Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Vacuum Test Procedure PDF

Cargado por

Danilo de JurasDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Vacuum Test Procedure PDF

Cargado por

Danilo de JurasCopyright:

Formatos disponibles

Sealed Enclosures

www.sealed-enclosures.com

Vacuum Test Procedure

These instructions are for leak testing a pressure resistant enclosure.

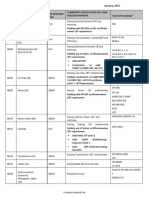

Equipment

A Vacuum pump is required, it will need to achieve at least 90% of a full vacuum and it

should also have a 1 hose on the inlet. The second requirement is the kit pictured below.

Plastic Insert

M20 x 1.5

Cap

Hub

Valve

Female Cone

Connection

Pressure Gauge

Maintenance

The Vacuum Test equipment should be kept clean, dry and protected from damage by impact

or abrasion. Seals should be lubricated with grease (either Silicon Grease or Pure Petroleum

Jelly) and because this attracts dirt inspect them frequently.

Always check the oil level in the Vacuum Pump. When the pump is transported by carrier the

oil should be drained to a clean plastic bottle.

Page 1 of 2

Testing the Equipment

Before testing the housings the equipment itself can be tested by screwing the Cap on the

Insert and then pushing the Insert into the Hub. Open the Valve and turn on the Pump. The

pipe from the pump should have the male taper fitted, insert this into the Female Cone

Connection, now observe the gauge, the pressure should fall until it reads approximately 100kPa or 30 in Hg. If the pressure read is held for two minutes, continue with the test. If the

pressure is not held, inspect the system for damage particularly the O Rings or their sealing

faces, remedy any damage found and re-test the equipment.

Testing the Housings

1. Remove the Blanking Plug.

2. Take the plastic insert and screw it in hand tight.

3. Push the Hub onto the Insert taking care not to damage the Pressure Gauge.

4. Open the Valve.

5. Start the Vacuum Pump.

6. Join the Male and Female Cone Connections.

7. Observe the pressure fall to -100kPa or 30 in Hg, one or two division less would be

OK.

8. Close the Valve.

9. Separate the Cone Connection.

10. Note time and the position of the pointer on the gauge.

11. After thirty minutes, note any change in the position of the pointer.

12. If the pointer has moved and indicated a leak, every potential leak path will have to

investigated, the problem found and remedied. The test will then need to be re-started.

13. Where the pointer has not moved, open the Valve and remove the fittings.

14. Carefully replace the Blanking Plug, mindful that this plug is the only fitting that has

not been tested.

Page 2 of 2

También podría gustarte

- 1 Imran Piping QC CVDocumento4 páginas1 Imran Piping QC CVkazim MirzaAún no hay calificaciones

- 1.13 Inspection & Test PlansDocumento1 página1.13 Inspection & Test Plansabimanyubawono100% (2)

- Boiler Hydro TestDocumento2 páginasBoiler Hydro TestKarthi KeyanAún no hay calificaciones

- Hydro TestDocumento9 páginasHydro TestPrathap JohnAún no hay calificaciones

- Paint Adhesion Tests (Part I Test Method A or X-Cut)Documento1 páginaPaint Adhesion Tests (Part I Test Method A or X-Cut)Bvel2019Aún no hay calificaciones

- Pipework Pretest Checklist (Empty)Documento1 páginaPipework Pretest Checklist (Empty)Jorge GarciaAún no hay calificaciones

- Hydrotest QI304-sampleDocumento3 páginasHydrotest QI304-sampleHanuman Rao100% (1)

- Zzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsDocumento1 páginaZzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsSARSAN NDTAún no hay calificaciones

- Pipeline TestingDocumento4 páginasPipeline Testingveljko2008100% (1)

- Hydrostatic Test - Wikipedia, The Free EncyclopediaDocumento4 páginasHydrostatic Test - Wikipedia, The Free Encyclopediaramthecharm_46098467Aún no hay calificaciones

- Halliburton Multi Chem Batch Plant Project: Purchase Order/Contract NumberDocumento7 páginasHalliburton Multi Chem Batch Plant Project: Purchase Order/Contract NumberTahseen Ahmed100% (1)

- 800D SeriesDocumento3 páginas800D Seriesvkeie0206Aún no hay calificaciones

- Hose Test MethodsDocumento5 páginasHose Test MethodstriagusmanAún no hay calificaciones

- 13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)Documento7 páginas13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)SANDEEP100% (1)

- Bondstrand Fiberglass Flanges Assembly Instructions - AmeronDocumento8 páginasBondstrand Fiberglass Flanges Assembly Instructions - AmeronFabio SilvaAún no hay calificaciones

- Inspection Checklist For: Control ValvesDocumento2 páginasInspection Checklist For: Control Valvesabdelkader benabdallahAún no hay calificaciones

- Pull Off Test Report RefinaryDocumento3 páginasPull Off Test Report RefinaryZaid Raslan AyoubAún no hay calificaciones

- Field Hydrostatic Pressure Testing of Polyethylene Pressure Pipelines, Waters&FarrDocumento7 páginasField Hydrostatic Pressure Testing of Polyethylene Pressure Pipelines, Waters&FarrGökhan TurhanAún no hay calificaciones

- HDPE Butt Fusion Weld Inspection and Imaging PDFDocumento19 páginasHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdAún no hay calificaciones

- Repair Procedure For Rubber LiningDocumento1 páginaRepair Procedure For Rubber LiningChuah Cheong JinAún no hay calificaciones

- GRE INS-009, Flange Bolting ProcedureDocumento6 páginasGRE INS-009, Flange Bolting Proceduresyed jafar100% (1)

- Hydrostatic Test of Pandi WaterDocumento7 páginasHydrostatic Test of Pandi WaterOscar C. GabinayAún no hay calificaciones

- Itp Pipe SupportsDocumento4 páginasItp Pipe SupportskamlAún no hay calificaciones

- Boiler 3.1Documento112 páginasBoiler 3.1Aldy Bagus PratamaAún no hay calificaciones

- Aws D.1.1 UtDocumento1 páginaAws D.1.1 UtAMIN_GOODARZI_NDTAún no hay calificaciones

- Chemical Resistance (LLDPE) PDFDocumento24 páginasChemical Resistance (LLDPE) PDFrubyshreeAún no hay calificaciones

- Table - Qw-416 Welding Variables For Welder PerformanceDocumento1 páginaTable - Qw-416 Welding Variables For Welder PerformanceAnonymous VohpMtUSN100% (1)

- Saes W 013Documento8 páginasSaes W 013Dhaval Patel100% (1)

- Nut & Bolt ScienceDocumento3 páginasNut & Bolt SciencetanujaayerAún no hay calificaciones

- Stationary Equipment Procedure (Pack 1)Documento5 páginasStationary Equipment Procedure (Pack 1)Farhan SheikhAún no hay calificaciones

- ASME SEC IX Article Iii, Welding Performance QualificationsDocumento11 páginasASME SEC IX Article Iii, Welding Performance QualificationsTeoxAún no hay calificaciones

- Hardness Pro Form1Documento2 páginasHardness Pro Form1gst ajah100% (1)

- Painting Report - FormatDocumento1 páginaPainting Report - FormatRyan FloresAún no hay calificaciones

- Skid Mounted Unit InstallationDocumento2 páginasSkid Mounted Unit Installationric leonisoAún no hay calificaciones

- Leak Testing For Closure Welds of Pressure Piping PDFDocumento4 páginasLeak Testing For Closure Welds of Pressure Piping PDFezzataAún no hay calificaciones

- RFI & ITR Workflow - 20200116Documento1 páginaRFI & ITR Workflow - 20200116nickoAún no hay calificaciones

- National Institute of Technology: M. Tech. DEGREE IN Non - Destructive TestingDocumento39 páginasNational Institute of Technology: M. Tech. DEGREE IN Non - Destructive TestingAvijit DebnathAún no hay calificaciones

- PI PE Drain PI PE: Mitsubishi Heavy Industries KX Installation Inspection ChecklistDocumento2 páginasPI PE Drain PI PE: Mitsubishi Heavy Industries KX Installation Inspection ChecklistRajesh Singh100% (1)

- Inspection report-GRVE BlankDocumento2 páginasInspection report-GRVE BlankJoseph Perez100% (1)

- Resume Suda Mara IDocumento5 páginasResume Suda Mara IMd AkhtarAún no hay calificaciones

- Hydrostatic Test Procedure: 1. ScopeDocumento5 páginasHydrostatic Test Procedure: 1. ScopeHassan SleemAún no hay calificaciones

- Flange Inspection - Part1Documento5 páginasFlange Inspection - Part1safwanAún no hay calificaciones

- F 941 - 99 - RJK0MQ - PDFDocumento3 páginasF 941 - 99 - RJK0MQ - PDFRománBarciaVazquezAún no hay calificaciones

- ARAMCO QM Number ListDocumento3 páginasARAMCO QM Number ListMohamed Yousuf Syed MohamedAún no hay calificaciones

- t209 PDFDocumento12 páginast209 PDF094-STEVEN EDWARD WINDARTO100% (1)

- NDT Acceptance Criteria PDFDocumento2 páginasNDT Acceptance Criteria PDFamit84indAún no hay calificaciones

- Barcol Hardness Test - 3101Documento2 páginasBarcol Hardness Test - 3101Muthuram NAún no hay calificaciones

- FRP Installation GuideDocumento8 páginasFRP Installation GuideDouglas HillAún no hay calificaciones

- Cylinder Data Sheet (FM200 Gas Bottle) PDFDocumento4 páginasCylinder Data Sheet (FM200 Gas Bottle) PDFKevin TsuiAún no hay calificaciones

- How To Select A Heat Shrink SleeveDocumento2 páginasHow To Select A Heat Shrink SleeveLava SatAún no hay calificaciones

- Letter For Testing of PQRDocumento1 páginaLetter For Testing of PQRPA PROJECTS PVT LTDAún no hay calificaciones

- Plant Piping Pressure Testing: (Exam For Inspectors Performing Test PKG & Sis Sheet Calculation Reviews)Documento3 páginasPlant Piping Pressure Testing: (Exam For Inspectors Performing Test PKG & Sis Sheet Calculation Reviews)aslam.ambAún no hay calificaciones

- Air Compressor Guide AICIP and CAAA - Guidelines and Requirements For Asset Management of Pressure VesselsDocumento4 páginasAir Compressor Guide AICIP and CAAA - Guidelines and Requirements For Asset Management of Pressure VesselsTim WilsonAún no hay calificaciones

- JXN ITR-A Piping PDFDocumento21 páginasJXN ITR-A Piping PDFAmyAún no hay calificaciones

- Leak Test PipingDocumento1 páginaLeak Test PipinguknowAún no hay calificaciones

- Sample of Corrosion Mapping Using Thickness Gauge Grid FileDocumento3 páginasSample of Corrosion Mapping Using Thickness Gauge Grid FileBagus HadiwibowoAún no hay calificaciones

- Flange ChecklistDocumento9 páginasFlange ChecklistxaviAún no hay calificaciones

- Anaesthetic Machine ChecklistDocumento1 páginaAnaesthetic Machine ChecklistSanj.etcAún no hay calificaciones

- Unitor ASSEMBLY MANUALDocumento6 páginasUnitor ASSEMBLY MANUALSvetlana TAún no hay calificaciones

- Charging of RefrigerantDocumento14 páginasCharging of RefrigerantMARIO BULANADIAún no hay calificaciones

- 514 - Painting of Structural Steel (2012) PDFDocumento21 páginas514 - Painting of Structural Steel (2012) PDFDanilo de JurasAún no hay calificaciones

- Standards Information Booklet: Fabricating of Steel Structures (Plating) National/Scottish Vocational QualificationDocumento51 páginasStandards Information Booklet: Fabricating of Steel Structures (Plating) National/Scottish Vocational QualificationDanilo de JurasAún no hay calificaciones

- Work Permit System: Saudi Arabian Oil Company (Saudi Aramco)Documento7 páginasWork Permit System: Saudi Arabian Oil Company (Saudi Aramco)Danilo de JurasAún no hay calificaciones

- General Instruction Manual: Organization Consulting DepartmentDocumento12 páginasGeneral Instruction Manual: Organization Consulting DepartmentDanilo de JurasAún no hay calificaciones

- 0006 - 005 RevDocumento14 páginas0006 - 005 RevDanilo de JurasAún no hay calificaciones