calificaciones

- 10 1016@j JMST 2020 03 039Documento23 páginas10 1016@j JMST 2020 03 039Aejitha mohanAún no hay calificaciones

- Optimization of Lifepo Nanoparticle Suspensions With Polyethyleneimine For Aqueous ProcessingDocumento8 páginasOptimization of Lifepo Nanoparticle Suspensions With Polyethyleneimine For Aqueous Processing201400738Aún no hay calificaciones

- 1 s2.0 S0048969722062040 MainDocumento12 páginas1 s2.0 S0048969722062040 MainAlbanny PerezAún no hay calificaciones

- Ijms 23 12652 v2Documento12 páginasIjms 23 12652 v2Deym GómezAún no hay calificaciones

- Semiconductor-Based Photocatalytic Hydrogen Generation: Xiaobo Chen, Shaohua Shen, Liejin Guo, and Samuel S. MaoDocumento68 páginasSemiconductor-Based Photocatalytic Hydrogen Generation: Xiaobo Chen, Shaohua Shen, Liejin Guo, and Samuel S. MaomuchaelAún no hay calificaciones

- Journal of Photochemistry & Photobiology A: Chemistry: SciencedirectDocumento17 páginasJournal of Photochemistry & Photobiology A: Chemistry: SciencedirectJorge Eduardo JuarezAún no hay calificaciones

- Density Functional Theory Investigations of Bismuth VanadateDocumento7 páginasDensity Functional Theory Investigations of Bismuth VanadateNurSalahuddinAún no hay calificaciones

- ELECTROPOLYMERIZATIONOFANILINESciIntLahore PDFDocumento12 páginasELECTROPOLYMERIZATIONOFANILINESciIntLahore PDFEkalavyan RKAún no hay calificaciones

- ELECTROPOLYMERIZATIONOFANILINESci Int LahoreDocumento12 páginasELECTROPOLYMERIZATIONOFANILINESci Int LahoreEkalavyan RKAún no hay calificaciones

- Jeong 2013Documento9 páginasJeong 2013gta gtaAún no hay calificaciones

- Optical Photocatalytic Electrochemical Magnetic DiDocumento19 páginasOptical Photocatalytic Electrochemical Magnetic DiTasawer Shahzad AhmadAún no hay calificaciones

- Molecules: A Review On Visible Light Active Perovskite-Based PhotocatalystsDocumento28 páginasMolecules: A Review On Visible Light Active Perovskite-Based PhotocatalystsVishal DhapaAún no hay calificaciones

- Conjugated Polyelectrolytes: Fundamentals and ApplicationsDe EverandConjugated Polyelectrolytes: Fundamentals and ApplicationsAún no hay calificaciones

- Revolutionizing Energy Storage Nanomaterial Solutions for Sustainable SupercapacitorsDe EverandRevolutionizing Energy Storage Nanomaterial Solutions for Sustainable SupercapacitorsAún no hay calificaciones

- FinalDocumento3 páginasFinalapi-258119727Aún no hay calificaciones

- Britt Proposal FinalDocumento4 páginasBritt Proposal Finalapi-258119727Aún no hay calificaciones

- Changes For Trans People and Queer YouthDocumento1 páginaChanges For Trans People and Queer Youthapi-258119727Aún no hay calificaciones

- Nobody Can Drag Me DownDocumento1 páginaNobody Can Drag Me Downapi-258119727Aún no hay calificaciones

- ErahandoutDocumento1 páginaErahandoutapi-258119727Aún no hay calificaciones

- Work and AmbitionDocumento1 páginaWork and Ambitionapi-258119727Aún no hay calificaciones

- Question 1: Short AnswerDocumento3 páginasQuestion 1: Short Answerapi-258119727Aún no hay calificaciones

- Me? Oppressed?: What Gives Me Strength? Seeing Women in Different Phases of Struggling With Oppression. SomeDocumento1 páginaMe? Oppressed?: What Gives Me Strength? Seeing Women in Different Phases of Struggling With Oppression. Someapi-258119727Aún no hay calificaciones

- Becoming The OtherDocumento1 páginaBecoming The Otherapi-258119727Aún no hay calificaciones

- Wgss 20 QuestionsDocumento1 páginaWgss 20 Questionsapi-258119727Aún no hay calificaciones

- Nature Vs BeautyDocumento1 páginaNature Vs Beautyapi-258119727Aún no hay calificaciones

- Britt CountryprojectDocumento8 páginasBritt Countryprojectapi-258119727Aún no hay calificaciones

- Elevatorspeechround 2Documento1 páginaElevatorspeechround 2api-258119727Aún no hay calificaciones

- Brittleckey AbortionpaperDocumento10 páginasBrittleckey Abortionpaperapi-258119727Aún no hay calificaciones

- Britt Cpla FinalDocumento8 páginasBritt Cpla Finalapi-258119727Aún no hay calificaciones

- Jmu Sci Fair Research Plan AbstractDocumento4 páginasJmu Sci Fair Research Plan Abstractapi-258119727Aún no hay calificaciones

- Britt Literary AnalysisDocumento6 páginasBritt Literary Analysisapi-258119727Aún no hay calificaciones

- Final Lit ReviewDocumento5 páginasFinal Lit Reviewapi-258119727Aún no hay calificaciones

- Internal Combustion Engines GuideDocumento216 páginasInternal Combustion Engines GuideRohit ThoratAún no hay calificaciones

- The Potentials of Renewable EnergyDocumento40 páginasThe Potentials of Renewable EnergyAravindh AAún no hay calificaciones

- 7M-2 Plate Heat ExchangerDocumento18 páginas7M-2 Plate Heat ExchangerZhengwei YinAún no hay calificaciones

- Armstrong Installation, Start-Up and Operating Instructions Armstrong Differential Condensate ControllerDocumento4 páginasArmstrong Installation, Start-Up and Operating Instructions Armstrong Differential Condensate ControllerWalid SaifAún no hay calificaciones

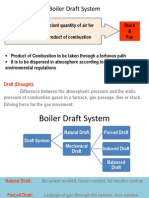

- Boiler Draft SystemDocumento56 páginasBoiler Draft SystemAmit Chauhan78% (9)

- Westinghouse Technology Systems Manual Section 3.2 Reactor Coolant SystemDocumento62 páginasWestinghouse Technology Systems Manual Section 3.2 Reactor Coolant SystemSheikh ShoaibAún no hay calificaciones

- Compressor Motor Types and Start RelaysDocumento7 páginasCompressor Motor Types and Start Relaysildiko1234Aún no hay calificaciones

- D4B804B254B-Heating Ventilation and Air ConditioningDocumento323 páginasD4B804B254B-Heating Ventilation and Air ConditioningDaniel CharlesAún no hay calificaciones

- Next Generation Nuclear Plant Intermediate Heat Exchanger Materials Research and Development PlanDocumento292 páginasNext Generation Nuclear Plant Intermediate Heat Exchanger Materials Research and Development PlanVanina GiselaAún no hay calificaciones

- Operating Instructions: Preparation For Start-UpDocumento8 páginasOperating Instructions: Preparation For Start-UpMiliani AhmedAún no hay calificaciones

- Hart Cooley Bvent Sizing GuideDocumento32 páginasHart Cooley Bvent Sizing GuidejimbobofdundeeAún no hay calificaciones

- NESC Diploma - MillwrightDocumento2 páginasNESC Diploma - MillwrightjamesAún no hay calificaciones

- PV ModuleDocumento2 páginasPV ModuleRoksana SobierajczykAún no hay calificaciones

- Gunung Megang - Final PDDDocumento56 páginasGunung Megang - Final PDDbapaobaoAún no hay calificaciones

- Stirling Engine Project ReportDocumento17 páginasStirling Engine Project ReportelangandhiAún no hay calificaciones

- 12 NDT150 SDocumento2 páginas12 NDT150 SEn La U100% (1)

- Yk Centrifugal: ... An Energy-Saving Approach To Your Service Needs..Documento3 páginasYk Centrifugal: ... An Energy-Saving Approach To Your Service Needs..jose2525100% (1)

- An Overview About: Bharti Pumps & Compressors Limited, Naini, AllahabadDocumento19 páginasAn Overview About: Bharti Pumps & Compressors Limited, Naini, AllahabadzotorolaAún no hay calificaciones

- CH 5 PDFDocumento24 páginasCH 5 PDFМихаил МироновAún no hay calificaciones

- Comparison Novec1230 Vs FM 200 Vs CO2Documento3 páginasComparison Novec1230 Vs FM 200 Vs CO2Innovative Safety MarinesAún no hay calificaciones

- Data Shhet Bomba de Diafragma PS15Documento2 páginasData Shhet Bomba de Diafragma PS15Leonardo Rios RuizAún no hay calificaciones

- Undra Undra Undra Undra: ChileDocumento1 páginaUndra Undra Undra Undra: ChileValentin Bustos MolinaAún no hay calificaciones

- Jindal Power Limited O.P.J.S.T.P.P, Tamnar, Raigarh: Commissioning DepartmentDocumento12 páginasJindal Power Limited O.P.J.S.T.P.P, Tamnar, Raigarh: Commissioning Departmentjp mishraAún no hay calificaciones

- KDE19STA3Documento3 páginasKDE19STA3Anonymous hlPPOmxXB7Aún no hay calificaciones

- 000000003002000049Documento2 páginas000000003002000049mhdsolehAún no hay calificaciones

- Handbook Chapter15 DisplacementVentilationDocumento41 páginasHandbook Chapter15 DisplacementVentilationJoao Sousa100% (1)