Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Control Valve Specification Sheet

Cargado por

Rahul DevaTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Control Valve Specification Sheet

Cargado por

Rahul DevaCopyright:

Formatos disponibles

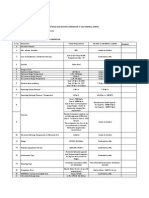

SPEC.NO.

: IP060-45-62-01

REV. 1

PROJECT NO.

: IP060

SH. 1 OF 5

DESCRIPTION

: CONTROL VALVE (GLOBE)

CHEMTEX

AREA : INSTRUMENTATION

IP060

FINE PROJECT

CONTROL VALVE (GLOBE)

(BUYER'S SCOPE)

PT. INDORAMA VENTURES INDONESIA

BANTEN, INDONESIA

REFERENCE SPEC. NO. EIT012-45-62-01 REV.2

THIS DOCUMENT IS PROPRIETARY AND CONFIDENTIAL INFORMATION OF CHEMTEX AND ITS LICENSOR AND MAY BE USED ONLY WITH THEIR PRIOR WRITTEN CONSENT.

REV.

0

1

DESCRIPTION

ISSUED FOR ENQUIRY

REVISED AS MARKED & REISSUED FOR ENQUIRY

STD56201.00X

PREP'D.

CHK'D

APPR'D.

DATE

RKM

RKM

VIM

VIM

SSG

SSG

MAY 24 2013

AUG 26 2013

FILE NAME : IP060-45-62-01-1.XLS

SPEC NO. IP060-45-62-01 REV. 1

CHEMTEX

SHEET 2 OF 5

CONTROL VALVE (GLOBE)

REV.

1

SCOPE:

THIS SPECIFICATION COVERS THE MINIMUM REQUIREMENTS FOR DESIGN, FABRICATION, TESTING AND

GUARANTEES FOR OPERATION AND PERFORMANCE OF THE INSTRUMENTS LISTED HEREIN. VENDOR SHALL

SUPPLY DOCUMENTATION PER "VENDOR DOCUMENT REQUIREMENT SCHEDULE" VD45-62

REFERENCE STANDARDS/ DESIGN CODES :

a)

b)

c)

d)

e)

f)

ISA 75.01.01, 2001

ASME B16.10, 2009

ASME B16.5, 2009

ANSI / FCI 70-2

ASME B16.34, 2004

ISA S75.08.01, 2003

:

:

:

:

:

:

FLOW EQUATIONS FOR SIZING CONTROL VALVES.

FACE TO FACE AND END TO END DIMENSIONS OF VALVES.

PIPE FLANGES AND FLANGED FITTINGS.

LEAKAGE CLASS FOR CONTROL VALVES.

VALVES - FLANGED, THREADED, AND WELDING END.

FACE TO FACE DIMENSIONS FOR INTEGRAL FLANGED GLOBE-STYLE

CONTROL VALVE BODIES.

CODES AND STANDARDS SHALL BE THE LATEST ISSUE TO THE DATE OF INQUIRY INCLUDING ADDENDA,

REVISIONS OR SUPPLEMENTS.

3

TECHNICAL REQUIREMENTS:

ANY DEVIATIONS FROM THE REQUIREMENTS OF THIS SPECIFICATION SHALL BE STATED AS EXCEPTIONS IN

VENDOR'S PROPOSAL. UNLESS SPECIFIC EXCEPTIONS ARE STATED, IT SHALL BE UNDERSTOOD THAT THE

INSTRUMENTS ARE IN COMPLETE ACCORDANCE WITH THE SPECIFICATION.

VALVE CAPACITY :

FOR EQUAL PERCENTAGE VALVES 1.8 TIMES THE CALCULATED CV AT NORMAL FLOW OR 1.3 TIMES THE CALCULATED CV AT MAX. FLOW

WHICHEVER IS GREATER.

VALVE POSITIONER :

VALVE POSITIONER SHALL BE TUBED TO CONTROL VALVE ACTUATOR, TUBING SHALL BE OF SS, 1/4" OD.

HOWEVER VENDOR TO ALTER TUBING SIZE DEPENDING UPON ACTUATOR SIZE & SPEED OF RESPONSE,

ELECTRICAL LEADS SHALL BE TERMINATED ON A JUNCTION BOX.FLYING LEADS ARE NOT ACCEPTABLE.

1/2" NPTF CABLE ENTRY SHALL BE PROVIDED.

AIR SETS :

AIR FILTER REGULATOR SHALL BE OF CAST ALUMINIUM HOUSING WITH 5 MICRON FILTER SIZE, 1/4" NPT

CONNECTION WITH A PRESSURE GAUGE. AIR FILTER REGULATOR SHALL BE MOUNTED & TUBED TO THE

CONTROL VALVE ACTUATOR.

NOISE :

VENDOR SHALL PERFORM NOISE & VELOCITY CALCULATION. MAX. PERMISSIBLE NOISE IS 85 db AT 3 FEET

DISTANCE. IN CASE OF EXCESSIVE NOISE, LOW db TRIM SHALL BE CONSIDERED.

NAMEPLATE :

EACH VALVE SHALL HAVE A CORROSION RESISTANT NAMEPLATE PERMANENTLY FASTENED TO THE VALVE

WITH DETAILS.

VENDOR TO PERFORM SIZING CALCULATIONS AND SHALL BE SUBMITTED ALONG WITH THE OFFER.

10

VENDOR TO PROVIDE STUD BOLTS (FULL THREAD, ASTM A193 GR. B7) & NUTS (HEAVY HEX NUTS, ASTM A194 GR. 2H)

11

ALL NECESSARY HARDWARE WITH VALVE TO ACHIEVE FAIL LOCK POSITION IS PROVIDED BY VENDOR

STD56201.00X

SPEC NO. IP060-45-62-01 REV. 1

CHEMTEX

SHEET 3 OF 5

CONTROL VALVE (GLOBE)

REV.

12

EACH VALVE SHALL HAVE A STAINLESS-STEEL NAMEPLATE PERMANENTLY FASTENED TO THE

SUPERSTRUCTURE, WHICH SHALL BE VISIBLE WHEN THE VALVE IS IN SERVICE AND FULLY INSULATED.

THIS NAMEPLATE SHALL INCLUDE FOLLOWING INFORMATION :

(a)

MANUFACTURE'S NAME

(b)

VALVE SERIAL NUMBER / MODEL NUMBER

(c)

VALVE TAG NUMBER

(d)

VALVE TYPE

(e)

MAXIMUM VALVE BODY PRESSURE RATING

(f)

VALVE BODY MATERIAL AND NOMINAL PIPE SIZE

(g)

TRIM MATERIAL, SIZE AND CHARACTERISTICS

(h)

STEM TRAVEL IN MM

(i)

VALVE ACTION ON AIR FAILURE

(j)

OPERATING SIGNAL RANGE

(k)

CV CAL / CV SEL

ACTUATOR SPRING RANGE

(l)

A SEPARATE TAG INDICATING PACKING MATERIAL.

(m)

13

ALSO, THE TAG NUMBER SHALL BE PROMINENTLY DISPLAYED BY MEANS OF A SEPARATE TAG PLATE

FASTENED TO THE ACTUATOR.

14

IN ADDITION, EACH VALVE SHALL BEAR AN ARROW STAMP ON THE BODY INDICATING THE DIRECTION

OF FLUID OR GAS FLOW.

15

RANGEABILITY :

RANGEABILITY SHALL BE 30:1 UNLESS OTHERWISE SPECIFIED.

16

FLOW DIRECTION :

FLOW DIRECTION ARROW SHALL BE SHOWN ON THE BODY OR PROVISION SHOULD BE MADE FOR

INDICATING SUCH DIRECTION.

17

FLOW DIRECTION SHALL GENERALLY BE AS FOLLOWS :

a) FLOW TENDING TO OPEN FOR SINGLE SEATED VALVES

b) FLOW ENTERING THE SEATS FOR DOUBLE SEATED VALVES

c) SIDE INLET AND BOTTOM OUTLET FOR ANGLE VALVES

18

STEM TRAVEL INDICATOR :

ALL VALVES SHALL BE EQUIPPED WITH A VALVE STEM TRAVEL INDICATOR, WHERE SO FEASIBLE.

19

TESTING :

VENDOR SHALL SUBMIT THEIR COMPLETE QUALITY ASSURANCE TESTING PROCEDURE FOR

CONTROL VALVES.

20

CERTIFICATION :

VENDOR SHALL PROVIDE CERTIFICATION FOR MATERIALS, MECHANICAL TESTS AND ELECTRICAL

CERTIFICATION FOR ACCESSORY, (INCLUDING STATUTORY REGULATIONS AND REQUIREMENTS).

21

VENDOR SHALL QUOTE FOR SPARES FOR TWO YEARS OF OPERATION.

STD56201.00X

SPEC NO. IP060-45-62-01 REV. 1

CHEMTEX

SHEET 4 OF 5

CONTROL VALVE (GLOBE)

REV.

TAG NO :

1810-PV-63535

SERVICE :

ATM AIR BLEED IN TO LRVP SYSTEM

P & ID NO.

503635-1810-060

FLUID :

AIR

NIL

% OF SOLIDS :

CRIT. TEMP.: -140.7 DEG C

UNITS

MAX

NORM

FLOW RATE

kg/hr

INLET PRESSURE

mmHg(A)

760

760

OUTLET PRESSURE

mmHg(A)

380

380

35

4

5

6

7

8

9

10

SERVICE CONDITIONS

FLUID STATE: GAS

11

INLET TEMPERATURE

MOL WT / DENSITY

VISCOSITY/SPEC HEAT RATIO

29

/ kg/m3

cP /

CALCULATED CV

%

TRAVEL

1.41

85

1

1

1

1 Kg/cm2G

1.41

SHUT OFF

0.019 /

dBA

ALLOW. / * PREDICTED SPL

CR. PRES: 38.5 kg/cm2 a

30

29

0.019 /

kg/cm2 a

VAPOR PRESSURE PV

MIN

*

-

85

12

1"

53

TYPE

SPRING & DIAPHRAGM

SCH 80

54

MFR & MODEL

15

LINE NO

1" SU-63515 PS-1

55

SIZE

16

TYPE

GLOBE

56

MODULATING

YES

17

SIZE (BODY / PORT)

*"

57

SPRING ACTION OPEN/CLOSE

CLOSE

18

MAX.PRESS/TEMP

58

MAX. ALLOWABLE PRESSURE

19

MFR & MODEL

59

MIN. REQUIRED PRESSURE

20

BODY/BONNET MATL

ASTM A216 GR.WCB

60

AVAILABLE AIR SUPPLY PRESS

MAX

kg/cm2G

LINER MATERIAL/ID

61

MIN

7.5

kg/cm2G

END

IN

*"

150# FF

62

FAIL POSITION

FAIL LOCK

CONNECTION

OUT

150# FF

24

25

26

*"

63

ACTUATOR ORIENTATION

VERTICAL UP

AS PER ASME B16.5

64

HANDWHEEL TYPE

--

END EXT/MATL

65

AIR FAILURE VALVE

--

FLOW DIRECTION

66

:

4-20 mA DC

TYPE OF BONNET

STANDARD

LUB & ISO VALVE

29

PACKING MATERIAL

PTFE

30

PACKING TYPE

67

LUBE: -

69

70

31

71

TYPE

SINGLE SEAT TOP GUIDED

33

SIZE

34

CHARACTERISTIC

EQUAL %

74

35

BALANCED/UNBALANCED :

75

36

RATED

SS 316

37

TRIM

32

CV

PLUG/BALL/DISK MATL.

INPUT SIGNAL

68

72

RATED TRAVEL: 100% 73

FL:

XT:

76

77

: E/P TYPE

MFR & MODEL

: *

ON INC SIG O/P INCR/DECR

: FIELD SELECTABLE

GAGES

: YES

CAM CHARACTERISTIC

: *

INPUT/OUTPUT SIGNAL

: 4-20mA /

TAG NO.

: -

MFR & MODEL

: -

VOLTS / HZ

: -

WATTS:

BODY MATERIAL

: -

78

CONDUIT CONNECTION

: -

RETAINER MATL.

SS 316

79

MFR & MODEL

: *

40

CAGE/GUIDE MATL.

80

SET PRESSURE

: -

41

STEM/SHAFT MATL.

SS316

81

FILTER

: YES

82

REGULATOR

: YES

: : CL. IV

45

46

47

48

49

50

51

AREA CLASSIFICATION

NON HAZARDOUS

83

HYDRO PRESSURE

ENCLOSURE CLASS

IP 65

84

LEAKAGE CLASS

52

85

VENDOR TO SPECIFY / CONFIRM.

86

87

88

TESTS

44

SPECIALS/ ACCESSORIES

43

AIRSET

SEAT RING/

39

42

89

90

91

92

STD56201.00X

DELETED

SET AT:

TYPE

38

EFF AREA:

28

27

1

-

FLG FACE FINISH

POSITIONER

23

SOL. VALVE

22

VALVE BODY/ BONNET

21

ASME CLASS : 150#

ACTUATOR

& SCHEDULE

14

LINE

PIPE LINE SIZE

13

BY-PASS: -

*

TYPE: -

MFR STD

GAGE: YES

SPEC NO. IP060-45-62-01 REV. 1

CHEMTEX

SHEET 5 OF 5

CONTROL VALVES

REV.

CHEMTEX

VENDOR DOCUMENT REQUIREMENT & SCHEDULE

INSTRUMENTATION

ITEM : CONTROL VALVES

PROJECT : IP060

SPECNO.: IP060-45-62-01

DESCRIPTION OF DOCUMENTATION

PO NO.:

----QUOTE---

VALIDATION DATE:

----------APPROVAL----------

QTY_P QTY_D QTY_P QTY_D

Outline Dimensional Drawings & Connections

Installation Drawings

Wiring / Termination Drawings

Specifications

Calculations - Cv & Noise Level

Calibration Procedures

FM Certificate (if applicable)

UL Certificate (if applicable)

Bill of Materials

I. O. M.

Dimensional Inspection Report (All Valves)

Quality Certificate

Certificate of Conformance (CFC)

Spare Parts List / Commissioning Spares

Hydrostatic Test (All Valves)

Functional Test (All Valves)

Hysteresis and dead band test for throttling valves (All Valves) (Random)

Seat Leakage Test (All Valves)

Capacity Test (Random)

Low Temp. Test (Type Approval, Production Testing)

Vacuum Test (Sample)

Fugitive Emission Test (Sample)

Post Weld Heat Treatment

2

2

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

LEAD (wks)

(4) ARO

----------CERTIFIED---------QTY_R QTY_P QTY_D

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

LEAD (wks)

(4) ARO

(4) ARO

(4) ARO

(4) ARO

(4) ADA

(4) ARO

(4) ARO

(4) ARO

(4) ARO

(4) ARO

(2) PTSR

(2) PTSR

(4) ARO

(4) ARO

(4) PTSR

(4) PTSR

(4) PTSR

(4) PTSR

(4) PTSR

INSTRUCTIONS :

1. Vendor shall be responsible for the correctness of all Drawings and Documents.

2. Vendor must obtain written approval from Chemtex for any deviation from Drawings / Documents specifications.

3. Vendor shall identify Drawings by printing the following information in the title box on each Drawing :

a.

Customer name.

b.

Chemtex Purchase Order Number and Vendor Order Number.

c.

Equipment Item Number and Name to which the print applies.

4. All final Documents are to be bound together with an index. This is to include all applicable items shown in the

table above.

5. Drawings will not be accepted unless the above information is incorporated on all Documents furnished by vendor.

NOTES :

APPROVAL:

CERTIFIED :

ADA

ARO

PTSR

Qty_P

Qty_R

Qty_D

QUOTE

:

:

:

:

:

:

:

Drawings/Documents require Chemtexs approval prior to fabrication.

Vendor shall certify that the Drawings/Documents being furnished accurately describe the

equipment/items covered by this purchase order.

After Drawing/Document Approval

After Receipt of Order

Drawings/Documents required Prior To Shipment Release

Quantity of Prints or Copies

Quantity of Reproducibles

Quantity of Digital Documentation

Prints or copies of Drawings / Documents required With Quotation.

SCHEDULE : VD45-62

REVISION : 14/03/07 REV. A

También podría gustarte

- Check List of 6.6kv PanelDocumento22 páginasCheck List of 6.6kv Panelsantoshkumar100% (1)

- Specification For Lube Oil and Dry Gas Seal SystemDocumento17 páginasSpecification For Lube Oil and Dry Gas Seal Systemjahosolaris5512Aún no hay calificaciones

- Dust Supression SystemDocumento5 páginasDust Supression SystemSUBHOAún no hay calificaciones

- Ni 2916Documento13 páginasNi 2916nandafontenelleAún no hay calificaciones

- SVSW 004110 G16 0001 Rev.a Datasheet For PumpDocumento6 páginasSVSW 004110 G16 0001 Rev.a Datasheet For Pumpnguyenquoc1988Aún no hay calificaciones

- Method Statemant HydroDocumento8 páginasMethod Statemant Hydrojay_rajeshirkeAún no hay calificaciones

- Gen Air TightnessDocumento13 páginasGen Air TightnessSam100% (2)

- Standard Spec For ROVDocumento10 páginasStandard Spec For ROVHitendra PanchalAún no hay calificaciones

- GAIL Metering SkidDocumento36 páginasGAIL Metering SkidSimbu ArasanAún no hay calificaciones

- Procedure For Pneumatic Test Dated 29-09-06Documento6 páginasProcedure For Pneumatic Test Dated 29-09-06ravi00098Aún no hay calificaciones

- Gate Valve DSDocumento5 páginasGate Valve DSkhaireddin100% (1)

- Pdvsa: Engineering Design ManualDocumento9 páginasPdvsa: Engineering Design ManualPedro Elias Castro ArenasAún no hay calificaciones

- 3701 - Safety Relief ValveDocumento10 páginas3701 - Safety Relief ValveSIVA50% (2)

- MM-ZTK-1A-ZPQ-PIP-DTS-0125 Rev A1Documento10 páginasMM-ZTK-1A-ZPQ-PIP-DTS-0125 Rev A1gracemanotocAún no hay calificaciones

- V383773001X00 PDFDocumento4 páginasV383773001X00 PDFSIVAAún no hay calificaciones

- Valve ActuatorsDocumento10 páginasValve Actuatorsluagu100% (1)

- Plan Prueba Stanadyne Db4629Documento4 páginasPlan Prueba Stanadyne Db4629Mas Inyeccion Electronica100% (2)

- Procedure For Governing Oil SystemDocumento29 páginasProcedure For Governing Oil SystemLakshmi NarayanAún no hay calificaciones

- Ultrasonic Gas Metering Skid SpecificationDocumento38 páginasUltrasonic Gas Metering Skid Specificationer_bhavin3119100% (1)

- Jspl-Refilling StationDocumento21 páginasJspl-Refilling StationNaveen Kumar ChauhanAún no hay calificaciones

- TR3 AzZOHOORDocumento32 páginasTR3 AzZOHOORislam el kadyAún no hay calificaciones

- Ip060-45!43!01 Pressure Transmitter (Electronic) (Buyer's Scope)Documento7 páginasIp060-45!43!01 Pressure Transmitter (Electronic) (Buyer's Scope)Rahul DevaAún no hay calificaciones

- General Instruments SpecificationsDocumento44 páginasGeneral Instruments Specificationsavinash1109Aún no hay calificaciones

- Electrical Tech SpecificationDocumento62 páginasElectrical Tech SpecificationNipun KohliAún no hay calificaciones

- InstrumentLst&Datasheets Rev0 PDFDocumento34 páginasInstrumentLst&Datasheets Rev0 PDFEnrique FuentesAún no hay calificaciones

- IACDocumento22 páginasIACSamAún no hay calificaciones

- Oil India Tender for Supply of Choke ManifoldsDocumento48 páginasOil India Tender for Supply of Choke ManifoldsMEHDIAún no hay calificaciones

- Control Valve Data SheetDocumento22 páginasControl Valve Data Sheetnileshana100% (1)

- ATEX-compliant centrifugal fansDocumento8 páginasATEX-compliant centrifugal fansCarlos PintoAún no hay calificaciones

- General Notes On PRDSDocumento6 páginasGeneral Notes On PRDSmkbeast60Aún no hay calificaciones

- Ine - Chiller Carrier - 30rb090Documento13 páginasIne - Chiller Carrier - 30rb090yves2329Aún no hay calificaciones

- City of Cape Town - Automatic Sprinkler Fire Extinguishing SystemDocumento12 páginasCity of Cape Town - Automatic Sprinkler Fire Extinguishing SystemSimonAún no hay calificaciones

- m25 Silencers and Spark Arresters CleanDocumento24 páginasm25 Silencers and Spark Arresters CleanKosol KosolkijwongAún no hay calificaciones

- HP by Pass System-ModifiedDocumento21 páginasHP by Pass System-Modifiedsrigirisetty208100% (1)

- Pre-Commissioning Check List of GeneratorDocumento26 páginasPre-Commissioning Check List of Generatorvikivarma14780% (15)

- APNEA-J-DSH-0002 Rev. 1Documento3 páginasAPNEA-J-DSH-0002 Rev. 1Michelle MartinezAún no hay calificaciones

- Specif-Dust Extraction SystemDocumento12 páginasSpecif-Dust Extraction SystemChristopher LloydAún no hay calificaciones

- PCPL 0532 4 407 03Documento4 páginasPCPL 0532 4 407 03tceterexAún no hay calificaciones

- LP Dosing AgecDocumento12 páginasLP Dosing AgecShameer MajeedAún no hay calificaciones

- Testing Schedule For Commissioning of Condensate Extraction PumpsDocumento13 páginasTesting Schedule For Commissioning of Condensate Extraction PumpsJackSparrow86100% (1)

- Stanadyne 05001Documento4 páginasStanadyne 05001José O TelloAún no hay calificaciones

- Technical Specification for Air Cooled CondenserDocumento7 páginasTechnical Specification for Air Cooled CondenserRajendran SrnAún no hay calificaciones

- Table of Contents: Viii. Instruments & ControlsDocumento72 páginasTable of Contents: Viii. Instruments & ControlsVijay RajAún no hay calificaciones

- TPG Trafo Bay DukongDocumento78 páginasTPG Trafo Bay DukongimhalidaAún no hay calificaciones

- Test Forms For SSDocumento105 páginasTest Forms For SSRakesh Kumar75% (4)

- Technical Comparison Format - Process Gas Reciprocating CompressorDocumento11 páginasTechnical Comparison Format - Process Gas Reciprocating CompressorAlvin Smith100% (1)

- Procedure of UT-TestDocumento2 páginasProcedure of UT-TestJohn ShermanAún no hay calificaciones

- Pressure Releaving StationDocumento11 páginasPressure Releaving StationSreejesh Sundaresan100% (1)

- Technical Specifications For The Mobile Oil Hydraulic Power PackDocumento4 páginasTechnical Specifications For The Mobile Oil Hydraulic Power PackdebasisAún no hay calificaciones

- Condenser Flood TestDocumento14 páginasCondenser Flood Testsrigirisetty208100% (1)

- HP Dosing - AgecDocumento12 páginasHP Dosing - AgecShameer MajeedAún no hay calificaciones

- Technical Specifications - CompDocumento57 páginasTechnical Specifications - CompAnonymous gr5Pr9AVAún no hay calificaciones

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitAún no hay calificaciones

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDe EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGAún no hay calificaciones

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1De EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Calificación: 3.5 de 5 estrellas3.5/5 (3)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDe EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryAún no hay calificaciones

- Flight Test Instrumentation: Proceedings of the Third International Symposium 1964De EverandFlight Test Instrumentation: Proceedings of the Third International Symposium 1964M. A. PerryAún no hay calificaciones

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsAún no hay calificaciones

- Ip060-45!23!05 Turbine FlowmeterDocumento4 páginasIp060-45!23!05 Turbine FlowmeterRahul DevaAún no hay calificaciones

- 1 AsDocumento6 páginas1 AsRahul DevaAún no hay calificaciones

- Efficient Placement of SensorsDocumento2 páginasEfficient Placement of SensorsRahul DevaAún no hay calificaciones

- Ip060-45!43!01 Pressure Transmitter (Electronic) (Buyer's Scope)Documento7 páginasIp060-45!43!01 Pressure Transmitter (Electronic) (Buyer's Scope)Rahul DevaAún no hay calificaciones

- SystemConfigurationReport CNGDocumento10 páginasSystemConfigurationReport CNGRahul DevaAún no hay calificaciones

- Loudspeaker BuilderDocumento85 páginasLoudspeaker BuilderRahul Deva100% (3)

- FAT Procedure Rev.1Documento9 páginasFAT Procedure Rev.1Rahul Deva100% (1)

- Ip060-45!20!02 Orifice Plate Assembly (Buyer's Scope)Documento5 páginasIp060-45!20!02 Orifice Plate Assembly (Buyer's Scope)Rahul DevaAún no hay calificaciones

- Distributorship 2012 LoDocumento1 páginaDistributorship 2012 LoRahul DevaAún no hay calificaciones

- PH1 Pull Handle Call Point Weatherproof Exd FeaturesDocumento2 páginasPH1 Pull Handle Call Point Weatherproof Exd FeaturesRahul DevaAún no hay calificaciones

- Hydraulic Calculation Tutorial #1Documento9 páginasHydraulic Calculation Tutorial #1Rahul DevaAún no hay calificaciones

- Cable and Connection ProductsDocumento26 páginasCable and Connection ProductsRahul DevaAún no hay calificaciones

- Fire Suppression Detecion PrincipleDocumento1 páginaFire Suppression Detecion PrincipleRahul DevaAún no hay calificaciones

- COO-CIS PertaminaDocumento1 páginaCOO-CIS PertaminaRahul DevaAún no hay calificaciones

- Belawan BuildingDocumento1 páginaBelawan BuildingRahul DevaAún no hay calificaciones

- Arun BuildingDocumento1 páginaArun BuildingRahul DevaAún no hay calificaciones

- ASTERIX Rack System CatalogueDocumento7 páginasASTERIX Rack System CatalogueRahul DevaAún no hay calificaciones

- 00 - Gas Detection BasicDocumento28 páginas00 - Gas Detection BasicRahul DevaAún no hay calificaciones

- CCF06032013 00000Documento1 páginaCCF06032013 00000Rahul DevaAún no hay calificaciones

- Ultima X Series Data Sheet - Pak KhunDocumento6 páginasUltima X Series Data Sheet - Pak KhunRahul DevaAún no hay calificaciones

- Experience List Pt. Arya Semesta: NO. Tahun Name of Project Description RemarkDocumento1 páginaExperience List Pt. Arya Semesta: NO. Tahun Name of Project Description RemarkRahul DevaAún no hay calificaciones

- CCF06032013 00003Documento1 páginaCCF06032013 00003Rahul DevaAún no hay calificaciones

- Eticket KMLFHX (1) 1Documento2 páginasEticket KMLFHX (1) 1Rahul DevaAún no hay calificaciones

- Lion Air Eticket Itinerary / Receipt: Condition For More InformationDocumento1 páginaLion Air Eticket Itinerary / Receipt: Condition For More InformationRahul DevaAún no hay calificaciones

- Lion Air Eticket Itinerary / Receipt: Condition For More InformationDocumento1 páginaLion Air Eticket Itinerary / Receipt: Condition For More InformationRahul DevaAún no hay calificaciones

- MSDS - GcaDocumento3 páginasMSDS - Gcapassword2013Aún no hay calificaciones

- Audio Line High-End Preamplifier With ICsDocumento3 páginasAudio Line High-End Preamplifier With ICsRahul DevaAún no hay calificaciones

- Emergency Lighting System Design GuideDocumento10 páginasEmergency Lighting System Design GuideRahul DevaAún no hay calificaciones

- Formulir IM2Documento2 páginasFormulir IM2Rahul DevaAún no hay calificaciones