Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Mechanical Completion and Commissioning: Norsok Standard

Cargado por

Renzo VidalTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Mechanical Completion and Commissioning: Norsok Standard

Cargado por

Renzo VidalCopyright:

Formatos disponibles

NORSOK STANDARD

COMMON REQUIREMENTS

MECHANICAL COMPLETION AND COMMISSIONING

Z-CR-007

Rev. 1, May 1996

Mechanical completion and commissioning

Z-CR-007

Rev. 1, May 1996

CONTENTS

1 FOREWORD

2 SCOPE

3 NORMATIVE REFERENCES

4 DEFINITIONS AND ABBREVIATIONS

4.1 Definitions

4.2 Abbreviations

2

2

4

5 COMPLETION PRINCIPLES

5.1 Overall goal

5.2 Completion phases

5.3 Responsibilities

5.4 Common requirements

5.5 Documentation

5.6 Project Completion System (PCS)

5.7 Planning

4

4

4

5

5

5

6

6

6 MECHANICAL COMPLETION

6.1 Introduction

6.2 Documentation for a MC Package

6.3 Handover at Mechanical completion

6.4 Carry Over Work Register (COWR)

6.5 Typical Mechanical completion activities

6

6

6

6

6

7

7 COMMISSIONING

7.1 Introduction

7.2 Typical commissioning preparation activities

7.3 Commissioning procedure content

7.4 Commissioning documentation and handover to operation

9

9

9

9

10

ANNEX A MECHANICAL COMPLETION DOCUMENTATION

11

ANNEX B COMMISSIONING DOCUMENTATION

21

NORSOK standard

Page 1 of 26

Mechanical completion and commissioning

Z-CR-007

Rev. 1, May 1996

FOREWORD

NORSOK (The competitive standing of the Norwegian offshore sector) is the industry initiative to

add value, reduce cost and lead time and remove unnecessary activities in offshore field

developments and operations.

The NORSOK standards are developed by the Norwegian petroleum industry as a part of the

NORSOK initiative and are jointly issued by OLF (The Norwegian Oil Industry Association) and

TBL (The Federation of Norwegian Engineering Industries). NORSOK standards are administered

by NTS (Norwegian Technology Standards Institution).

The purpose of this industry standard is to replace the individual oil company specifications for use

in existing and future petroleum industry developments, subject to the individual company's review

and application.

The NORSOK standards make extensive references to international standards. Where relevant, the

contents of this standard will be used to provide input to the international standardisation process.

Subject to implementation into international standards, this NORSOK standard will be withdrawn.

SCOPE

This standard defines the principles and structure of Mechanical completion and commissioning.

NORMATIVE REFERENCES

ISO 9000 series standards

DEFINITIONS AND ABBREVIATIONS

4.1

Definitions

Normative references

Informative references

Shall

Should

May

Can

Project Completion System

(PCS)

NORSOK standard

Shall mean normative in the application of NORSOK standards.

Shall mean informative in the application of NORSOK standards.

Shall is an absolute requirement which shall be followed strictly in

order to conform with the standard.

Should is a recommendation. Alternative solutions having the same

functionality and quality are acceptable.

May indicates a course of action that is permissible within the limits

of the standard (a permission).

Requirements are conditional and indicates a possibility open to the

user of the standard.

Is a computerised system for electronic documentation of

Mechanical completion, commissioning and preservation by system,

subsystem, area, commissioning package, MC package and/or

individual tag.

Page 2 of 26

Mechanical completion and commissioning

System

Mechanical Completion

Status Index (MCSI)

Subsystem

Commissioning Package

MC Package

Commissioning (C)

Mechanical Completion

(MC)

Preservation

Factory Acceptance Test

(FAT)

Mechanical Completion

Certificate (MCC)

Mechanical Completion

Check Record (MCCR)

Punch List (PL)

Status "OK"

Status "NA"

Status "PA"

Status "PB"

Punch List Register (PLR)

Carry Over Work Register

NORSOK standard

Z-CR-007

Rev. 1, May 1996

An operational system or a non-operational system.

Operational systems are dynamic process, utility or facility systems

such as sea water, diesel, HVAC, telecom, main power and control

system

Non-operational systems are systems such as surface protection,

insulation, civil, structural steel, markings and signs, cable and

tubing trays.

This is a listing of all items/tags with associated check record status

for each MC (or commissioning) package. The MCSI should be

produced from the EDP based Project completion system.

A system broken down into functional subsystems.

A practical scope of work unit within a system or subsystem for

commissioning, constituting a functional unit which can be tested by

commissioning to confirm its suitability for operation.

A practical unit of the scope of work for one discipline within a

commissioning package.

Is the functional verification of equipment and facilities that are

grouped together in systems.

The checking and testing of equipment and construction to confirm

that the installation is in accordance with drawings and specifications

and ready for commissioning in a safe manner and in compliance

with project requirements.

The preventive maintenance carried out on equipment before it is

taken into use.

Testing to be performed at suppliers workshop to verify the

equipment's performance/functionality.

A MC Certificate issued by the Executor to document that his MC

scope has been carried

out. The MC Certificates shall be used per MC package.

A discipline checklist for the various equipment. These records form

the basis of the MC documentation. MC Check Records are prepared

for one or more items for recording of

the results from checking and testing performed during MC.

A Punch List describes incomplete work or malfunction of

equipment or construction.

This status means that this item is cleared and there is no further

work associated with this item.

This status means that the check is not applicable to the item

referenced in the Check Record (CR). The item may however be

applicable for subsequent executors.

This means that this check item is not completed, and that remaining

work is category 'A', i.e. must be completed prior to commissioning.

This means that this check item is not completed and that remaining

work is category 'B',

i.e. may be completed prior to or after commissioning.

A punch list register is a listing of all punch list items, prepared at a

time when installation, functions or activities should have been

completed.

A register where incomplete items are documented sufficiently for

Page 3 of 26

Mechanical completion and commissioning

(COWR)

MC dossier

Commissioning dossier

Executor

Z-CR-007

Rev. 1, May 1996

work preparation and completion. The COWR is based on the Punch

Lists Register and describes punch listed work to be transferred to

the next project executor.

MC documentation compiled in MC package.

Commissioning documentation compiled in Commissioning dossier.

An organisation, supplier, contractor that performs a predefined

scope of work.

4.2

Abbreviations

C

Commissioning

COWR

Carry Over Work Register

CR

Check Record

FAT

Factory Acceptance Test

MC

Mechanical Completion

MCC

Mechanical Completion Certificate

MCCR

Mechanical Completion Check Record (MCCR)

MCSI

Mechanical Completion Status Index

MSL

Material Status List

PCS

Project Completion System

PL

Punch List

PLR

Punch List Register

RFCC

Ready for Commisioning Certificate

COMPLETION PRINCIPLES

5.1

Overall goal

The overall goal of Mechanical completion and commissioning is to verify that the system is

designed and built to fulfil its purpose and specified requirements.

The completion execution and documentation shall have as a goal to fulfil "NPD" rules as given in

"Regulations for production and auxiliary systems".

Life cycle cost principles and safety should govern all decisions and actions.

Early establishment of commissioning packages is essential for an orderly and effective project

completion. The commissioning plan shall have maximum priority to enable reversed planning in

all project phases. All fabrication and installation planning shall be system oriented.

Mechanical completion, commissioning, FAT, Preservation and suppliers assistance requirements

shall be specified in the purchase orders.

Repeating of MC/C checks performed at suppliers and assembly sites should be avoided, wherever

possible.

5.2

Completion phases

5.2.1 Definition phase

In this phase the following is carried out:

Completion philosophy.

NORSOK standard

Page 4 of 26

Mechanical completion and commissioning

Z-CR-007

Rev. 1, May 1996

Coding structure and system breakdown.

Completion requirements to suppliers and contractors.

5.2.2 Engineering phase

In this phase the following is carried out:

Commissioning Package & MC Package definition.

Define commissioning network.

Produce commissioning procedures.

5.2.3 Suppliers completion phase

Equipment suppliers shall execute MC, FAT and commissioning and preservation as specified in

the purchase order. The completion shall be documented as part of the completion system which

leads up to handover to the company/client.

5.2.4 Construction/assembly Phase

Executor shall perform MC and commissioning and preservation as specified in purchase

order/contract documents. The completion is documented as part of the completion system which

leads up to handover to the company.

5.3

Responsibilities

Responsibilities are defined in the contract.

MC execution and registration/documentation, shall be performed by anyone who has a scope of

work to be performed, such as equipment suppliers, fabrication contractors, installation contractor

and hook-up contractors.

Commissioning registration and documentation shall be performed by anyone who has this

responsibility implemented in their scope of work.

5.4

Common requirements

This standard shall be used as a basis for preparing plans, procedures and documentation for

Mechanical completion and commissioning. The implementation of this standard requires the use of

a coding system for item and system numbering, e.g. NORSOK Z-DP-002, Coding system.

5.5

Documentation

Mechanical completion documentation shall be completed/executed per item/MC package.

Commissioning documentation shall be documented on a commissioning package level.

All check/test records shall end up in a status OK-PA-PB.

NORSOK standard

Page 5 of 26

Mechanical completion and commissioning

Z-CR-007

Rev. 1, May 1996

5.6

Project Completion System (PCS)

An electronic based system for administration of Mechanical completion, commissioning

and Punch List Register, should be used.

5.7

Planning

All MC activities shall be planned on fully integrated fabrication, Mechanical completion and

commissioning schedules on system prioritised basis in order to meet the optimal sequence of

completion.

MECHANICAL COMPLETION

6.1

Introduction

This chapter forms the basis for the execution and documentation of mechanical activities.

Mechanical completion takes place through all phases of the project, starting at equipment supplier

and continuing through fabrication up to commissioning phase.

Mechanical completion encompasses all disciplines.

The detailed responsibilities are described in the contract.

Executor of MC activities is responsible for establishing and compiling the MC dossiers and

report status into PCS.

6.2

Documentation for a MC Package

The MC package shall consist of an MC Certificate, a MC Status Index and a Punch List Register

printout as described below.

A Mechanical Completion Certificate (MCC) is a form completed by the Executor after all MC

is carried out. The MCC is the cover sheet for each MC package. A MC package shall when signed

be ready for start of commissioning.

The Check Records (CR) are the forms on which the Executors record the results of all checks,

inspections and tests carried out for each individual item.

A Punch List Register (PLR) shall be prepared by the Executor along with the MC activity. In

each MC package a printout from the PLR shall be included to document the incompleted work.

A MC Status Index (MCSI) listing the status of all CRs for the completed MC package shall be

included in the MC documentation dossier.

6.3

Handover at Mechanical completion

Handover at Mechanical completion to commissioning shall be at commissioning package level,

documented by the Ready for Commissioning Certificate (RFCC).

6.4

Carry Over Work Register (COWR)

The Carry Over Work Register lists all punch items that the Project accepts as cannot be completed

during present phase. The COWR is used for the release of the work from the Executor and will as

such be an input to the scheduling and planning of outstanding work to be performed during later

phases.

NORSOK standard

Page 6 of 26

Mechanical completion and commissioning

Z-CR-007

Rev. 1, May 1996

The COWR Item Number and cross reference to the Punch List Register/Check Records shall be

given. COWR work shall be marked up on drawings or sketches and be included in the records.

COWR Material Status List (MSL) and marked up drawings/instruction shall contain sufficient

information for job setting in a later phase.

6.5

Typical Mechanical completion activities

Mechanical completion activities includes checking of fabrication and installation work.

Executor shall complete packages related to listed disciplines and as required by the MCSI.

Executor shall complete the check list items as per the MCCR's. The activities shall include but not

be limited to:

(see also Annex A for typical check records)

6.5.1 Mechanical

Visual inspection for complete and correct installation.

Internal inspection of tanks and vessels.

Alignment.

Load testing of lifting equipment.

Hot oil flushing.

Bolt tensioning.

Dimension control.

Preservation.

6.5.2 Electrical

Visual inspection for complete and correct installation.

Insulation and continuity testing of cables.

Insulation testing of generator, transformers and motors, panels, distribution board etc.

Earthing checks.

Static check of switches and control devices.

Battery preparations.

Lighting and socket outlet checks.

Area completion.

Heat tracing.

Preservation.

6.5.3 Instrument/Telecommunication

Calibration and testing of instruments prior to installation.

Visual inspection for complete and correct installation.

Insulation and continuity testing of cables.

Cleaning, flushing, pressure and leak testing of pneumatic and hydraulic tubing.

Adjustment of control, alarm and shutdown settings.

Loop testing.

Function testing of control systems.

Function testing of field instruments.

Hot oil flushing of instrument tubing.

Area completion.

NORSOK standard

Page 7 of 26

Mechanical completion and commissioning

Z-CR-007

Rev. 1, May 1996

Preservation.

6.5.4 Piping

NDE carried out.

Welding procedures.

Removal of all items subject to damage during flushing, cleaning and pressure testing.

Flushing of pipework.

Chemical cleaning and testing of pipework.

Drying of tested pipework.

Preservation of tested pipework.

Reinstatement of all items after testing.

Final inspection of pipework.

Test ISO's and P&ID's showing the extent of each pressure test.

Pneumatic and hydraulic tubing.

Hot oil flushing of pipework.

Bolt tensioning.

Pipe supports completed.

Insulation.

Flow coding.

6.5.5 HVAC

Visual inspection for complete and correct installation.

Cleaning of ductwork.

Leak testing of ductwork.

Alignment checks.

Mechanical functions checks of equipment.

Preservation.

Flow coding.

6.5.6 Safety

Visual inspection for complete and correct installation.

Preservation.

Area completion

6.5.7 Mechanical completion of non-operational systems

Mechanical completion of non-operational systems includes completion status and checks on an

area basis. Disciplines included structural, surface protection, insulation, fireproofing and

architectural.

6.5.8 Structural

Visual inspection for complete and correct installation.

QC documentation.

NDE carried out.

Welding.

Load testing of lifting lugs and monorails.

NORSOK standard

Page 8 of 26

Mechanical completion and commissioning

Z-CR-007

Rev. 1, May 1996

6.5.9 Surface protection, Insulation and Fire proofing

Visual inspection for complete and correct application.

Thickness checks carried out.

Adhesion checks carried out.

Preservation.

Insulation.

Painting.

Fire proofing.

6.5.10 Architectural

Visual inspection for complete and correct installation.

Preservation.

Doors.

COMMISSIONING

7.1

Introduction

This chapter forms the basis for preparation and execution of commissioning.

Commissioning take place when Mechanical completion is completed for a system or part of a

system.

Commissioning can be divided into three main activities:

Commissioning preparation

Commissioning execution

Commissioning documentation and handover to operation

Establishment of a commissioning network and definition of commissioning packages early in a

Project in order to establish fabrication/installation priorities and milestones.

Definition of commissioning of part systems is essential in order to achieve an early commissioning

completion.

7.2

Typical commissioning preparation activities

The preparatory work shall consist of activities such as:

Development of commissioning organisation

Development of system breakdown (partsystem)

Commissioning packages definition

Commissioning schedules

Commissioning budget including spare parts for commissioning

Commissioning preparation check record (ref. Annex B for typicals)

7.3

Commissioning procedure content

Commissioning shall be executed by guidance of a detailed procedure describing:

7.3.1 Objective

Details the operating parameters to be achieved.

NORSOK standard

Page 9 of 26

Mechanical completion and commissioning

Z-CR-007

Rev. 1, May 1996

7.3.2 Description

Shall contain a brief description of the system/partsystems to be commissioned, including marked

up P&ID as a basis for all functions to be tested.

7.3.3 Lists of temporary equipment and consumables

Lists all consumables, temporary equipment tools and requirements for suppliers

assistance.

7.3.4 Health/Environment/Safety

A list of all toxic and polluting fluids and materials shall be made, describing their handling and

disposal. A check list of all required safety precautions including requirements for work permit

shall be made. Prior to energization of electrical equipment a livening up notice shall be issued in

order to inform all involved parties of forthcoming energising.

7.3.5 Preservation

Requirements for removal of existing preservatives/protection shall be made and subsequent new

preservation of the system if the system shall be out of operation for a period.

7.3.6 Scope

The scope shall detail the work to be done step by step including the commissioning preparation,

check record (ref. Annex B).

Irregularities and/or faults shall be logged.

Equipment suppliers start-up procedures shall be incorporated.

Performance parameters shall be included for comparison of results with actual result achieved

during commissioning.

7.3.7 Planning

Detailed commissioning plans for system/part system shall be worked out and shall include manhours per discipline, including supplier assistance man-hours.

7.3.8 Handover

The handover shall contain a certificate and other documents agreed with operation.

7.4

Commissioning documentation and handover to operation

Handover of systems from Executor to project/operation shall be according to a formal procedure

which as a minimum should consist of:

Completion acceptance certificate (signed by both parties).

Commissioning P&ID showing the extent of the completed system.

Authority certificates (if any).

Operational procedures and handbooks.

NORSOK standard

Page 10 of 26

Mechanical completion and commissioning

Annex A

ANNEX A

Z-CR-007

Rev. 1, May 1996

MECHANICAL COMPLETION DOCUMENTATION

(TYPICALS) (INFORMATIVE)

CONTENTS

Documentation for a MC package ........................................................................15

MC certificate (MCC) ...........................................................................................16

Piping completion status .......................................................................................17

MC check record - Instrument installation and inspection ...................................18

MC check record - Electrical motors ....................................................................19

MC check record - Centrifugals/schrewpump, compressor and hydr.motor ........20

Punch list...............................................................................................................21

MC documentation for a Commissioning package ...............................................22

Ready for commissioning certificate (RFCC).......................................................23

NORSOK standard

Page 11 of 26

Mechanical completion and commissioning

Annex A

Z-CR-007

Rev. 1, May 1996

Documentation for a MC - Package

Punch List

MCCR

MCSI

MCC

for

MC - Pack

Mechanical Completion Certificate (MCC):

States that all discipline related inspections and tests for a MC package have been carried out

according to relevant contract documents.

Mechanical Completion Status Index (MCSI):

A Computerised listing of all Tag/Cable/Test/MCCR in a MC Pack, which gives MC scope of work

and status for a completed package.

Mechanical Completion Check Record (MCCR):

Discipline checklist for the various equipment. These records form the basis of the MC documentation.

MC Punch List (PL):

Is the form on which the supplier and contractor record any outstanding work.

NORSOK standard

Page 12 of 26

Mechanical completion and commissioning

Annex A

Z-CR-007

Rev. 1, May 1996

MC CERTIFICATE

MCC

(Rev. 1, May 1996)

<Project>

MC Package No.

MCC Description

MCC Area

MCC Site

System

Sub System

:

:

:

:

:

Comm. Package No.

SCOPE OF ACCEPTANCE

Discipline code:

Mechanical Complete as per attached MCSI

MCC status:

Date:

It is hereby certified that the plant/equipment referenced has been inspected, tested and accepted in accordance with the attached MC check Records and other

documents, but with the exception of outstanding word according to attached Punch List register.

COMMENTS:

VERIFIED

SUPPLIER

FABRICATION

HOOK-UP

Name

Sign

Date

Name

Sign

Date

NORSOK standard

Page 13 of 26

Mechanical completion and commissioning

Annex A

Z-CR-007

Rev. 1, May 1996

PIPING COMPLETION STATUS

Sheet No.

<Project>

PIPING COMPLETION STATUS

(Rev. 1, May 1996)

TEST

PRESS.

(bar)

DESIGN

PRESS.

(bar)

System

Tag No.

MC Package No.

Subsystem

Comm. Package No.

10

NDE

CLEARED

PIPES

SUPPORTED

EARTHING

GRP.PIPES

FLUSHED

PRESSURE

TESTED

CHEMICAL

CLEANED

PRESERVED

VIDEO

INSPECTION

HOT OIL

FLUSHED

REINSTALLED

ISO No.

Spool

No.

Area

Line No.

P&ID No.

Remarks

It is hereby certified that the plant/equipment referenced has been inspected, tested and accepted in accordance with the attached acceptable records and other

documents, but with the exception of the outstanding work according to attached punch list register.

VERIFIED

SUPPLIER

FABRICATION

HOOK-UP

Name

Sign

Date

Name

Sign

Date

NORSOK standard

Page 14 of 26

Mechanical completion and commissioning

Annex A

Z-CR-007

Rev. 1, May 1996

Sheet No.

MC CHECK RECORD

<Project>

INSTRUMENT INSTALLATION AND

INSPECTION

(Rev. 1, May 1996)

Tag No.

Description

:

:

Area

MC Package No.

PO No.

Manufacturer

:

:

System

Subsystem

:

:

INSTALLATION CHECK

01

SUPPL.

Comm.Package No.

FABR.

HOOK-UP

Punchlist item No.

Check instrument against data sheet

02

Check CE marking

03

Check calibration certificate

04

Installation check

05

Leakage test

06

Flushing carried out

COMMENTS:

VERIFIED

SUPPLIER

FABRICATION

HOOK-UP

Name

Sign

Date

Name

Sign

Date

NORSOK standard

Page 15 of 26

Mechanical completion and commissioning

Annex A

Z-CR-007

Rev. 1, May 1996

Sheet No.

MC CHECK RECORD

<Project>

ELECTRICAL MOTORS

(Rev. 1, May 1996)

Tag No.

Description

:

:

Area

MC Package No.

PO No.

Manufacturer

:

:

System

Subsystem

:

:

EQUIPMENT INSPECTION, DE-ENERGISED STATE

Check for no voltage and proper earthing applied

01

Check nameplate data and (ex)-markings against data sheet

02

Check CE-marking

03

No mechanical damage

04

No fluid leaks

05

Nuts and bolts tight

06

Terminal boxes and glanding correct

07

All labelling and warning marks correct

08

Internal earthing correct and securely tight

09

All internal cabling and aux. wiring neat and healthy

10

Heaters correctly installed

11

Check motor insulation resistance. Record lowest reading

12

Check bearing lubrication

13

Check free rotation with driven equip. uncoupled

14

Check cooling system, dust and debris removed

SUPPL.

Comm.Package No.

FABR.

HOOK-UP

Punchlist item No.

(MOHM):

15

Communication arrangement and brushes correct (DC only)

16

Motor preservation correct

17

Push button station:

a)

Property supported

b) No mechanical damage

c)

18

Labelling & identification correct

Preservation carried out.

COMMENTS:

VERIFIED

SUPPLIER

FABRICATION

HOOK-UP

Name

Sign

Date

Name

Sign

Date

NORSOK standard

Page 16 of 26

Mechanical completion and commissioning

Annex A

Z-CR-007

Rev. 1, May 1996

Sheet No.

MC CHECK RECORD

<Project>

CENTRIFUGAL, SCHREWPUMP,

COMPRESSOR

AND HYDR.MOTOR

(Rev. 1, May 1996)

Tag No.

Description

:

:

Area

MC Package No.

PO No.

Manufacturer

:

:

System

Subsystem

:

:

INSPECTION ITEM

01

SUPPL.

Comm.Package No.

FABR.

HOOK-UP

Punchlist item No.

Dataplate complies with data sheet

02

Check CE-marking

03

Skid installation correct

04

Dowels fitted in pump feet

05

Alignment Jack screws fit for driver

06

Correct shimspack for driver fitted

07

Alignment checked, see procedure

08

Jack screws retracted after alignment

09

Transmission checked

10

Coupling guard checked

11

Lubricant or preservation oil filled

12

Constant oiler removed

13

Grease nipples fitted

14

Gland packing fitted

15

Gland cooling fitted

16

Mechanical seal fitted

17

Pumpcase drain valve installed

18

Pumpcase vent valve installed

19

Drain line from skid pan installed

20

Inlet/Outlet checked

21

Skid mounted valves checked

22

Paintwork completed

23

NDE carried out

24

Material certificate checked

25

Pressure test carried out

COMMENTS:

VERIFIED

SUPPLIER

FABRICATION

HOOK-UP

Name

Sign

Date

Name

Sign

Date

NORSOK standard

Page 17 of 26

Mechanical completion and commissioning

Annex A

Z-CR-007

Rev. 1, May 1996

PUNCH LIST

<Project>

DISCIPLINE

(Rev. 1, May 1996)

MC Package No.

Package Description

Area

PO No.

Manufacturer

:

:

System

:

Subsystem :

Comm.Package No.

Page

of

CLEARED BY (INIT.)

Status A: Must be completed prior to milestone

Status B: Can be left to a later stage, If appr. by Company

DESCRIPTION (TAG NUMBER, DRAWING OR DOCUMENT REF.)

VERIFIED

SUPPLIER

FABRICATION

HOOK-UP

Name

Sign

Date

Name

Sign

Date

NORSOK standard

Page 18 of 26

Mechanical completion and commissioning

Annex A

Z-CR-007

Rev. 1, May 1996

MC Documentation for an Commissioning-Package

Punch List

Register

MCSI

RFCC

for

Commissioning

Package No.

From : Executor

Accep. : Commissioning

Ready for Commissioning Certificate (RFCC):

Formal document for transfer a Commissioning Package from MC Executor to Commissioning.

Mechanical Completion Status Index (MCSI):

A Computerised listing of all Tag/Cable/Test(MCCR) with status for the completed package.

MC Punch List Register:

Is the form which describes any incomplete work per MC package.

NORSOK standard

Page 19 of 26

Mechanical completion and commissioning

Annex A

Z-CR-007

Rev. 1, May 1996

READY FOR COMMISSIONING

CERTIFICATE

RFCC

(Rev. 1, May 1996)

System

Subsystem

Commissioning Package No.

Commissioning Package Description

Mechanical completed as per attachment

<Project>

- MCSI

- Punch List Register

- Preservation Status

Site:

RFCC Status:

Block letters:

Signature:

Date:

Signature:

Date:

Status

verified by

executor

Yes

No

Punch list items

Comments:

Block letters:

Accepted ready

for Commissioning

by Com.responsible

NORSOK standard

Page 20 of 26

Mechanical completion and commissioning

Annex B

ANNEX B

Z-CR-007

Rev. 1, May 1996

COMMISSIONING DOCUMENTATION

(TYPICALS) (INFORMATIVE)

CONTENTS

Commissioning preparation check record - Electrical equipment ........................26

Commissioning preparation check record - Water Mist. System..........................27

Commissioning preparation check record - Field check (HVAC)........................28

Commissioning preparation check record - Diesel Engine...................................29

Commissioning preparation check record - Field P&ID Check ...........................30

NORSOK standard

Page 21 of 26

Mechanical completion and commissioning

Annex B

Z-CR-007

Rev. 1, May 1996

COMM. PREPARATION CHECK

RECORD

ELECTRICAL EQUIPMENT

(Rev. 1, May 1996)

System

Site Code

Subsystem

Comm.Package No.

Tag No

Description

P.O. No.

Supplier

Chkp.

No.

Check

Description

Mechanical Completion Status.

02

Preservation removed.

03

Equipment cleaned.

04

Earthing correctly installed. Megger-test performed.

05

Living Up Notice (LUN) obtained.

06

In Operation Tag fitted.

07

All Safety Requirements satisfied.

Name

Date:

Verified by:

<Project>

Area:

Supplier

01

Executor

Check Record

No.:

Status

Onshore

Offshore

Date:

Supplier:

Onshore:

Offshore:

NORSOK standard

Page 22 of 26

Mechanical completion and commissioning

Annex B

Z-CR-007

Rev. 1, May 1996

COMM. PREPARATION CHECK

RECORD

WATER MIST SYSTEM

(Rev. 1, May 1996)

System

Site Code

Subsystem

Comm.Package No.

Tag No

Description

P.O. No.

Supplier

Chkp.

No.

Check

Description

Mechanical Completion status.

02

Maintenance access.

03

Operation access.

04

Equipment cleaned.

05

Preservation removed.

06

Valve stroked (Do Not Release).

07

Water tank filled.

08

Air bottle charged.

09

Operating instruction visible.

10

Piping/nozzle system: Use MC Check Record.

Name

Date:

Verified by:

<Project>

Area:

Supplier

01

Executor

Check Record

No.:

Status

Onshore

Offshore

Date:

Supplier:

Onshore:

Offshore:

NORSOK standard

Page 23 of 26

Mechanical completion and commissioning

Annex B

Z-CR-007

Rev. 1, May 1996

COMM. PREPARATION CHECK

RECORD

FIELD CHECK (HVAC)

(Rev. 1, May 1996)

System

Site Code

Subsystem

Comm.Package No.

Tag No

Description

P.O. No.

Supplier

Chkp.

No.

Check

Description

01

Mechanical Completion status.

02

Maintenance access.

03

Operational access.

04

Equipment cleaned.

05

Preservation removed.

06

Inspection hatches.

07

Flexible connections.

08

Bulkhead penetrations.

09

Supports set.

10

Sufficient insulation.

11

Flow directions correct.

12

All instruments hooked up.

13

All safety precautions carried out.

14

Dust blinds removed.

15

Check according to D&ID

Executor

Name

Check Record

No.:

Area:

Supplier

Date:

Verified by:

<Project>

Status

Onshore

Offshore

Date:

Supplier:

Onshore:

Offshore:

NORSOK standard

Page 24 of 26

Mechanical completion and commissioning

Annex B

Z-CR-007

Rev. 1, May 1996

COMM. PREPARATION CHECK

RECORD

DIESEL ENGINE

(Rev. 1, May 1996)

System

Site Code

Subsystem

Comm.Package No.

Tag No

Description

P.O. No.

Supplier

Chkp.

No.

Check

Description

Mechanical Completion status.

02

Maintenance access.

03

Operational access.

04

Dustblindes removed.

05

Safety valves installed.

06

Blinds correct status.

07

Preservation removed.

08

Externally clean.

09

Check all filters.

10

Lubricants filled.

11

Aux. Lubricant Oil pump run.

12

Engine hand cranked 2 turns.

13

Alignment checked. Use MC Check Record.

14

Coupling filled.

15

Radiator checked.

16

Coolant filled.

17

Aspirating system checked.

18

Exhaust system checked.

19

Start system checked.

20

Crank case vent checked.

21

Fuel supply system checked/filled.

22

Remote shut down ready.

Name

Date:

Verified by:

<Project>

Area:

Supplier

01

Executor

Check Record

No.:

Status

Onshore

Offshore

Date:

Supplier:

Onshore:

Offshore:

NORSOK standard

Page 25 of 26

Mechanical completion and commissioning

Annex B

Z-CR-007

Rev. 1, May 1996

COMM. PREPARATION CHECK

RECORD

FIELD P&I DIAGRAM CHECK

(Rev. 1, May 1996)

System

Site Code

Subsystem

Comm.Package No.

Tag No

Description

P.O. No.

Supplier

Chkp.

No.

Check

Description

All pressure tests included in Commissioning pack.

02

Adjust and set pipe supports.

03

Valves and equipment flow direction correct.

04

Blinds installed in correct position.

05

Orifice plates installed.

06

All instruments hooked up.

07

Insulation and heat tracing sufficient.

08

Check free movement of manual valve handles.

09

Remove dustblinds against safety valves etc.

10

Install required temporary filters.

11

Install required temporary blindings.

12

Install required temporary piping/hoses.

13

Required video inspection carried out.

14

Remove preservation where necessary.

15

Mark piping with Comm. tape/warning signs.

Name

Date:

Verified by:

<Project>

Area:

Supplier

01

Executor

Check Record

No.:

Status

Onshore

Offshore

Date:

Supplier:

Onshore:

Offshore:

NORSOK standard

Page 26 of 26

También podría gustarte

- Z 007 5913722 PDFDocumento56 páginasZ 007 5913722 PDFLegend AnbuAún no hay calificaciones

- Norsok Mechanical Completion and Commissioning Z-007Documento56 páginasNorsok Mechanical Completion and Commissioning Z-007smithwork50% (2)

- PDF MC NorskDocumento56 páginasPDF MC NorskIsaac EliasAún no hay calificaciones

- Witnessing Matrix SGP GEN 00 U PR 852061 001 - 2Documento22 páginasWitnessing Matrix SGP GEN 00 U PR 852061 001 - 2odeinatusAún no hay calificaciones

- ConocoPhillips Grissik USM Pipeline MC DossierDocumento3 páginasConocoPhillips Grissik USM Pipeline MC DossierMiftah Masrur0% (1)

- NORSOK Z-006 - PreservationDocumento20 páginasNORSOK Z-006 - Preservationjoaocavti100% (4)

- Drilling Facilities: NORSOK Standard D-001Documento70 páginasDrilling Facilities: NORSOK Standard D-001Well Control100% (1)

- Erd - 10-01Documento29 páginasErd - 10-01kattabomman100% (1)

- Marine Cable Product CatalogDocumento214 páginasMarine Cable Product CatalogJose Luius100% (1)

- Procedure For Test Header CertificationDocumento16 páginasProcedure For Test Header CertificationAdeoye OgunlamiAún no hay calificaciones

- 70109011 (2)Documento28 páginas70109011 (2)finiteinjustice50% (2)

- FLEXIBLE FLOWLINE RELOCATION & TIE-IN PROCEDURE Rev A - 12022-AMC-TIN-PRO-0016 - IssuedDocumento94 páginasFLEXIBLE FLOWLINE RELOCATION & TIE-IN PROCEDURE Rev A - 12022-AMC-TIN-PRO-0016 - IssuedWilliam O Okolotu100% (1)

- SCP004-MS30-QA-PLN-00002 A01 - ITP Cleaning and GaugingDocumento4 páginasSCP004-MS30-QA-PLN-00002 A01 - ITP Cleaning and GaugingAbdulkadir Berk MalkoçAún no hay calificaciones

- Norsok L-004-2016Documento32 páginasNorsok L-004-2016nguyenmainamAún no hay calificaciones

- Work Breakdown Structure and Plant-Equipment Designation System Numbering Scheme For The Hight Temperature Gas Reactor PDFDocumento22 páginasWork Breakdown Structure and Plant-Equipment Designation System Numbering Scheme For The Hight Temperature Gas Reactor PDFArini RizalAún no hay calificaciones

- A4-Jgs1ep-Epc1-Qp-016 Rev. B (Flange Management Procedure)Documento20 páginasA4-Jgs1ep-Epc1-Qp-016 Rev. B (Flange Management Procedure)Darrel Espino Aranas100% (1)

- Z-018 - Supplier's Documentation of Equipment Ed1, May2005Documento32 páginasZ-018 - Supplier's Documentation of Equipment Ed1, May2005Dragoslav DzolicAún no hay calificaciones

- U-102 2nd 2012 Remotely Operated Vehicle (ROV) ServicesDocumento52 páginasU-102 2nd 2012 Remotely Operated Vehicle (ROV) Servicesmechmohan26100% (1)

- Commissioning Plan Rev 0 240K-C2-OT-05-005-0Documento55 páginasCommissioning Plan Rev 0 240K-C2-OT-05-005-0Julio Rojas67% (3)

- Turret Bouy Tech DescriptionDocumento36 páginasTurret Bouy Tech Descriptiondbekos100% (1)

- Pre Commissioning Manual PDFDocumento44 páginasPre Commissioning Manual PDFMira Reda100% (2)

- Valve Car SealDocumento3 páginasValve Car SealRicAún no hay calificaciones

- List Shell Dep Amp Mesc Spe PDFDocumento9 páginasList Shell Dep Amp Mesc Spe PDFAzhar Ahmad100% (1)

- FLNGDocumento14 páginasFLNGPavin PiromAún no hay calificaciones

- TDW SmartPlug BrochureDocumento6 páginasTDW SmartPlug BrochureRodolfo Cabrera100% (2)

- Release For Shipment and Installation Note: HEX-V6109 16-200-001 3Documento7 páginasRelease For Shipment and Installation Note: HEX-V6109 16-200-001 3Mohd AshrafAún no hay calificaciones

- GP 00 02 Engineering Technical Practice (ETP) Governance and Management PrinciplesDocumento10 páginasGP 00 02 Engineering Technical Practice (ETP) Governance and Management PrinciplesSHANZAY21111111Aún no hay calificaciones

- Ebs1 Fsfa11 Saip Plin 1002 d01 Flange Mangement ProcedureDocumento16 páginasEbs1 Fsfa11 Saip Plin 1002 d01 Flange Mangement ProcedureYousif AlmusawiAún no hay calificaciones

- C-051-VP-040-CLTW-PRO-0007 Rev. A Pre Commissioning Commissioning ProcedureDocumento11 páginasC-051-VP-040-CLTW-PRO-0007 Rev. A Pre Commissioning Commissioning ProcedureMidha NeerAún no hay calificaciones

- Norsok Z 002 DP Norwegian Coding System PDFDocumento38 páginasNorsok Z 002 DP Norwegian Coding System PDFsouheil boussaid100% (1)

- Munck CraneDocumento268 páginasMunck CraneEduardo OvalleAún no hay calificaciones

- Theoretical overview of surge analysesDocumento14 páginasTheoretical overview of surge analysesdAún no hay calificaciones

- CommissioningDocumento4 páginasCommissioningowaise007Aún no hay calificaciones

- K2S-CW230907-BA6008-00005 - A01 - Manual Operated Valve Test ProcedureDocumento13 páginasK2S-CW230907-BA6008-00005 - A01 - Manual Operated Valve Test ProcedureAzeta RobertAún no hay calificaciones

- Pre-Commissioning and Commissioning PlanDocumento17 páginasPre-Commissioning and Commissioning PlanapssainiAún no hay calificaciones

- Riser Flowlines Fpso PartDocumento0 páginasRiser Flowlines Fpso PartspacevibesAún no hay calificaciones

- Compound Document Structure IndexDocumento4 páginasCompound Document Structure Indexg_sanchetiAún no hay calificaciones

- GU-629 Application and Selection of Standard Pipe Supports (Formerly SP1187)Documento48 páginasGU-629 Application and Selection of Standard Pipe Supports (Formerly SP1187)Ibrahim Naguib100% (1)

- Livening Up NotesDocumento1 páginaLivening Up NotesAceel FitchAún no hay calificaciones

- Pipeline Connection & Repair Systems (PCRS)Documento12 páginasPipeline Connection & Repair Systems (PCRS)Yang Gul Lee100% (2)

- Autoclave Subsea Ball ValvesDocumento20 páginasAutoclave Subsea Ball Valvesvp989Aún no hay calificaciones

- Petroleum Development Oman L.L.C.: Unrestricted Document ID: PR-1259 September 1999-09-12 Filing KeyDocumento43 páginasPetroleum Development Oman L.L.C.: Unrestricted Document ID: PR-1259 September 1999-09-12 Filing KeyAnjani PrabhakarAún no hay calificaciones

- SP-2311 Hazardous Area Clasification 2022Documento51 páginasSP-2311 Hazardous Area Clasification 2022Chris EasterAún no hay calificaciones

- FAT Test Procedure NKT Flexible Hose PDFDocumento10 páginasFAT Test Procedure NKT Flexible Hose PDFTomasPavlovicAún no hay calificaciones

- ALP-WP-3.08 Rev 1 PDFDocumento46 páginasALP-WP-3.08 Rev 1 PDFOliverBrayanAún no hay calificaciones

- PLEM Design Methodology: StructureDocumento4 páginasPLEM Design Methodology: StructureErik AlfiandyAún no hay calificaciones

- QP Guideline Safety Pigging FacilitiesDocumento10 páginasQP Guideline Safety Pigging FacilitiesDeepak Kannan100% (1)

- DNV 271 Annex1Documento6 páginasDNV 271 Annex1Andy TaylorAún no hay calificaciones

- 12 01 01 GL V01 - Commissioning Management GuidelineDocumento32 páginas12 01 01 GL V01 - Commissioning Management Guidelinedestiny2bn100% (2)

- SP-1108 (ESOP-01) Issue of PDO Electrical Safety Rules andDocumento2 páginasSP-1108 (ESOP-01) Issue of PDO Electrical Safety Rules andaslam.ambAún no hay calificaciones

- MS-HKSS-Pigging Testing Drying Rev A - YNB 16''Documento64 páginasMS-HKSS-Pigging Testing Drying Rev A - YNB 16''AAISATAún no hay calificaciones

- Master Document MRB Index Rev TDocumento10 páginasMaster Document MRB Index Rev TDele TedAún no hay calificaciones

- BHP Billiton Calm BuoyDocumento4 páginasBHP Billiton Calm BuoyAndré ManhãesAún no hay calificaciones

- 5 - 1 - Norsok Norsok VDocumento1 página5 - 1 - Norsok Norsok VmeeAún no hay calificaciones

- Commissioning ProceduresDocumento28 páginasCommissioning ProceduresSun TikouAún no hay calificaciones

- Mechanical Completion & ComissioningDocumento56 páginasMechanical Completion & ComissioningRustam Riyadi100% (1)

- 2 - 1 - Norsok Norsok VDocumento1 página2 - 1 - Norsok Norsok VmeeAún no hay calificaciones

- NORSOK N-005 Rev.1 PDFDocumento43 páginasNORSOK N-005 Rev.1 PDFHG LeeAún no hay calificaciones

- Norsok Standard Odr0011996 Operational PrinciplesDocumento11 páginasNorsok Standard Odr0011996 Operational PrinciplesФокусник с нуляAún no hay calificaciones

- Norsok ST 2001Documento131 páginasNorsok ST 2001mamounsdAún no hay calificaciones

- Dciq-5ea47-069877 Dfo 310 Tbi 25Documento14 páginasDciq-5ea47-069877 Dfo 310 Tbi 25Wilkin Llanca BlasAún no hay calificaciones

- NORSOK Z-008 Risk Based Maintenance & Consequence ClassificationDocumento44 páginasNORSOK Z-008 Risk Based Maintenance & Consequence ClassificationWilkin Llanca Blas100% (2)

- Z-008 Criticality Analysis For Maintenance PurposesDocumento34 páginasZ-008 Criticality Analysis For Maintenance PurposesGustavo Farelo SuarezAún no hay calificaciones

- The New York Blower Company: Fan DesignDocumento2 páginasThe New York Blower Company: Fan DesignLuis GrijalvaAún no hay calificaciones

- 01 002 - D PDFDocumento1 página01 002 - D PDFWilkin Llanca BlasAún no hay calificaciones

- MIL STD 721RevC PDFDocumento20 páginasMIL STD 721RevC PDFNicolás Fernando Galindo MagnaAún no hay calificaciones

- Norsok Z-008-2011Documento46 páginasNorsok Z-008-2011julian_sanabria_1100% (4)

- Cost Effective Maintenance For Competitve AdvantagDocumento99 páginasCost Effective Maintenance For Competitve AdvantagWilkin Llanca BlasAún no hay calificaciones

- 01 002 - D PDFDocumento1 página01 002 - D PDFWilkin Llanca BlasAún no hay calificaciones

- 01 002 - D PDFDocumento1 página01 002 - D PDFWilkin Llanca BlasAún no hay calificaciones

- 3 - Maintenance ManualDocumento104 páginas3 - Maintenance ManualVictor MartinezAún no hay calificaciones

- ModuDense ManualDocumento43 páginasModuDense ManualWilkin Llanca BlasAún no hay calificaciones

- Dciq-38af4-071287 Dfo 36Documento13 páginasDciq-38af4-071287 Dfo 36Wilkin Llanca BlasAún no hay calificaciones

- DownfloOvalSpecDrawingDFO312wHopperLegs r10Documento5 páginasDownfloOvalSpecDrawingDFO312wHopperLegs r10Wilkin Llanca BlasAún no hay calificaciones

- 1 - Installation ManualDocumento18 páginas1 - Installation ManualWilkin Llanca BlasAún no hay calificaciones

- ShowerJet C66BM - Pulp-and-Paper Catalog PDFDocumento5 páginasShowerJet C66BM - Pulp-and-Paper Catalog PDFWilkin Llanca BlasAún no hay calificaciones

- Computers: What Is A Computer Program?Documento11 páginasComputers: What Is A Computer Program?fabiobonadiaAún no hay calificaciones

- Incubator 8000 IC / SC / NC Electrical Safety Test in The USA and Canada According To UL2601-1 / Table 19.100 and Table IVDocumento4 páginasIncubator 8000 IC / SC / NC Electrical Safety Test in The USA and Canada According To UL2601-1 / Table 19.100 and Table IVVinicius Belchior da SilvaAún no hay calificaciones

- Assembly InstructionsDocumento22 páginasAssembly InstructionsMarcos GodoyAún no hay calificaciones

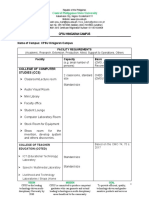

- Cpsu Hinigaran Campus: Central Philippines State UniversityDocumento3 páginasCpsu Hinigaran Campus: Central Philippines State UniversityChristian anthony SerfinoAún no hay calificaciones

- Who Needs To Comply With BS EN 1090Documento2 páginasWho Needs To Comply With BS EN 1090Scott TrainorAún no hay calificaciones

- Dhruv Sap CVDocumento3 páginasDhruv Sap CVarpangupta007Aún no hay calificaciones

- Column and Wall Load Take Down Spreadsheet v1.0 - CLDocumento28 páginasColumn and Wall Load Take Down Spreadsheet v1.0 - CLBilal KhattabAún no hay calificaciones

- As We May ThinkDocumento8 páginasAs We May ThinkPaulla PereiraAún no hay calificaciones

- 10Gbps XFP Optical Transceiver: RTXM226-405Documento8 páginas10Gbps XFP Optical Transceiver: RTXM226-405Lerner MapurungaAún no hay calificaciones

- Dokumen - Tips Cardioline Ar 1200 Service Manual (07!05!2020)Documento38 páginasDokumen - Tips Cardioline Ar 1200 Service Manual (07!05!2020)juniorAún no hay calificaciones

- OC - Automotive Engine MechanicDocumento5 páginasOC - Automotive Engine MechanicMichael NcubeAún no hay calificaciones

- Python Modes and OperatorsDocumento27 páginasPython Modes and OperatorsTejas BhagitAún no hay calificaciones

- Rolling StockDocumento11 páginasRolling Stockshiva_ssk17Aún no hay calificaciones

- CR QS 3.5 - Service Manual For Download 2009-11-16Documento605 páginasCR QS 3.5 - Service Manual For Download 2009-11-16Fernando Chavarría MarínAún no hay calificaciones

- SS3 DP 2ND TermDocumento14 páginasSS3 DP 2ND TermThe-INKS crewAún no hay calificaciones

- W441 - Mustang Power Wheel ManualDocumento26 páginasW441 - Mustang Power Wheel ManualMarcos JuarezAún no hay calificaciones

- Assemblies of Switchgear and Control Panels 1Documento6 páginasAssemblies of Switchgear and Control Panels 1sabeerAún no hay calificaciones

- Design and Implementation of An Iot-Based Smart Home Security SystemDocumento8 páginasDesign and Implementation of An Iot-Based Smart Home Security SystemaniAún no hay calificaciones

- Installation Guide Alcatel 1350 Management Suite 1350 Rel.7.4 Network ReleaseDocumento184 páginasInstallation Guide Alcatel 1350 Management Suite 1350 Rel.7.4 Network ReleaseFarhad NaderianAún no hay calificaciones

- Meet Patel - M7 Assessment 4 - CPW1 Action Minutes TemplateDocumento4 páginasMeet Patel - M7 Assessment 4 - CPW1 Action Minutes TemplatepreetAún no hay calificaciones

- Unit-3 & 4 Embedded Systems (A1430) Rtos PDFDocumento179 páginasUnit-3 & 4 Embedded Systems (A1430) Rtos PDFManojPaidimarriAún no hay calificaciones

- IP5407 InjoinicDocumento13 páginasIP5407 InjoinicWillyPVAún no hay calificaciones

- Capturing Deleted Records of Source in WarehouseCapturing Deleted Records of Source in WarehouseDocumento2 páginasCapturing Deleted Records of Source in WarehouseCapturing Deleted Records of Source in WarehouseAsad HussainAún no hay calificaciones

- Global Engineering Consultancy ProfileDocumento6 páginasGlobal Engineering Consultancy ProfileOladunni AfolabiAún no hay calificaciones

- Business Incubation in IndiaDocumento15 páginasBusiness Incubation in IndiaraveendramanipalAún no hay calificaciones

- EURANEDocumento19 páginasEURANEsatti2628Aún no hay calificaciones

- VIG Node ReplacementDocumento8 páginasVIG Node ReplacementNooruddin DeroAún no hay calificaciones

- Multitrack HistoryDocumento5 páginasMultitrack HistoryMatt GoochAún no hay calificaciones

- Order Confirmation for 5 Passengers from Geneva to ParisDocumento6 páginasOrder Confirmation for 5 Passengers from Geneva to ParisDiego Campos EspinozaAún no hay calificaciones