Documentos de Académico

Documentos de Profesional

Documentos de Cultura

NSL Loler Matrix

Cargado por

Jogi Oscar SinagaTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

NSL Loler Matrix

Cargado por

Jogi Oscar SinagaCopyright:

Formatos disponibles

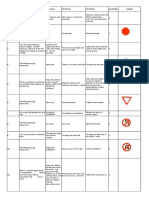

LIFTING APPLIANCES

LEGEND

LIFTING ACCESORIES

LOAD

IND.

LIFTING EQUIPMENT

CRANE (PEDESTAL / MOBILE) (UNDER 20t)

BS7121 / BS EN 13001

CRANES (PEDESTAL / MOBILE) (20t-50t)

BS7121 / BS EN 13001

CRANES (PEDESTAL / MOBILE) (OVER 50t)

BS7121 / BS EN 13001

ELECTRIC OVERHEAD TRAVELLING CRANES

BS7121 / BS EN 13001

MARINE LIFEBOAT DAVITS

BS MA41

DAVIT BLOCKS & ASSOC. EQUIPMENT

BS MA41

FORKLIFT TRUCKS

BS.ISO 5057 / BS EN 1726-1/2

PALLET STACKERS

BS5778 / ISO 5766

ll

ll

ll

ll

ll

ll

ll

ll

PALLET TRUCKS

BS ISO 509 (1996)

s s

10

PERSONNEL & GOODS LIFTS

BS2655 / BS5655 / BS5656

11

SUSPENDED CRADLES

BS2830 / 5974

12

POWERED HOISTS (ELECTRIC)

BS EN 13001

13

POWERED HOISTS (PNEUMATIC)

DIN F.E.M. 9.751

14

MANUAL HOISTS (CHAIN BLOCKS)

BS3243 / BS EN 13157 (see note 5)

15

LEVER HOISTS (PULLIFTS)

BS4898 / BS EN 13157 (see note 5)

16

WIRE ROPE HOISTS (TIRFORS)

BS EN 13157 (see note 5)

17

WIRE ROPES FOR ABOVE

BS302 / BS EN 12385

18

BEAM TROLLEYS

BS EN 13157 (see note 5)

19

BEAM CLAMPS

BS EN 13157 (see note 5)

20

PLATE CLAMPS

21

SINGLE SHEAVE BLOCKS (UP TO 25t)

BS4536 / 4018 / BSEN13157 (note 5)

22

SINGLE SHEAVE BLOCKS (OVER 25t)

BS4536 / BS EN 13157 (see note 5)

23

MULTI-SHEAVE BLOCKS (UP TO 25t)

BS4536 / BS EN 13157 (see note 5)

24

MULTI-SHEAVE BLOCKS (OVER 25t)

BS4536 / BS EN 13157 (see note 5)

25

CRANE HOOK BLOCKS (UP TO 25t)

BS4536 / BS EN 13157 (see note 5)

26

CRANE HOOK BLOCKS (OVER 25t)

BS4536 / BS EN 13157 (see note 5)

27

WINCH (PNEUMATIC)

BS MA31 / ISO 3078

28

WINCH (MAN-RIDING)

29

WINCH (MANUAL)

BS3701 / BS EN 13157 (see note 5)

30

WINCH (DAVIT)

BS EN 13157 (see note 5)

31

STABBING BOARDS

32

RUNWAY BEAMS

BS2853 (see note 1)

33

LIFTING BEAMS (UP TO & INC. 3t)

BS EN 13001 (see note 1)

34

LIFTING BEAMS (OVER 3 UP TO & INC. 6t)

BS EN 13001 (see note 1)

35

LIFTING BEAMS (OVER 6t UP TO & INC. 20t)

BS EN 13001 (see note 1)

36

LIFTING BEAMS (OVER 20 UP TO & INC. 40t)

BS EN 13001 (see note 1)

37

LIFTING BEAMS (OVER 40t)

BS EN 13001 (see note 1)

ll

ll

ll

ll

ll

ll

ll

ll

ll

ll

ll

ll

ll

ll

ll

ll

ll

ll

ll

ll

ll

ll

ll

ll

ll

ll

ll

ll

38

HYDRAULIC RAMS & JACKS

39

MANUAL JACKS

40

TRANSIT CONTAINERS

BS7072 / BS EN 12079 - 1999

41

TRANSIT CONTAINERS

SI 1984 No. 1890

42

MOBILE WORK PLATFORMS

BS 7171 / BS EN 280 - 2001

43

FABRICATED PADEYES & CLAMPS

BS EN 13001 (see note 1)

44

DYNAMOMETERS / CRANE WEIGHERS

BS EN ISO 7500-1

45

LOADS CELLS

BS EN ISO 7500-1

46

SAFE LOADS INDICATORS / RCIs

BS7262 (1990) (see note 2)

47

WIRE ROPE

BS302 / BS EN 12385

48

WIRE ROPE (ON PASSENGER LIFTS)

BS302 / BS EN 12385

49

WIRE ROPE (DIVING OPERATIONS)

BS302 / BS EN 12385

50

WIRE ROPE (MAN-RIDING WINCHES)

BS302 / BS EN 12385

51

WIRE ROPE SLINGS

BS EN 13414 / 1-3

52

WIRE ROPE SLINGS (MULTI-LEG)

BS EN 13414 / 1-3

53

CHAIN SLINGS-GRADE 80

BS EN 818-1 / ISO 3076

54

CHAIN HOOKS & FITTINGS - GRADE 80

ISO 8539

55

POLYESTER SLINGS

BS EN 1492 PT 1, 2 & 4

56

SHACKLES - ALLOY (UP TO 20t)

RR-C 27 1D TYPE IV

57

SHACKLES - ALLOY (OVER 25t)

RR-C 27 1D TYPE IV

58

SHACKLES - HIGHER TENSILE (UP TO 25t)

ISO 2415

59

SHACKLES - HIGHER TENSILE (OVER 25t)

ISO 2415

60

EYEBOLTS (BRITISH)

BS4278 / BS EN ISO 3266

61

EYEBOLTS (U.S.)

62

RIGGING SCREWS (BRITISH)

BS4429

63

RIGGING SCREWS (TURNBUCKLES) (U.S.)

FF-T-791-TYPE 1 FORM 1

64

OPEN WEDGE SOCKETS (BRITISH)

BS7166 / BS EN 13411-6

65

OPEN WEDGE SOCKETS (U.S.)

RR-S-550D TYPE C

l

l

l

l

l

STATUTORY REQUIREMENTS

i

l

s

COMPANY POLICY INCLUDES LIFTING MACHINES IN 6-MONTHLYS

FUCTION TEST ONLY

AMERICAN PATTERN BLOCKS

REFER TO L.R.O.S. / D.N.V. PROCEDURE

DESCENT RATE MUST ALSO FALL BETWEEN 90-180 FT / MIN

AT THE DISCRETION OF THE INSPECTION BODY

ACCEPTED PRACTICE

MUST BE CALIBRATED ANNUALLY

SAMPLE TO BE DESTRUCTED TO VERIFY MATERIALS

F.O.S. VARIES - REFER TO BS5655 / PD 6500

W

N

METAL END FITTINGS ONLY

NOTE 1

l

l

l

l

ll

ll

ll

ll

l

ll

ll

ll

ll

ll

ll

ll

ll

ll

ll

l

l

l

l

PLUS N.D.T. REPORT

l

l

l

i

i

i

i

i

l

l

l

l

l

l

i

i

i

i

i

i

i

i

i

i

l

l

l

l

l

l

l

t

l

l

l

l

l

l

l

l

l

n

l

l

l

l

l

l

l

l

l

l

i l

i l

ll

i l

l

l

l

i

i

i

H

H

H

H

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

LIFTING SUPPORT STEELWORK SUCH AS RUNWAY BEAMS, LIFTING

FRAMES, PADEYES, ETC. WITH NO MOVING PARTS CAN HAVE THEIR

PERIODICITY EXTENDED TO 12 MONTHS AS LONG AS:

i) THEY ARE NOT USED FOR SUPPORTING PERSONNEL.

ii) THEIR USE IS INFREQUENT TO THE EXTENT THAT WEAR IS NOT AN

ADVERSE FACTOR AND...

iii) THEY ARE ADEQUETELY COATED / PROTECTED SO THAT

CORROSION IS NOT AN ADVERSE FACTOR.

NOTE 2

IN ADDITION TO THE ANNUAL EXAMINATION, SAFE LOAD INDICATORS

MUST BE FUNCTION CHECKED ON A DAILY BASIS AND CHECKED FOR

CALIBRATION WEEKLY.

NOTE 3

HAND SPLICED TERMINATIONS MUST NOT BE SUBJECTED TO PROOFLOAD TESTING AS EXCESSIVE LOADING CAN DAMAGE AND WEAKEN

THE SPLICE.

NOTE 4

SI 2006 No 2184 (MARINE VERSION OF LOLER) REQUIRES THAT ALL

SHIPS LIFTING EQUIPMENT MUST BE TESTED BY A COMPETENT

PERSON EVERY 5 YEARS.

l

l

n

n

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

i

l

l

l

l

l

l

l

l

NOTE 5

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

N

l

l

FACTORS OF SAFETY

OTHER

4:1

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

t

t

t

t

t

t

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

ll

ll

ll

ll

ll

ll

ll

l

l

l

l

l

l

l

l

l

l

l

l

H

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

N

N

3:5:1

5:1

4:5:1

6:1

7:1

6:5:1

8:1

THESE MAY VARY SLIGHTLY

DEPENDANT ON MANUFACTURERS

10:1

OTHER

STRESS CALCULATIONS

CALIBRATION CERTIFICATE

S.I. 1890

l

l

l

l

l

l

REFER TO SPECIFIC DESIGN CODES

INITIAL FACTORY TEST

i

i

i

i

i

i

i

s s

ll

ll

12 12 30

l

l

s s

ll

ll

ll

ll

LOLER SI 1998 No 2307

LOLER SI 2006 No 2184

OTHER

FULL FABRICATION PACKAGE

10

DESTRUCTION SAMPLE CERT.

MTHS M

DOCUMENTATION

REQUIREMENTS

CERT. OF CONFORMITY / TEST

10 25 50 100 300 3

BS EN 12079 1999

EXCESS

LOAD (t)

REFER TO I.L.O. PAMPHLET 188

% ABOVE SWL

SWL x 2.5

PROOF LOADS

SWL x 2.2

ANNUALLY

QUADRENNIALLY

PERIODIC

EXAM. REQ.

PROOF LOAD TESTING

EVERY 5 YEARS (see note: 4)

MANUFACTURING

CODES / STANDARDS

EQUIPMENT TYPE

2014 Edition

PRIOR TO FIRST USAGE

Lifting Equipment

Legislation Matrix

AFTER REPAIR / MODIFICATION

INITIAL

EXAM / TEST

l

l

l

l

l

l

l

l

l

l

l

ALTHOUGH BRITISH STANDARDS ARE FOR GUIDANCE ONLY AND AS

SUCH, COMPLIANCE IS NOT MANDATORY, WE USUALLY RECOMMEND

THAT THE GUIDANCE CONTAINED WITHIN THESE STANDARDS IS

FOLLOWED AS THIS WILL USUALLY HELP YOU COMPLY WITH YOUR

DUTIES UNDER HEALTH & SAFETY LEGISLATION. HOWEVER, SOME

STANDARDS HAVE BEEN REVISED / REWRITTEN BY EUROPEAN

TECHNICAL COMMIT TEES AND UNFORTUNATELY, ONE OF THE

REPLACEMENT STANDARDS, SPECIFICALLY BS EN 13157, APPEARS TO

HAVE BEEN WRITTEN BY PERSONS WITH VERY LITTLE OR INDEED NO

PRIOR KNOWLEDGE OF LIFTING EQUIPMENT, I.E. THE NEW STANDARD

DOES NOT CONTAIN THE QUALITY TECHNICAL INFORMATION

NOR SAFETY ADVICE CONTAINED IN THE VARIOUS STANDARDS IT

SUPERSEDED. IT ALSO ADDRESSES LIFTING EQUIPMENT THAT

HAS NEVER EXISTED (NOR NEVER WILL). FOR THAT REASON, AND

IN SIMILAR CIRCUMSTANCES, WE WILL CONTINUE TO QUOTE THE

PREVIOUS WITHDRAWN STANDARDS.

42 Queens Road, Aberdeen AB15 4YE

Tel: +44(0)1224 208988

email: info@nsl-aberdeen.com | web: nsl.ascoworld.com

Copyright North Sea Lifting Limited 1989 (Revised 2014)

También podría gustarte

- Training Text SK200-8Documento284 páginasTraining Text SK200-8Ade Herdiana100% (23)

- EXJ - 19A99 Jeep XJ Service ManualDocumento12 páginasEXJ - 19A99 Jeep XJ Service ManualhottubdocAún no hay calificaciones

- NSL Loler MatrixDocumento1 páginaNSL Loler MatrixBrian McIntoshAún no hay calificaciones

- Loler AcopDocumento71 páginasLoler AcopMoheb BotrosAún no hay calificaciones

- Zoomlion Mobile Crane RT75 Load Chart ManualDocumento49 páginasZoomlion Mobile Crane RT75 Load Chart Manualmonsieur_son100% (1)

- LEEA 030 2a1 Certificate of Thorough Examination (Overseas) (Assc)Documento1 páginaLEEA 030 2a1 Certificate of Thorough Examination (Overseas) (Assc)hastmishAún no hay calificaciones

- Loler MatrixDocumento1 páginaLoler MatrixjohnsonpintoAún no hay calificaciones

- Traffic SymbolDocumento27 páginasTraffic SymbolraviAún no hay calificaciones

- Testing ProcedureDocumento6 páginasTesting Procedure810806100% (1)

- Wire Rope Discard CriteriaDocumento14 páginasWire Rope Discard CriteriaDhanraj Patil100% (1)

- SI-01 - R03 Banksman-Crane Operations PDFDocumento64 páginasSI-01 - R03 Banksman-Crane Operations PDFFatih D. PrasetioAún no hay calificaciones

- Mewps Operator Practical Only Assessment Sheets 2021 MercuryDocumento4 páginasMewps Operator Practical Only Assessment Sheets 2021 MercuryWILLIAM KEAGUE100% (1)

- BS 7121-2-12012 AbstractDocumento7 páginasBS 7121-2-12012 AbstractPrasanth Varrier0% (1)

- Lifting Insp StandardsDocumento3 páginasLifting Insp StandardsChandrasekhar Sonar100% (2)

- Iso 18893-2014Documento32 páginasIso 18893-2014ali ahmadAún no hay calificaciones

- Owen Falls MovementsDocumento12 páginasOwen Falls Movementssemuwemba100% (2)

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocumento1 páginaAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithAún no hay calificaciones

- Daily Crane Inspection OHS PR 009 FM 01 033Documento1 páginaDaily Crane Inspection OHS PR 009 FM 01 033cmrig74100% (1)

- User Manual - X904Documento26 páginasUser Manual - X904Foad MirzaieAún no hay calificaciones

- Service Boom Inspection and RepairDocumento60 páginasService Boom Inspection and RepairJEILER1982Aún no hay calificaciones

- BS 07121-2-4-2013Documento36 páginasBS 07121-2-4-2013Abdel Rahman SalahAún no hay calificaciones

- FerrulesDocumento22 páginasFerrulesJogi Oscar Sinaga100% (1)

- FerrulesDocumento22 páginasFerrulesJogi Oscar Sinaga100% (1)

- Sans2415 PDFDocumento27 páginasSans2415 PDFCwenga CwestarAún no hay calificaciones

- Suruhanjaya TenagaDocumento43 páginasSuruhanjaya Tenagaavenged sevenfold6989% (9)

- Visual and Ultrasonic Inspection of CraneDocumento7 páginasVisual and Ultrasonic Inspection of CranePDDELUCA100% (2)

- Cargo Net l3 Ast Le Adma 314Documento6 páginasCargo Net l3 Ast Le Adma 314Anwar DeenAún no hay calificaciones

- Reverse Engineering Serial ProtocolDocumento19 páginasReverse Engineering Serial ProtocolRichardmsiska100% (1)

- Iso 1496-5 1991 Amd 1-1993 PDFDocumento8 páginasIso 1496-5 1991 Amd 1-1993 PDFchertanAún no hay calificaciones

- BS en Iso 10855-3-2018Documento26 páginasBS en Iso 10855-3-2018beshoyAún no hay calificaciones

- EMMARDocumento5 páginasEMMARNisar DeenAún no hay calificaciones

- Crane Pre Mobilization Check ListDocumento2 páginasCrane Pre Mobilization Check ListvadivvelkavinAún no hay calificaciones

- NSL Loler MatrixDocumento1 páginaNSL Loler MatrixAndrew Grimes100% (1)

- LEEA-059-2 Documentation and Marking - Part 2 Powered Lifting MachinesDocumento6 páginasLEEA-059-2 Documentation and Marking - Part 2 Powered Lifting MachinesnoormanmubarakAún no hay calificaciones

- LEEA 059 6 Documentation&Marking-Part6Documento24 páginasLEEA 059 6 Documentation&Marking-Part6GaniyuAún no hay calificaciones

- LEEA Report of Thorough ExaminationDocumento1 páginaLEEA Report of Thorough ExaminationengmuhmudAún no hay calificaciones

- Indra: Method Statement For Load Test of Trolley Beams, A-Frame and Jib Crane (Davit Type) (JGC Direct Work)Documento57 páginasIndra: Method Statement For Load Test of Trolley Beams, A-Frame and Jib Crane (Davit Type) (JGC Direct Work)med chabaneAún no hay calificaciones

- LEEA - Instruction For Safe Use of Flat Woven Webbing SlingsDocumento2 páginasLEEA - Instruction For Safe Use of Flat Woven Webbing Slingsdonnyars1979Aún no hay calificaciones

- NSL LOLER Matrix PDFDocumento1 páginaNSL LOLER Matrix PDFdel3333100% (1)

- Unit 1.14 - Shackles: 1.1 Body and Pin Forging 1.2 Heat Treatment 1.3 FinishDocumento8 páginasUnit 1.14 - Shackles: 1.1 Body and Pin Forging 1.2 Heat Treatment 1.3 Finisheetua100% (2)

- Lifting Standards List: Item Description Standard / Last Edition Remarks 1 2 3 4Documento1 páginaLifting Standards List: Item Description Standard / Last Edition Remarks 1 2 3 4Ahmed Awwad100% (1)

- 1 IntroductionToArtificialLiftMethodsDocumento29 páginas1 IntroductionToArtificialLiftMethodsMahesh MahajanAún no hay calificaciones

- List of Lifting StandardsDocumento3 páginasList of Lifting StandardsJawad Ramadan LebzoAún no hay calificaciones

- LEEA Handbook PDFDocumento1 páginaLEEA Handbook PDFparamarthasom1974Aún no hay calificaciones

- LEEA-051 Guidance On Design Inspection and Use of Water Bags As Test Weights in The Offshore Industry Version 1 October 2012Documento7 páginasLEEA-051 Guidance On Design Inspection and Use of Water Bags As Test Weights in The Offshore Industry Version 1 October 2012GaniyuAún no hay calificaciones

- BS en 474-6-2022Documento29 páginasBS en 474-6-2022Lijo M100% (2)

- As 1353.1-1997 Flat Synthetic-Webbing Slings Product SpecificationDocumento7 páginasAs 1353.1-1997 Flat Synthetic-Webbing Slings Product SpecificationSAI Global - APAC0% (1)

- Fork Extensions Crepa-22Documento13 páginasFork Extensions Crepa-22Jogi Oscar SinagaAún no hay calificaciones

- ISO - 13284 - EN - Forklift Extention PDFDocumento6 páginasISO - 13284 - EN - Forklift Extention PDFArsénio MatolaAún no hay calificaciones

- Crane Sheave - Early FailuresDocumento14 páginasCrane Sheave - Early FailuresMichael WoodAún no hay calificaciones

- Loc Guidelines For Marine LiftingDocumento32 páginasLoc Guidelines For Marine LiftingFoxg98924Aún no hay calificaciones

- MSC in Lift Engineering, University of NorthamptonDocumento6 páginasMSC in Lift Engineering, University of NorthamptonJogi Oscar Sinaga100% (1)

- BS ISO 2330 FLT FORK ARMS TestingDocumento12 páginasBS ISO 2330 FLT FORK ARMS TestingEderAún no hay calificaciones

- BS en 13414-1 2003 PresentationDocumento6 páginasBS en 13414-1 2003 PresentationAlbadeel Inspection & Conformity Co. ltd100% (1)

- LEEA 059 5 Guidance To Documentation & Marking Part5Documento23 páginasLEEA 059 5 Guidance To Documentation & Marking Part5GaniyuAún no hay calificaciones

- Examen Nivel III SNT TC 1A - BasicoDocumento4 páginasExamen Nivel III SNT TC 1A - BasicoLeon Heart FCAún no hay calificaciones

- Guidance To The Verification of Sockets and Davits.: Document Reference LEEA 061Documento18 páginasGuidance To The Verification of Sockets and Davits.: Document Reference LEEA 061GaniyuAún no hay calificaciones

- Wire Rope TerminationsDocumento16 páginasWire Rope TerminationschinphengAún no hay calificaciones

- Opito Rigger TrainingDocumento61 páginasOpito Rigger TrainingTasia DiAún no hay calificaciones

- Product Life CycleDocumento36 páginasProduct Life CycleArun Narayanan67% (6)

- LEEA 032 Guide To Written Schemes Free VersionDocumento7 páginasLEEA 032 Guide To Written Schemes Free VersionGaniyu100% (1)

- Certificate of Visual Examination and Mpi: Description of Equipment Crane HookDocumento12 páginasCertificate of Visual Examination and Mpi: Description of Equipment Crane HookMichael OkwuwaAún no hay calificaciones

- BS Din en 13411-3 - 2009Documento32 páginasBS Din en 13411-3 - 2009Rakesh DasAún no hay calificaciones

- Sabs GuideDocumento3 páginasSabs Guidealextentwenty0% (1)

- Bs 7121 Part2-2003 (Code of Practice For Safe Use of Cranes-IDocumento1 páginaBs 7121 Part2-2003 (Code of Practice For Safe Use of Cranes-ISmeb PoltAún no hay calificaciones

- EIAC Requirements TrainingDocumento52 páginasEIAC Requirements TrainingFarrukh AhmedAún no hay calificaciones

- Jib Crane Inspection Report 04-1005195 - J1610688 - NQC1154 - PDFDocumento3 páginasJib Crane Inspection Report 04-1005195 - J1610688 - NQC1154 - PDFAnonymous N2Se0bYAún no hay calificaciones

- LEEA-059-1 Documentation and Marking - Part 1 Manual Lifting Machines - Version 2 PDFDocumento14 páginasLEEA-059-1 Documentation and Marking - Part 1 Manual Lifting Machines - Version 2 PDFopreamihAún no hay calificaciones

- CIA-Brochure Crane Institute of AmericaDocumento8 páginasCIA-Brochure Crane Institute of AmericaJonathan Soto OlayaAún no hay calificaciones

- 2012 OL1 1.2 E Student 017717 Marker 42Documento3 páginas2012 OL1 1.2 E Student 017717 Marker 42alexedamalaAún no hay calificaciones

- LEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories Non Fixed Load Lifting Attachments - Version 2 - Feb 2015Documento17 páginasLEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories Non Fixed Load Lifting Attachments - Version 2 - Feb 2015Ulviyye ElesgerovaAún no hay calificaciones

- Model m25 Free Fall Service ManualDocumento44 páginasModel m25 Free Fall Service ManualManuel Rodriguez100% (1)

- As 2359.15-2005 Powered Industrial Trucks Fork-Arm Extensions and Telescopic Fork Arms - Technical CharacteriDocumento8 páginasAs 2359.15-2005 Powered Industrial Trucks Fork-Arm Extensions and Telescopic Fork Arms - Technical CharacteriSAI Global - APACAún no hay calificaciones

- 8689-2018 Sixco Chain SlingDocumento2 páginas8689-2018 Sixco Chain SlingAnonymous wuugFvOBjZAún no hay calificaciones

- TNT 02-2Documento8 páginasTNT 02-2Jogi Oscar SinagaAún no hay calificaciones

- Ufc 3 430 07Documento84 páginasUfc 3 430 07Jogi Oscar SinagaAún no hay calificaciones

- 41953Documento18 páginas41953Jogi Oscar SinagaAún no hay calificaciones

- AB-012 Pressure Vessel Inspection ReportDocumento1 páginaAB-012 Pressure Vessel Inspection ReportJogi Oscar SinagaAún no hay calificaciones

- WLL Veification of Lifting Set Base On BS en 12079Documento3 páginasWLL Veification of Lifting Set Base On BS en 12079JogiAún no hay calificaciones

- Extra Heavy Wire Rope ThimblesDocumento1 páginaExtra Heavy Wire Rope ThimblesJogi Oscar SinagaAún no hay calificaciones

- Hoisting in House Training Providers Guidelines For Registration 1Documento4 páginasHoisting in House Training Providers Guidelines For Registration 1Jogi Oscar SinagaAún no hay calificaciones

- Tank 182Documento2 páginasTank 182Jogi Oscar SinagaAún no hay calificaciones

- Hydrogen Embrittlement: Causes, Effects & Prevention: Sidheshwar Kumar 107MM024Documento24 páginasHydrogen Embrittlement: Causes, Effects & Prevention: Sidheshwar Kumar 107MM024Jogi Oscar SinagaAún no hay calificaciones

- Budgit® Push and Hand-Geared TrolleysDocumento2 páginasBudgit® Push and Hand-Geared TrolleysJogi Oscar SinagaAún no hay calificaciones

- Threadprotrusion 110731084506 Phpapp02 PDFDocumento163 páginasThreadprotrusion 110731084506 Phpapp02 PDFJogi Oscar SinagaAún no hay calificaciones

- RC Build FlyDocumento46 páginasRC Build FlyBlashko GjorgjievAún no hay calificaciones

- Forklift Truck 3T, Logistic Forklift, China Lifting Equipment ManufacturerDocumento2 páginasForklift Truck 3T, Logistic Forklift, China Lifting Equipment ManufacturerJogi Oscar SinagaAún no hay calificaciones

- Sub Button2Documento2 páginasSub Button2Jogi Oscar SinagaAún no hay calificaciones

- 1Documento1 página1Jogi Oscar SinagaAún no hay calificaciones

- Spreader BarDocumento1 páginaSpreader BarJogi Oscar SinagaAún no hay calificaciones

- Budgit Hvy Duty Rigid MNT IBeam and Pat Track Trolley 113534 99Documento12 páginasBudgit Hvy Duty Rigid MNT IBeam and Pat Track Trolley 113534 99Jogi Oscar SinagaAún no hay calificaciones

- PpeDocumento16 páginasPpeJogi Oscar SinagaAún no hay calificaciones

- Spreader BarDocumento1 páginaSpreader BarJogi Oscar SinagaAún no hay calificaciones

- BUDGIT Electric Hoists and Trolley BrochureDocumento16 páginasBUDGIT Electric Hoists and Trolley BrochureJogi Oscar SinagaAún no hay calificaciones

- PVAR Catalog PDFDocumento16 páginasPVAR Catalog PDFrodriguez.gaytanAún no hay calificaciones

- JDN Air Hoists Profi 3 Ti / 6 Ti: The JDN Solution For Subsea HoistingDocumento2 páginasJDN Air Hoists Profi 3 Ti / 6 Ti: The JDN Solution For Subsea HoistingJogi Oscar SinagaAún no hay calificaciones

- COMMSCOPE CAT6 - CAT5E Patch PanelDocumento3 páginasCOMMSCOPE CAT6 - CAT5E Patch PanelZulkifle Norul NizaAún no hay calificaciones

- Interior Trim: Section: 9GDocumento16 páginasInterior Trim: Section: 9GBlakess SpanAún no hay calificaciones

- Mtag Howto Singlesignonforapexapplicationsusingkerberos 150330020541 Conversion Gate01Documento29 páginasMtag Howto Singlesignonforapexapplicationsusingkerberos 150330020541 Conversion Gate01Quique FLow-ersAún no hay calificaciones

- Durco IOM Big MX Butterfly Valve V-380-E PDFDocumento28 páginasDurco IOM Big MX Butterfly Valve V-380-E PDFUtku Kepcen100% (1)

- RLUDocumento3 páginasRLUMadhuri KomanduriAún no hay calificaciones

- Manuel - Manual RPL23 Rev1.6 EngDocumento10 páginasManuel - Manual RPL23 Rev1.6 EngMayur GuptaAún no hay calificaciones

- SBJX 20170913Documento20 páginasSBJX 20170913mAún no hay calificaciones

- Object Oriented ProgrammingDocumento70 páginasObject Oriented ProgrammingVijaysai PanchadiAún no hay calificaciones

- Jere SignatureDocumento198 páginasJere SignatureMa. Luisa A. AngsincoAún no hay calificaciones

- Easergy PS100 48VDC Power SupplyDocumento2 páginasEasergy PS100 48VDC Power SupplyRichard SyAún no hay calificaciones

- Cimcool Cimperial HD 812 02Documento2 páginasCimcool Cimperial HD 812 02tribolasAún no hay calificaciones

- Cosmoplast Upvc Drainage Pipes FittingsDocumento34 páginasCosmoplast Upvc Drainage Pipes FittingsBahar AbdulqadirAún no hay calificaciones

- Official Websites: How To Determine Applicable Product Safety Standards: 5 MethodsDocumento9 páginasOfficial Websites: How To Determine Applicable Product Safety Standards: 5 MethodsChandru HanchinalAún no hay calificaciones

- FibracousticDocumento2 páginasFibracousticPratik ThakkarAún no hay calificaciones

- Foreword: Water Conveyance System Design Guidelines DoedDocumento5 páginasForeword: Water Conveyance System Design Guidelines DoedlucaAún no hay calificaciones

- RWF40 Modulating Feedwater Control Valve Application Guide: RWF40 Compact Universal ControllerDocumento24 páginasRWF40 Modulating Feedwater Control Valve Application Guide: RWF40 Compact Universal ControllersakarisoAún no hay calificaciones

- Cartridge WorldDocumento13 páginasCartridge World田中Aún no hay calificaciones

- Din 862 Caliper Accuracy Standards Jis B7507 Caliper Accuracy StandardsDocumento1 páginaDin 862 Caliper Accuracy Standards Jis B7507 Caliper Accuracy StandardsImanuel KurniawanAún no hay calificaciones

- Bullivants - PWB Anchor 8 Materials HandlingpdfDocumento60 páginasBullivants - PWB Anchor 8 Materials HandlingpdfJill McIntoshAún no hay calificaciones

- Material Handling Control Procedure PDF FreeDocumento9 páginasMaterial Handling Control Procedure PDF FreeAli KayaAún no hay calificaciones

- Australian Standard: Conveyors-Safety RequirementsDocumento8 páginasAustralian Standard: Conveyors-Safety RequirementsCyron Elden T. BodegasAún no hay calificaciones

- ADMSDocumento6 páginasADMSNick SalomoneAún no hay calificaciones

- SGT5-8000H Brochure PDFDocumento16 páginasSGT5-8000H Brochure PDFmyegnrAún no hay calificaciones