Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Quemadores Charles A. Hones Buzzer Catalog

Cargado por

Eduardo Alberto Fiadino0 calificaciones0% encontró este documento útil (0 votos)

10 vistas26 páginasCatálogo de quemadores marca Charles Hones Buzzer

Título original

Quemadores Charles a. Hones Buzzer Catalog

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCatálogo de quemadores marca Charles Hones Buzzer

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

10 vistas26 páginasQuemadores Charles A. Hones Buzzer Catalog

Cargado por

Eduardo Alberto FiadinoCatálogo de quemadores marca Charles Hones Buzzer

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 26

Girls A. Hones, Inc.

Manufacturers of Industial Gas Equipment

i. Burners

So where's the “Buzzer” in these burners,

anyhow?

We keep saying it, and It's true: Hones’ Venturi burners are exceptionally quiet, as operation

requires no blowers or compressed air. So why do we call them Buzzer burners? Well, my

grandfather told me his grandfather had told him this story:

It was late one evening in the early 1900's, and our

founder Charles A. Hones had been indulging his

passion for testing his newly developed Bunsen

burners in the kitchen of his Brooklyn apartment for

hours. Now in those days, the gas supply was a far

cry from what you'd find in a contemporary kitchen.

‘The old Brookiyn “water gas” was valued

at only about 440 BTUH/ft* compared

to the 2,500 BTUH/ft’ rating of modern

propane and was used more for lighting

than heating. It also contained

considerable impurities, causing it to Charles A. Hones

sputter, whistle and pop a bit as it

burned. Anyhow, it seems the notse was

more than Mrs. Hones could bear to hear

coming out of her kitchen until all hours.

Raising her voice above the din, she

christened his burners: “Charlie, it’s late!

‘Turn that buzzer off and come to bed!”

Founder of our

family’s company,

which was then

Incorporated in 1911.

‘And so buzzer it was, and buzzer it remains. We keep calling them Buzzer burners in honor

of Charles A. and the dedication to performance that drove him. But you can rest assured

you won't hear a bit of buzz from your new burner - the purity of our modern gas supply

‘ensures whisper quiet operation even Charlie would have loved. So now you know!

At your service! - The family business today

R. Michael Hones Susan E, Hones Robert A. Hones

4th generation 4th generation 5th generation

&

Key

Venturi Air Mixer 1

Venturi Nozzle Burner 3

Immersion Heater Burner 5

Venturi High Pressure Nozzle Burner 8

Pipe Burner with Venturi Air Mixer 10

Raised Port Ring Burner 13

Radial Burner 14

Discport Burner 15

Rectangular Burner U7.

Plain Air Mixer 18

Pipe Burner with Plain Air Mixer 19

Ring Burner 21

Urn Burner 22

Venturi Air Mixer hes Se

“scompid ne SS

‘The Buzzer Venturi air mixer operates

efficiently on natural or propane gas to

produce a hot blue flame. Our Venturi is

recommended by natural gas companies,

service technicians, propane suppliers

and equipment manufacturers because it

is durable, efficient, and simple in design.

It inspirates a greater amount of primary

combustion air through the mixing tube,

requiring less secondary (make-up) air in

the combustion chamber. A very high

rate of efficiency is obtained, producing aol

the hottest and quickest heat without a

blower. With more than a dozen standard ‘i

sizes (all made of rugged cast iron), the ee Pasa

Buzzer Venturi is the time-proven answer

to all your heating questions: since 1911,

Hones is how.

Features

‘The Venturi air mixer is manufactured on Long Island, New York, using class 30

grey cast iron. Our simple all cast iron construction will withstand high ambient

temperatures and provide the durability and ruggedness expected of a Buzzer

engineered product. The standard Buzzer Venturi mixer will operate on either low

or high (above 1 PSI) pressure natural or propane gas.

Standard Venturi

All standard Venturi mixers come equipped with a fixed brass orifice. In most cases

we will supply a #70 guide hole unless a different drill size or BTU output is

specified. The advantage of a fixed orifice is that it will provide a pre-determined

BTU output that cannot be mistakenly altered. If a change in orifice is needed, (for

instance when switching from natural gas to propane), the orifice assembly can be

removed without disconnecting the Venturi mixer from the gas line (sizes 1"- 6”

only).

‘The standard Buzzer Venturi comes with NPT pipe connections on both inlet and

outlet. Standard NPT pipe threads allow for both easy installation, using readily

available pipe fittings, and easy replacement of worn parts. Note: the machined

outlet on the cast iron Venturi is a male pipe thread ranging from '/." to 6”

diameter. However, a steel coupling is supplied on the outlet end both to protect the

male pipe threads and to facilitate simple installation to a threaded pipe.

1s

ae Venturi Air Mixer

Ve \-

‘Mer gcbanens Since

N-type Venturi

For the most demanding applications, we offer our Buzzer N-type Venturi. The N-

type Venturi is specially machined with an extra-wide mixing throat, which allows it

to inspirate additional primary air for increased BTU output. We manufacture N-

type Venturis in the most popular sizes, including 1'/.", 1'/2" and 2”; all are made of

durable cast iron.

Applications

Industrial applications for the Buzzer Venturi air mixer include melting furnaces, heat

treating furnaces, forging equipment, casting ovens, ceramic kilns, as well as heating

tanks, chemicals, liquids, and various solutions from black oxide to hot rinse tanks.

Commercial applications include pizza ovens, bakery ovens, rotisseries, BBQ's,

cookers, roasters, scalders, boilers, steam tables and kettles. The durable cast iron

Venturi is also used on most equipment manufactured by Charles A. Hones, Inc.

pe see in inches Leng im nes ‘Weightim pounds Gas connection in inches_—_«U pr bur in 10008

he Phe os Ys 5 to 10

he 9 1 Ve 10 to 20

1 1 Vhs Ve 15 to 35

Vhs 14 De fe 25 to 65

L/.N type 4 4 fs 35 to 75

Ve 15 Bi “Ie 40 to 80

1/2 N type 15, 5 “se 50 to 120

2 18'/a 6 Ye 60 to 150

2N type 19 Bi Va 70 to 175

Bh 23'/. u 1 90 to 180

3 27'/. 15'/2 1 125 to 300

4 35'/s 35 Ve 250 to 600

6 46 70 Va 600 to 1,250

Please note: length is figured from end of coupling to end of nipple. Sizes from 1/2" to 3” are available with

adjustable orifices. Ranges of gas consumption shown are those at which these Venturi air mixers are designed

to give their best efficiency using low pressure gas (under 1 PSD; there are conditions, however, under which it

is not advisable to go to the maximum.

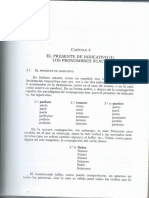

1. No

gosonet_ NOCOMPrESSe

Venturi Nozzle Burner

10'/2

‘VNB 100 ¥ 11 13

A

‘VNB 125 oe 14'/s 16°/s

VNB 150 il 15'/2 18

B ‘VNB 200 14 20 22/2

‘VNB 250 17s 23/5 26'/s

Cc ‘VNB 300 19'/« 28 31's

‘VNB 400 25'/2 36'/2 40'/2

‘VNB 600, 23 52 57

ME ma RSsunkh« palthiaes emeuueteas Bie aees nee

nc as

‘VNB 50 Ya Vf/o 1 Js 9

VNB 75 Ys 12*/2 VA Ie 15

‘VNB 100 1 15 Vhs ds 25

‘VNB 125 ye 19 5 Ye 50

VNB 150 Vf 22 Bh Ys 65

‘VNB 200 2 26/2 l/s ‘Ya 100

‘VNB 250 Bo 33 19%/+ 1 150

‘VNB 300 3 39'/s 32 t 250

‘VNB 400 4 53/2 70 vA 500

‘VNB 600 6 75/2 129 Vh 1,250

Pauls ah igoa tos GAO Goa oan Ul dg GAL Sees eae a a

crap er Sp rear Pre eee acer erent er ahenp

Immersion Heater Burner ="

Immersion heater burner with pilot and safety valve.

The classic method of applying heat to a liquid by firing a gas burner into a

submerged coil was pioneered by Buzzer engineers, as well as other manufacturers,

almost 70 years ago. The immersion burner concept was first developed as a means

of converting early steam-heated tanks to gas heat back in the early 1930's. Today,

the immersion burner method of applying heat to a liquid can deliver efficiencies

that approach 80% when combined with modern lightweight and highly insulating

refractories, microprocessor-based digital controls, and proper coil length and

design.

‘The Buzzer immersion heater burner provides a strong and efficient torch type

flame using low pressure natural or propane gas. It provides quick intense heat

with a wide range of flexibility. By firing into the submerged flue coil, the available

heat is concentrated and rapidly transferred into the liquid, minimizing heat loss.

‘The all cast iron construction provides a husky burner suitable for machine shop,

tool room, and other industrial environments.

Features

All Buzzer immersion burners come equipped with the Buzzer Venturi air mixer,

made in the USA of class 30 grey cast iron. Engineered for efficiency, our Venturi

mixes combustion air at atmospheric pressure for the quickest and hottest flame

without a blower, The Buzzer Venturi inspirates maximum primary air to require

less secondary air in the combustion chamber, operates without flashback, provides

excellent turn-down, and delivers a superior “Bunsen blue” flame.

Immersion heater burners also include a cast iron adapter which secures the

burners to the proper sized coil. The cast iron adapter is designed to allow both

secondary and make-up air to come freely around the nozzle, helping to keep the

nozzle cool and extending its productivity. The open and simple design of our cast

iron adapter secures tightly to the coil and to the nozzle. This unique Venturi style

burner is both rugged and simple and can be fitted with flame safety, spark ignition,

and temperature controls which are readily available for your convenience.

5s

se, Immersion Heater Burner

\\

‘Sti estan one

Applications

‘The Buzzer immersion heater burner is

primarily used for heating liquids, including

water, oils, detergents, chemicals, and other

solutions. It is commonly used for

evaporators, asphalt heating, degreasing

tanks, quench tanks, black oxide tanks,

plating tanks, dip tanks, boilers, and spray

washers. It is also used in limited

commercial and air heating applications for

heating green houses, storage areas, and

specialty ovens. Immersion heater burners

are also used in food preparation with Genndard ieyeue'cusieing cll

stainless steel coils for boiling seafood, submerged within an

poultry, bagels, vegetables, and meat prior insulated welded steel tank.

to smoking.

Moe LPS. Col sze colt ent ‘Weight in pounds (Gas connection [BTU pee hour in

infect nines 1000

IH-100 2 Bis Bh Is 25

1H-125 3 Bia o/s “he 50

TH-150 3 9 By fe 65

1H-200 4 ny 18 th 100

TH-250 5 13/ 30 1 150

IH-300 6 18/+ 39 1 250

IH-400 8 av) 85 Lh 400

Please note: universal ratings are for straight burners with “N” type nozzle operating on low pressure gas.

‘90° ells can be supplied but will soften flame. To get a flame {dentical to that of a straight burner, use “N" type

‘Venturis, or reduce input as follows: IH-100, and IH-125 by 15%; IH-150 by 10%; TH-200 by 5%; remaining

burners are unchanged. Adapters for oversize colls are available for a nominal additional charge. Pressure

gauges with 2'/:" dial available for 0-15" w/c and 0-60" w/c.

+66

; Nocompr

yo owet Pred ap

Immersion Heater Burner

onplcd ppg S18"

Immersion burner dimensions

A: Width of cast iron adapter

B: Length of cast iron adapter

C: Length from adapter to Venturi, including elbow

D: Length from cast iron nozzle to end of Venturi in 90° ell layout

E: Length from cast iron nozzle to end of gas cock in 90° ell layout

F: Length from tip of cast iron adapter to end of Venturi in straight layout

G: Length from tip of cast iron adapter to end of gas cock in straight layout

H: Minimum distance coil must protrude from tank to slip into adapter properly

I: Coil size - schedule 40 pipe (L.P.S.)

Burner 4 B © > e r e H 1

TH-100 3 3 8 ll 12%/ 14fs 16'/e She 2

TH-125 4 B/2 P/s 14 16°/s 18°/s Qf. Ys 3

TH-150 4 Bir 12 15'/s 18 aus 23%/s Sls 3

TH-200 Bi/s By. 15'/« 17, aus 27s 30 Me 4

TH-250 Css 7 M/s 23'/s 26°/. 33'/2 36/2 "he 5

TH-300 Pls Th 21 26 31's 39'/. 42'/2 1 6

TH-400 D/a 12'/s 30 36'/2 40'/> 53 57 Vs 8

Please note: all measurements on this chart are in inches:

77+

« Venturi HP Nozzle Burner

‘Venturi high pressure burner with pressure gauge and needle valve

‘The Buzzer high pressure nozzle burner offers a powerful and efficient torch type

flame using high pressure (1 PSI and above) natural or propane gas. The high

pressure burner provides a quick and very intense heat without the need for

blowers, compressed air, or complicated piping. Our all cast iron construction and

flexible Venturi design make them ideal performers in the metal working, foundry,

forging, heat treating, glass, and ceramic fields.

Features

High pressure nozzle burners come equipped with our retaining port nozzle. This

unique nozzle is designed with a series of small retaining ports encircling the main

exit port. The recessed design and angle position of the retaining ports prevent the

main flame from being blown off the nozzle. This self-piloting design provides a

stable flame operating on gas pressures exceeding 25 pounds. Burner output can

be increased simply by increasing the gas pressure. As you can see in the

accompanying orifice chart, a VNB 200-HP operating at 5 PSI is rated at 280,000

BTU/hr., while the same burner operating at 15 PSI is rated at 480,000 BTU/hr.

Buzzer high pressure nozzle burners come equipped with either a heavy duty

needle valve ('/s", '/+", #/s", and '/:” sizes) or a globe valve (1” and 1'/." sizes). These

valves are made of brass and provide a very accurate degree of turndown. The

“needle” valve may be of particular interest to potters, kiln users, and those who

require both fine tuning and measurability in order to replicate heat conditions in

subsequent firings.

Venturi HP Nozzle Burner

Pre-packaged burner with safety valve,

pressure gauge, and pilot.

otto NOMI

“ccomtcctggng SO"

Applications

The Buzzer high pressure nozzle burner can be positioned to fire horizontally or

vertically (upwards).

ell if space is limited. If the application calls for firing vertically down (toward the

It can be supplied as a straight burner or equipped with a 90°

floor), burners can be equipped with a 45° ell so that the Venturi remains horizontal

and the nozzle can be positioned to fire down at a 45° angle. Venturi nozzle burners

are commonly used as high powered torches for singeing, flame treating, pre-

heating, and ladle/crucible heating, They are widely used in heat treating ovens,

foundry equipment, metal melting furnaces, glass annealing kilns, and pottery kilns.

Natural

cy ae ste Fr o#tleaimensions |

wos UE per ee een

‘VNB 50-HP 73 is) 5 12 16 20 25 HPS5O ‘fe UA V/s

‘VNB 75-HP 66 70 9 20 29 35 46 HP75 hs V/s ha

‘VNB 100-HP = =60. 63 16 35 50 61 78 HP100 1 1/5 Bhs

‘VNB 125HP 50 53 41 94 130 160 210 HP12 V/a V/s Qs

VNB 150-HP 9-43. 48 68 150 212 250 310 HP150) l/s /e QWs

‘VNB 200-HP —"/s 38 125 280 390 480 620 HP200 2 2/0 Ba

VNB 250-HP 29 32 160 360 500 620 800 HP250 2'/2 ay as

‘VNB 300-HP 17 26 260 580 820 1,000 1,300 HP300 3 ass 5

‘VNB 400-HP 3 16 360 840 1,200 1,500 1,900 HP400 4 6 BY

‘VNB 600-HP */w Pp 1,000 2,500 3,500 4,800 5,300 HP600 6 8 8

0-15" w/c and 0-60" w/c,

Please note: these nozzles are use with Buzzer Venturi air mixers on air heate-s to retain burner flames under

suction, Measurements given in inches. Pressure gauges with 2'/:" dial available: 0-15 PSI, 0-80 PSI, 0- 60 PSI,

ee Pipe Burner with

x Venturi Air Mixer

¢

barnes, Since

Pipe burner equipped with cast iron legs

‘The Buzzer pipe burner equipped with our Venturi air mixer provides a simple and

efficient way to heat a large variety of processing tanks, Our pipe burners can be

used to heat tanks constructed of carbon steel, cast iron, or stainless steel. With

some 50 standard sizes and an almost limitless number of custom modifications,

Buzzer pipe burners can be used to heat large, small, square, rectangular, sloping,

V-bottom, or any specialty shaped tank. Pipe burners provide a very uniform heat

source and represent one of the simplest, most cost-effective ways to apply heat in a

wide range of applications.

Features

‘The pipe burner includes a precisely drilled burner pipe, pipe cap (or welded plug,

on larger sizes), cast iron Venturi air mixer, and quarter turn gas cock. Cast iron

legs (as shown in photograph) are available for all standard sizes for an additional

fee. Our cast iron legs offer secure placement and easy installation. They are

shipped loose and attach quickly and easily to the burner pipe using a simple set

screw.

All standard pipe burners are fabricated of sturdy schedule 40 black steel pipe.

Custom pipes can be fabricated of stainless steel in order to meet the unique needs

of various applications such as industrial heating or commercial cooking.

Our standard burner pipes are manufactured using a combination of automated

machine drilling and precision hand drilling to ensure accuracy and a professional

appearance. Buzzer plain drilled pipe burners come standard with a single row of

drilled ports (1'/." and smaller) or a double row of drilled ports (1'/2" and larger).

Buzzer plain drilled pipe burners provide rapid lighting, a stable and uniform flame,

a wide range of turn-down, and excellent on/off cycling for use with the latest flame

monitoring systems and temperature controls, Our pipe burners can be set up to

operate on either natural or propane gas, requiring only a simple orifice change to

convert from one gas to the other. All Buzer pipe burners come equipped with the

Buzzer Venturi air mixer, made in the USA of class 30 grey cast iron. Engineered

for efficiency, our Venturi mixes combustion air at atmospheric pressure for the

quickest and hottest flame without a blower. The Buzzer Venturi inspirates

maximum primary air to require less secondary air in the combustion chamber,

operates without flashback, provides excellent turn-down, and delivers a superior

“Bunsen blue” flame. S04

Pipe Burner with =e

Venturi Air Mixer

iclppme SB

Pre-packaged burner with legs, 90° ell,

Buzzer pilot and safety valve.

Applications

Buzzer pipe burners can supply efficient gas heat for many industrial heating

applications, including casting ovens, OEM heating equipment, low temperature

ovens, plating tanks, black oxide tanks, evaporators, and cleaning tanks. Additional

heating applications include bakery ovens, food processing, commercial cooking,

singeing, flame treating, heat processing, pre-heating, curtain burners and pilots.

Multiple pipe burner with Venturi air mixers

with Baso™ safety set, solenoid valve,

and Buzzer cross-flame pilot

at eating

for he

08

ot

Pipe Burner with

Venturi Air Mixer

¢

"St gtanan Since

Gas BTUs per Gas TVs per

ee eee Ne cee Ko nae "eee tiene “nates 100

Ye 12 23%/s hs 7 Ph 48 6r/. os 55

fe 16 27/6 Ye 8 Bh 84 73%. fs 60

Ye 20 31's ‘fe 9 Lh 60 79°/s ss 65

fs 12 25'/s ‘he a 2 36 59'/. ‘h 62

%s 18 ars Ye 12 2 42 65/1 Ye co)

%s 24 36'/s Ys 13 2 48 m/s Ye 80

of 30 42'/s Ye 15 2 54 Is fe 83

1 18 33°/s Ye 13 2 60 83'/. A 86

1 24 39%/s Ys 16 2 66 89'/. s 90

1 30 45%/. Ys 20 2 2 96'/. he 93

1 36 51"/s Me 22 2 84 108%. fs 100

1 42 BT'/s hs 24 2 72 99'/. 1 106

1 48 63"/s oA 25 af 84 112 1 14

1 50 65"/s ss 30 2h 96 124/s 1 ug

bys 24 42"/0 4s 47 af. 108 187°/. 4 121

Lh 30 48*/5 fe 22 2s 120 150'/s 1 130

Lh 36 54/5 fs 26 Qf. 132 163 1 140

Ly 42 60'/s ss 31 ah 144 176/. 1 150

Lhe 48 66"/s “fs 40 3 84 1168/2 1 123

Lh 54 72/6 “fs 50 3 108 142'/s 1 146

Lip 18 87s fs 28 3 132 164/s 1 149

Lh 24 43°/4 % 36 3 156 (194/s 1 164

Lip 30 49%/. of 45 3 180 220*/s 1 188

Vp 36 85"/. of 50 3 204 246'/2 1 200

Vp 42 61/s “f 58 38 228 —-268'/s 1 250

Please note: total length is from end of Venturi air mixer to end of cap, not including gas cock. For gas cock,

‘add approximately 12/1" for '/:",°/<" and 1” burners: add 2'/.* for 1'/*, 1'/a" and 2° burners. ‘Height of legs is 4”

for t/2".*/¢" and 1° burners; 7'/." for 1'/s*, 1'/:" and 2° burners. Pressure gauges with 2'/." dial available for

0-15" w/e and 0-60" w/e. sis

Raised Port Ring Burner »=“"“«

Ao, g

pad pg. SH

‘The Buzzer raised port ring

burner is the Clydesdale

workhorse of our industrial

ring burner family. They are

ideal for use in high ambient

temperatures where resistance

to radiated heat is required.

Each ring is constructed of

cast iron to provide exceptional

strength and ruggedness,

making them dependable

performers in the metal

working industries, heat

treating, tool room, and

foundry.

‘V15 raised port

ring burner assembly

Features

All five standard sizes feature raised cast iron ports which produce short, tight

flames requiring minimum head space and combustion space. The raised port ring

burner is also designed with ample space between each burner ring to allow

secondary and make-up air to pass up in between individual rings, which

contributes to shorter, more efficient and uniform flames.

Our raised port ring burner is equipped with the Buzzer Venturi air mixer, made in

the USA of class 30 grey cast iron. Engineered for efficiency, our Venturi mixes

combustion air at atmospheric pressure for the quickest and hottest flame without a

blower, The Buzzer Venturi inspirates maximum primary air to require less

secondary air in the combustion chamber, operates without flashback, provides

excellent turn-down, and delivers a superior “Bunsen blue” flame.

Buzzer raised port ring burners can be set up to operate on either natural gas or

propane. Ideal for heavy duty OEM heating equipment, these rugged high output

cast iron burners are easily converted from one gas to the other is desired.

Applications

Buzzer raised port ring burners are used to supply gas heat for tanks, kettles, and

furnaces for a variety of applications from metal melting to micro-brewing.

Applications include cleaning tanks, hot rinse tanks, black oxide tanks, quench

tanks, pre-heating, heat exchanges, boilers, and flame treating.

Dae “Tar Tragie Weight aa conneton BT per Bou

Mode! Rings In tnces tn ines tn tnches pounds in inches ‘1.000%

vi 1 Sh 21/s 6h 12 fe 47

vi2 2 of 28 7 34 ve 122

vis 3 14/4 31 7 66 ve 232

vis 4 19°/« 33'/2 7 112 Lh 382

vis, 5 24°/+ 42 Zz 200 2 532

Please note: To order burners with special combinations, speciy ring to be omitted. For example, V19 less V1

will contain the V13 and V12 rings only. Pressure gauiges with 2'/:" dial available for 0-15" w/c and 0-60" w/c.

+136

sone AR tg

Radial Burner

\\-

"Stigma Snce

811 radial burner with gas cock

‘The Buzzer radial gas burner offers cast iron port construction to outlast and outperform

mass-produced burners made of stamped-out sheet metal when resistance to radiated

heat is required. Our radial gas burners are designed for rugged and dependable

performance in high ambient temperatures. They are appreciated by both the industrial

metals industry and the commercial cooking industry for providing high BTU output

combined with economical design.

Features

‘The radial burner head is constructed of cast iron and features raised cast iron ports

which produce short, tight flames, requiring minimum head space and combustion space.

Slotted burner head design allows secondary and make-up air to pass through the center,

producing shorter, more efficient and uniform flames. The free movement of secondary air

around the burner head helps to keep it cool and extend its productivity.

All radial burners are equipped with the Buzzer Venturi air mixer, made in the USA of

class 30 grey cast iron. Engineered for efficiency, our Venturi mixes combustion air at

atmospheric pressure for the quickest and hottest flame without a blower. The Buzzer

‘Venturi inspirates maximum primary air to require less secondary air in the combustion

chamber, operates without flashback, provides excellent turn-down, and delivers a

superior “Bunsen blue” flame.

Applications

Buzzer radial burners can supply gas heat for vats, tanks, kettles, and furnaces for a

variety of applications from metal melting to micro-brewing. Common applications include

cleaning tanks, hot rinse tanks, black oxide tanks, quench tanks, pre-heating, boilers, heat

exchanges, and flame treating.

Dame Ta Taga Waar Tas Connection TT per Rou

Model In aches sn inehes sn inehes sn pounds inimenen 1.110008

vi06 6 15. ae 5 Ye 33,

307 7 19 6 Bi/e a 60

308 8 20 6 wih ss 75

311 12 26 7 20 fe 100

312 16 33 7 42 Uf 180

313 21 33 i 52/2 Lh 270

Please note: diameter of 313 listed is at the widest point. Narrowest point measures 16 inches. Optional stand is 4°

in diameter and increases height 2 inches. Pressure gauiges with 2'/2° dial available for 0-15" w/c and 0-60" w/c.

+ 14-

Discport Burner ete My

605 discport burner pre-packaged with

optional stand, pilot, and safety valve

{top port style)

‘The Buzzer discport burner is designed to provide a large volume of heat within a tight

combustion chamber. Our simple discport burners have been steady workhorses for

over 85 years, providing quick and intense heat for a wide variety of industrial heating

applications, ‘The flexible discport burner is easily modified to operate on high pressure

natural or propane gas (which at 5 PSI will double the listed BTU output). The discport

burner is also available with two styles of “space-saving” cast iron burner heads.

Features

‘The discport burner comes with one of two different “space-saving” burner heads,

depending upon the model chosen. Our original style cast iron head (see

accompanying photograph) produces a circular flame slightly smaller than the burner

diameter. This circular flame is not as focused or as concentrated as a torch-type

flame, making it softer on applications in which flame impingement occurs. Our

original discport burner head is constructed of thick cast iron and will perform well in

high ambient conditions.

‘The newer style burner head (designated with the suffix “A’) is available on all five

standard sizes. Our A-style burner head produces a shorter and wider flame pattern.

This shorter pattern is ideal for combustion chambers in which vertical head space is

highly limited, Our newer style head (see accompanying photograph) produces a 360°

flame generated from between the top and bottom section of the burner. This uniform

flame pattern is about 6 inches larger than the diameter of the burner head. Our A-

style burner head is also constructed of thick cast iron and will perform well under

high ambient conditions.

‘The discport burner can be set up to operate on natural or propane gas. Conversion

from one type of fuel to the other requires only a simple orifice change.

+ 15+

&

%

oc rel etn

“82s burners. Since

Sing

i

Discport Burner

GO6A discport burner

(side port style)

Applications

The Buzzer discport burner can supply efficient gas heat for tanks, kettles, and

furnaces to meet the need of a wide variety of industrial applications. Common

applications include: die casting machinery, battery manufacturing, and other

metal melting equipment. They are also commonly used on cleaning tanks, hot

rinse tanks, evaporators, boilers, heat exchangers, asphalt melting, pre-heating,

singeing, and flame-treating applications.

ee Bee a a et ee Rs

605, v/s 19 7 10'/. “fs 50

606 5 22 Bf 14/0 he 80

607 8 28 10 30 1 125

608 8 33 i 40 t 175

605A. as 19 Th 10 wi 65

606A 5 22 9 14 he 100

607A 28 10'/2 30 1 150

ona 8 2 4 0 1 250

Please note: length is measured from end of burner head to end of gas cock. Height is from bottom of ell to top

of burner head. Ratings for Nos. 605A through 607A can be increased slightly in the fleld during installation by

raising adjustable cover and enlarging orifice. Ratings will then increase from about 10% on No. 605A to about

20% on No. 607A. Pressure gauges with 2'/:° dial available for 0-15" w/c and 0-60" w/c. Optional stand is 4”

in diameter and adds 3 inches to height.

+166

jontt_Nocompresed

Rectangular Burner

“compcespiing. SI

‘The Buzzer rectangular gas burner offers cast iron port construction to ensure our

burner will outlast and outperform mass-produced burners made of stamped-

out sheet metal when resistance to radiated heat is required. Our rectangular gas burners

are designed for rugged and dependable performance in high ambient temperatures. They

are appreciated by both the industrial metals industry and the commercial cooking

industry for providing high BTU output combined with affordable and economical design.

Features

‘The rectangular burner head is constructed of cast iron and features raised cast iron ports

which produce short, tight flames, requiring minimum head space and combustion space.

Slotted burner head design allows secondary and make-up air to pass through the center,

producing shorter, more efficient and uniform flames. The free movement of secondary air

around the burner head helps to keep it cool and extend its productivity.

Rectangular burners can be set up to operate on either low pressure natural or propane

gas. Conversion from one type of fuel to another requires only a simple orifice change,

easily accomplished in the factory or out in the field.

Applications

Buzzer rectangular burners can supply gas heat for vats, tanks, kettles, and furnaces for a

variety of applications from metal melting to micro-brewing. Common applications include

cleaning tanks, hot rinse tanks, black oxide tanks, quench tanks, food processing, low

temperature salt baths, pre-heating, boilers, heat exchanges, and flame treating, In

general, our rectangular gas burners with cast iron burner heads can replace lesser quality

sheet steel stampings which quickly burn through in high heat applications.

Tahar

Mode bbumer head Length Height Weight Gas connection TW per hour

‘minches inches snvinches sn pounds imines in 1.0008

114 i/o By ah af Ye 30

314 w/a 16 7 16/« ha 90

315 Bf 12. Bile 10 fe 50

ase note: engi stad is for burner head. Total ngs inching gas cock are: 16° for 114,26" for 14 and 21°/:" for 815.

stand i four inches in dlameter and adds three inches to height. Pressure gauges with 2/:" dal avadable for 0-15" w/cand G60" w/c.

217+

ont or et tetng

ss

Plain Air Mixer

fe .

“i gacbamen Sine

‘The Buzzer plain air mixer is made of

rugged cast iron and can be used on

either propane or natural gas to

produce a hot blue gas flame. Since

1911 our plain air mixers have found

frequent use supplying gas heat for

EL pizza ovens, bakery ovens, rotisseries,

cookers, BBQ's, scalders, boilers,

90M (left) and steam tables, and a variety of light

125M slip-on industrial applications.

Features

Our economical plain air mixer is still entirely made in the USA. Casting,

machining, and assembly are done by skilled foundry men and metal working

craftsmen. The Buzzer plain air mixer is manufactured of class 30 grey cast iron

and measures over '/s” thick in most sections to provide a durable, heavy-duty

mixer able to withstand high ambient temperatures. It is engineered to inspirate a

large volume of combustion air, requiring less secondary or “make-up” alr around

the burner flames. Our plain air mixer provides good turndown and operates

without flashback or coughing. The sturdy Buzzer cast iron plain air mixer can be

handled with traditional tools such as pipe wrenches and channel locks without

becoming twisted, crushed, dented or damaged. Our plain air mixers are supplied

with standard (NPT) pipe connections: no metric sizing, no fussing with RP pipe

threads or gaskets.

‘The 100M through 200M plain air mixers are designed to slip onto an unmachined

or unthreaded schedule 40 black steel or stainless steel pipe. Our mixer slips on

over the pipe and is secured using a simple set screw. These styles come equipped

with a machined hex brass spud. Unless otherwise specified, we will supply a guide

hole only (#70 drill size) as an orifice. The 50M through 90M plain air mixers are

designed to screw onto a threaded schedule 40 black or stainless steel pipe. All

pipe threads should be standard NPT (National Pipe Thread) for proper fit and

tightness. These smaller plain air mixers come standard with '/s" threaded inlets.

We stock our standard '/s” brass spud which comes with a guide hole only (#70 drill

size if no other size is specified).

ve oe en us conmcon en eae

50M ‘fe ‘fe ‘fe

75M hs ‘fe ‘he

90M. 1 ‘fe Ya

100M 1 Ys VA

125M Ve %e 1

150M. Vf “fo Vs

200M. 2 va De

Please note: special 50M, 75M and 90M slip-ons all have '/." threaded inlet unless otherwise specified.

+ 18 +

qotiowtt NOcOMpresed

Pipe Burner with

Plain Air Mixer

S

plicated piping. Sin

Pipe burner equipped with plain air mixer, gas cock and cast iron legs

‘The Buzzer pipe burner equipped with our plain air mixer provides both a moderate

amount of heat and a simple economical design to serve most commercial heating

and cooking applications. Our pipe burners are often recommended for outdoor

BBQ's, cookers, scalders, rotisseries, ovens, griddles, and a host of other

commercial and light industrial applications. With over 34 standard sizes from 12”

to 90" flame length, we manufacture a Buzzer pipe burner to meet most small and

large heating applications. Our rugged steel pipe burners provide a very uniform

and evenly distributed heat source and when combined with lava rocks (which

assist in further heat distribution for many cooking applications), they represent one

of the simplest and most cost effective ways to apply gas heat to a wide range of

commercial heating projects.

Features

‘The pipe burner includes a precisely drilled burner pipe, pipe cap, cast iron plain

air mixer, and quarter turn gas cock. Upon request cast iron legs (as shown in the

photograph) are available for all standard sizes. Our cast iron legs offer secure

placement and easy installation. The legs are shipped loose and are quickly and

easily attached to the burner pipe using a simple set screw.

All standard pipe burners are fabricated of sturdy schedule 40 black steel pipe.

Upon request, pipes can be specially fabricated of stainless steel in order to meet

individual requirements. Our standard burner pipes are manufactured using a

combination of automated machine drilling and precision hand drilling to ensure

accuracy and a professional appearance. 180° drilling is readily available upon

request. When pipe burners are being used with lava rocks, we recommend ports

drilled on 180° centers for optimum heat distribution. The 180° drilling will also

protect the ports (holes in burner pipe) from becoming clogged by grease or

drippings which fall through the lava rocks and down to the pipe burner.

aces HE ting

eS

Pipe Burner with

. << Plain Air Mixer

"rigas burners, SINCE

TTT

Pipe burner with slip-on mixer and gas cock

Applications

Buzzer pipe burners equipped with cast iron plain air mixers can supply a

moderate amount of heat to meet many commercial and light industrial

applications. Such applications include heating vats, tanks, kettles, steam tables,

griddles, BBQ's, ovens, rotisseries, cookers, and scalders. These economical

burners have been used for everything from melting waxes and chemicals for

cosmetic manufacturing to cooking apple pies and pancakes at large fairs and

carnivals.

Gas BTUs per Gas BTUs per

Pipe size Flame lenglh Total length connection hour in. | Pipesize Flame length Tota length connection hour in

ininches "“ininehes In inches”—ininehes’ 1,000 | ininches "in inches" In inches in oches’ 1,000

Ye 12 17 Ws 6 Vs 15 26 “fe 22

he 16 21 Ms 2 Vs 18. 29 Ss 24

h 20 25 Ms 8 Ih 24 35 fe 31

he 12 18/6 Me 9 Vhs 30 4l fs 39

% 18 24°/s Us 10 Mh 36 a7 ofa 43

sh 24 30°/s Ye n Lh 42 53 “fs 45

fe 30 36°/s Me 13, Ih 48 59 ofa 50

a 18 257/s Me n Mh 54 65 fa 55

1 24 317/s Ue 14 2 30 44 ‘he 55

1 30 3877/5 Me 7 2 36 50 ih 61

1 36 43°/s Ms 19 2 42 56 fe 65

a 42 49"/s se 20 2 48 62 fe 67

1 48 55"/s Ye 21 2 54 68 ‘f n

Vs 24 33/s oh 15 2 60 74 Ye 73

Ls 30 39°/s he 19 2 66 80 fe 76

Ve 36 45°/s She 22 2 72 86 Ya 79

Ve 42 51°/s he 26 2 78 92 he 80

Ls 48 57°/s oa 30 2 84 98 th 82

V/s 54 63°/s “Ye 34 2 90 104 % 85

Please note: total length is from end of plain air mixer to end of cap, nat including gas cock. For gas cock, add

approximately 1!/«" for '/2",3/° and 1” burners; add 3!/" for 1'/." and 1°/:" burners : and 3'/: for2" burners.

Height of legs is 4° for */2",*/«" and 1” burners; 7'/4" for 1'/«", 1'/2" and 2° burners. Pressure gauges with 2'/."

dial available for 0-15" w/e and 0-60" w/e.

+ 20 +

‘The Buzzer ring burner

provides quick, intense heat

and offers dependable all

cast iron construction.

Ring Burner

Designed to provide a

moderate amount of heat to

meet the heating needs of

our customers’ smaller

applications. ‘They are ideal

for installations in which

little head space (vertical

combustion space) is

available.

Features

#116 ring burner with raised port design, equipped

ryanet_ NOCOMPEAeY

npleact png SO

with pilot and flame safety shut-off valve.

Some features of our ring burners vary by model. The #112, #113, and #116 ring

burners feature raised cast iron ports which produce tight flames, requiring minimum

head space and combustion space. The #109, #110, and #111 ring burners feature

plain drilled burner heads, which provide adequate heat with an economical design. All

Buzzer ring burners have a slotted head design which allows secondary air to pass

through the center of the burner head, producing shorter, more efficient and uniform

flames. All ring burners have side port entry into the burner head, making them

appropriate for applications where little vertical space is available.

All of our ring burners are equipped with the Buzzer plain air mixer, made in the USA.

of class 30 grey cast iron. This simple economical mixer produces a hot blue flame with

a wide range of turndown. The plain air mixer is ideally suited to meet the heating

requirements of many commercial and light industrial applications. All ring burners can

be set up to operate on either low pressure natural or propane gas. Conversion from

one type of fuel to another requires only a simple orifice change.

Applications

Buzzer ring burners can supply a moderate amount of gas heat for tanks, kettles,

cookers, and food processing, as well as for heating water, oil, and other liquids. They

also find uses in laboratory and commercial heating applications ranging from heating

large glass beakers to heating professional style woks.

Diameter Length Hest Ween ‘Gas conneeton U8 per hour

Mosel finches sone sninches sm pout in mehes in 10008

109 as 10°/2 V/s 2a fn 10

10 Bie Ivf Bs 4 ts 15

ul Bs 16 Bs 5 Me 25

112 Pl 16/2 24 8 be 35

113 Pl. rf 2s fs of 50

116 12 28/0 4 30 ih 125

21

heat rating

ss tig Urn Burner

he .

"tereesbamen, Since

The Buzzer urn burner provides

quick, intense heat and offers

dependable all cast iron

construction. Sizes range from

11,000 to 60,000 BTU/hr. to

meet a wide range of heating

needs. Unlike many mass-

produced stampings, our all cast

iron burners will stand up to

high ambient temperatures.

Features

‘The #106, #107, and #108 urn #106 (left), and #4 urn burners

burners feature raised cast iron

ports which produce tight flames

requiring minimum head space

and combustion space. They also have a slotted head design which allows

secondary air to pass through the center, producing shorter, more efficient and

uniform flames. These models can be fitted with extension nipples to raise the

burner head closer to the item being heated. This will take advantage of better

efficiency and better heat transfer.

The #3 and #4 urn burners feature plain drilled burner heads which provide

moderate heat with an economical design. They have a single row of ports along the

outer edge of the burner head, allowing adequate secondary air around each burner

flame. These models are cast as one piece and offer a very simple design.

Our urn burner is equipped with the Buzzer plain air mixer and can be set up to

operate on either natural or propane gas. Conversion from one type of fuel to

another requires only a simple orifice change.

Applications

‘The Buzzer urn burner can supply a moderate amount of gas heat for tanks,

kettles, cookers, and food processing, as well as for heating water, oil, and other

liquids.

Top Tae Tiegh Wait Tas conn BIDE per

Model ‘inches sn inches tn pounds ‘a inches "000

3 3 3/5 Vs Ys 1

4 4 Bf 2 fe 20

106 6 Bi 4 Ye 30

107 7 Ths ess ye 45,

108 8 Bi/s Bf oe 60

Please note: height i from alr shutter to top of burner. Pressure gauges with 2:/* dial available for 0-15" w/e and 0-60" w/e.

+ 22+

Catalog 1608.01BR

Need further information or want to place an order? Our local

factory representative for your area, listed below, would be happy

to assist you. If no representative is listed, please contact our

Long Island office directly. We look forward to your call!

Tel: 631.842.8886

Fax; 631.842.9300

www.CharlesAHones.com

607 Albany Ave

P.O, Box 518

North Amityville, Long Island

New York 11701-0518

E-mail: info@charlesahones.com

También podría gustarte

- Introduccion Al Analisis Termico y de Fluidos Mediante Ansys PDFDocumento152 páginasIntroduccion Al Analisis Termico y de Fluidos Mediante Ansys PDFJuan Carlos Castro Sandoval100% (3)

- 1 Ficha 1 Lectura RecetaDocumento4 páginas1 Ficha 1 Lectura RecetaRosa DrowaAún no hay calificaciones

- Libro Mecanica de Medios Continuos PDFDocumento348 páginasLibro Mecanica de Medios Continuos PDFJhon Alvarez100% (1)

- Libro Mecanica de Medios Continuos PDFDocumento348 páginasLibro Mecanica de Medios Continuos PDFJhon Alvarez100% (1)

- Ups - ST003497Documento60 páginasUps - ST003497Eduardo Alberto FiadinoAún no hay calificaciones

- TFG I 258Documento154 páginasTFG I 258aot1979Aún no hay calificaciones

- Tratamiento Primario Avanzado - Agua LatinoaméricaDocumento6 páginasTratamiento Primario Avanzado - Agua LatinoaméricaAndre RasAún no hay calificaciones

- Caracterizacion Suelos RegadosDocumento7 páginasCaracterizacion Suelos RegadosEduardo Alberto FiadinoAún no hay calificaciones

- 1 PDFDocumento245 páginas1 PDFToño NavarreteAún no hay calificaciones

- Valoración Físico-Química y Fitotóxica de Las Aguas Residuales Depuradas/regeneradas Destinadas Al Riego AgrícolaDocumento5 páginasValoración Físico-Química y Fitotóxica de Las Aguas Residuales Depuradas/regeneradas Destinadas Al Riego AgrícolaEduardo Alberto FiadinoAún no hay calificaciones

- Apuntes de Energia Solar Dpto Energia Electrica y Energetica Universidad de Cantabria PDFDocumento242 páginasApuntes de Energia Solar Dpto Energia Electrica y Energetica Universidad de Cantabria PDFEduardo Alberto Fiadino100% (1)

- Secuencia Un Cilindro Con TemporizadorDocumento13 páginasSecuencia Un Cilindro Con TemporizadorEduardo Alberto FiadinoAún no hay calificaciones

- Catalog Other&Tool HolderDocumento58 páginasCatalog Other&Tool HolderjorgeAún no hay calificaciones

- I IntrodEntornoDocumento12 páginasI IntrodEntornosantovaron123Aún no hay calificaciones

- FundicionDocumento31 páginasFundicionvictor fredyAún no hay calificaciones

- Manual Estufa SARA AutoconstructoresDocumento32 páginasManual Estufa SARA AutoconstructoresabextrAún no hay calificaciones

- Tolerancia S de FabricacionDocumento5 páginasTolerancia S de FabricacionpepopetaAún no hay calificaciones

- Trabajo VirtualDocumento9 páginasTrabajo Virtualhalkibrothers100% (1)

- Ocw - Usal.es - Educommons - Ensenanzas-Tecnicas - Ingenieria-Civil - Contenido - TEMA 8-TEORIA Y CALCULO DE ESTRUCTURAS PDFDocumento32 páginasOcw - Usal.es - Educommons - Ensenanzas-Tecnicas - Ingenieria-Civil - Contenido - TEMA 8-TEORIA Y CALCULO DE ESTRUCTURAS PDFhemarnoAún no hay calificaciones

- Accesorios FamiqDocumento5 páginasAccesorios FamiqEduardo Alberto FiadinoAún no hay calificaciones

- Electricidad y MagnetismoDocumento22 páginasElectricidad y MagnetismoEduardo Alberto FiadinoAún no hay calificaciones

- Automatismo de Motores TrifasicosDocumento10 páginasAutomatismo de Motores TrifasicosProductos LacteosAún no hay calificaciones

- Accesorios FamiqDocumento5 páginasAccesorios FamiqEduardo Alberto FiadinoAún no hay calificaciones

- Dialnet OptimizacionDeUnProtocoloDeExtraccionDeQuitinaYQui 4320335 PDFDocumento7 páginasDialnet OptimizacionDeUnProtocoloDeExtraccionDeQuitinaYQui 4320335 PDFRenan Gonzalez GutierrezAún no hay calificaciones

- Tabla de Tolerancias Iso 2768 MKDocumento27 páginasTabla de Tolerancias Iso 2768 MKAngel CurielAún no hay calificaciones

- Pequeñas charlas para montaje industrial: tolerancias y ajustesDocumento15 páginasPequeñas charlas para montaje industrial: tolerancias y ajustesJuliAn BolivAr100% (2)

- Ministerio de Energía y MineríaDocumento1 páginaMinisterio de Energía y MineríaEduardo Alberto FiadinoAún no hay calificaciones

- C5F08124B20FDocumento1 páginaC5F08124B20FEduardo Alberto FiadinoAún no hay calificaciones

- Charla Alumnos TALLER MecanicaDocumento27 páginasCharla Alumnos TALLER MecanicaRamiro Choque0% (1)

- WL 43165 Es EsDocumento30 páginasWL 43165 Es EsGermánAún no hay calificaciones

- Lectura Sopa Compartida 5to GradoDocumento1 páginaLectura Sopa Compartida 5to Gradocamposmaritza260712Aún no hay calificaciones

- Resumen Cocina 6500Documento1 páginaResumen Cocina 6500Arnau FernandezAún no hay calificaciones

- Las Endorfinas EscaneadoDocumento5 páginasLas Endorfinas EscaneadoAnaAún no hay calificaciones

- Vol 1 ASM Handbooks Iran-Mavad - Com (4140)Documento2 páginasVol 1 ASM Handbooks Iran-Mavad - Com (4140)Dave SanchezAún no hay calificaciones

- Matriz de Asignación de Enlaces para Las Jornadas de VinculaciónDocumento12 páginasMatriz de Asignación de Enlaces para Las Jornadas de VinculaciónLeonel PazmiñoAún no hay calificaciones

- Catalogo Sosa PDFDocumento64 páginasCatalogo Sosa PDFPancho Sagrera AlmuzaraAún no hay calificaciones

- La Bruja EnamoradaDocumento2 páginasLa Bruja EnamoradaCecilia HarrisonAún no hay calificaciones

- Dulces Sorpresas Recetario de Postres NestleDocumento147 páginasDulces Sorpresas Recetario de Postres Nestlejosegus1097% (150)

- Cómo hacer lasaña en casaDocumento3 páginasCómo hacer lasaña en casaJose Luis PinedaAún no hay calificaciones

- Manual de Operación y Mantenimiento Del Autoclave - 64705Documento156 páginasManual de Operación y Mantenimiento Del Autoclave - 64705Kevin VargasAún no hay calificaciones

- Manual de Gramática Italiana para HispanohablantesDocumento187 páginasManual de Gramática Italiana para HispanohablantesAna Ruiz Junquera100% (2)

- Urbanidad PDFDocumento22 páginasUrbanidad PDFSergio Andres Ramirez CorreaAún no hay calificaciones

- Manual de Preparacion Examen CISA 2008Documento700 páginasManual de Preparacion Examen CISA 2008MónicaCarolinaAcostaZambrano80% (5)

- Jordi Roca I Fontané: Repostero Restaurante El Celler de Can Roca (Girona)Documento3 páginasJordi Roca I Fontané: Repostero Restaurante El Celler de Can Roca (Girona)Ricardo MedinaAún no hay calificaciones

- Manual de Evaluación de Riesgos Por Fenomenos NaturalesDocumento209 páginasManual de Evaluación de Riesgos Por Fenomenos NaturalesDavid Prudencio MendozaAún no hay calificaciones

- Quiroz Manual de Ortopedia FuncionalDocumento117 páginasQuiroz Manual de Ortopedia FuncionalMaribel Méndez100% (1)

- Plan Semanal - 26 Al 30 de JulioDocumento3 páginasPlan Semanal - 26 Al 30 de JulioGabriel Buendia GallegosAún no hay calificaciones

- Manual Pratico de Diseño de FloresDocumento44 páginasManual Pratico de Diseño de FloresCarlos Alberto RodriguezAún no hay calificaciones

- Formato TezeDocumento5 páginasFormato TezeSimplicio GoncalvesAún no hay calificaciones

- Manual para Preparación CIA - Parte I - (2 de 5)Documento36 páginasManual para Preparación CIA - Parte I - (2 de 5)andreaAún no hay calificaciones

- Manual Aiwa NSX s777, s778Documento24 páginasManual Aiwa NSX s777, s778Jorge Cundapí Vicente33% (3)

- Prime Video Una Pizca de Magia - 2a TemporadaDocumento1 páginaPrime Video Una Pizca de Magia - 2a TemporadaAndrejs KurjanovicsAún no hay calificaciones

- Manual Gerencia Estrategica de NegociosDocumento206 páginasManual Gerencia Estrategica de NegociosYanina Maldonado MaldonadoAún no hay calificaciones

- Libros de Dominós FamososDocumento8 páginasLibros de Dominós FamososHilber MataAún no hay calificaciones

- 793D Manual Operacion y MantenimientoDocumento207 páginas793D Manual Operacion y Mantenimientofredy60% (5)

- Diagrama de Deposito Con TodoDocumento2 páginasDiagrama de Deposito Con Todoyuliana8riascosAún no hay calificaciones

- Presentacién Resumen Del Año Doodle Scrapbook Papel Blanco NegroDocumento11 páginasPresentacién Resumen Del Año Doodle Scrapbook Papel Blanco NegroRalph Salazar laveriano0% (1)

- Libros Necesarios para VivirDocumento3 páginasLibros Necesarios para VivirxXlilithXxAún no hay calificaciones

- Manual Tecnico Mercedes MB 100 (En Frances)Documento61 páginasManual Tecnico Mercedes MB 100 (En Frances)Alex Cardoso80% (5)