Documentos de Académico

Documentos de Profesional

Documentos de Cultura

How To Test A Home Refrigerator Comressor For Proper Operation

Cargado por

Samurai Appliance Repair ManTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

How To Test A Home Refrigerator Comressor For Proper Operation

Cargado por

Samurai Appliance Repair ManCopyright:

Formatos disponibles

Component Testing

! WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all ground wires are connected before certifying unit as repaired and/or operational.

Component Description Test Procedures

Compressor When compressor electrical circuit is Resistance test

energized, the start winding current 1. Disconnect power to unit.

causes relay to heat. After an amount of 2. Discharge capacitor by shorting across terminals with a resistor for 1 minute.

starting time, the start winding circuit NOTE: (Some compressors do not have a run capacitor.)

turns off. The relay will switch off the start 3. Remove leads from compressor terminals.

winding circuit even though compressor 4. Set ohmmeter to lowest scale.

has not started (for example, when 5. Check for resistance between

attempting to restart after momentary Terminals “S” and “C”, start winding

power interruption). Terminals “R” and “C”, run winding

If either compressor winding reads open (infinite or very high resistance) or

With “open” relay, compressor will not dead short (0 ohms), replace compressor.

start because there is little or no current Ground test

to start windings. Overload protection will 1. Disconnect power to refrigerator.

open due to high locked rotor run winding 2. Discharge capacitor, if present, by shorting terminals through a resistor.

current. 3. Remove compressor leads and use an ohmmeter set on highest scale.

4. Touch one lead to compressor body (clean point of contact) and other probe

With “shorted” relay or capacitor, to each compressor terminal.

compressor will start and overload

• If reading is obtained, compressor is grounded and must be replaced.

protector will quickly open due to high

current of combined run and start Operation test

windings. If voltage, capacitor, overload, and motor winding tests do not show cause for

failure, perform the following test:

With open or weak capacitor, compressor 1. Disconnect power to refrigerator.

will start and run as normal but will 2. Discharge capacitor by shorting capacitor terminals through a resistor.

consume more energy. 3. Remove leads from compressor terminals.

4. Wire a test cord to power switch.

5. Place time delayed fuse with UL rating equal to amp rating of motor in test

cord socket. (Refer to Technical Data Sheet)

6. Remove overload and relay.

7. Connect start, common and run leads of test cord on appropriate terminals of

compressor.

8. Attach capacitor leads of test cord together. If capacitor is used, attach

capacitor lead to a known good capacitor of same capacity.

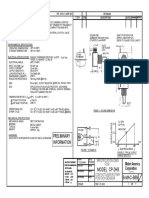

To AC supply

Switch

Compressor

Fuses

C S

Capacitor

Test configuration

9. Plug test cord into multimeter to determine start and run wattage and to check

for low voltage, which can also be a source of trouble indications.

10. With power to multimeter, press start cord switch and release.

• If compressor motor starts and draws normal wattage, compressor is okay

and trouble is in capacitor, relay/overload, freezer temperature control, or

elsewhere in system.

• If compressor does not start when direct wired, recover refrigerant at high

side. After refrigerant is recovered, repeat compressor direct wire test. If

compressor runs after recovery but would not run when direct wired before

recover, a restriction in sealed system is indicated.

• If compressor does not run when wired direct after recovery, replace faulty

compressor.

©2005 Maytag Services 16025629 5

Courtesy of Fixitnow.com Samurai Appliance Repair Man

También podría gustarte

- ASKO T700-Series Dryer Service ManualDocumento65 páginasASKO T700-Series Dryer Service ManualSamurai Appliance Repair Man80% (5)

- Whirlpool Optical Ice Maker Revised DiagnosticsDocumento3 páginasWhirlpool Optical Ice Maker Revised DiagnosticsSamurai Appliance Repair Man100% (1)

- Ge Wall Oven Touchpad Ohm TestDocumento1 páginaGe Wall Oven Touchpad Ohm TestSamurai Appliance Repair ManAún no hay calificaciones

- Bosch Dishwasher Multi-Model Test ProgramsDocumento10 páginasBosch Dishwasher Multi-Model Test ProgramsSamurai Appliance Repair Man75% (4)

- Frigidaire Refrigerator FRS3R5EMBA Tech Sheet and SchematicDocumento2 páginasFrigidaire Refrigerator FRS3R5EMBA Tech Sheet and SchematicSamurai Appliance Repair Man100% (1)

- LG LRSC SXS Refrigerator Dispenser DisassemblyDocumento1 páginaLG LRSC SXS Refrigerator Dispenser DisassemblySamurai Appliance Repair ManAún no hay calificaciones

- FrigidaIre Front Load Washer Rear Bearing ReplacementDocumento7 páginasFrigidaIre Front Load Washer Rear Bearing ReplacementSamurai Appliance Repair Man100% (1)

- Frigidaire Range Model FEF352A Parts and Wiring DiagramsDocumento11 páginasFrigidaire Range Model FEF352A Parts and Wiring DiagramsSamurai Appliance Repair Man100% (1)

- KitchenAid Cooktop KFGU766VSS00 Tech SheetDocumento4 páginasKitchenAid Cooktop KFGU766VSS00 Tech SheetSamurai Appliance Repair ManAún no hay calificaciones

- Amana Refrigerator Tech SheetDocumento11 páginasAmana Refrigerator Tech SheetSamurai Appliance Repair ManAún no hay calificaciones

- Microwave Oven TroubleshootingDocumento2 páginasMicrowave Oven TroubleshootingSamurai Appliance Repair ManAún no hay calificaciones

- GE Hydro Wave Washer: Replacing The Shaft and Mode Shifter AssemblyDocumento7 páginasGE Hydro Wave Washer: Replacing The Shaft and Mode Shifter AssemblySamurai Appliance Repair ManAún no hay calificaciones

- Maytag Triple Lip and Bearing Kit Installation InstructionsDocumento8 páginasMaytag Triple Lip and Bearing Kit Installation InstructionsSamurai Appliance Repair ManAún no hay calificaciones

- Fisher-Paykel DD603 Dishdrawer DiagnosticsDocumento3 páginasFisher-Paykel DD603 Dishdrawer DiagnosticsSamurai Appliance Repair Man100% (2)

- Whirlpool Duet Washer Component TestingDocumento6 páginasWhirlpool Duet Washer Component TestingSamurai Appliance Repair Man50% (2)

- Diagnosing and Repairing Spin and Agitate Problems in A Whirlpool / Kenmore Direct Drive WasherDocumento1 páginaDiagnosing and Repairing Spin and Agitate Problems in A Whirlpool / Kenmore Direct Drive WasherSamurai Appliance Repair ManAún no hay calificaciones

- Frigidaire Range FEFB65ASC Parts List and Wiring DiagramDocumento10 páginasFrigidaire Range FEFB65ASC Parts List and Wiring DiagramSamurai Appliance Repair ManAún no hay calificaciones

- Bosch WFMC Washer Door Latch ReplacementDocumento1 páginaBosch WFMC Washer Door Latch ReplacementSamurai Appliance Repair ManAún no hay calificaciones

- Removing The Water Dispenser Fill Tube in A Whirlpool SXS RefrigeratorDocumento2 páginasRemoving The Water Dispenser Fill Tube in A Whirlpool SXS RefrigeratorSamurai Appliance Repair ManAún no hay calificaciones

- Frigidaire Refrigerator Next Generation Controls - Replacing The Control and Damper AssemblyDocumento3 páginasFrigidaire Refrigerator Next Generation Controls - Replacing The Control and Damper AssemblySamurai Appliance Repair Man100% (2)

- Replacing The Door Boot in A Maytag Neptune WasherDocumento2 páginasReplacing The Door Boot in A Maytag Neptune WasherSamurai Appliance Repair ManAún no hay calificaciones

- How To Remove / Replace The Motor Control Unit (MCU) in A Whirlpool Duet Sport WasherDocumento2 páginasHow To Remove / Replace The Motor Control Unit (MCU) in A Whirlpool Duet Sport WasherSamurai Appliance Repair ManAún no hay calificaciones

- KitchenAid-Fisher Paykel Dish Drawer Job AidDocumento72 páginasKitchenAid-Fisher Paykel Dish Drawer Job AidSamurai Appliance Repair Man100% (1)

- Diagnostic Flowcharts For GE Refrigerators With A MuthaboardDocumento10 páginasDiagnostic Flowcharts For GE Refrigerators With A MuthaboardSamurai Appliance Repair Man86% (7)

- KitchenAid (Not Fisher Paykel-Built) 2008 Drawer Dishwasher Service Manual 4317427Documento70 páginasKitchenAid (Not Fisher Paykel-Built) 2008 Drawer Dishwasher Service Manual 4317427Samurai Appliance Repair Man100% (1)

- Microwave Oven Troubleshooting TableDocumento2 páginasMicrowave Oven Troubleshooting TableSamurai Appliance Repair Man100% (1)

- De-Stinkifying Duet HE3 and HE4 WashersDocumento2 páginasDe-Stinkifying Duet HE3 and HE4 WashersSamurai Appliance Repair ManAún no hay calificaciones

- Whirlpool Gas Dryer Conversion Kit Instructions W10301479ADocumento4 páginasWhirlpool Gas Dryer Conversion Kit Instructions W10301479ASamurai Appliance Repair ManAún no hay calificaciones

- Maytag Refrigerator Adaptive Defrost Control (ADC)Documento2 páginasMaytag Refrigerator Adaptive Defrost Control (ADC)Samurai Appliance Repair Man100% (1)

- Whirlpool Duet Washer Job AidDocumento72 páginasWhirlpool Duet Washer Job AidSamurai Appliance Repair Man100% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- CIGRE A3 - ps2 - q2.19 - Back-To-Back Capacitor Bank SwitchingDocumento2 páginasCIGRE A3 - ps2 - q2.19 - Back-To-Back Capacitor Bank Switchinglbk50Aún no hay calificaciones

- Introduction To Semiconductor Lasers For Optical CommunicationsDocumento369 páginasIntroduction To Semiconductor Lasers For Optical CommunicationsDetian WangAún no hay calificaciones

- Acs 550Documento16 páginasAcs 550pubudunishanthaAún no hay calificaciones

- Haier HTAF21C Manual de ServicioDocumento19 páginasHaier HTAF21C Manual de Serviciopepino464100% (1)

- Rubix Reference Eng01 WDocumento31 páginasRubix Reference Eng01 WAntonio NinniAún no hay calificaciones

- AD8232-EVALZ User Guide: Evaluating The Single-Lead Heart Rate Monitor Front EndDocumento8 páginasAD8232-EVALZ User Guide: Evaluating The Single-Lead Heart Rate Monitor Front EndBorislav GanevAún no hay calificaciones

- Compact Wideband Circularly Polarized Microstrip Antenna Array For 45Ghz ApplicationDocumento5 páginasCompact Wideband Circularly Polarized Microstrip Antenna Array For 45Ghz Applicationnguyễn đắc huyAún no hay calificaciones

- Wiring DiagramsDocumento70 páginasWiring DiagramsEmerson Fonte Dos Santos FreireAún no hay calificaciones

- An 9005Documento15 páginasAn 9005MANOEL SAMPAIOAún no hay calificaciones

- IMA Batteries & ChargersDocumento3 páginasIMA Batteries & Chargersdiegobc5Aún no hay calificaciones

- General Physics 2Documento35 páginasGeneral Physics 2St. DymphaMaralit, Joyce Anne L.Aún no hay calificaciones

- Disclosure To Promote The Right To InformationDocumento15 páginasDisclosure To Promote The Right To InformationduonzaAún no hay calificaciones

- Istar Edge Install Quick Start Guide Ra3 - LT - enDocumento26 páginasIstar Edge Install Quick Start Guide Ra3 - LT - enJose ElenilsonAún no hay calificaciones

- Wire Joints and Splices GuideDocumento9 páginasWire Joints and Splices GuideGamer BoyAún no hay calificaciones

- Chapter 15 - Magnetic PropertiesDocumento10 páginasChapter 15 - Magnetic PropertiesThành Phương TấnAún no hay calificaciones

- ABB ACS 1000 Tech Catalog RevDDocumento161 páginasABB ACS 1000 Tech Catalog RevDElena Koneva50% (2)

- Group 3 Section (H) (Lab Report 2)Documento8 páginasGroup 3 Section (H) (Lab Report 2)Shoaib KhanAún no hay calificaciones

- Preliminary Information: B-MAC-B69 Model Cp-2HbDocumento1 páginaPreliminary Information: B-MAC-B69 Model Cp-2HbCykhong KhongAún no hay calificaciones

- 3.8 Power in Three-Phase AC Circuits: Per-Phase Powers in (A) A Delta-Connected Load and (B) A Star-Connected LoadDocumento16 páginas3.8 Power in Three-Phase AC Circuits: Per-Phase Powers in (A) A Delta-Connected Load and (B) A Star-Connected LoadBaquiran John Paul BaquiranAún no hay calificaciones

- Solving Circuit ProblemsDocumento33 páginasSolving Circuit Problems19027 PrantoBiswasAún no hay calificaciones

- Electrical Energy Panorama PDFDocumento40 páginasElectrical Energy Panorama PDFShihabudin QolyubiAún no hay calificaciones

- Effect of Surge Current Testing On Reliability of Solid Tantalum CapacitorsDocumento18 páginasEffect of Surge Current Testing On Reliability of Solid Tantalum CapacitorsRoberto FernandezAún no hay calificaciones

- Tonio Buonassisi Associate Professor of Mechanical Engineering Thesis SupervisorDocumento59 páginasTonio Buonassisi Associate Professor of Mechanical Engineering Thesis SupervisorMINH NGUYỄN THẾAún no hay calificaciones

- PLC01 Psu1 AI/O1: SiemensDocumento1 páginaPLC01 Psu1 AI/O1: SiemensSyachrial YusufAún no hay calificaciones

- About HVDCDocumento29 páginasAbout HVDCserban_elAún no hay calificaciones

- Product Information: Toshiba X-Ray Tube D-0712 / D-0712S / D-0712SB Stationary Anode X-Ray TubeDocumento8 páginasProduct Information: Toshiba X-Ray Tube D-0712 / D-0712S / D-0712SB Stationary Anode X-Ray TubeKamilAún no hay calificaciones

- Huawei OptiX Metro 1000 Commissioning Guide (V300R007)Documento143 páginasHuawei OptiX Metro 1000 Commissioning Guide (V300R007)Thunder-Link.comAún no hay calificaciones

- Lightning Shielding Analysis of EHV and UHV Transmission Lines: On The Effect of Terrain TopographyDocumento6 páginasLightning Shielding Analysis of EHV and UHV Transmission Lines: On The Effect of Terrain TopographypedramAún no hay calificaciones

- TLRF QB UNIT Full QBDocumento54 páginasTLRF QB UNIT Full QBSri Nisha Tharani S100% (1)

- DS-BLI - Thyssen KruppDocumento2 páginasDS-BLI - Thyssen Kruppgulatimanish1985Aún no hay calificaciones