Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Triplex Pump Part 1

Cargado por

Rodolfo CastroDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Triplex Pump Part 1

Cargado por

Rodolfo CastroCopyright:

Formatos disponibles

Triplex Pump

Training Module

PAGE : 1

December 1999

Schlumberger Confidential

Introduction

This module introduces you to the Dowell PG Series of Triplex Pumps

commonly used in our Cementing, Acidizing and general pumping

work. The aim is to give you a thorough understanding of the ratings,

limitations, care and maintenance of one of the most important pieces

of machinery used by Dowell. More than 90% of our revenue is

pumping related. So you need to know all about our Triplex Pumps,

caring for them and maintaining them according to our standards.

Objectives:

To provides an overview of the Triplex Pump, its main components

and operating principles.

To describe the basic specifications and ratings of the Triplex

pump.

To review the lubrication system for this piece of machinery.

To discuss STEM operations.

To explain and teach the proper care and maintenance of the

Triplex Pump and its ancillary equipment, including how to repack

a fluid end correctly.

The Appendix includes color diagrams of the Triplex Pump and

Fluid End, with part numbers. There is a Trouble-shooting Guide

for the more common problems you might encounter in everyday

service, relevant Maintenance Bulletins.

1.0 An Overview of the Triplex Pump

The Triplex Pump is the general name given to any type of pump

assembly having three (cylinders) plungers. By the same reasoning,

the Quintiplex Pump will have five cylinders and the Duplex Pump

(seen working as mud pumps) will have two cylinders.

Triplex Pump

Training Module

PAGE : 2

December 1999

Schlumberger Confidential

Triplex Fluid End

Triplex Pump

Training Module

PAGE : 3

December 1999

Schlumberger Confidential

Quintuplex Fluid End

Triplex Pump

Training Module

PAGE : 4

December 1999

Schlumberger Confidential

The purpose of any pump is to convert mechanical energy, provided by

motors, engines, turbines and other prime movers into fluid energy as

efficiently as possible. The pump assembly has to be light, compact,

simple and easy to maintain whilst providing the efficiency and the power

required. It is the most efficient type of pump for pumping abrasive laden

fluids at high pressures (1000 psi and above) and requiring the least

maintenance is the Reciprocating Plunger type pump. For maximum

smoothness (no pulsations), at least 3 plungers are required for proper

balancing of the load.

Most Reciprocating pumps such as the Triplex pump are considered to

be positive displacement pumps, this means that as the pump is working,

100% of the fluid that enters each cylinder will exit each cylinder. In a

Centrifugal Pump fluid exiting the pump can be stalled and the fluid in

the pump will relieve to the suction side of the pump. In the Triplex pump

the fluid on the discharge side cannot be stalled, as the plunger will apply

as much force as that being applied to through the power-end. This is the

reason we must utilize safety devices such as burst disc in the suction

valves of the Fluid end and Over-pressure shut-downs on the controls of

the Triplex pumps.

Every type of pump assembly has a designed operating limitation based

on pressure, rate or horsepower ratings.

Triplex Pump

Training Module

PAGE : 5

December 1999

Schlumberger Confidential

There are mechanical limitations as to how much horsepower can be

supplied to any given pump, and the pump cannot add or create any more

horsepower than what is put into it.

A simple explanation is:

Horsepower output = Horsepower in efficiency lost.

Conventional prime movers output their power by means of rotation and

torque on a shaft. A pump assembly needs to convert this rotational

power by some means into fluid hydraulic power, which is measured by

the combination of volume of output and pressure at that output rate.

Most types of plunger pump assemblies have 3 main components:

1. A Speed Reducer to reduce the input shaft rpm, i.e. to change the high

speed low torque shaft output from a prime mover to a low speed high

torque shaft input to a pump. Dowell uses Chain Cases and gear type

speed reducers.

2. On a reciprocating pump, a device called the Power End converts this

rotational power into reciprocating power, which is transferred to the

Fluid End to transfer the power to the fluid.

3. The Fluid End receives the power from the Power End, and by using

the plungers, fluid received at low pressure is forced or pushed by the

plungers so that it exits the fluid end at a much higher pressure.

Triplex Pump

Training Module

PAGE : 6

December 1999

Schlumberger Confidential

Dowell uses various combinations of transmissions, chain cases and

power ends to cover our range of pumping requirements efficiently. By far,

the most commonly used pump in our business is the PG Series of

Triplex Pumps, which we use to pump fluids such as cement slurries and

corrosive fluid systems at high pressures and rates.

1.1 The Chain Case

Most of Dowell's Triplex Pumps (with the exception of Turbine-driven

units and some Stimulation units) use Chain Cases as the first stage of

inputting power from the output shaft of a prime mover, which could be an

engine/transmission combination, or a electric motor being used to drive a

pump.

The Chain Case performs 2 important functions:

1. The chain case provides flexibility when mounting the Pump assembly

in different locations with respect to the prime mover output shaft

center-line. Chain case can be assembled to accept the input from

ether side and mounted on either end of the power end as seen in the

picture below.

Triplex Pump

Training Module

PAGE : 7

December 1999

Schlumberger Confidential

2. The chain case converts a low torque high rpm engine output to a high

torque low rpm output more suited to the requirements of the power

end. The ratio of reduction on a P.G. Series Pump is 1:675 (sprocket

27-40 tooth)

This drawing shows a typical chain case. A chain travels over the upper

sprocket mounted on the pump pinion shaft (40 teeth) and over the lower

sprockets driven by the prime mover (27 tooth). When the prime mover

rotates the lower input shaft, the chain transmits the power to the upper

output (pinion) shaft and rotates it as well. This shaft then transfers the

rotation to the Pinion Shaft of the power end. The different diameters of

the two sprockets in the chain case acts to reduce the prime movers

output speed (rpm) and increase the torque input to the pump.

Each chain case is secured to the chassis or skid by means of a pair of

Torque Rods. They prevent the chain case from moving when power is

applied.

Triplex Pump

Training Module

PAGE : 8

December 1999

Schlumberger Confidential

1.2 Power End

The Power End functions very much the same way as does a crankshaft

in a conventional motorcar engine. The output shaft of the chain case is

actually the P.G. Series pump pinion shaft. The pinion shaft drives the

crankshaft via the crankshaft bull gears. The gear ratio between the

pinion shaft and bull gears is 1:4.31 (on the P.G. series pump). By using

eccentrics the rotation of the Mainshaft is changed into a reciprocating

action. This reciprocating force is transferred to the Connecting Rods

and Crossheads, which in turn move the plungers in the Fluid End.

Triplex Pump

Training Module

PAGE : 9

December 1999

Schlumberger Confidential

Most of the load on the triplex pump assembly is taken by the Power End,

especially by the Eccentrics. It can be easily seen that the Crossheads

and Connecting Rods exert a force back to the eccentrics while pumping

under pressure, and if this force exceeds a certain design limit, the power

end will quickly fail. This limitation is commonly called the Maximum Rod

Loading.

One of the limiting factors of Rod load is the amount of force that the

Connecting rod can withstand before the lubrication is squeezed out from

between it and the eccentric bushing causing metal-to-metal contact.

When this occurs, failure is imminent.

The centerline of the Main Shaft in relationship to the centerline of the

eccentrics determines the length of the Stroke of the power end.

There are basically three types of power ends made by Dowell.

They are:

(a) The 5-inch stroke (PG Series with Rod Load = 110,000 lbs), rated at

285 BHP (Brake Horsepower) input and are the most commonly used in

cementing operations. They are available in either Steel for offshore

application or Magnesium for truck applications where weight is a

consideration.

(b) The 6-inch stroke (PC, PT with a Standard Rod Load = 195,000lbs

and the upgraded version with Rod load = 237,000) and PQ Series

with Rod Load = 165,000 LB)

Triplex Pump

Training Module

PAGE : 10

December 1999

Schlumberger Confidential

(c) The 8-inch stroke (PD Series with Rod load = 115,000 LB).

Triplex Pump

Training Module

PAGE : 11

December 1999

Schlumberger Confidential

Most of the P Series power ends except for the PG Series are being

phased out as the new generation of power ends and fluid ends will take

their place. The Gardner Denver GD 700 Lite Weight is one of the

replacement power ends being installed on some of the new equipment

today.

The GD 700 is available with ether a right angle drive gear as shown above and

also available with the standard direct drive into the pinion shaft

Triplex Pump

Training Module

PAGE : 12

December 1999

Schlumberger Confidential

Two other common type of Power ends are:

OPI (Odessa Pump Inc) which was the original Manufacture of this

Crankshaft style Fracturing Triplex pump in the early 70s. Later other

manufactures made similar versions of the OPI style power end. Dowell

at the time was purchasing the power ends but manufacturing our own

fluid ends to use with the OPI power ends.

In the past Gardner Denver has purchased a number of the

manufactured OPI style Power Ends and today GD manufactures the

GD1250, GD2000 as replacements for the OPI 1300 and 1800 series

power ends. The Number indicates the Max Brake Horsepower input. For

example GD 1250- 1250 brake horsepower input.

The GD 1250 power ends have a Rod Load rating = 200,000 lbs.

Triplex Pump

Training Module

PAGE : 13

December 1999

Schlumberger Confidential

The GD2000 power end have a Rod Load rating = 237,000 lbs. This is a

direct replacement for the OPI 1800 power end.

The SD2000 Power Ends were manufactured for Dowell by Twentieth

Century Manufacturing for use with the In-Line Fluid ends. Although the

life of the In-Line fluid end was short lived the SD2000 with its 325,000 LB

Rod Load was refitted to accept a cross-bore style fluid end and is a very

good Frac pump in our fleet today.

Triplex Pump

Training Module

PAGE : 14

December 1999

Schlumberger Confidential

1.3 Fluid End

The Fluid End of the pump assembly is the part of the pump, which

receives fluid at low pressure, applies horsepower to the liquids, and

discharges the liquid at high pressure. The mechanical pumping action is

again very similar to that of a conventional piston-type internal

combustion engine or a reciprocating piston type air compressor. This

type fluid end is referred to as a Cross-Bore Type fluid end because the

two borings intersect each other to create the cylinder.

Triplex Pump

Training Module

PAGE : 15

December 1999

Schlumberger Confidential

As the plunger is drawn towards the Power End (suction stroke), the

pressure inside the chamber between the Suction and Discharge Valves

is reduced. This causes the suction valve to lift and the fluid to be drawn

into the suction manifold, through the suction ports, around the suction

valves, and into the chamber. At this moment, the suction valve is opened

by the fluid entering the fluid end, and the discharge valve is kept closed

by its check valve-type action and the discharge valve spring.

When the plunger starts to move in the opposite direction towards the

Fluid End (discharge stroke), the fluid inside the chamber, being

incompressible is forced out. The suction valve closes immediately like a

check valve, and the fluid then lifts the discharge valve from its valve seat

and is forced out around the discharge valve and into the pump discharge

chamber.

The usual suction or intake pressure is low (about 30 psi) but the

discharge pressure can be in the range of thousands of psi. Some Fluid

Ends made by Dowell are rated to work at 15,000 psi working, pressure

and some can even go as high as 20,000 psi.

Triplex Pump

Training Module

PAGE : 16

December 1999

Schlumberger Confidential

The plungers, in the fluid end, receive energy from the power end. Each

time the main shaft makes one revolution, all the plungers in the pump

makes a complete cycle (i.e. a stroke forward and backward). Therefore,

by counting the revolutions of the main shaft and multiplying the RPM

(revolutions per minute) times a volume factor, we can get a volume

amount in BPM (barrels per minute), liters per minute or accumulative

amount of fluid pumped. This volume is only a mechanical indication of

volume, not an actual volume, so if the supply to the pump is restricted,

the volume calculated this way can be inaccurate. That is why in Dowell

we also use absolute volume measures like unit displacement tanks.

Fluid ends are designed for specific series of power ends, that is, the

stroke length of the fluid end is always the same as the stroke length of

the power end. Fluid ends are manufactured with various plunger

diameters for each series of power end. Plunger diameters range from the

smallest diameter of 2 inch to the largest of 7 inch. Obviously, the

larger the plunger diameter, the larger the volume of liquid displaced per

stroke of the plunger(s). However, the largest diameter plunger does not

necessarily mean the best. By making simple calculations, it can be seen

that for a particular Maximum Rod Load (as limited by each power end

series), the maximum pressure the fluid end can pump is limited by the

diameter of the plungers. So, the larger the plunger diameter, the lower is

the Maximum Pressure Rating of the fluid end. Should the Fluid End be

used to pump fluids in excess of its designed working pressure rating, the

first component of the triplex assembly that will fail is the power end.

Therefore, it is extremely important that the fluid end is not taken beyond

its maximum pressure ratings. Failure will occur because the force

exerted on the eccentric bushing (bearing) and the crosshead pin bushing

causes the lubrication to be squeezed out creating a metal-to-metal

contact. Once this occurs there is no reversing the damage and

catastrophic failure is inevitable.

Triplex Pump

Training Module

PAGE : 17

December 1999

Schlumberger Confidential

Each type of fluid end can easily be identified by a code of letters and

numbers, which are stamped on each fluid end. An example: a fluid end

stamped TG06 would mean it is a 3 3/4 diameter plunger rated at a

maximum working pressure of 10,000 psi and a maximum output of 5.8

BPM for a 5 inch stroke (PG series) pump. There is also a serial number

stamped with the code to keep track of individual fluid ends. The fluid end

specifications, identification codes, volume factors, plus the rate and

maximum pressure ratings for each fluid end are given in the appendix of

this manual, the Dowell treating Equipment Manual or on a "quick

reference" card ratings shown below for different power end series:

Power end data:

Power end = 5 stroke PG series

Maximum rod loading = 110,000 lb

4.32 ratio, internal gears

Fluid

end

Plunger

size/diameter

(inches)

Standard

maximum

pressure

(Psi)

Pump

rate

(Bpm)

bbl/rev.

Pinion

Shaft

bbl/rev

Main

shaft

TSO 2-1/2 20,000 2.6 0.00170 0.0074

TRO 3 15,000 3.7 0.00245 0.0106

TGO 3-3/4 10,000 5.8 0.00383 0.0166

TLO 4-1/2 7,000 8.3 0.00552 0.0238

THO 5 5,500 10.3 0.00681 0.0294

Power end data:

Power end = 6 stroke MD 1000

Maximum rod loading = 135,000 lb

4.125 ratio, internal gears

Triplex Pump

Training Module

PAGE : 18

December 1999

Schlumberger Confidential

Fluid

end

Plunger

size/diameter

(inches)

Standard

maximum

pressure

(Psi)

Pump

rate

(Bpm)

bbl/rev.

Pinion

Shaft

bbl/rev

Main shaft

M 3 20,000 7.1 0.00308 0.0127

F 3-3/4 12,200 11.1 0.00482 0.0199

E 4-1/2 8,500 15.9 0.00694 0.0286

D 5 6,800 19.7 0.00856 0.0353

Power end data:

Power end = 6 stroke MD 1000

Maximum rod loading = 135,000 lb

5.474 ratio, internal gears

Fluid

end

Plunger

size/diameter

(inches)

Standard

maximum

pressure

(Psi)

Pump

rate

(Bpm)

bbl/rev.

Pinion

Shaft

bbl/rev

Main

shaft

M 3 20,000 5.3 0.00232 0.0127

F 3-3/4 12,200 8.3 0.00363 0.0199

E 4-1/2 8,500 12.0 0.00523 0.0286

D 5 6,800 14.8 0.00645 0.0353

Triplex Pump

Training Module

PAGE : 19

December 1999

Schlumberger Confidential

Power end data:

Power end = 8 stroke GD 700 series

Maximum rod loading = 175,000 lb

10:1 Ratio

Fluid

end

Plunger

size/diameter

(inches)

Standard

maximum

pressure

(Psi)

Pump

rate

(Bpm)

bbl/rev.

Pinion

Shaft

bbl/rev

Main

shaft

FGD 3-3/4 15,800 7.9 0.00265 0.0265

XGD 4 13,900 9.0 0.00301 0.0301

EGD 4-1/2 11,000 11.4 0.00381 0.0381

HGD 5 8,900 14.1 0.00471 0.0471

IGD 5-1/2 7,400 17.1 0.00570 0.0570

YGD 6 6,200 20.3 0.00678 0.0678

Triplex Pump

Training Module

PAGE : 20

December 1999

Schlumberger Confidential

Power end data:

Power end = 8 stroke GD 1250 series

Maximum rod loading = 200,000 lb

6:1 Ratio

Fluid

end

Plunger

size/diameter

(inches)

Standard

maximum

pressure

(Psi)

Pump

rate

(Bpm)

bbl/rev.

Pinion

Shaft

bbl/rev

Main

shaft

FGD 3-3/4 18,000 7.9 0.00441 0.0265

XGD 4 16,000 9.0 0.00502 0.0301

EGD 4-1/2 12,500 11.4 0.00636 0.0381

HGD 5 10,000 14.1 0.00785 0.0471

IGD 5-1/2 8,400 17.1 0.00950 0.0570

YGD 6 7,000 20.3 0.01130 0.0678

Power end data:

Power end = 8 stroke PD 1250 series

Maximum rod loading = 115,000 lb

5.0 Ratio, internal gears

Fluid

end

Plunger

size/diameter

(inches)

Standard

maximum

pressure

(Psi)

Pump

rate

(Bpm)

bbl/rev.

Pinion

Shaft

bbl/rev

Main

shaft

TTO 2-1/2 20,000 3.1 0.00235 0.0118

TMO 3 15,000 4.4 0.00339 0.0170

TFO 3-3/4 10,500 6.9 0.00530 0.0265

TEO 4-1/2 7,500 9.9 0.00763 0.0381

TDO 5 6,000 12.2 0.00942 0.0471

TNO 5-3/4 4,500 16.2 0.01246 0.0623

TJO 6-3/4 3,500 22.3 0.01716 0.0858

TKO 7-3/4 2,500 29.4 0.02263 0.1131

Triplex Pump

Training Module

PAGE : 21

December 1999

Schlumberger Confidential

Power end data:

Power end = 8 stroke OPI 1800, HD 2000 series

Maximum rod loading = 195,000 lb (standard), 237,000 (upgraded)

6.353 : 1 Ratio

Fluid

end

Plunger

size/diameter

(inches)

Standard

maximum

pressure

(Psi)

Pump

rate

(Bpm)

bbl/rev.

Pinion

Shaft

bbl/rev

Main

shaft

FOPI 3-3/4 17,500 8.7 0.00417 0.0265

EOPI 4-1/2 12,000 12.6 0.00600 0.0381

HOPI 5 10,000 15.5 0.00741 0.0471

IOPI 5-1/2 8,000 18.8 0.00897 0.0570

UOPI 6-1/2 6,000 26.3 0.01253 0.0796

JOPI 6-3/4 5,500 28.3 0.01351 0.0858

Power end data:

Power end = 11 SD 2000 series, In-line pump

Maximum rod loading = 350,000 lb (standard)

8.4958: 1 Ratio

Fluid

end

Plunger

size/diameter

(inches)

Standard

maximum

pressure

(Psi)

Pump

rate

(Bpm)

bbl/rev.

Pinion

Shaft

bbl/rev

Main

shaft

H-205 5 16,500 14.5 0.0647

I-255 5-1/2 13,500 17.5 0.0783

U-265 6-1/2 10,000 24.5 0.1094

Triplex Pump

Training Module

PAGE : 22

December 1999

Schlumberger Confidential

Power end data:

Power end = 11 SD 2000 series, Cross Bore pump

Maximum rod loading = 350,000 lb(standard)

8.4958: 1 Ratio

Fluid

end

Plunger

size/diameter

(inches)

Standard

maximum

pressure

(Psi)

Pump

rate

(Bpm)

bbl/rev.

Pinion

Shaft

bbl/rev

Main

shaft

H-205 4-1/2 20,000 12 0.0536

I-255 5-1/2 15,000 17.5 0.0783

U-265 6 12,500 21.2 0.0946

Note: Pumps volumetric efficiency = 97%

Many fluid end parts such as valves, valve seats, springs are interchangeable

with fluid ends of different series (stroke length) pumps. Other parts such as

packings, adaptor rings, spacers, gland nuts and lantern glands are also

interchangeable for use in pumps with plungers of the same diameter regardless

of the stroke length. (A chart showing interchangeable parts is included in the

appendix:

Triplex Pump

Training Module

PAGE : 23

December 1999

Schlumberger Confidential

PG Series Fluid End Assembly

Triplex Pump

Training Module

PAGE : 24

December 1999

Schlumberger Confidential

The GD lite weight series fluid ends utilize a different concept in fluid end

adaptability. They use a stuffing box as shown below that threads into the fluid

end, this stuffing box is were the packing seals seat. Some have different size

stuffing boxes as listed below. The pressure rating will due to the power ends

Rod load Rating. The same fluid end will fit on a GD 700 or GD 1250 powerend.

You should reference either the Treating Equipment manual or the Pump Card

via the Web for the latest and most accurate ratings.

The High Pressure Fluid End

3-3/4- (FGD) not Stuffing Box design (Conventional Design)

The Medium Pressure Fluid End

4-1/2- (EGD)

5 - (HGD)

5-1/2 (IGD)

The Low Pressure Fluid End

5-1/2 (IGD)

6 (YGD)

6-1/2 Under development

Incidentally the new fluid ends were designed to accept and use the same

packing and brass as that used in the same size fluid end in the PG series

Power End.

The plungers are different.

Triplex Pump

Training Module

PAGE : 25

December 1999

Schlumberger Confidential

Power end = 8 stroke GD 700 series

Maximum rod loading = 175,000 lb

10:1 Ratio

Fluid

end

Plunger

size/diameter

(inches)

Standard

maximum

pressure

(Psi)

Pump

rate

(Bpm)

bbl/rev.

Pinion

Shaft

bbl/rev

Main

shaft

FGD 3-3/4 15,800 7.9 0.00265 0.0265

XGD 4 13,900 9.0 0.00301 0.0301

EGD 4-1/2 11,000 11.4 0.00381 0.0381

HGD 5 8,900 14.1 0.00471 0.0471

IGD 5-1/2 7,400 17.1 0.00570 0.0570

YGD 6 6,200 20.3 0.00678 0.0678

Power end = 8 stroke GD 1250 series

Maximum rod loading = 200,000 lb

6:1 Ratio

Fluid

end

Plunger

size/diameter

(inches)

Standard

maximum

pressure

(Psi)

Pump

rate

(Bpm)

bbl/rev.

Pinion

Shaft

bbl/rev

Main

shaft

FGD 3-3/4 18,000 7.9 0.00441 0.0265

XGD 4 16,000 9.0 0.00502 0.0301

EGD 4-1/2 12,500 11.4 0.00636 0.0381

HGD 5 10,000 14.1 0.00785 0.0471

IGD 5-1/2 8,400 17.1 0.00950 0.0570

YGD 6 7,000 20.3 0.01130 0.0678

Triplex Pump

Training Module

PAGE : 26

December 1999

Schlumberger Confidential

Triplex Pump

Training Module

PAGE : 27

December 1999

Schlumberger Confidential

2.0 Specifications and Ratings for the PG Series Triplex Pump

2.1 Chain case

Case Steel (fabricated)

Chain Diamond 80-4

Ratio 27:40

RPM Maximum input 2240 RPM

RPM Maximum output 1512 RPM

Rated HP 353

Rotation Normal rotation is counter clockwise facing drive end of

the triplex pump pinion shaft.

Coupling input: spicer 1700 series drive flange output: chain case

sprocket mounted on triplex pump pinion shaft.

Weight 500 lbs (227 kg)

The Chain Case can be extended by adding a spacer and increasing the

chain length. Most Dowell Twin Pump Cement Units (CPS, CPT) use a

standard 23.15" center-to-center Chain Case for the Down Hole Pump,

which has a chain that is 90 pitches long. The Mixing Pump uses an

extended Chain Case (6" extension section) which increases the Chain

Case length to 29.15" center-to-center and uses a chain that is 95 pitches

long. Both chains are known as Quad 80 chain, which means 80 pitch

(length from pin to pin) and 4 links wide.

Triplex Pump

Training Module

PAGE : 28

December 1999

Schlumberger Confidential

Typical Twin P.G. Pump Layout

The torque arms are designed to stabilize and control the reaction of the torque

being applied through the chain case. The torque arms are to be adjusted as

follows. The torque arms have left hand threads on one end so they will change

length when rotated. Set one of the torque arms to the desired position. Assuring

the driveshaft clears all obstructions. Then adjust the other torque arm in any

direction to tighten and lock the chaincase into position. Tighten all locking nuts

in position.

Triplex Pump

Training Module

PAGE : 29

December 1999

Schlumberger Confidential

2.2 Power End

Pump Model PG05 (steel)

PG03 (magnesium)

Type Single Acting Triplex Reciprocating

Positive Displacement

Configuration Horizontal-in-Line

Stroke 5"(127mm)

Maximum Input Speed 2240 RPM

Maximum Mainshaft Speed 350 RPM

Maximum Pinion Shaft Speed 1512 RPM

Maximum Rod Load 110,000 lbs (50 tonnes)

Maximum Recommended Oil Temperature 160 degF (70 deg C)

Maximum Input Horse Power (HP) 353 HP

Rated Output Hydraulic Horsepower 300 HHP (224 kW)

Mechanical Efficiency (with Chain Case) 85%

Triplex Pump

Training Module

PAGE : 30

December 1999

Schlumberger Confidential

The P.G. Pump can be configured in two different ways so that the power

end can be driven from the left or right hand side. These two

configurations do not require different parts but is distinguished by the

way the pinion shaft is installed in the power end frame. When changing

the position of the pinion shaft the timing gears must be re-timed.

Note:

There are a few instances where the P.G. series power end turns in the

opposite direction (Reverse Rotation). This is not common, but you will

find it on units where the two P.G. Pumps face each other (mirror image)

and are driven by conventional diesel engines.

También podría gustarte

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!De EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Calificación: 5 de 5 estrellas5/5 (2)

- Section 11 EquipmentDocumento18 páginasSection 11 EquipmentaistopAún no hay calificaciones

- Triplex Pump Part 2Documento20 páginasTriplex Pump Part 2Rodolfo Castro50% (4)

- RePacking HT 400Documento113 páginasRePacking HT 400AL__5286% (7)

- (Equip (Accumulator)Documento34 páginas(Equip (Accumulator)Nagendra Singh Ranawat100% (4)

- Mission Centrifugal PumpsDocumento60 páginasMission Centrifugal PumpsWell Site Ranger100% (2)

- Jet 04 Basic Oilfield v1-1 April 02 2007 4127828 01 PDFDocumento88 páginasJet 04 Basic Oilfield v1-1 April 02 2007 4127828 01 PDFVladyslav100% (1)

- Nitrogen PumpingDocumento41 páginasNitrogen PumpingVladyslavAún no hay calificaciones

- Hydra Rig Coil Tubing Manual DownloadDocumento3 páginasHydra Rig Coil Tubing Manual Downloadeliseo cardosoAún no hay calificaciones

- Seahawk Baker Cementing Offshore UnitDocumento2 páginasSeahawk Baker Cementing Offshore UnitDeni SetiawanAún no hay calificaciones

- Operation and Maintenance Manual Double Pump Skid B01!00!073 - A英文说明书Documento57 páginasOperation and Maintenance Manual Double Pump Skid B01!00!073 - A英文说明书Doni Kurniawan100% (1)

- Bomba Demay Hd500 - AxonDocumento34 páginasBomba Demay Hd500 - AxonOSCAR PABA100% (1)

- Serva Pumps Parts Service 113015 LR PagesDocumento20 páginasServa Pumps Parts Service 113015 LR Pagesjjjjjj33% (3)

- Choke 'E-S' MANUAL REL.1.1.15.03ADocumento38 páginasChoke 'E-S' MANUAL REL.1.1.15.03AJulian Estaun100% (3)

- B+V ELEVATOR SIDE DOOR Collar Type VS09 A4Documento19 páginasB+V ELEVATOR SIDE DOOR Collar Type VS09 A4Игорь ШиренинAún no hay calificaciones

- Dsa4 Side DoorDocumento24 páginasDsa4 Side DoorДудла СтаніславAún no hay calificaciones

- BJ Services Cement Unit Specs TUCANO BrazilDocumento2 páginasBJ Services Cement Unit Specs TUCANO Brazildanielmcae100% (1)

- Tws600s Manual - Or7179Documento96 páginasTws600s Manual - Or7179achampney6796100% (8)

- SPM Dart Valve Manual PDFDocumento32 páginasSPM Dart Valve Manual PDFYM Edwin Gil Beltran100% (1)

- 230L2M551 - Cement Mixing EquipmentDocumento43 páginas230L2M551 - Cement Mixing Equipmentyao nestorAún no hay calificaciones

- Batch Mixer ManualDocumento40 páginasBatch Mixer ManualAndrew ArAún no hay calificaciones

- User Manual of S-Type Ram BOPDocumento26 páginasUser Manual of S-Type Ram BOPhebert perez100% (1)

- SPM Pump Product CatalogDocumento44 páginasSPM Pump Product CatalogRay100% (1)

- Duplex Power Pump Operating & Service ManualDocumento27 páginasDuplex Power Pump Operating & Service ManualDanny Espinoza Castro75% (4)

- Skid Mounted HT-400 Pumping Unit - Drilling ExchangeDocumento2 páginasSkid Mounted HT-400 Pumping Unit - Drilling ExchangeIng DimatiguzAún no hay calificaciones

- JET Module Low Pressure EquipmentDocumento61 páginasJET Module Low Pressure EquipmentUmar Draz100% (2)

- Well Control EquipmentDocumento8 páginasWell Control Equipmentyamid muñozAún no hay calificaciones

- JET 1 Treating EquipmentDocumento60 páginasJET 1 Treating Equipmentmasterab100% (3)

- 120 Ton Power Swivels PISDocumento17 páginas120 Ton Power Swivels PISgheorgheAún no hay calificaciones

- Controll Cabin OEM PDFDocumento47 páginasControll Cabin OEM PDFOvRrj AhmedAún no hay calificaciones

- HT-400 Parts ListDocumento3 páginasHT-400 Parts ListlionelAún no hay calificaciones

- BJ Coiled Tubing Equipment Manual Version 1Documento90 páginasBJ Coiled Tubing Equipment Manual Version 1Franklyn Frank95% (39)

- 81W12186 (P12136) Operation and Maintenance Manual For LGT360 - English VersionDocumento289 páginas81W12186 (P12136) Operation and Maintenance Manual For LGT360 - English VersionMARIO FABRISAún no hay calificaciones

- JWS-165 Well Service Pump: Parts ListDocumento13 páginasJWS-165 Well Service Pump: Parts ListGildardo Mora100% (2)

- Truck / Trailer / Skid Mounted Cementing UnitDocumento2 páginasTruck / Trailer / Skid Mounted Cementing UnitRudi Cressa100% (2)

- Bombas Cementacion DowellDocumento2 páginasBombas Cementacion DowellEd CalheAún no hay calificaciones

- Mud Pump GTS FinalDocumento77 páginasMud Pump GTS FinalSanjiv Pathak0% (1)

- Triplex Drilling Mud Pump Fluid ExpendablesDocumento6 páginasTriplex Drilling Mud Pump Fluid ExpendablesClevin Zhao100% (1)

- CT Basics and Applications For StudentDocumento230 páginasCT Basics and Applications For Studentanon_969492799Aún no hay calificaciones

- Mud Pump Expendables Gardner DenverDocumento8 páginasMud Pump Expendables Gardner Denverleo0% (1)

- Cat III Inspection Mud 2021Documento56 páginasCat III Inspection Mud 2021Fāōū ZīAún no hay calificaciones

- Mud PumpDocumento2 páginasMud PumpMohsin AwanAún no hay calificaciones

- 4) Well Control EquipmentDocumento77 páginas4) Well Control Equipmentoswaldo58100% (3)

- 2020.4 GNZCQ Vacuum Degasser Manual (REV01)Documento36 páginas2020.4 GNZCQ Vacuum Degasser Manual (REV01)GeorgeAún no hay calificaciones

- T3-FC & T3-F Gate Valve BrochureDocumento32 páginasT3-FC & T3-F Gate Valve BrochureKalpana BansalAún no hay calificaciones

- Haliburton Offshore Cementing EquipmentDocumento8 páginasHaliburton Offshore Cementing Equipmentknn52unn100% (1)

- Pump GDDocumento2 páginasPump GDdelcololalunaAún no hay calificaciones

- Tech 1183 Man StripperDocumento19 páginasTech 1183 Man StripperDonna Gray100% (1)

- Halliburton Coiled Tubing PDFDocumento4 páginasHalliburton Coiled Tubing PDFCarlos David Rodriguez Rojas100% (3)

- RMX Manual PDFDocumento372 páginasRMX Manual PDFharounAún no hay calificaciones

- JWS 400Documento2 páginasJWS 400николайAún no hay calificaciones

- 03 Coil Tubing Pressure Control EquipmenDocumento5 páginas03 Coil Tubing Pressure Control EquipmenAdolfo AnguloAún no hay calificaciones

- Gardner Denver PZ-11revF3Documento47 páginasGardner Denver PZ-11revF3pipeo25100% (4)

- Triplex Pump Part 1 PDFDocumento30 páginasTriplex Pump Part 1 PDFvenkysaranAún no hay calificaciones

- Triplex Pump Part 1Documento30 páginasTriplex Pump Part 1Sergio Fabian VasicekAún no hay calificaciones

- Mud Pump Mechanical V3 (Part 1)Documento56 páginasMud Pump Mechanical V3 (Part 1)BRAHIM FEKAOUNIAún no hay calificaciones

- Title: Author: Course: Year: Main Functional Requirement: Design ParameterDocumento4 páginasTitle: Author: Course: Year: Main Functional Requirement: Design ParameterVinu KumarAún no hay calificaciones

- Vertical Turbine Pump InformationDocumento10 páginasVertical Turbine Pump Informationraghu_mn100% (1)

- Engineering Encyclopedia: Centrifugal PumpsDocumento70 páginasEngineering Encyclopedia: Centrifugal PumpsMajdi Belguith67% (3)

- Manual Chicksan FMC PDFDocumento25 páginasManual Chicksan FMC PDFRodolfo Castro100% (2)

- Cameron Block Valve Body StylesDocumento3 páginasCameron Block Valve Body StylesRodolfo CastroAún no hay calificaciones

- Tenar Is BlueDocumento12 páginasTenar Is BlueRodolfo CastroAún no hay calificaciones

- H03713 ShockToolDocumento2 páginasH03713 ShockToolRodolfo CastroAún no hay calificaciones

- Gyrodata SWDDocumento1 páginaGyrodata SWDRodolfo CastroAún no hay calificaciones

- Intelligent Fields SupplementDocumento24 páginasIntelligent Fields SupplementRodolfo CastroAún no hay calificaciones

- Expansion JointDocumento1 páginaExpansion JointRodolfo CastroAún no hay calificaciones

- Una Comparasión de Costos de Perforación Entre Pozos Geotermicos y GasiferosDocumento15 páginasUna Comparasión de Costos de Perforación Entre Pozos Geotermicos y GasiferosRodolfo CastroAún no hay calificaciones

- Operator'S Manual: Electric WinchDocumento24 páginasOperator'S Manual: Electric WinchFiroz PawaskarAún no hay calificaciones

- Emaux Sb30 SB SR Pump Leaflet English Double Page VersionDocumento2 páginasEmaux Sb30 SB SR Pump Leaflet English Double Page Versionper stockmanAún no hay calificaciones

- Power ToolsDocumento31 páginasPower ToolsErwin Lobiano BalduezaAún no hay calificaciones

- Aircraft Control SystemsDocumento14 páginasAircraft Control SystemsSubhash pragatheeswaranAún no hay calificaciones

- Window Milling - Cement WhipstockDocumento9 páginasWindow Milling - Cement WhipstockAdel Ahmed AlkhaligyAún no hay calificaciones

- How Fast MSDocumento5 páginasHow Fast MSsaadAún no hay calificaciones

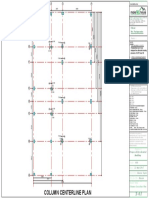

- 1 Column Centerline PlanDocumento1 página1 Column Centerline PlanRhishikesh IngoleAún no hay calificaciones

- Roland Service Manual Vs540iDocumento296 páginasRoland Service Manual Vs540iJohn Swanson100% (1)

- Benchmark's ORBI-SHAKER™ JR. Orbital Shaker: Model BT300 Instruction ManualDocumento1 páginaBenchmark's ORBI-SHAKER™ JR. Orbital Shaker: Model BT300 Instruction ManualrafaelAún no hay calificaciones

- 507 Mechanical Movements PDFDocumento138 páginas507 Mechanical Movements PDFmimi_chan_17100% (3)

- CYLINDER TAIYO 100z-1Documento25 páginasCYLINDER TAIYO 100z-1Daniel MarAún no hay calificaciones

- Operation and Maintenance Manual: Series 92/93 Pneumatic ActuatorDocumento14 páginasOperation and Maintenance Manual: Series 92/93 Pneumatic ActuatorInstrumentistas de Turno ARCO MezclasAún no hay calificaciones

- Ares Ultra BT A - Instruction Manual 7Documento22 páginasAres Ultra BT A - Instruction Manual 7marian hotineanuAún no hay calificaciones

- Juicer Mixer Grinder Mixer Grinder: Instruction Manual Warranty CardDocumento16 páginasJuicer Mixer Grinder Mixer Grinder: Instruction Manual Warranty Cardssohal133Aún no hay calificaciones

- ATPL Principles of Flight SummaryDocumento8 páginasATPL Principles of Flight SummaryPrvoslav Vojinović86% (7)

- DYNEXQuick ReferenceDocumento15 páginasDYNEXQuick ReferenceDJGGAún no hay calificaciones

- SE-A KOM Mini Project List-1Documento2 páginasSE-A KOM Mini Project List-1AbhiAún no hay calificaciones

- Hand Taps - Button Dies - Die Nuts - Screw Extractors - Holders - SetsDocumento26 páginasHand Taps - Button Dies - Die Nuts - Screw Extractors - Holders - SetsQC RegianAún no hay calificaciones

- Api 53a PDFDocumento1 páginaApi 53a PDFGaurang SolankiAún no hay calificaciones

- Train Prog - Sling-Chain & Lift GearDocumento21 páginasTrain Prog - Sling-Chain & Lift Gearcio davinsiAún no hay calificaciones

- Pompa Dan ValveDocumento4 páginasPompa Dan ValveIkhwan IdhamAún no hay calificaciones

- 7 2 A HolesholenotesDocumento11 páginas7 2 A Holesholenotesapi-234212327Aún no hay calificaciones

- 00306V16 Micropipette 1,0 MLDocumento3 páginas00306V16 Micropipette 1,0 MLRessa AjaAún no hay calificaciones

- A320-27-1254 R04Documento95 páginasA320-27-1254 R04Kumar VishalAún no hay calificaciones

- Hydraulic Systems - Hydraulic Schema - Pilot Circuit: Suction, Delivery and Return CircuitDocumento28 páginasHydraulic Systems - Hydraulic Schema - Pilot Circuit: Suction, Delivery and Return Circuitroparts clujAún no hay calificaciones

- Interior Roof GirderDocumento5 páginasInterior Roof Girderclam2014Aún no hay calificaciones

- Question Bank Strength of MaterialDocumento19 páginasQuestion Bank Strength of MaterialSanjay TiwariAún no hay calificaciones

- Culvert Fitting Design Sheet KM: Left RightDocumento1 páginaCulvert Fitting Design Sheet KM: Left Rightjoshua ndalo100% (1)

- Minox 103 Elbow (Inch) 2019Documento1 páginaMinox 103 Elbow (Inch) 2019MBI Heineken RonaldAún no hay calificaciones

- Asus X556UJ-RGDocumento6 páginasAsus X556UJ-RGTeofilTrif100% (1)