Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Conrol

Cargado por

Juan Diego Calsin TapiaTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Conrol

Cargado por

Juan Diego Calsin TapiaCopyright:

Formatos disponibles

9

Sliding Mode Control of DC Drives

Dr. B. M. Patre1, V. M. Panchade2 and Ravindrakumar M. Nagarale3

1Department of Instrumentation Engineering

S.G.G.S. Institute of Engineering and Technology, Nanded

2Department of Electrical Engineering

G.H. Raisoni Institute of Engineering &Technology Wagholi, Pune

3Department of Instrumentation Engineering

M.B.E.Societys College of Engineering, Ambajogai

India

1. Introduction

Variable structure control (VSC) with sliding mode control (SMC) was first proposed and

elaborated in early 1950 in USSR by Emelyanov and several co researchers. VSC has

developed into a general design method for wide spectrum of system types including

nonlinear system, MIMO systems, discrete time models, large scale and infinite dimensional

systems (Carlo et al., 1988; Hung et al., 1993; Utkin, 1993). The most distinguished feature of

VSC is its ability to result in very robust control systems; in many cases invariant control

systems results. Loosely speaking, the term invariant means that the system is completely

insensitive to parametric uncertainty and external disturbances.

In this chapter the unified approach to the design of the control system (speed, Torque,

position, and current control) for DC machines will be presented. This chapter consists of

parts: dc motor modelling, sliding mode controller of dc motor i.e. speed control, torque,

position control, and current control. As will be shown in each section, sliding mode control

techniques are used flexibly to achieve the desired control performance. All the design

procedures will be carried out in the physical coordinates to make explanations as clear as

possible. Drives are used for many dynamic plants in modern industrial applications.

The simulation result depicts that the integral square error (ISE) performance index for

reduced order model of the system with observer state is better than reduced order with

measured state.

Simulation results will be presented to show their agreement with theoretical predications.

Implementation of sliding mode control implies high frequency switching. It does not cause

any difficulties when electric drives are controlled since the on off operation mode is the

only admissible one for power converters.

2. Dynamic modelling of DC machine

Fig. 1 shows the model of DC motor with constant excitation is given by following state

equations (Sabanovic et al., 1993; Krause, 2004).

www.intechopen.com

168

Sliding Mode Control

Fig. 1. Model of DC motor with constant excitation.

di

= u Ri 0 w

dt

dw

j

= kt i l

dt

L

(1)

where

i

armature current

w shaft speed

R armature resistance

0 back emf constant

l load torque

u terminal voltage

j inertia of the motor rotor and load

L armature inductance

kt torque constant.

Its motion is governed by second order equations (1) with respect to armature current i and

shaft speed w with voltage u and load torque kt . A low power-rating device can use

continuous control. High power rating system needs discontinuous control. Continuously

controlled voltage is difficult to generate while providing large current.

3. Sliding mode control design

DC motors have been dominating the field of adjustable speed drives for a long time

because of excellent operational properties and control characteristics. In this section

different sliding mode control strategies are formulated for different objectives e.g. current

control, speed control, torque control and position control.

3.1 Current control

Let i * be reference current providing by outer control loop and i be measured current.

Fig. 2 illustrates Cascaded control structure of DC motors.

www.intechopen.com

169

Sliding Mode Control of DC Drives

Consider a current control problem, by defining switching function

Design a discontinuous control as

s = i* i

(2)

u = u0 sign(s )

(3)

Where u0 denotes the supplied armature voltage.

ss$ = s(

di * R

1

+ i + 0 w ) u0 s

dt L

L0

L

(4)

Choice of control u0 as

u0 > L

di *

+ Ri + 0 w

dt

Makes (4)

ss$ < 0 Which means that sliding can happen in s = 0 .

Fig. 2. Cascaded control structure of DC motors.

3.2 Speed control

w * be the reference shaft speed, then the second order motion equation with respect to the

error e = w * w is of form. State variable x1 = e & x2 = e$

x$ 1 = x2

x$ 2 = a1x1 a2 x2 + f (t ) bu

Where

a1 =

kt 0

k

R

, a2 = & b = t

jL

L

jL

$$ + a2 w

$ * + a1 w * +

f (t ) = w

are constant values.

www.intechopen.com

R l $l

+

jL

j

(5)

170

Sliding Mode Control

The sliding surface and discontinuous control are designed as

s = c( w * w ) +

d *

( w w)

dt

(6)

u = u0 sign(s )

This design makes the speed tracking error e converges to zero exponentially after sliding

mode occurs in s = 0 , where c is a positive constant determining the convergence rate for

implementation of control (6), angle of acceleration x2 = e$ is needed. The system motion is

independent of parameters a1 , a2 , b and disturbances in g(t).

Combining (1) & (6) produces

k

k

1

c

$* +w

$$ ( kt l ) + l + t ( Ri + kt w ) t u

s$ = cw

j

j

jL

jL

= g( t )

kt

u

jL

k

k

1

c

$* +w

$$ ( kt l ) + l + t ( Ri + kt w ) t u

g(t ) = cw

j

j

jL

jL

if u0 >

jL

g(t ) , ss$ < 0

kt

(7)

(8)

(9)

Then sliding mode will happen (Utkin,1993).

The mechanical motion of a dc motor is normally much slower then electromagnetic

dynamics. It means that L << j in (1).

a. Reduced -order Speed control with measured speed

Following reduced order control methods proposed below will solve chattering problem

without measuring of current and acceleration ( x2 ) .

Speed tracking error is we = w * w . The dc motor model (1) in terms of we :

di

= u Ri 0 ( w * we )

dt

dw

$*

j e = kt i + l + jw

dt

L

(10)

Let L be equal to zero due to L << j . Then (10) becomes with L = 0

i=

0

R

( w * we )

kt

$*

u + l + jw

R

(11)

Substituting (11) into (10) results in

j

dwe kt 0 *

k

$*

( w we ) t u + l + jw

=

dt

R

R

(12)

Equation (12) is a reduced order (first order) model of dc motor. The discontinuous control

is designed as

www.intechopen.com

171

Sliding Mode Control of DC Drives

u = u0 sign( we )

and the existence condition for the sliding mode we = 0 will be

u0 > 0 ( w * we ) +

lR

kt

$*

jRw

kt

(13)

(14)

The principle advantage of the reduced order based method is that the angle acceleration

( x2 = e$ ) is not needed for designing sliding mode control (Carlo et al.,1988).

b. Reduced -order Speed control with observer speed

The unmodelled dynamics (1) may excite non-admissible chattering.

Let us design an a asymptotic observer to estimate we (Utkin,1993).

j

e kt 0 *

dw

k

e ) t u + l + jw

we )

$ * l1 ( w

=

(w w

dt

R

R

dwe kt 0 *

k

$*

=

( w we ) t u + l + jw

dt

R

R

(15)

dl

= l2 ( w * we )

dt

where

e

w

Estimated error

e we

we = w

Speed tracking error

l1 , l2

Observer gain

e (Utkin,1993) will be

The discontinuous control designed using estimate state w

e)

u = u0 sign( w

(16)

The sliding mode will happen if

e) +

u0 > 0 ( w * w

l R

kt

$ * l1 R *

jRw

+

( w we )

kt

kt

(17)

= 0 & = 0 .

And w

Under the control scheme, chattering is eliminated, but robustness provided by the sliding

mode control is preserved within accuracy of L << 1 . The observer gains l1 , l2 should be

j

chosen to yields mismatch dynamics slower than the electrical dynamics of the dc motors to

is close to w , the real speed w tracks the desired

prevent chattering. Since the estimated w

speed w* . Fig. 3 shows the control structure based on reduced order model and observed

state. Chattering can be eliminated by using reduce observer states. The sliding mode occurs

in the observer loop, which does not contain unmodelled dynamics.

3.3 Position control

To consider the position control issue, it is necessary to augment the motor equations (1) with

www.intechopen.com

172

Sliding Mode Control

Fig. 3. Speed control based on reduced order model and observed state.

d

=w

dt

where denotes the rotor position.

The switching function s for the position control is selected as

s$ = ($$* $$) + c 1 ($ * $ ) + c 2 ( * )

and the discontinuous control is

(18)

(19)

u = u0 sign(s )

(20)

s$ = h(t )

(21)

Combining (1), (18), (19)

kt

u

jL

where

$$ * + c1 w

$ * + c2 w*

h(t ) = w

k

1

c1

( kt i l ) c 2 w + $l + t ( Ri + kt w )

j

j

jL

(22)

Choice of u0 as

u0 >

jL

h(t )

kt

(23)

Makes ss$ < 0 which means that sliding mode can happen s = 0 with properly chosen

c1 , c 2 .We can make velocity tracking error e = w * w converges to zero.

3.4 Torque control

The torque control problem by defining switching function

s = *

www.intechopen.com

(24)

173

Sliding Mode Control of DC Drives

As the error between the reference torque * and the real torque developed by the motor.

Design a discontinuous control as

u = u0 sign(s )

(25)

Where u0 is high enough to enforce the sliding mode in s = 0 , which implies that the real

torque tracks the reference torque * .

s$ = $ * kt i

k Ri k w k

= $ * + t + t 0 t u

L

L

L

kt

= f (t ) u

L

(26)

kt Ri kt 0 w

+

L

L

depending on the reference signal for

Where

f (t ) = $ * +

u0 >

L

f (t )

kt

k

ss$ = sf (t ) t u0 s < 0

L

(27)

So sliding mode can be enforced in s = 0 .

4. Simulation results

4.1 Simulation results of current control

Examine inequality (2 & 4), if reference current is constant, the link voltage u0 needed to

enforce sliding mode should be higher than the voltage drop at the armature resistance plus

back emf, otherwise the reference current i * cannot be followed.

Figure 4 depicts a simulation result of the proposed current controller. The sliding mode

controller has been already employed in the inner current loop thus, if we were to use

another sliding mode controller for speed control, the output of speed controller i * would

*

be discontinuous, implying an infinite di and therefore destroying in equality (4) for any

dt

implement able u0

4.1 Simulation results of speed control

To show the performance of the system the simulation result for the speed control of dc

machine is depicted. Rated parameters of the dc motor used to verify the design principle

are 5hp, 240V, R=0.5, L=1mH, j=0.001kgm2, kt = 0.008NmA-1 , 0 = 0.001v rad s -1 and

l = Bw where B=0.01 Nm rads-1.

Figure 5 depicts the response of sliding mode reduced order speed control with measured

speed. It reveals that reduced order speed control with measured speed produces larger

overshoot & oscillations.

www.intechopen.com

174

Sliding Mode Control

14

Measured current i

Reference current i* (speed controller output)

12

Current (Ampere)

10

8

6

4

2

0

-2

0.5

1.5

Time(sec.)

x 10

Fig. 4. Cascade current control of dc motor.

120

Reduced order speed control with measured speed

100

Reference speed

Speed(rad./sec.)

80

60

40

20

-20

500

1000

1500

2000

time(sec.)

2500

3000

3500

Fig. 5. Response of sliding mode reduced order speed control with measured speed.

www.intechopen.com

175

Sliding Mode Control of DC Drives

Figure 6 depicts the response of sliding mode reduced order speed control with observer

speed. It reveals that reduced order speed control with observer speed produces smaller

overshoot & less oscillation.

Fig. 7(a), 7(b), 7(c) & 7(d) depicts the simulation result of response of sliding mode speed

control, variation of error, squared error and integral square error (ISE) with reference speed

of 75 radian per sec respectively. Fig. 8 reveals that variation of the controller for reduced

order speed control with observed speed at load condition. Fig. 9 reveals that variation of

the controller for reduced order speed control with measured speed at load condition.

Fig. 10 depicts the response of sliding surface in sliding mode control. Fig. 11 depicts the

robustness (insensitivity) to parameters (+10%) variation. Fig. 12 depicts the robustness

(insensitivity) to parameters (-10%) variation. The high frequency chatter is due to

neglecting the fast dynamics i.e. dynamics of the electric of the electric part. In order to

reduce the weighting of the large initial error & to Penalise small error occurring later in

response move heavily, the following performance index is proposed.The integral square

error (ISE) is given by (Ogata,1995).

ISE = e 2 (t )dt

T

(28)

The minimum value of ISE is obtained as gain tends to infinity.

120

Reduced order speed control with observer speed

Reference speed

100

speed(rad/sec.)

80

60

40

20

-20

500

1000

1500

time(sec.)

2000

2500

3000

Fig. 6. Response of sliding mode reduced order speed control with observer speed.

www.intechopen.com

176

Sliding Mode Control

5. Conclusions

The SMC approach to speed control of dc machines is discussed. Both theoretical and

implementation result speed control based on reduced order with measured speed and

reduced order with observer speed, using simulation are conducted. Besides, reduced order

observer deals with the chattering problem, en-counted often in sliding mode. Control area

Selection of the control variable (angular position, speed, torque) leaves basic control

structures unchanged. Inspection of Fig. 7(a), 7(b), 7(c) & 7(d) reveals that reduced order

speed control with observer speed produces smaller overshoot & oscillation than the

reduced order speed with measure speed (Panchade et al.,2007). The system is proven to be

robust to the parameters variations, order reduction, fast response, and robustness to

disturbances.

80

speed error of reduced order speed control with

observer speed

speed error of reduced order speed control with

measured speed

120

Reduced order speed control with observer speed speed

Reduced order speed control with measured speed

speed error(rad/sec.)

100

80

Speed(rad/sec.)

60

60

40

40

20

20

-20

0

-20

100

200

300

400

500

600

time(sec.)

700

800

900

-40

1000

100

200

300

400

500 600

time(sec.)

(a)

700

800

900

1000

(b)

5

3.5

6000

Reduced order speed control with observer speed

Reduced order speed control with measured speed

Integral square error ( ISE )

squared speed error

5000

4000

3000

2000

2.5

Reduced order with observer speed

Reduced order with measured speed

2

1.5

0.5

1000

x 10

100

200

300

400

500

600

time(sec.)

(c)

700

800

900

1000

0

0

50

100

150

200

250

300

Time(sec.)

(d)

Fig. 7. (a) Response of the sliding mode speed control with reference speed 75 radian per

sec. (b) The variation error with reference speed 75 radian per sec. (c) The variation of

squared error with reference speed 75 radian per sec (d) Integral square error (ISE)

www.intechopen.com

350

177

Sliding Mode Control of DC Drives

1500

Armature voltage(volts)

1000

500

-500

-1000

-1500

100

200

300

400

500

600

Time(sec.)

700

800

900

1000

Fig. 8. Variation of the controller for reduced order speed control with observed speed at

load condition

600

armature vlitage(volts)

400

200

-200

-400

-600

100

200

300

400

500

600

Time(sec.)

700

800

900

1000

Fig. 9. Variation of the controller for reduced order speed control with measured speed at

load condition

www.intechopen.com

178

Sliding Mode Control

switching surface

(a)

x 10

Reduced order with measured speed

0.5

0

-0.5

-1

500

1000

switching surface

x 10

1500

2000

time(sec.)

2500

3000

3500

Reduced order with observer speed

0

-1

-2

500

1000

1500

2000

time(sec.)

2500

3000

3500

Fig. 10. Response of sliding surface in sliding mode speed control.

speed(rad/sec.)

150

100

speed response with armature resistance of 0.55 ohm

& La of 0.0011H

50

0

-50

speed (rad/sec.)

0

200

500

1000

1500

2000

2500

3000

speed response with armature resistance of 0.5 ohm &

La of 0.001 H

100

0

-100

500

1000

1500

time(sec.)

2000

Fig. 11. Robust (Insensitivity) to parameters (+10%) variation.

www.intechopen.com

2500

3000

179

Sliding Mode Control of DC Drives

200

Speed(rad/sec.)

speed at Ra=0.5 Ohm&La=0.001H

100

-100

500

1000

1500

2000

2500

3000

Speed(rad/sec.)

200

speed at Ra=0.45Ohm &La=0.0009H

100

0

-100

500

1000

1500

Time(sec.)

2000

2500

3000

Fig. 12. Robust (insensitivity) to the parameters (-10%) variation

6. Acknowledgements

We are extremely grateful to Shri Sunil Raisoni, Chairmen of Raisoni Group of Institutions

and Ajit Tatiya, Director, Raisoni group of Institutions (Pune campus) for their holehearted

support.

We would also like to express my deep sense of gratitude to Dr. R. D. Kharadkar, Principal

of G. H. Raisoni Institute of Engineering & Technology Pune and Prof. B. I. Khadakbhavi

Principal College of Engineering Ambajogai for their support, kind co-operation and

encouragement for pursuing this work.

7. References

John Y. Hung, W. Gao, J.C. Hung. Variable Structure Control: A survey, IEEE Trans. on

Industrial Electronics, Vol.40, no.1, pp.1- 22, February 1993.

De Carlo, Zak S. H. Mathews G.P. Variable structure control of nonlinear multivariable

systems: A Tutorial, Proceedings of IEEE, Vol.76, No.3, pp. 212-232, March 1988.

V.I. Utkin.Sliding mode control design principles and applications to Electric drives, IEEE

Trans on Industrial Electronics, Vol.40, no.1, pp. 23-36, February 1993.

A. Sabanovic, KenzoWada, Faruk Ilalovic, Milan Vujovic. Sliding modes in Electrical

machines control systems Proceedings of IEEE, vol., No., pp.73-78, 1993.

N. Sabanovic, A. Sabanovic,k. Jezernik O.M.Vujovic.Current control in three phase

switching converters and AC electrical machines, in Proceedings of the International

IECON94, pp. 581-586.

www.intechopen.com

180

Sliding Mode Control

P.C. Krause, O.Wasynczuk, Scottd D. Sudhoff. Analysis of Electric Machinery and Drive

systems, IEEE Press John Wiley & Sons Inc. Publication, 2nd edition 2004, pp. 67-96.

V. Utkin , Jurgen Guldner, J. Shi, Sliding mode control in Electromechanical Systems, Taylor and

Francis London, 1999.

Katsuhiko Ogata. Modern Control Engineering, Prentice Hall of India Pvt. Ltd. New Delhi,

2nd edition, 1995, pp. 295-303.

V.M.Panchade, L.M.Waghmare,B.M.Patre,P.P.Bhogle. Sliding Mode Control of DC Drives ,

Proceedings of 2007 IEEE International Conference on Mechatronics and Automation,

ISBN 1-4244-0828-8 ,pp.1576-1580, August 5 - 8, 2007, Harbin, China.

www.intechopen.com

Sliding Mode Control

Edited by Prof. Andrzej Bartoszewicz

ISBN 978-953-307-162-6

Hard cover, 544 pages

Publisher InTech

Published online 11, April, 2011

Published in print edition April, 2011

The main objective of this monograph is to present a broad range of well worked out, recent application

studies as well as theoretical contributions in the field of sliding mode control system analysis and design. The

contributions presented here include new theoretical developments as well as successful applications of

variable structure controllers primarily in the field of power electronics, electric drives and motion steering

systems. They enrich the current state of the art, and motivate and encourage new ideas and solutions in the

sliding mode control area.

How to reference

In order to correctly reference this scholarly work, feel free to copy and paste the following:

B. M. Patre, V. M. Panchade and Ravindrakumar M. Nagarale (2011). Sliding Mode Control of DC Drives,

Sliding Mode Control, Prof. Andrzej Bartoszewicz (Ed.), ISBN: 978-953-307-162-6, InTech, Available from:

http://www.intechopen.com/books/sliding-mode-control/sliding-mode-control-of-dc-drives

InTech Europe

University Campus STeP Ri

Slavka Krautzeka 83/A

51000 Rijeka, Croatia

Phone: +385 (51) 770 447

Fax: +385 (51) 686 166

www.intechopen.com

InTech China

Unit 405, Office Block, Hotel Equatorial Shanghai

No.65, Yan An Road (West), Shanghai, 200040, China

Phone: +86-21-62489820

Fax: +86-21-62489821

También podría gustarte

- Sony KV-29FS120 (Chassis BA-6) PDFDocumento81 páginasSony KV-29FS120 (Chassis BA-6) PDFJuan Diego Calsin TapiaAún no hay calificaciones

- Sensorless SMC Controls DFIG Grid ConnectionDocumento25 páginasSensorless SMC Controls DFIG Grid ConnectionJuan Diego Calsin TapiaAún no hay calificaciones

- ControlDocumento23 páginasControlJuan Diego Calsin TapiaAún no hay calificaciones

- Various/lc Meter PanelDocumento1 páginaVarious/lc Meter Paneljaelani_jelAún no hay calificaciones

- 200 Chess Problems by HealeyDocumento76 páginas200 Chess Problems by HealeyBercin DassAún no hay calificaciones

- ControlDocumento13 páginasControlJuan Diego Calsin TapiaAún no hay calificaciones

- 200 Chess Problems by HealeyDocumento76 páginas200 Chess Problems by HealeyBercin DassAún no hay calificaciones

- Various/lc Meter PanelDocumento1 páginaVarious/lc Meter Paneljaelani_jelAún no hay calificaciones

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Russian Tea Market Growth and Brand PreferenceDocumento6 páginasRussian Tea Market Growth and Brand PreferenceKing KhanAún no hay calificaciones

- Ch07 Spread Footings - Geotech Ultimate Limit StatesDocumento49 páginasCh07 Spread Footings - Geotech Ultimate Limit StatesVaibhav SharmaAún no hay calificaciones

- Artificial IseminationDocumento6 páginasArtificial IseminationHafiz Muhammad Zain-Ul AbedinAún no hay calificaciones

- Postnatal Assessment: Name Date: Age: D.O.A: Sex: Hospital: Marital Status: IP .NoDocumento11 páginasPostnatal Assessment: Name Date: Age: D.O.A: Sex: Hospital: Marital Status: IP .NoRadha SriAún no hay calificaciones

- Modern Indian HistoryDocumento146 páginasModern Indian HistoryJohn BoscoAún no hay calificaciones

- Statement of Compulsory Winding Up As On 30 SEPTEMBER, 2008Documento4 páginasStatement of Compulsory Winding Up As On 30 SEPTEMBER, 2008abchavhan20Aún no hay calificaciones

- JSA - 0026 Chipping & Granite cutting and lying Work At PB-19Documento2 páginasJSA - 0026 Chipping & Granite cutting and lying Work At PB-19Koneti JanardhanaraoAún no hay calificaciones

- PharmacologyAnesthesiology RevalidaDocumento166 páginasPharmacologyAnesthesiology RevalidaKENT DANIEL SEGUBIENSE100% (1)

- The Online Medical Booking Store Project ReportDocumento4 páginasThe Online Medical Booking Store Project Reportharshal chogle100% (2)

- Username: Password:: 4193 Votes 9 Days OldDocumento6 páginasUsername: Password:: 4193 Votes 9 Days OldΘώμηΜπουμπαρηAún no hay calificaciones

- Emergency Room Delivery RecordDocumento7 páginasEmergency Room Delivery RecordMariel VillamorAún no hay calificaciones

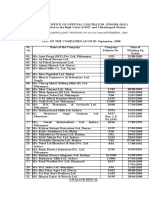

- Supreme Court rules stabilization fees not trust fundsDocumento8 páginasSupreme Court rules stabilization fees not trust fundsNadzlah BandilaAún no hay calificaciones

- Condy LatorDocumento11 páginasCondy LatorrekabiAún no hay calificaciones

- ĐỀ SỐ 3Documento5 páginasĐỀ SỐ 3Thanhh TrúcAún no hay calificaciones

- Ks3 Science 2008 Level 5 7 Paper 1Documento28 páginasKs3 Science 2008 Level 5 7 Paper 1Saima Usman - 41700/TCHR/MGBAún no hay calificaciones

- Boiler Check ListDocumento4 páginasBoiler Check ListFrancis VinoAún no hay calificaciones

- Lesson 2 Mathematics Curriculum in The Intermediate GradesDocumento15 páginasLesson 2 Mathematics Curriculum in The Intermediate GradesRose Angel Manaog100% (1)

- ROPE TENSIONER Product-Catalog-2019Documento178 páginasROPE TENSIONER Product-Catalog-2019jeedanAún no hay calificaciones

- Honors Biology Unit 2 - Energy Study GuideDocumento2 páginasHonors Biology Unit 2 - Energy Study GuideMark RandolphAún no hay calificaciones

- Doe v. Myspace, Inc. Et Al - Document No. 37Documento2 páginasDoe v. Myspace, Inc. Et Al - Document No. 37Justia.comAún no hay calificaciones

- Abinisio GDE HelpDocumento221 páginasAbinisio GDE HelpvenkatesanmuraliAún no hay calificaciones

- Environmental Technology Syllabus-2019Documento2 páginasEnvironmental Technology Syllabus-2019Kxsns sjidAún no hay calificaciones

- HistoryDocumento144 páginasHistoryranju.lakkidiAún no hay calificaciones

- Translation EquivalenceDocumento6 páginasTranslation EquivalenceJamal Anwar TahaAún no hay calificaciones

- How To Check PC Full Specs Windows 10 in 5 Ways (Minitool News)Documento19 páginasHow To Check PC Full Specs Windows 10 in 5 Ways (Minitool News)hiwot kebedeAún no hay calificaciones

- Fong vs. DueñasDocumento2 páginasFong vs. DueñasWinter Woods100% (3)

- Symmetry (Planes Of)Documento37 páginasSymmetry (Planes Of)carolinethami13Aún no hay calificaciones

- Irctc Tour May 2023Documento6 páginasIrctc Tour May 2023Mysa ChakrapaniAún no hay calificaciones

- 27 MARCH 2020: Assignment 5 Question PaperDocumento4 páginas27 MARCH 2020: Assignment 5 Question PaperShadreck SandweAún no hay calificaciones

- Radio Theory: Frequency or AmplitudeDocumento11 páginasRadio Theory: Frequency or AmplitudeMoslem GrimaldiAún no hay calificaciones