Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Under Reamed Pile Foundation

Cargado por

lprose33%(3)33% encontró este documento útil (3 votos)

4K vistas8 páginasUnder reamed piles have mechanically formed enlarged bases that have been as much as 6 m in diameter. Piles are bored cast in situ concrete piles having bulb shaped enlargement near base. Cost advantages are due to the reduced pile shaft diameter, resulting in less concrete needed to replace the excavated material.

Descripción original:

Derechos de autor

© © All Rights Reserved

Formatos disponibles

DOCX, PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoUnder reamed piles have mechanically formed enlarged bases that have been as much as 6 m in diameter. Piles are bored cast in situ concrete piles having bulb shaped enlargement near base. Cost advantages are due to the reduced pile shaft diameter, resulting in less concrete needed to replace the excavated material.

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como DOCX, PDF, TXT o lea en línea desde Scribd

33%(3)33% encontró este documento útil (3 votos)

4K vistas8 páginasUnder Reamed Pile Foundation

Cargado por

lproseUnder reamed piles have mechanically formed enlarged bases that have been as much as 6 m in diameter. Piles are bored cast in situ concrete piles having bulb shaped enlargement near base. Cost advantages are due to the reduced pile shaft diameter, resulting in less concrete needed to replace the excavated material.

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como DOCX, PDF, TXT o lea en línea desde Scribd

Está en la página 1de 8

Under Reamed Pile Foundation

Under Reamed Pile

Under reamed piles have mechanically formed enlarged bases that have been as much as 6 m in

diameter. The form is that of an inverted cone and can only be formed in stable soils. In such conditions

they allow very high load bearing capacities.

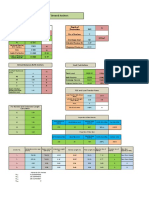

The diameter of the pile stem (D) varies from 20 to 50 cm. The diameter of the under-ream bulbs (Du) is

normally 2.5 times the diameter of the pile stem. It may however, vary form 2 to 3 times (D) under

special circumstances. In case of double or multi-under-reamed piles, the centre to centre vertical

spacing between two bulbs may vary from 1 to 1 times the under-reamed diameter (Du). The length

of under-reamed piles varies from 3 to 8 meter and their centre to centre spacing should normally be

not less than 2 times the under-reamed diameter.

Under reamed piles are the most safe and economical foundation in Black cotton soil. Under reamed

piles are bored cast in situ concrete piles having bulb shaped enlargement near base. A Pile having one

bulb is called single under reamed pile. In its closed position, the under reamer fits inside the straight

section of a pile shaft, and can be expanded at the base of the pile to produce the enlarged base.

The cost advantages of under-reamed piles are due to the reduced pile shaft diameter, resulting in

less concrete needed to replace the excavated material.

Under reamed piles are of two types:

1. Pre-cast under reamed piles

2. In-situ cast under reamed piles

1. Pre-cast under reamed piles

Pre-cast piles require specialized pile driving equipments. They are advantageous over in-situ cast pile

because they dont need holes to be bored and the pile is already cast complete with the reinforcing

steel in place.

2. In-situ cast under reamed piles

This type of pile installation is used to replace soil removed by drilling rather than occupying the space

of displaced soil as in driven piles and thus, it mostly relies on end-bearing capacity of the earth layer at

the drilled depth.

Under reamed pile foundation for Black cotton soil

The bearing capacity of the pile is increased by increasing the number of bulbs at the base. Such type of

foundations is ideally suitable in the areas where the black cotton soil or expansive soil is beyond 2.50

meter. The basic principle of under reamed pile is to anchor the structure at a depth where ground

movements are negligible due to moisture variation or other reasons.

Simple tools are required for construction of under-reamed piles like spiral auger, under reaming tool,

and boring guide. This is a well proven and established technology for construction of foundation in

expansive soils. For speeding up the construction bore and under ream for large diameter and deeper

pile a mechanical rig can be used. The construction and design of such foundation can be done in

accordance with Indian Standard Code of Practice IS 2911-Part III.

These piles are best suited in soils where considerable ground movements occur due to seasonal

variations, filled up grounds or in soft soil strata. Provision of under reamed bulbs has the advantage of

increasing the bearing and uplift capacities. It also provides better anchorage at greater depths. These

piles are efficiently used in machine foundations, over bridges, electrical transmission tower foundation

sand water tanks.

Under-Reamed Piles: Safest Foundation Solution for Black Cotton soil

Swelling and shrinkage due to the property of volumetric changes of

expansive soil like black cotton soil results movement of the ground

producing cracking of the order of (sometimes) 15 to 20 cm wide and 2.5 to

4 m deep. This property is very dangerous for the structures supposed to be

founded on it. Many techniques are discussed previously in various post

published in this blog. Some of these are provision for reinforced concrete

ties or bands all around the main walls of the building, removing entire black

cotton soil where possible or commencing construction during dry seasons.

It is found that under-reamed piles provide an ideal solution to foundation in

black cotton soil or other similar types of expansive soils. The design

guidelines of under-reamed pile are briefly discussed below:

Under-Reamed Pile Foundation for Black Cotton Soil

Design guidelines for Under-Reamed Pile Foundation

The diameter of the pile stem (D) varies from 20 to 50 cm. The diameter of

the under-ream bulbs (D

u

) is normally 2.5 times the diameter of the pile

stem. It may however, vary form 2 to 3 times (D) under special

circumstances. In case of double or multi-under-reamed piles, the centre to

centre vertical spacing between two bulbs may vary from 1 to 1 times

the under-reamed diameter (D

u

). The length of under-reamed piles varies

from 3 to 8 meter and their centre to centre spacing should normally be not

less than 2 times the under-reamed diameter.

Types of Piles

Piles can by classified on the basis of following characteristics:

1. Mechanism of Load Transfer

2. Method of Installation

3. Type of Materials

Classification of Piles on the basis of load transfer

Types of piles based on the mechanism of Load Transfer:

End/Point Bearing Piles:

If a bedrock or rocklike material is present at a site within a reasonable depth, piles can be

extended to the rock surface. In this case, the ultimate bearing capacity of the pile depends

entirely on the underlying material; thus the piles are called end or point bearing piles. In most

of these cases the necessary length of the pile can be fairly well established.

Instead of bedrock, if a fairly compact and hard

stratum of soil is encountered at a reasonable

depth, piles can be extended a few meters into the

hard stratum.

Friction Piles:

In these types of piles, the load on pile is resisted

mainly by skin/friction resistance along the side

of the pile (pile shaft). Pure friction piles tend to

be quite long, since the load-carrying. Capacity is

a function of the shaft area in contact with the

soil. In cohesion less soils, such as sands of

medium to low density, friction piles are often

used to increase the density and thus the shear

strength. When no layer of rock or rocklike material is present at a reasonable depth at a site,

point/end bearing piles become very long and uneconomical. For this type of subsoil condition,

piles ate driven through the softer material to specified depth.

Friction cum end bearing piles

In the majority of cases, however, the load-carrying capacity is dependent on both end-bearing

and shaft friction.

Driven or displacement piles

They are usually pre-formed before being driven, jacked, screwed or hammered into ground.

This category consists of driven piles of steel or precast concrete and piles formed by driving

tubes or shells which are fitted with a driving shoe. The tubes or shells which are filled with

concrete after driving. Also included in this category are piles formed by placing concrete as the

driven piles are withdrawn.

Bored or Replacement piles

They require a hole to be first bored into which the pile is then formed usually of reinforced

concrete. The shaft (bore) may be eased or uncased depending upon type of soil.

Types of Piles based on Materials

Timber piles

Timber piles are made of-tree trunks driven with small end as a point

Maximum length: 35 m; optimum length: 9 - 20m

Max load for usual conditions: 450 kN; optimum load range = 80 - 240 kN

Disadvantages of using timber piles:

Difficult to splice, vulnerable to damage in hard driving, vulnerable to decay unless treated with

preservatives (If timber is below permanent Water table it will apparently last forever), if

subjected to alternate wetting & drying, the useful life will be short, partly embedded piles or

piles above Water table are susceptible to damage from wood borers and other insects unless

treated.

Advantages:

Comparatively low initial cost, permanently submerged piles are resistant to decay, easy to

handle, best suited for friction piles in granular material.

Steel piles

Maximum length practically unlimited, optimum length: 12-50m

Load for usual conditions = maximum allowable stress x cross-sectional area

The members are usually rolled HP shapes/pipe piles. Wide flange beams & I beams

proportioned to withstand the hard driving stress to which the pile may be subjected. In HP pile

the flange thickness = web thickness, piles are either welded or seamless steel pipes, which may

be driven either open ended or closed end. Closed end piles are usually filled with concrete after

driving.

Open end piles may be filled but this is not often necessary., dm

Advantages of steel piles:

Easy to splice, high capacity, small displacement, able to penetrate through light obstructions,

best suited for end bearing on rock, reduce allowable capacity for corrosive locations or provide

corrosion protection.

Disadvantages:

Vulnerable to corrosion.

HP section may be damaged/deflected by major obstruction

Concrete Piles

Concrete piles may be precast, prestressed, cast in place, or of composite construction

Precast concrete piles may be made using ordinary reinforcement or they may be prestressed.

Precast piles using ordinary reinforcement are designed to resist bending stresses during picking

up & transport to the site & bending moments from lateral loads and to provide sufficient

resistance to vertical loads and any tension forces developed during driving.

Prestressed piles are formed by tensioning high strength steel prestress cables, and casting the

concrete about the cable. When the concrete hardens, the prestress cables are cut, with the

tension force in the cables now producing compressive stress in the concrete pile. It is common

to higher-strength concrete (35 to 55 MPa) in prestressed piles because of the large initial

compressive stresses from prestressing. Prestressing the piles, tend to counteract any tension

stresses during either handling or driving.

Max length: 10 - 15 m for precast, 20 - 30 m for prestressed

Optimum length 10 - 12 m for precast. 18 - 25m prestressed

Loads for usual conditions 900 for precast. 8500 kN for prestressed

Optimum load range: 350 - 3500 kN

Advantages:

1. High load capacities, corrosion resistance can be attained, hard driving possible

2. Cylinder piles in particular are suited for bending resistance.

3. Cast in place concrete piles are formed by drilling a hole in the ground & filling it with concrete.

The hole may be drilled or formed by driving a shell or casing into the ground.

Disadvantages:

1. Concrete piles are considered permanent, however certain soils (usually organic) contain

materials that may form acids that can damage the concrete.

2. Salt water may also adversely react with the concrete unless special precautions are taken when

the mix proportions are designed. Additionally, concrete piles used for marine structures may

undergo abrasion from wave action and floating debris in the water.

3. Difficult to handle unless prestressed, high initial cost, considerable displacement, prestressed

piles are difficult to splice.

4. Alternate freezing thawing can cause concrete damage in any exposed situation.

Composite piles

In general, a composite pile is made up of two or more sections of different materials or different

pile types. The upper portion could be eased cast-in-place concrete combined with a lower

portion of timber, steel H or concrete filled steel pipe pile. These piles have limited application

and arc employed under special conditions.

También podría gustarte

- UNDER-REAMED PILES: KEY FACTS ABOUT CONSTRUCTION AND DESIGNDocumento7 páginasUNDER-REAMED PILES: KEY FACTS ABOUT CONSTRUCTION AND DESIGNAnonymous nwByj9LAún no hay calificaciones

- Under Reamed Piles NPTELDocumento5 páginasUnder Reamed Piles NPTELGaddam SudheerAún no hay calificaciones

- Cement Concrete Road DesignDocumento8 páginasCement Concrete Road Designmdshah1308Aún no hay calificaciones

- Retaining Wall With Relief SlabDocumento7 páginasRetaining Wall With Relief Slabrajivkannan100% (2)

- Pressure Bulb CalculationDocumento24 páginasPressure Bulb CalculationKarishma JuttunAún no hay calificaciones

- RR Masonary Retaing Wall DesignDocumento41 páginasRR Masonary Retaing Wall DesignAbhay KumarAún no hay calificaciones

- Bored Pile Capacity Is Final 08-01-18Documento20 páginasBored Pile Capacity Is Final 08-01-18a duttaAún no hay calificaciones

- Design of FoundationDocumento26 páginasDesign of Foundationmessinho70% (1)

- GT Report Open Cutting at Ch. 34 KM MizoramDocumento15 páginasGT Report Open Cutting at Ch. 34 KM MizoramAnil kumarAún no hay calificaciones

- Lecture Notes On Foundation EngineeringDocumento60 páginasLecture Notes On Foundation EngineeringAnonymous PeFQLw19Aún no hay calificaciones

- Pile Design Check - SHDocumento2 páginasPile Design Check - SHJennifer HudsonAún no hay calificaciones

- Eccentric Foundation Bearing CapacityDocumento20 páginasEccentric Foundation Bearing CapacityAli SaeedAún no hay calificaciones

- SPRING-KDocumento5 páginasSPRING-KA.K.M Shafiq MondolAún no hay calificaciones

- Design of Ground Anchors For ClaysDocumento1 páginaDesign of Ground Anchors For ClaysMUHAMMAD ALIAún no hay calificaciones

- GEO TALK Ground AnchorDocumento50 páginasGEO TALK Ground AnchorWidodo WidodoAún no hay calificaciones

- Design of Pile FoundationDocumento16 páginasDesign of Pile FoundationD SRINIVASAún no hay calificaciones

- Design of CulvertDocumento12 páginasDesign of CulvertDebajani DekabaruahAún no hay calificaciones

- Design of Foundations PDFDocumento41 páginasDesign of Foundations PDFolomizanaAún no hay calificaciones

- Design of Circular ChimneyDocumento15 páginasDesign of Circular ChimneyPatel TosifAún no hay calificaciones

- 5-Design of Raft FoundationDocumento2 páginas5-Design of Raft FoundationheshamAún no hay calificaciones

- Static Pile Load TestingDocumento18 páginasStatic Pile Load Testinganon_789699787100% (1)

- Pile CapacityDocumento6 páginasPile Capacitymailmaverick8167Aún no hay calificaciones

- Raft Foundations Bearing Capacity and Settlement Report PDFDocumento9 páginasRaft Foundations Bearing Capacity and Settlement Report PDFixynnuddoAún no hay calificaciones

- Pile Driving ChartDocumento3 páginasPile Driving ChartRio HandokoAún no hay calificaciones

- Summary of Structural Calculation of 1-Barrel Box CulvertDocumento30 páginasSummary of Structural Calculation of 1-Barrel Box CulvertTony Hartono BagioAún no hay calificaciones

- Calculation of Safe Bearing Capacity of Soil: - Based On IS: 6403Documento31 páginasCalculation of Safe Bearing Capacity of Soil: - Based On IS: 6403sourabh_gupta_54100% (1)

- 6 Pile DesignDocumento40 páginas6 Pile DesignETHJDTJRYJ2Aún no hay calificaciones

- Design of Bored Piles Is 2911-Part 1sec2Documento5 páginasDesign of Bored Piles Is 2911-Part 1sec2Armaan GuptaAún no hay calificaciones

- Bridge Design Report - Docx 150Documento17 páginasBridge Design Report - Docx 150nephembaniAún no hay calificaciones

- BIS Hume PipeDocumento7 páginasBIS Hume PipeShiv Pratap SinghAún no hay calificaciones

- 3.3.1 Retaining WallDocumento31 páginas3.3.1 Retaining WallNeil SonAún no hay calificaciones

- Calculation For 1.4m X 1.5m RCC Box CulvertDocumento4 páginasCalculation For 1.4m X 1.5m RCC Box Culvertrupesh417Aún no hay calificaciones

- Water Tank Design - B-300mmDocumento59 páginasWater Tank Design - B-300mmrachana0% (1)

- Counter Fort Reatining WAll With HORZONTAL Bach FillDocumento35 páginasCounter Fort Reatining WAll With HORZONTAL Bach FillUlasi IfeanyiAún no hay calificaciones

- Box Culvert-Structural DesignDocumento5 páginasBox Culvert-Structural DesignsivaAún no hay calificaciones

- Analysis and Design of Foundation SystemsDocumento31 páginasAnalysis and Design of Foundation SystemsJAY PATELAún no hay calificaciones

- Trial Pile Design ExcelDocumento48 páginasTrial Pile Design ExcelSandeep Kumar100% (2)

- Calculation of Safe Bearing Capacity as per IS 6403 - 1981Documento11 páginasCalculation of Safe Bearing Capacity as per IS 6403 - 1981navneet3bawaAún no hay calificaciones

- Project: Client: Made by Date Location: Subject: Checked Revision Job NoDocumento2 páginasProject: Client: Made by Date Location: Subject: Checked Revision Job NothaoAún no hay calificaciones

- Road Estimate FormatDocumento7 páginasRoad Estimate Formatalok jhaAún no hay calificaciones

- GeoTechnical Design of PileDocumento2 páginasGeoTechnical Design of PileSabbir Siddique100% (1)

- DESIGN OF GRAVITY RETAINING WALLDocumento10 páginasDESIGN OF GRAVITY RETAINING WALLD.V.Srinivasa RaoAún no hay calificaciones

- Pile-Capacity - All CalculationDocumento6 páginasPile-Capacity - All CalculationAhamed Imran100% (2)

- Design For RR Stone Masonary Retaining Wall: General DataDocumento2 páginasDesign For RR Stone Masonary Retaining Wall: General DataRajesh GangwalAún no hay calificaciones

- Soil C and Phi ValuesDocumento3 páginasSoil C and Phi ValuesthamiradAún no hay calificaciones

- Ultimate Load Carrying Capacity of An Under Reamed Piles 1Documento1 páginaUltimate Load Carrying Capacity of An Under Reamed Piles 1eco protection100% (1)

- Column-Footing Size 3Documento8 páginasColumn-Footing Size 3Anonymous HJ7hmihhAún no hay calificaciones

- Design of Culvert - Jal Dubba PDFDocumento12 páginasDesign of Culvert - Jal Dubba PDFYogen SthaAún no hay calificaciones

- Bored Pile Design and Acceptance CriteriaDocumento2 páginasBored Pile Design and Acceptance CriterialaurenjiaAún no hay calificaciones

- Brick Wall Footing Design-1Documento12 páginasBrick Wall Footing Design-1mumarbsc7244Aún no hay calificaciones

- Design of square box culvert and RCC slab bridgeDocumento25 páginasDesign of square box culvert and RCC slab bridgeAnonymous cYcLLOmmk80% (1)

- Pile Foundation TypesDocumento17 páginasPile Foundation Typessad jam100% (6)

- Pile Foundation Need and FunctionsDocumento8 páginasPile Foundation Need and FunctionsReemALMousawiAún no hay calificaciones

- Pile Foundation - Need and FunctionsDocumento8 páginasPile Foundation - Need and Functionsريام الموسويAún no hay calificaciones

- ARBT05 PrelimResearch1Documento22 páginasARBT05 PrelimResearch1keithAún no hay calificaciones

- Different Types of PileDocumento16 páginasDifferent Types of PileBayu Suprayogi100% (1)

- تقرير اسسDocumento9 páginasتقرير اسسarno assassinAún no hay calificaciones

- Short Piles 2Documento94 páginasShort Piles 2vivek_gesAún no hay calificaciones

- Types of Piles: Classification of Piles On The Basis of Load TransferDocumento4 páginasTypes of Piles: Classification of Piles On The Basis of Load TransferAnkush PendhariAún no hay calificaciones

- Project On Parle GDocumento22 páginasProject On Parle Glprose100% (1)

- Online Exa Syste (Repaired)Documento36 páginasOnline Exa Syste (Repaired)Mohammed ThariqAún no hay calificaciones

- R.T.O SystemDocumento45 páginasR.T.O Systemlprose80% (5)

- Introduction HRDocumento9 páginasIntroduction HRlproseAún no hay calificaciones

- AirtelDocumento42 páginasAirtelraghavsaaniAún no hay calificaciones

- JITENS%20 CVDocumento3 páginasJITENS%20 CVlproseAún no hay calificaciones

- Internet BankingDocumento13 páginasInternet BankinglproseAún no hay calificaciones

- Vipul Vyas May field expenses reportDocumento2 páginasVipul Vyas May field expenses reportlproseAún no hay calificaciones

- Service Switching Behavior Among Mobile Phone Users: Farzana Q. Habib, Aliah Hanim M. Salleh and Nor Liza AbdullahDocumento9 páginasService Switching Behavior Among Mobile Phone Users: Farzana Q. Habib, Aliah Hanim M. Salleh and Nor Liza AbdullahlproseAún no hay calificaciones

- DOH 90 % Site Inspection Required ChecklistDocumento3 páginasDOH 90 % Site Inspection Required Checklistarshad209Aún no hay calificaciones

- Cat Sos 793&793b TrucksDocumento7 páginasCat Sos 793&793b TrucksmkAún no hay calificaciones

- Perforadora Cop-1432MEDocumento52 páginasPerforadora Cop-1432MEsandropemaAún no hay calificaciones

- A320 Airframe and Engine CT 2019-3Documento8 páginasA320 Airframe and Engine CT 2019-3Teow Chee MengAún no hay calificaciones

- Economics of Power GenerationDocumento22 páginasEconomics of Power Generationbhaskar123321Aún no hay calificaciones

- Illustrated Parts List: FRO-16210C November 2012Documento46 páginasIllustrated Parts List: FRO-16210C November 2012Luis Enrique Castro ManzanedaAún no hay calificaciones

- Ruta de Cancun A Mexico MexicanaDocumento20 páginasRuta de Cancun A Mexico MexicanaJesus MorenoAún no hay calificaciones

- Proceedings of The Inter-ISC 18 PDFDocumento240 páginasProceedings of The Inter-ISC 18 PDFLiviu GruiaAún no hay calificaciones

- REINFORCED CONCRETE SLAB DESIGNDocumento23 páginasREINFORCED CONCRETE SLAB DESIGNMohamed AbdAún no hay calificaciones

- ElectronicsDocumento264 páginasElectronicszamalahmed132Aún no hay calificaciones

- SA Steam GenerationDocumento6 páginasSA Steam GenerationRajagopalAún no hay calificaciones

- Eng2001 NotesDocumento12 páginasEng2001 NotesRohan KaickerAún no hay calificaciones

- Computer History Timeline2Documento31 páginasComputer History Timeline2Janina CalimlimAún no hay calificaciones

- Lift Car Hidrolis Dan SelingDocumento32 páginasLift Car Hidrolis Dan SelingMuhammad Arief PrasetyaAún no hay calificaciones

- LPG Chapter 09-18Documento12 páginasLPG Chapter 09-18DINESH SIVAAún no hay calificaciones

- Synopsis SamsungDocumento20 páginasSynopsis Samsungankitsingh91188Aún no hay calificaciones

- ECE Board HistoryDocumento2 páginasECE Board HistoryPats Renato CarmonaAún no hay calificaciones

- 02.lecture - 02 - Intro To IC EngineDocumento112 páginas02.lecture - 02 - Intro To IC Enginemahbububur rahmanAún no hay calificaciones

- Catalog 201506 PDFDocumento75 páginasCatalog 201506 PDFDairo OvalleAún no hay calificaciones

- Definition of Computer SecurityDocumento13 páginasDefinition of Computer SecuritysuhanitaAún no hay calificaciones

- 0653 s16 QP 62Documento20 páginas0653 s16 QP 62yuke kristinaAún no hay calificaciones

- Aerodynamics II NotesDocumento166 páginasAerodynamics II NotesAlexShearAún no hay calificaciones

- Progress Update on Construction of Serang-Panimbang Toll Road Section 3Documento39 páginasProgress Update on Construction of Serang-Panimbang Toll Road Section 3Pandu Haris AnantoAún no hay calificaciones

- AN1671 MC145170 PSpice Modeling KitDocumento14 páginasAN1671 MC145170 PSpice Modeling KitfahkingmoronAún no hay calificaciones

- PMP SLD 5th EdDocumento170 páginasPMP SLD 5th EdSohail Khan100% (1)

- Standard Operating Procedure - CapsuleDocumento7 páginasStandard Operating Procedure - CapsuleIntan NajiihahAún no hay calificaciones

- Gels in Polyethylene Films - enDocumento5 páginasGels in Polyethylene Films - enNanh TrắngAún no hay calificaciones

- Net CoolDocumento2 páginasNet CoolCarlos Martin Uribe NichoAún no hay calificaciones

- List of Approved Vendors - Wagon Dte ItemsDocumento3 páginasList of Approved Vendors - Wagon Dte ItemsPramodAún no hay calificaciones

- Cherrington Model 4600XL Presentation Booklet EMAIL 22712Documento16 páginasCherrington Model 4600XL Presentation Booklet EMAIL 22712Jamal HabbasAún no hay calificaciones