Documentos de Académico

Documentos de Profesional

Documentos de Cultura

La Pretencion Es Mejor Que La Cura

Cargado por

jmerinonovoa2885Descripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

La Pretencion Es Mejor Que La Cura

Cargado por

jmerinonovoa2885Copyright:

Formatos disponibles

NORTH SEA

platform maintenance

Prevention is better

than cure

The majority of platforms

in the North Sea were

designed for an operating

life of 25 years. Several of

these are now

approaching 40 years old

and many more are being

considered for a further

extension of life by up to

20 years. Dr Peter Millar*,

Lloyds Register EMEA,

explains how many of the

problems from which such

ageing platforms suffer

can be prevented with

increased inspection and

maintenance regimes.

Figure 1: Lack of inspection and maintenance on a flange and bolts

ne way of considering the life of

an oil or gas platform is to compare it to a human body. As

every one of us knows, the older we get

the more problems we have. Once we

have been affected by the early childhood diseases, such as mumps and

measles, we normally have a relatively

healthy life during our teens, twenties

and thirties. Things start to slide in our

forties and fifties and, by our sixties, the

majority of us have had some kind of

health problems. Cancer is normally

predominant, with breast cancer being

the biggest natural killer of women

and prostate cancer being the biggest

natural killer of men. Other cancers

such as lung and skin cancer are usually

self-inflicted and, to a great extent, can

be prevented by not smoking or having

prolonged exposure to the sun.

Oil platforms follow a similar pattern.

After the initial minor commissioning

and start-up problems the majority of

platforms have a relatively trouble-free

life until they are retired from service

and decommissioned. However, with

many now having exceeded their design

life, we are seeing the results of old age

and the increasing number of problems

that go with extended use. Just like the

situation with the human body, many

of these problems can be prevented

with increased inspection and maintenance regimes. (See Figure 1.)

Steel cancer

Corrosion is basically the cancer of steel

and the old expression Rust never

sleeps holds very true. Steel is actually

thermodynamically unstable with

respect to its oxides and rusting is the

primary way for steel to lose the energy

that was added in transforming iron

ore into a steel ingot. Under normal

onshore circumstances, steel which has

been given a generous paint coating

and is inspected and repainted regularly would be expected to remain in

sound structural condition for many

tens of years.

PETROLEUM REVIEW

JULY

2006

Targetted inspection

Figure 2: Typical corrosion under insulation

Offshore, things are not so simple.

The ocean is one of the harshest environments on the planet. Not only is sea

water and salt spray highly corrosive,

wave motion and wind will also impart

fatigue loading, which combines to

give corrosion fatigue. Corrosion

fatigue is considered synergistic. This

can be thought of as 2 + 2 = 5, which

means that the combination of corrosion and fatigue acting together is

worse than the effects of them both

acting separately.

Delayed diagnosis

Many human diseases remain undiagnosed and hidden for years and only

become noticeable when they start to

affect other organs or bodily systems.

The same is true for offshore platforms.

Take, for example, corrosion under

insulation (CUI). CUI is insidious and

fairly difficult to detect. An inspection

regime requires the removal and reinstatement of the insulation and, in

many cases, scaffolding is needed to

gain access to the area. For this reason

CUI has tended to only become noticeable once the piping has perforated.

Figure 2 shows a typical example.

Given adequate time, money and

resources, inspection regimes can be

developed to ensure not only the present integrity of offshore structures and

facilities but also guarantee their

extended working lives. However, in

locations like the North Sea, unknowns

such as the weather and fog can intervene to sabotage even the best inspection plans.

Another point that is often overlooked also correlates with the medical

PETROLEUM REVIEW

JULY

2006

model, and that is frequency of inspection. In our youth and midlife we tend

to have very infrequent visits to the

doctor; however, in later years, these

increase significantly as our bodies succumb to the ravages of time and, in

many cases, neglect. The same is true

for offshore installations. The inspection frequency profile for a platform

cannot remain static; it has to be a

living, dynamic thing that changes as

the asset ages. No one would argue

that the inspection and maintenance

schedules for a three-year-old platform

are the same as for a 30-year-old one

yet, at times, it is easy to forget that

simple fact. (See Figure 3.)

As an independent inspection authority,

the Lloyds Register group is instrumental in providing integrity services to

many operators worldwide. Part of that

job involves providing solutions to

ongoing integrity problems.

With the relatively recent increase in

oil prices and the intention of many

operators to extend the working life of a

number of platforms, the Lloyds Register

group has started to focus on the problems associated with ageing assets. In the

human body, old age targets certain

areas. Arteries, hearts and lungs are of

primary concern. Muscles, tendons and

skin can largely be ignored. On ageing

platforms, it is the hydrocarbon lines that

should receive the lions share of the

inspection resources. Produced water

and drains may show as much degradation, but the impact of failure on the

environment, platform integrity and,

more importantly, peoples lives, will be

much less. Given limited inspection budgets and resources for older assets, the

focus has to be not just inspection and

maintenance, but targetted, prioritised

and smart inspection and maintenance.

Ultimately, old platforms are like old

people. The amount of care and looking

after they need depends on how they

have been looked after all their lives.

The old saying applies to both

Prevention is better than cure.

*Dr Peter McClean Millar is involved

with Lloyds Register EMEA integrity

services in the North Sea. He has a

degree in Metallurgy, a Masters in

Offshore Engineering, an MBA and a

PhD in Corrosion Fatigue. He is also a

Doctor of Chiropractic.

Figure 3: Degradation of platform gratings

También podría gustarte

- Mine Tailings Dams: When Things Go WrongDocumento13 páginasMine Tailings Dams: When Things Go WrongZonoiko Arafat100% (1)

- IS 1079 Hot Rolled Carbon Steel SheetsDocumento12 páginasIS 1079 Hot Rolled Carbon Steel Sheetssdmel75% (8)

- Consequences of CorrosionDocumento5 páginasConsequences of Corrosionvkto100% (2)

- ClearFlo Manual Ver0709 PDFDocumento33 páginasClearFlo Manual Ver0709 PDFPhineas Magellan0% (1)

- Ship Hull Coatings PDFDocumento36 páginasShip Hull Coatings PDFNur Hidayatul Nadhirah75% (4)

- SpeechDocumento6 páginasSpeechaaron.kharel3657Aún no hay calificaciones

- Section I Significance of CorrosionDocumento101 páginasSection I Significance of CorrosiontayyabAún no hay calificaciones

- CH 08 Inspections & Detection of Defects & DamagesDocumento8 páginasCH 08 Inspections & Detection of Defects & DamagesAmit PandeyAún no hay calificaciones

- For The Guidance of Wise MenDocumento8 páginasFor The Guidance of Wise MenManoj VarrierAún no hay calificaciones

- Thesis Statement Oil SpillsDocumento6 páginasThesis Statement Oil Spillsobyxqnief100% (2)

- BMTDSL Corrosion Resistant Ship WhitepaperDocumento30 páginasBMTDSL Corrosion Resistant Ship WhitepaperDino PedutoAún no hay calificaciones

- LP Briefing - Hatch Cover MaintenanceDocumento7 páginasLP Briefing - Hatch Cover MaintenanceYuzong Zheng100% (1)

- Example of Research Paper About Oil SpillDocumento5 páginasExample of Research Paper About Oil Spillh00yfcc9100% (1)

- Sample Thesis About Oil SpillDocumento4 páginasSample Thesis About Oil Spilldwc59njw100% (2)

- For The Guidance of Wise MenDocumento8 páginasFor The Guidance of Wise MenmarinedgeAún no hay calificaciones

- FracturingDocumento75 páginasFracturingShashank SharmaAún no hay calificaciones

- Enstu 300 Max Graves Final Paper Final DraftDocumento18 páginasEnstu 300 Max Graves Final Paper Final Draftapi-534825627Aún no hay calificaciones

- Oil Spill Research PaperDocumento5 páginasOil Spill Research Paperc9snjtdx100% (1)

- Oil Spill DissertationDocumento7 páginasOil Spill DissertationWriteMyEnglishPaperForMeUK100% (1)

- Oil Spill Research Paper ExampleDocumento7 páginasOil Spill Research Paper Examplen1dihagavun2100% (1)

- Pollution - Regulatory and Liability Regimes Around The WorldDocumento115 páginasPollution - Regulatory and Liability Regimes Around The WorldClyde & Co OffshoreAún no hay calificaciones

- Bio FoulingDocumento7 páginasBio FoulingCatherine Joy Dela CruzAún no hay calificaciones

- Peb 702 Engineering and Society SEMESTER 1 2020 Group Bce-BDocumento1 páginaPeb 702 Engineering and Society SEMESTER 1 2020 Group Bce-Bpramesh naiduAún no hay calificaciones

- 1 - Introduction - 2021 - Techniques For Corrosion MonitoringDocumento5 páginas1 - Introduction - 2021 - Techniques For Corrosion MonitoringKhalil Abdul RazakAún no hay calificaciones

- Term Paper On Nuclear PollutionDocumento5 páginasTerm Paper On Nuclear Pollutionc5p64m3t100% (1)

- Research Paper On Oil SpillsDocumento7 páginasResearch Paper On Oil Spillsgz8reqdcAún no hay calificaciones

- Oil Spill Research Paper IntroductionDocumento5 páginasOil Spill Research Paper Introductionfvj8675e100% (1)

- Research Paper On Marine Pollution PDFDocumento5 páginasResearch Paper On Marine Pollution PDFfealwtznd100% (3)

- BP Oil Spill Research Paper ThesisDocumento5 páginasBP Oil Spill Research Paper Thesisaflefvsva100% (1)

- April May 2014Documento11 páginasApril May 2014Abishek RavichandranAún no hay calificaciones

- Brake MechanismDocumento48 páginasBrake MechanismSanjay GuptaAún no hay calificaciones

- Corrosion HandbookDocumento5 páginasCorrosion HandbookTroy ThomasAún no hay calificaciones

- Ocean Dumping Research PaperDocumento6 páginasOcean Dumping Research Paperqtbghsbnd100% (1)

- Its Time To Stop Pretending Bringing It All Together... : The International Maritime Human Element BulletinDocumento8 páginasIts Time To Stop Pretending Bringing It All Together... : The International Maritime Human Element Bulletindanielandrea13Aún no hay calificaciones

- Thesis Marine PollutionDocumento5 páginasThesis Marine PollutionLinda Garcia100% (2)

- Ocean Pollution Research PaperDocumento9 páginasOcean Pollution Research Paperjzczyfvkg100% (1)

- Demolition Dust: Hazards and ControlDocumento11 páginasDemolition Dust: Hazards and ControlSasi KumarAún no hay calificaciones

- SLB. Corrosion MonitoringDocumento67 páginasSLB. Corrosion MonitoringMauricio Sanchez BAún no hay calificaciones

- Effect of Marine Growth On Offshore StructuresDocumento22 páginasEffect of Marine Growth On Offshore StructuresBolarinwaAún no hay calificaciones

- Term Paper About Oil SpillDocumento6 páginasTerm Paper About Oil Spillc5rk24gr100% (1)

- Research Paper Oil SpillsDocumento5 páginasResearch Paper Oil Spillsaflbskzqa100% (1)

- Thesis Water PollutionDocumento7 páginasThesis Water Pollutionaflpbevnrabaqk100% (2)

- Tailings Dam FailuresDocumento13 páginasTailings Dam FailuresWayne HempelAún no hay calificaciones

- Marine Pollution Thesis StatementDocumento5 páginasMarine Pollution Thesis Statementjoyceknightjackson100% (2)

- Gulf Oil Spill Thesis StatementDocumento4 páginasGulf Oil Spill Thesis Statementafknnkmeo100% (2)

- Marine Engineering Thesis ExamplesDocumento7 páginasMarine Engineering Thesis Examplespatriciaviljoenjackson100% (1)

- Lloyd's - Marine Corrosion ManagementDocumento23 páginasLloyd's - Marine Corrosion ManagementMoustafa BayoumiAún no hay calificaciones

- Thesis Statement On Ocean PollutionDocumento7 páginasThesis Statement On Ocean Pollutionfczeohief100% (1)

- Deepwater Horizon Oil Spill: The Compromise of SafetyDocumento10 páginasDeepwater Horizon Oil Spill: The Compromise of SafetyEduardo SanchezAún no hay calificaciones

- An Ounce of Prevention: Maintaining Well Control Barriers Under Any ConditionDocumento4 páginasAn Ounce of Prevention: Maintaining Well Control Barriers Under Any ConditionSureshAún no hay calificaciones

- Research Paper Topics On FrackingDocumento5 páginasResearch Paper Topics On Frackingikrndjvnd100% (1)

- BMRDocumento710 páginasBMRJarid WadeAún no hay calificaciones

- Review of Related Literature Marine PollutionDocumento7 páginasReview of Related Literature Marine Pollutionafmzyywqyfolhp100% (1)

- Environmental Management Exam 1Documento101 páginasEnvironmental Management Exam 1Muhammad UzairAún no hay calificaciones

- Trends Toward Sustainable Developlment in ShippingDocumento40 páginasTrends Toward Sustainable Developlment in ShippingRaluca MaziluAún no hay calificaciones

- Econ Eportfolio AgDocumento5 páginasEcon Eportfolio Agapi-284522232Aún no hay calificaciones

- Water Pollution Research Paper OutlineDocumento6 páginasWater Pollution Research Paper Outlineafeascdcz100% (1)

- Marine Pollution Term PaperDocumento8 páginasMarine Pollution Term Paperafmzumwfxexgao100% (1)

- A Place For SuDS OnlineDocumento40 páginasA Place For SuDS OnlinepaularupAún no hay calificaciones

- Builders' Risks - Shipyard Risk Assessment: Gard News 191, August/October 2008Documento6 páginasBuilders' Risks - Shipyard Risk Assessment: Gard News 191, August/October 2008jorge9820Aún no hay calificaciones

- S31803Documento2 páginasS31803Elliott RussellAún no hay calificaciones

- Material ASTMDocumento14 páginasMaterial ASTMAdit NugrahaAún no hay calificaciones

- FINAL SMAW-12-Quarter-3-module 3 PDFDocumento20 páginasFINAL SMAW-12-Quarter-3-module 3 PDFRandy Sacatani100% (1)

- Api 571 PDFDocumento3 páginasApi 571 PDFumnartkhAún no hay calificaciones

- 1.1-1.10 - Loading Direct Reduced Iron (Dri)Documento9 páginas1.1-1.10 - Loading Direct Reduced Iron (Dri)Yevgeniy RAún no hay calificaciones

- A Paradigm Shift For Process ControlDocumento4 páginasA Paradigm Shift For Process ControlFranklin Santiago Suclla PodestaAún no hay calificaciones

- 19-5601 Unfired Pressure VesselDocumento30 páginas19-5601 Unfired Pressure VesselANRSrinivasan0% (1)

- Welding Qualification: by Hema SantoshDocumento45 páginasWelding Qualification: by Hema Santoshravi00098Aún no hay calificaciones

- SMAW Welding Skill (W-01) 1Documento57 páginasSMAW Welding Skill (W-01) 1hardish_trivedi7005100% (7)

- Astm A 385 2011Documento8 páginasAstm A 385 2011Sathish Kumar100% (1)

- Upgrading A Draught System With Optimal Materials and MaintenanceDocumento23 páginasUpgrading A Draught System With Optimal Materials and MaintenanceAnonymous hP6ab2D1ppAún no hay calificaciones

- SoR 2014-15 - Without CalculationDocumento139 páginasSoR 2014-15 - Without CalculationNani BalagoniAún no hay calificaciones

- Astm A1001Documento5 páginasAstm A1001zaper664100% (1)

- Comflor Floordecking PDFDocumento39 páginasComflor Floordecking PDFing urbanAún no hay calificaciones

- E45.1207960-1 Determining The Inclusion Content of SteelDocumento19 páginasE45.1207960-1 Determining The Inclusion Content of Steel0511018Aún no hay calificaciones

- WPS PDFDocumento30 páginasWPS PDFtheerapat patkaewAún no hay calificaciones

- Q3, Module 2, Lesson 3Documento9 páginasQ3, Module 2, Lesson 3Jerome A. Gomez100% (2)

- GB700-88 Carbon Structural SteelsDocumento7 páginasGB700-88 Carbon Structural SteelsyuAún no hay calificaciones

- The F638 SE/S2 Is An Extreme Heavy Duty Slurry Control Valve, With An Extended Body Style and Replaceable Body SleeveDocumento11 páginasThe F638 SE/S2 Is An Extreme Heavy Duty Slurry Control Valve, With An Extended Body Style and Replaceable Body SleeveCapacitacion TodocatAún no hay calificaciones

- Global Roofing Solutions Bond-Dek Composite Deck: The Smart Decking PeopleDocumento12 páginasGlobal Roofing Solutions Bond-Dek Composite Deck: The Smart Decking PeopleMedi YuhendraAún no hay calificaciones

- 1a11. IS 228 - Part - 11 - 1990Documento6 páginas1a11. IS 228 - Part - 11 - 1990hhr2412Aún no hay calificaciones

- Votator Mantequilla-MantecaDocumento9 páginasVotator Mantequilla-Mantecaharry sanchez arroyoAún no hay calificaciones

- AWS G2.1.tmpDocumento12 páginasAWS G2.1.tmpgazaliAún no hay calificaciones

- 29006.eng - Cpi.std - Painting Systems SheetsDocumento37 páginas29006.eng - Cpi.std - Painting Systems SheetsMatteoAún no hay calificaciones

- F Surface CoatingsDocumento5 páginasF Surface CoatingsajayAún no hay calificaciones

- 34A - LNG StorageDocumento29 páginas34A - LNG StoragePutu Indra MahatrisnaAún no hay calificaciones

- CVRU FinalDocumento20 páginasCVRU FinalSOBHARANI KOTHAKOTAAún no hay calificaciones

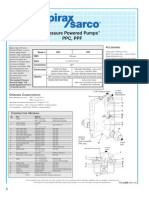

- Spirax Pressure Powered PumpsDocumento2 páginasSpirax Pressure Powered Pumpshappale2002Aún no hay calificaciones

- 50 Grades of Stainless SteelDocumento60 páginas50 Grades of Stainless Steelphutd09Aún no hay calificaciones