Documentos de Académico

Documentos de Profesional

Documentos de Cultura

BNR

Cargado por

selmir_9Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

BNR

Cargado por

selmir_9Copyright:

Formatos disponibles

BIOLOGICAL NITROGEN REMOVAL

Chapters 3, 4 & 5 - EPA Manual

p. 218 - 255 - Benefield & Randall

p. 699 - 733 - Metcalfe & Eddy

Three-Stage Biological Removal

- nitrification and denitrification

- to mazimize rates, US practice has been to utilize three reactors in series,

each with its own clarifier to recycle the optimum biomass.

Stage 1 - carbonaceous BOD removal

- short SRT (2 - 4 d.) to prevent significant nitrification from

occurring

- short nominal HRT (1 - 2 hrs.)

Stage 2 - nitrification

- required SRT will be 4 to 15 days, depending upon temperature

- still fairly short HRT (3 - 5 hrs.)

- (see comparison table for single sludge system) p. 4 - 14, EPA

Manual

Stage 3 - denitrification

- SRT of 2 - 10 days (if methanol used)

- HRT of 1 - 2 hrs. (if methanol used)

- if a portion of raw sewage bypassed to stage 3 for use as

carbon source, HRT must increase markedly, especially in cold

climates (5 hrs?)

aerobic

nitrification

stage

RAS

aerobic

SC

carbonaceous

stage

RAS

SC

anoxic

RAS

SC

Methanol

denitrification

stage

FIG. 1 THREE STAGE NITROGEN REMOVAL

simple carbon

stirred tank

SINGLE SLUDGE NITROGEN REMOVAL

a) Post-denitrification

x x x x x

x x x x

x

x x

Q

Q

Q

RS

Aeration Anoxic Removal

- either add methanol, or bypass part of influent, or provide long anoxic

HRT

- relative mixing regimes in aerobic and anaerobic respiration?

- A/V in denitrification zone?

- DO level in aerobic?

- problems in clarifier?

b) Pre-denitrification

x x x x

Q Q

x x

x x

x x x x

QR

Q

RS

c) Pre and Post-denitrification

x

x x x x

x

x x

Q Q

Q

RS

x x

x x

x x x x

QR

QUESTIONS:

1) What differences in design total SRT would you anticipate between

alternatives a, b, and c?

2) What differences in clarifier performance might one expect between

alternatives a, b, and c?

3) For a given nominal HRT in the bioreator, what would determine max.

practical QR? (in terms on N-removal).

4) What would you anticipate to be the relative design sizes of the 2 anoxic

(anaerobic respiration) zones in alternative c?

5) For an "average" North American Sewage (BOD = 200 mg/L, tot. N = 40 mg/L),

what aerobic SRT (and total SRT) would be advisable at a mixed liquor

temperature of 10

o

C?

TABLE 4-2

CALCULATED DESIGN PARAMETERS FOR A 1 MGD

COMPLETE MIX ACTIVATED SLUDGE PLANT

Minimum

temp. for

nitrification, C

Maximum

possible

nitrifier

growth rate

N, day-1

Assumed

allowable

MLSS/MLVSS

mg/l

Safety

Factor,

SF

Design

solids

retention

time, days

d

c

Steady state

effluent

NH

4

+

-N,

mg/L

Organic

removal

rate

lb BODrem/

lb MLVSS-day

Hydraulic

retention

time,

a

hours

BOD

5

loading

(volumetric)

lb/1000/cf/day

b

10

0.175

2.0

2.5

3.0

11.5

14.3

17.2

0.23

0.15

0.11

0.21

0.19

0.17

11.0

12.8

14.0

20.5

17.5

15.8

15

0.285

2.0

2.5

3.0

7.0

8.8

10.5

0.40

0.27

0.20

0.29

0.25

0.22

6.4

7.5

8.5

34.9

29.9

26.5

20

0.465

2.0

2.5

3.0

4.3

5.4

6.4

0.73

0.49

0.36

0.44

0.36

0.32

4.4

5.2

6.0

51.5

43.0

37.3

1,500

2,000

1,875

2,500

2,250

3,000

a

At ADWF

x

x x x x

x

x x

Q Q

Q

RS

x x

x x

x x x x

QR

b

62.4 lb/1000 cf/day = kg/m

3

/day

ZONE

PRIMARY

EFFLUEN

T

RAS

PRE-ANOXIC

ANAEROBIC

RECYCLE

ANOXIC

AEROBIC

CLARIFIER

2 3 4 SLUDGE EFFLUENT

D.O.

ORP.

BOD

TSS

TKN

NH3

Q

NO

X

Air Flow

T-P

Ortgho P

BIOCHEMISTRY OF NITROGEN REMOVAL

A. Nitrification

2NH

4

+

+ 3O

2

2 NO

2

-

+ 4H

+

+ 2H

2

O

2NO

2

+

+ O

2

2 NO

3

-

Nitrosomonas

(Autotroph)

NH

4

+

+ 2O

2

1 NO

3

-

+ 2H

+

+ H

2

O

Nitrobacter

(Autotroph)

QUESTION: What happens to pH?

Let's say we have a wastewater with:

TKN = 35 mg/L as N

alkalinity = 250 mg/L as CaCO

3

moles/L TKN = 35 x 10

-3

g/L = 2.5 x 10

-3

14 g/gmm

equiv./L alkalinity = 250 x 10

-3

= 5 x 10

-3

100 g/g - eq.

2

If all alkalinity is present as HCO

3

-

(which will be essentially true at normal

pH of raw sewage [pH < 7.5]), then equiv./L = moles/L.

[HCO

3

-

] = 5 X 10

-3

m/L

From eq. , one mole NH

4

+

produces 2 moles H

+

H+ released during nitrification = 5 x 10

-3

m/L

If there was alkalinity present, what would pH drop to?

pH = log 1 = log 1

[H

+

] 5 x 10

-3

= 2.3 (pretty low!!)

With alkalinity of 5 x 10

-3

m/L of HCO

-3

, H+ will be used up to convert

HCO

-3

to H

2

CO

3

and CO

2

.

H

2

CO

3

= H

+

+ HCO

-3

K = 4.2 x 10

-7

(H+) (HCO

-3

) = 4.2 x 10-7

(H

2

CO

3

)

At sewage pH of, say, 7.0

(H

2

CO

3

) = (10

-7

) (5 x 10

-3

)

(4.2 x 10

-7

)

= 1.2 x 10

-3

After all this H

+

is added due to nitrification, the approximate

situation will be:

new (H

2

CO

3

) = 1.2 x 10

-3

+ 5 x 10

-3

= 7.2 x 10

-3

m/L

new (HCO

3

-1

) = 5 x 10

-3

- 5 x 10

-3

= 0

(in fact, it will not go to zero, because some H

+

will also react with OH

-

to

form H

2

O).

Without doing a more complex calculation, lets say new (HCO

-3

) = 10

-5

m/L.

new (H

+

) = (4.2 x 10

-7

) (7.2 x 10

-3

)

(10

-5

)

= 3 x 10

-4

m/L

or pH = 3.5 (still pretty low)

B. Denitrification

Empirical total effect of conversion to:

1. ammonia for cell synthesis

2. nitrogen gas during use as an elector acceptor in place of oxygen

NO

-3

+ 1.08 CH

3

OH + H

+

.065 C

5

H

2

O

2

N

+ .47 N

2

+ .76 CO

2

+ 2.44 H

2

O

(assuming methanol as carbon source)

o one mole NO

-

3

uses up one mole H

+

loss of alkalinity if use denitrification after nitrification is

only about 50% of what it would be under nitrification

MANUAL DESIGN EXAMPLE

Skavinge, Denmark

des. population = 10,000

Q avg. = 4830 m

3

/d

Qpk DWF = 9450 m

3

/d

Qpk WWF = 1040 m

3

/hr

BOD

5

(DWF) = 140 mg/L

Tot.N (DWF) = 30 mg/L

Tot.P (DWF) = 12 mg/L

SS (DWF) = 95 mg/L

alkalinity = 180 mg/L as CaCO

3

B

ecause of low BOD/N, don't remove primary solids.

BOD

5

to bioreactor ~ 140 mg/L

Assumptions and design decisions:

1. MLVSS = 0.7 MLSS = 1800 mg/L

2. Winter mixed liquor T = 6

o

C

3. Design for complete nitrification and denitrification

4. Nitrified recycle = 4 Q avg.

5. RAS = 0.75 Q avg.

Design effluent quality:

1. Complete nitrification

2. Total N < 6 mg/L

a) Check adequacy of alkalinity when denitrification not occurring

avg. NH

4

+

conversion = 30 - 1.5 = 28.5 mg/L as N

alkalinity consumed = 7.1 mg CaCO

3

/mg N ox.

or, 7.1 (28.5) = 202 mg/L alkalinity as CaCO

3

plus, better allow for

peaking loads

standby alkalinity feed = (202 - 180) + 50 = 72 mg/L as CaCO

3

b

) When denitrification is occurring - say 5 mg/L NO

3

-N not denitrified

denitrification = 30 - 1.5 - 5 = 23.5 mg/L

alkalinity recovered = 23.5 (.5) (202)

28.5

= 83 mg/L

Since have pre-denitrification, alkalinity increases before it decreases

residual alkalinity = 180 + 83 - 202

= 61 mg/L as CaCO

3

This might be adequate, but will have to have pH monitor in aerobic

zone.

c) Process schematic

Q

Qr

aerobic

anoxic

RAS = 0.75 Q

d) Nitrifier growth rate

assume non-limiting DO & pH conditions (Kn < N)

Kn = half-saturation coef. for Nitrosomonas (~ 1.0 for sewage)

N = ammonia N concentration

NITROGEN & ORGANIC CARBON REMOVAL IN A SINGLE SLUDGE SYSTEM

In this type of system we will generally get a mixed culture of organisms that

includes:

1. heterotrophs that require oxygen

2. denitrifying heterotrophs

3. nitrifying autotrophs

The kinetics of growth and decay of these groups have been found by various

investigators to be dis-similar, and changing environmental conditions affect each

group differently. This makes the design of a bioreactor-clarifier system fairly

complicated, since trial and error solutions are required to satisfy the

requirements for carbonaceous assimilation, nitrification, and denitrification.

In designing such a plant for a community in the Okanagan Valley, for instance, it

will be important to check both summer and winter designs, because:

1. summer loads for BOD and TKN are generally higher than winter

2. winter kinetic rates are lower than summer, especially for denitrification

Let's look at an example:

FREDERIKSWAERK, DENMARK

Design ADWF - 12,700 m

3

/d

Design PDWF - 810 m

3

/hr

Design PWWF - 1900 m3/hr

win er t sum er m

BOD

5

128 mg/L 170 mg/L

TKN 28 mg/L 36 mg/L

Tot.P 8.7 mg/L 11.4 mg/L

anticipated mixed liquor temperatures:

coldest month - 5

o

C

warmest month - 20

o

C

Initial design assumptions:

1. primary clarifier removes 25% of BOD

2. MLVSS = 0.7 MLSS (high SRT)

3. Nitrified recycle = 4 times Q

in

4. Return activated sludge = 0.75 times Q

in

A. Nitrification (winter)

N

itrogen assimilated ~ 3% of BOD5 utilized

N

ass.

= (128 (.75) - 5) .03 = 2.7 mg/L

eff. BOD

Organic nitrogen that will not be oxidized ~ 1 mg/L

(average for domestic sewage)

QPE

QRS/QPE = 0.75

aerobic anoxic

QIR/QPE = 4.0

AN AR

Q eff.

N oxidized by autotrophs = 28 - 2.7 - 1 = 24.3 mg/L

f

raction of nitrifiers in active mass:

f

n

= 0.15 Nox.

0.15 Nox. + aSr

a = cell yield for heterotrophs

= 0.6 mg MLVSS/mg BOD

5

removed

Sr = mg/L BOD5 removed in bioreactor

f

n

= 0.15 (24.3)

0.15 (24.3) + 0.6 (128) (.75)

= .06 g nitrifiers/g MLVSS

nitrification rate

20

at a DO

concentration

of 2 mg/L

k

n

= 1.04 mg NH

3

-N/mg. nitrifiers - d.

T 20 T-20

k

n

= k

n

(1.05)

T T-20

R

n

= f

n

X

v

(1.04) (1.05) (DO) mg/L-d

2

Lets try X

v

= 3000 mg/L and DO = 2.5 mg/L

N to be oxidized by autotrophs = 28 - 2.7 - 1

= 24.3 mg/L

fraction of nitrifiers in "active" solids

fn = 0.15 Nox.

0.15 Nox. + aSr

where a = Y = cell yield for heterotrophs

= 0.6 mg/ MLVSS/mg BOD

5

removed

Sr = BOD

5

removed

= 128 (.75) = 96 mg/L

f

n

= fn = .15 (24.3) = .06

.15 (24.3) + 0.6 (96)

aerobic SRT

m = maximum specific growth rate @ bioreactor conditions

.098 (T-15)

= [0.8 e ] [ DO ]

Ko

2

+ DO

(Table 11 - 15, Metcalfe & Eddy)

where KO

2

= half velocity constant for DO 1.3 (Table 11 - 15, Metcalfe & Eddy)

let's use a design DO of 2 mg/L

-1

= 0.23 d (growth rate of nitrifiers)

k = rate of NH

3

-N removal = m

Y

where Y = 0.15 for nitrifiers

.098 (5-15)

f m = 0.8 e [ ] [ 2 ]

1.3 + 2

-1

k = 0.23 = 1.52 d

0.15

Now can calculate minimum SRT using equation 8 - 54 (Metcalfe & Eddy)

1 = Y k - k

d

c

m

where k

d

= endogenous decay rate .05

1 = .15 (1.52) - .05 = 0.18

c

m

c

m

= 5.6 d. (1.75) = 9.8 days

to determine design

c

, apply an appropriate safety factor (1.5 < s.f. < 2.5)

depending on importance of maintaining nitrifier population at all times

I generally use 1.75 or 2.

d

= 5.6

c

Aerobic HRT

The design substrate utilization rate for NH

3

-N can be calculated from:

1 = Y U - k

d

(U = design utilization rate)

c

(eq'n. 8 - 46, Metcalfe & Eddy)

1 = .15 U - .05

9.8

U = .152 = 1.01 d

-1

.15

HRT = N

o

-N (Assuming zero order reaction)

UX

nitrification

If make design decision for MLSS = 3500

then X

nitrification

= 3500 (.75) (.06) = 160 mg/L

HRT = 24.3 - 1 = 0.15 d = 3.6 hr.

1.01 (160)

Anoxic HRT

rate of denitrification at 20

o

= .05 mg NO

3

-N/mg VSS - d (endogenous respiration)

= .15 mg NO

3

-N/mg VSS - d (raw sewage)

= .5 mg NO

3

-N/mg VSS - d (Short Chain Carbon Compounds)

our rate at 5

o

= k

20

(1.09)

5-20

den

= 0.1 (1.09)

-15

= .027

- NO

3

-N at end of aerobic zone (mass balance)

= 24.3 (Q) = 4.2 mg/L

5.75 Q

- NO

3

-N entering anoxic zone = 4.2 (4.75)

(5.75)

= 3.5 mg/L

HRT

den

= 3.5 = .053 d

.027 (3500)(.75)(.94)

Nominal HRT

den

= .053 (24) (5.75) = 7.3 hr.

What would bioreactor look like?

Design depth for fine bubble aeration = 4.5 m

for total HRT = 7.3 + 3.6 = 10.9 hr.,

need bioreactor A = 13,000 m

2

/d (10.9)

4.5 m 24

= 1320 m

2

Generally use a minimum of 2 bioreactors (660 m

2

each)

15 m

15 m

aerobic

44 m

O recycle

to Secondary clarifier

anoxic

anoxic

aerobic

O recycle

10 m

5 m

PE

to Secondary clarifier

BNitR BIOREACTOR DESIGN SPREADSHEET

WITH NO FERMENTER OR ANAEROBIC ZONE

WITH SEPARATE ANOXIC FOR RAS DENITRIFICATION

Q (avg) ML/d 12.7

BOD5 mg/L 128 Tot. MLSS yield kg/d 982.3

TKN to be oxid. mg/L 24.7

TKN mg/L 28 u(t) 0.3

Tot P mg/L 8.7 Aer. SRT (nitr.) 6.8

TSS vol. fraction 0.75 Tot. SRT 23.7

Temp. deg. C 5 Bioreactor Volume (cu.m.) 6649.7

Bioreactor HRT hr 12.6

Nitrifier fraction 0.063

Tot. solids yield kg/kg BOD 0.85

fr. MLVSS that are viable organisms 1 NO3-N ent. 2nd ax mg/ 3.0

2nd ax. AHRT hr 1.4

k(den) -1st ax. g NO3-N/g mlss-d 0.027 2nd ax. NHRT hr 7.8

k(den) -2nd ax. g NO3-N/g mlss-d 0.02 2nd ax. Volume cu.m. 4153.1

u(nit) (20 deg C) 0.8 NO3-N ent. 1st ax mg/ 1.8

safety factor - nitr. SRT 1.75 1st ax. AHRT hr 0.6

1st ax. NHRT hr 1.1

PC efficiency - BOD 0.25 1st ax. Volume cu.m. 576.8

PC efficiency - TSS 0.6

min. aer. vol. cu.m. 3657.3

N synthesized g N/g BOD rem. 0.03 des. aer. vol. cu.m. 1919.7

MLSS(max) mg/L 3500

eff. organic N mg/L 1

bioreactor SWD m 4.5

a recycle multiplier 4

eff. BOD mg/L 5

min. aerobic mass fraction 0.55

RAS multiplier 0.75

nitrifier yield gVSS/gNH3-N 0.15

heterotroph yield gVSS/BOD 0.6

BNitR BIOREACTOR DESIGN SPREADSHEET

WITH NO FERMENTER OR ANAEROBIC ZONE

WITH SEPARATE ANOXIC FOR RAS DENITRIFICATION

Q (avg) ML/d 12.7

BOD5 mg/L 128 Tot. MLSS yield kg/d 982.3

TKN to be oxid. mg/L 24.7

TKN mg/L 28 u(t) 0.3

Tot P mg/L 8.7 Aer. SRT (nitr.) 6.8

TSS vol. fraction 0.75 Tot. SRT 23.7

Temp. deg. C 5 Bioreactor Volume (cu.m.) 5172.0

Bioreactor HRT hr 9.8

Nitrifier fraction 0.063

Tot. solids yield kg/kg BOD 0.85

fr. MLVSS that are viable organisms 1 NO3-N ent. 2nd ax mg/ 3.0

2nd ax. AHRT hr 1.1

k(den) -1st ax. g NO3-N/g mlss-d 0.027 2nd ax. NHRT hr 6.1

k(den) -2nd ax. g NO3-N/g mlss-d 0.02 2nd ax. Volume cu.m. 3230.2

u(nit) (20 deg C) 0.8 NO3-N ent. 1st ax mg/ 1.8

safety factor - nitr. SRT 1.75 1st ax. AHRT hr 0.5

1st ax. NHRT hr 0.8

PC efficiency - BOD 0.25 1st ax. Volume cu.m. 448.6

PC efficiency - TSS 0.6

min. aer. vol. cu.m. 2844.6

N synthesized g N/g BOD rem. 0.03 des. aer. vol. cu.m. 1493.1

MLSS(max) mg/L 4500

eff. organic N mg/L 1

bioreactor SWD m 4.5

a recycle multiplier 4

eff. BOD mg/L 5

min. aerobic mass fraction 0.55

RAS multiplier 0.75

nitrifier yield gVSS/gNH3-N 0.15

heterotroph yield gVSS/BOD 0.6

BNitR BIOREACTOR DESIGN SPREADSHEET

WITH NO FERMENTER OR ANAEROBIC ZONE

WITH SEPARATE ANOXIC FOR RAS DENITRIFICATION

Q (avg) ML/d 20

BOD5 mg/L 90 Tot. MLSS yield kg/d 1062.5

TKN to be oxid. mg/L 17.4

TKN mg/L 20 u(t) 0.3

Tot P mg/L 5 Aer. SRT (nitr.) 6.8

TSS vol. fraction 0.75 Tot. SRT 24.2

Temp. deg. C 5 Bioreactor Volume (cu.m.) 6425.8

Bioreactor HRT hr 2.2

Nitrifier fraction 0.065

Tot. solids yield kg/kg BOD 0.85 Aerobic Volume (des) cu.m. 1829.0

fr. MLVSS that are viable organisms 1 NO3-N ent. 2nd ax mg/ 2.1

2nd ax. AHRT hr 0.8

k(den) -1st ax. g NO3-N/g mlss-d 0.027 2nd ax. NHRT hr 4.8

k(den) -2nd ax. g NO3-N/g mlss-d 0.02 2nd ax. Volume cu.m. 4036.2

u(nit) (20 deg C) 0.8 NO3-N ent. 1st ax mg/ 1.3

safety factor - nitr. SRT 1.75 1st ax. AHRT hr 0.4

1st ax. NHRT hr 0.7

PC efficiency - BOD 0.25 1st ax. Volume cu.m. 560.6

PC efficiency - TSS 0.6

min. aer. vol. cu.m. 3534.2

N synthesized g N/g BOD rem. 0.03 des. aer. vol. cu.m. 1816.8

MLSS(max) mg/L 4000

eff. organic N mg/L 1

bioreactor SWD m 4.5

a recycle multiplier 4

eff. BOD mg/L 5

min. aerobic mass fraction 0.55

RAS multiplier 0.75

nitrifier yield gVSS/gNH3-N 0.15

heterotroph yield gVSS/BOD 0.6

BNitR BIOREACTOR DESIGN SPREADSHEET

WITH NO FERMENTER OR ANAEROBIC ZONE

WITH SEPARATE ANOXIC FOR RAS DENITRIFICATION

Q (avg) ML/d 20

BOD5 mg/L 90 Tot. MLSS yield kg/d 1062.5

TKN to be oxid. mg/L 17.4

TKN mg/L 20 u(t) 0.3

Tot P mg/L 5 Aer. SRT (nitr.) 6.8

TSS vol. fraction 0.75 Tot. SRT 24.1

Temp. deg. C 5 Bioreactor Volume (cu.m.) 6413.6

Bioreactor HRT hr 7.7

Nitrifier fraction 0.065

Tot. solids yield kg/kg BOD 0.85

fr. MLVSS that are viable organisms 1 NO3-N ent. 2nd ax mg/ 2.1

2nd ax. AHRT hr 0.8

k(den) -1st ax. g NO3-N/g mlss-d 0.027 2nd ax. NHRT hr 4.8

k(den) -2nd ax. g NO3-N/g mlss-d 0.02 2nd ax. Volume cu.m. 4036.2

u(nit) (20 deg C) 0.8 NO3-N ent. 1st ax mg/ 1.3

safety factor - nitr. SRT 1.75 1st ax. AHRT hr 0.4

1st ax. NHRT hr 0.7

PC efficiency - BOD 0.25 1st ax. Volume cu.m. 560.6

PC efficiency - TSS 0.6

min. aer. vol. cu.m. 3527.5

N synthesized g N/g BOD rem. 0.03 des. aer. vol. cu.m. 1816.8

MLSS(max) mg/L 4000

eff. organic N mg/L 1

bioreactor SWD m 4.5

a recycle multiplier 4

eff. BOD mg/L 5

min. aerobic mass fraction 0.55

RAS multiplier 0.75

nitrifier yield gVSS/gNH3-N 0.15

heterotroph yield gVSS/BOD 0.6

EDMONTON GOLD BAR

Design & Operational Considerations for BNR

1. Effluent Quality Requirements

Total P < 1 mg/L

NH

3

-N < 10 mg/L winter

< 5 mg/L summer

All other parameters are immaterial.

2. Nitrification Considerations

Maintain SRT such that:

a) growth rate of nitrifiers (must be > wash-out rate)

b) effect of NH

3

-N concentration in the aerobic zone of bioreactor

(high concentration

=

high removal rate)

c) effect of NH

3

-N mass load - need more volume at given MLVSS to

remove increased mass.

d) effect of DO concentration

e) effect of temperature

f) effect of inhibition (prevalent at Gold Bar)

3. Denitrification Considerations

a) NO

3

-N concentration

b) NO

3

-N mass loadings

c) RBCOD concentration

d) Temperature (Readily Biodegradable COD)

e) RAS rate keep RAS as low as possible 0.75 Q

f) internal recycle rate

4. Phosphorus Removal Considerations

a) P release and organic carbon storage

- negligible O

2

and NO

3

- presence of VFA (SCC) (RBCOD)

- release up to 15 or 20 mg/L is normal in healthy anaerobic zone

(< 10 mg/l as a troubleshooting check)

b) P uptake and stored carbon utilization

- may occur anoxically or will occur aerobically

- anoxic P uptake not well understood

- uses stored carbon for growth; hence fast conversion (driven by

biochemical reaction)

- P uptake rate and capacity is dependent upon amount of stored C

- (N.B. have to have stored carbon for P removal)

- soluble Mg has been linked to good P removal (mg appears to

be a stabilizing effect)

-

Bioreactor 9 & 10 Inhibition Fixes (31 ML/d) 37.2 ml/d max month)

1. With Winter Denitrification

ax an ax

aer

aer

aer

PE

RAS

VFA

o

to Final Clarifier

Design MLSS for normal max = 3600 mg/L

a) indication of inhibition

- afternoon NH

3

-N breakthroughs of about 2 mg/L for 3 or 4

consecutive days

- beauty of online analyzers

b) mitigation

- turn off internal recycle pump, and initiate aeration of 2

nd

anoxic zone

c) effect

- increases aerobic SRT by 15%, which should reverse effects of

15% max inhibition

- increased NH3-N concentration in converted anoxic zone raises in-situ

rate of nitrification (increased concentration of reacting substance)

2. With No Winter Denitrification

aer an ax

aer

aer

aer

PE

RAS

VFA

to Final Clarifier

Design MLSS for normal max = 2900 mg/L

mitigation

- turn off wasting (or at least reduce) as soon as evidence of inhibition is

observed

- let MLSS climb to ~ 3600 mg/l (or until evidence of NH

3

breakthrough is gone)

1. Relative Benefits of Two Scenarios

- Scenario 1 will result in slightly lower blower power requirement as

long as inhibition not present

- Scenario 2 will result in lower solids loading on FC's as long as

inhibition not present

Air Requirements for BNR

A. Total amount can be divided into three components:

1. Carbon Removal (carbonaceous BOD)

2. Nitrification

3. Endogenous Respiration

- bugs eating each other

- as they they get eaten (cannibalization)

Generally speaking, we would design blowers to deliver the above amount

of air at design max. day loads with one compressor on standby.

Designed for Max Day

- not peak hour

- not max month

B. Air Delivery System

- since O

2

is not required at a uniform rate along the whole length of the

aerobic zone, we must provide air injection devices at varying spacing

along the bioreactor aerobic zone.

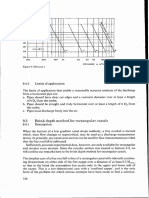

- if the bioreactor is designed and operated at "optimum" SRT, and

hence MLSS, the relative air demands along the tank look like the

following chart.

- Identifies: blower size

Diffuser density

Carbonaceous BOD

nitrification

endogenous respiration

Distance Along Aerated Zone

Air

Demand

(m

3

/min.)

with denitrification

}

effluent to clarifer

zero order

reaction

(good assumption)

2/3 of bioreactor

1st order reaction

Remember recover

1/2 air demand with

denitrification

Modelling Results - Bioreactor 9 & 10

- 50 % of PS fermented

- design avg. flow per module = 31 ML/d

Conditions

Temp.

MLSS

PO

4

- P

Tot.- P

NH

3

-N

NO

3

-N

Max. month, zone 4 ax.

no inhibition

12 3680 0.16 0.8 4.9 10.8

Max. month, zone 4 ax.

no inhibition

12

3500

0.1

0.7

9.9

7.1

NY Step Feed/RC Step Feed 12 3150 1.3 1.7 4.9 8.2

12 3410 2.9 3.2 5.0 6.9

Max. month, zone 4 aer.

no inhibition

12 2890 1.0 1.5 5.0 14.0

Max. month, zone 4 aer.

no inhibition

12 2850 0.1 0.6 9.8 11.2

Max. month, zone 4 ax.

no inhibition

20 1680 1.0 1.2 3.6 9.4

Avg. month, zone 4 ax.

no inhibition

12 2960 0.1 0.6 4.8 6.9

Avg. month, zone 4 aer.

no inhibition

12 2370 0.4 0.8 4.7 11.0

Max. month, zone 4 ax.

10% inhibition

12 4140 0.4 1.1 4.9 9.6

Max. month, zone 4 aer.

20% inhibition

12 3760 0.7 1.3 4.8 14.3

Avg. month, zone 4 ax.

20% inhibition

12 3870 0.1 0.8 4.9 6.9

Avg. month, zone 4 aer.

20% inhibition

12 3060 0.16 0.7 4.7 11.2

PHOSPHORUS STORING ORGANISM GROWTH

Organism Characteristics

1. Aerobic heterotrophs (just like those that we use to remove BOD)

2. Some can also use nitrate as the electron acceptor (anaerobic respiration)

3. Are also capable of improving their energy level under anaerobic

fermentation conditions (does not grow) - no biomass grows

4. Energy level increase then gives that organism a metabolic advantage in

any subsequent aerobic (or anoxic) zone.

(Out competes other organisms in anoxic/aerobic zones)

BIOCHEMICAL MODEL OF P RELEASE

(ANAEROBIC)

Fermentation not Respiration

Ac

Acetyl - P

H

+

H

+

Ac

3H

+

Acetyl CoA

H

B

C

o

A

P

H

B

P

O

4

PO

4

P

n-1

Poly -P

C

e

ll W

a

ll

Simple carbon source

in cysts/granules

Acetate

(Acetic Acid)

Together to balance

Together

Mg help P release (uptake)

PHB

Poly

Hydroxy

Butyrate

PHA

Poly

Hydroxy

Acetate

Alkanates

phosphate

cell wall

ATP

PHB

poly-P

organic carbon

ADP

TCA cycle

(can be methanol)

fu

n

c

tio

n

o

f V

F

A

's

FIG. 4 AEROBIC METABOLISM

BIOLOGICAL PHOSPHORUS REMOVAL

General References

1. Water Quality Management: Biological Nutrient Removal

eds. - Barnard, Randall & Stensel

pub. - Technomic Publishing Co. Inc.

851 New Holland Ave.

Box 3535

Lancaster, PA 17604

Fax: (717) 295-4538

2. Design of Municipal Wastewater Treatment Plants ( 2 volumes)

WEF Manual of Practice #8 (1992)

Water Environment Federation

601 Wythe St.

Alexandria, VA 22314-1994

A. Why Does Any Specific Biologically Mediated Process Work?

A number of environmental conditions and substrate characteristics have

significant impacts on the types of organisms that flourish in bioreactors.

Some of the more important are:

1. specific substrates present

2. temperature

3. length of time that organisms are in contact with the substrate

(SRT)

4. length of time that substrate is in contact with the organisms (HRT)

5. presence of desired electron acceptor for metabolic activities

a) dissolved oxygen (aerobic)

b) NO

3

-

, SO

4

=

, etc. (anoxic) (anaerobic respiration)

c) organic carbon (anaerobic fermentation)

6. pH

7. toxics - different compounds can have extremely variable effects on

different metabolic pathways. (lyse the cell or block or partially

block metabolic pathway)

Vinces Notes: Not as critical for phosphorus uptake as for

nitrogen conversion.

B. How Do These Parameters Impact the Design and Operation of

Conventional Secondary Treatment Processes?

- widely accepted kinetic model of the process at steady state is:

(complete mix) or plug flow assuming a

zero order reaction

x = c Y (So - S)

(1 + kd c)

where:

X = MLVSS in complete-mix reactor

c = SRT (d)

= HRT = V/Q (d)

Y = cell yield (mg VSS/mg BOD

5

)

So = influent BOD

5

(mg/L)

S = effluent BOD

5

(mg/L)

kd = endogenous decay coef. (d

-1

)

S = Ks (1 + c kd)

Equation 8.43 Metcalf & Eddy

c (Yk - kd)

-1

where: Ks = half velocity constant (mg/L BOD

5

)

= substrate concentration at one half the max. growth rate

k = max. rate of substrate util. (mg used/mg VSS.d)

- the measured values of the "constants" (coefficients) and "unit rates" are in

the following ranges for municipal sewage treatment:

Y - 0.4 to 0.8

kd - 0.025 to 0.075

Ks - 25 to 100

k - 2 to 10

}

at 20

o

C

- the reasons that they vary over such a wide range relate back to the list

given on page 2. For instance, if a sewage happens to be higher than

normal in % of BOD that is due to proteins or lipids (as opposed to

carbohydrates, k will be low and Ks will probably be high - hence effluent S

will be higher for a given c.

- generally speaking, the designer uses average values for these constants

(coefficients) and the operator then adjusts the actual c (SRT) as needed

to achieve the necessary effluent value of S.

- usual steps:

i) choose values for Ks, kd, Y, and k

ii) choose a desired value of c, based on type of activated sludge

process desired

iii) calculate expected S, and check if adequate

iv) choose either a desired value of X or of , and calculate the other

v) if satisfactory, design recycles, clarifier, etc.

vi) if not satisfactory, redesign process - computer programs are

available to do this job, using this kinetic model, or others. The

important thing to remember is that any model is only as good as the

estimates for the wastewater characteristics and the various model

coefficients. Piloting may be necessary to determine them in some

situations.

vii) temperature impacts on these model coefficients are usually

determined by an equation of the type

r

T

2

= r

20

(T-20)

may have to be determined experimentally

C. What Additional Biochemical Processes Do We Wish to Promote in Bio-P

Removal?

- since P cannot be biologically converted to a gas (like nitrogen forms

can), the best we can do is have it taken into microbial cells and then

dispose of it as part of the waste biomass.

- the observed results of such a process were first documented in the

mid-sixties

Jour. WPCF, 39, 750 - 777 (1967)

Science, 155, 1269 - 1271 (1967)

but neither the biochemical pathways involved, nor the environmental

conditions necessary to promote such end results were known.

D. Initial Process Development

1. Much of the original scientific work associated with understanding the

process sufficiently to allow the purposeful removal of P in an activated

sludge system was carried out by Barnard

Water Research, 9, 485 - 490 (1975)

Water Pollution Control, 74, 2, 143 - 154 (1975)

2. The primary requirement for successful P removal that arose from this

early work was the necessity for the biomass to be recycled through a

zone of deep anaerobic stress before being re-introduced into the

aerobic reactor of an activated sludge system.

3. To ensure the presence of deep anaerobic conditions, it was quickly

realized that any nitrate formed in the aerobic zone needed to be

removed before the Return Activated Sludge (RAS) is returned to the

anaerobic zone. Hence, bio-P plants also tended to be designed for

nitrification and denitrification as well.

(Remove nitrates they block P pathways) (University of Cap Town)

Q in

Q eff.

aer. recycle

an. ax. aer.

UCT Process

anoxic recycle

(nitrate ~ O mg/L)

RAS

denitrification

Modified

aer. recycle

an. ax.

aer.

Bardenpho

ax.

a

e

r

.

3. General Design Requirements in Early 1980's (for weak North American

sewage) - original Kelowna SRTs 18 day summer 30 d winter

- now SRTs 8 day summer 10 d winter

a) SRT - 8 to 30 days, depending upon temperature, and whether

purposeful nitrogen removal was necessary

b) HRT (nominal) = V/Q

in

- anaerobic zone - 2 to 3 hrs.

- first (main) anoxic zone - 2 to 4 hrs. depending on: mass of nitrate

returned in RAS, or in RAS plus aerobic recycle (UCT Process);

mass of nitrate in aerobic recycle (Bardenpho).

- aerobic zone - 4 to 7 hrs. to get carbon metabolized and P taken up.

- would be increased to perhaps 10 hrs. if nitrification also required

(see combined N & P removal notes).

- second anoxic zone - 2 to 3 hrs. to remove the nitrates that didn't get

recycled to the first anoxic zone (Bardenpho).

- final aerobic zone - 1/2 to 1 hr. to "sweeten" the mixed liquor so that

no significant denitrification occurs in the clarifier (Bardenpho).

E. What Have We Learned since the Early 80's?

1. Several species of bacteria are capable of storing polyphosphate

internally, but the main ones that have been isolated from successfully

operating bio-P plants are members of the Acinetobacter group.

- they are aerobic heterotrophs (require O

2

as an electron acceptor,

and organic carbon for cell synthesis)

- at least some Acinetobacter species are also capable of using NO

-

3

in the absence of oxygen (anaerobic respiration)

- under anaerobic fermentation conditions, they are capable of

improving their internal energy levels by

i) ingesting organic carbon, converting it and then storing it as

polyhydroxy alkanoates (PHA); and

ii) releasing some previously stored polyphosphate. These

observed occurrences can be explained by biochemical

models developed at UBC and modified by researched in

South Africa

- in a subsequent aerobic environment, they utilize the stored PHA as

readily available substrate, and concurrently take up large amounts

of soluble phosphate to be ready for their next encounter with the

hostile anaerobic environment.

2. The provision of a consistently high level of simple carbon compounds to

the flow entering the anaerobic zone allowing sufficient PHA storage in

Acinetobactor organisms to occur within a very short time frame (1/2

hour). For our wastewater characteristics (5 to 7 mg/L of total P), some

25 mg/L of volatile fatty acids (VFA), expressed as HAC, is sufficient.

(Generally 5 mg/l VFA for 1 mg/l P to be removed)

3. Purposeful fermentation of primary sludge is easily capable of providing

the VFA concentration required in the anaerobic zone of the bioreactor.

4. Denitrification of RAS can occur concurrently with P uptake in a well

designed anoxic zone.

5. Well designed and well operated secondary clarifiers are mandatory to

achieve consistently good P removal.

6. WAS handling must be done in such a way as to avoid significant release

of previously stored P, if any liquid recycles to the main process are used.

Can release P under aerobic conditions (secondary P release)

endogenous respiration

F. How does this Knowledge Translate into Design Requirements?

1. Primary clarifier - see "Ancillary Processes"

Conventional AS highest BOD removal efficiency BNR and provide a

sludge to be fermented to drive P removal in bioreactor.

2. Nominal HRT of Bioreactor

- anaerobic zone - 1/2 to 1 hr., with good VFA presence (VFA/p ~ 5/1).

- anoxic zone - 1 to 4 hrs., depending upon:

i) whether purposeful nitrification is practiced

ii) whether nitrogen removal is to be practiced

iii) whether significant VFA (or other short chain organics) are still

available entering the anoxic zone

- aerobic zone - 4 to 8 hrs., depending upon raw wastewater

characteristics and degree of nitrification desired.

SRT

- 6 to 20 days, depending upon wastewater characteristics (simplicity

of carbon available), and desire to achieve nitrification.

3. Configuration of Bioreactor

Important considerations are:

- flexibility of zonal HRT's

- good DO control in all aerobic cells

- by-pass capabilities in high growth rate municipality

- flexibility of recycle sources and destinations

- careful attention to mixing energy and mixer placement (low mixing

energy as long as properly placed).

4. Use of Design Mathematical Models

- Bio Sim (produced by Dr. Peter Dold) is a very useful steady state

model

BUT

it still requires a very good understanding of some 10 to 15 design

coefficients that are necessary to get meaningful results.

- a new non-steady state model developed by Dr. Gilles Patry and his

company is newly available. Its usefulness as a design model is still

to be proven.

- if process design for a "green fields" plant is being undertaken, the

degree of accuracy needed for the model inputs is not so great.

Previous experience can be usually used to set the design

coefficients.

- if retrofit of an existing activated sludge plant is being considered,

where the necessary degree of de-rating is very important to the

economic viability of the project, much more pilot-scale work may be

necessary to obtain accurate values of the coefficients.

COMPLETE BNR (13 Cell Bioreactor)

1. Possible Effluent Quality

tot. P < 0.5 mg/L

ortho-P < 0.3 mg/L

nitrate-N < 3 mg/L

amm.-N < 1 mg/L

tot.-N < 5 mg/L

2. High Nitrate in Effluent

- "a" recycle too low

- 2

nd

anoxic zone too short

- lack of VFA in anoxic zone and lack of denitrifying bio-P bugs

- too much O

2

getting back to 2

nd

anoxic

- toxics

a) if NO

3

-N = O (or close) at the end of 2

nd

anoxic, then "a" recycle is

too low

b) if NO

3

-N significant at the end of second anoxic (say > 2 mg/L),

then check mass denitrification rate (g NO

3

-N reduced/g MLVSS-d).

- if it is lower than expected, then probably have O

2

or toxics

problem.

- could help the situation temporarily by increasing RAS, if

there is spare denitrification potential in 1

st

anoxic zone

3. High Ammonia in Effluent

- aerobic SRT too low for temperature conditions

- aerobic HRT too low

- toxics

- O

2

in aerobic zone too low (2.0 mg/l N.B.)

a) check DO probes and historical air demand to rule out low O

2

b) test nitrification mass removal rates, and compare to standard. If

lower than normal, may have

- lower than normal fraction of nitrifiers

- temporary toxic impact

If normal, may need more HRT or move DO to cope with an increased

NH

3

load.

FERMENTATION OF PRIMARY SLUDGE

PURPOSE

- To change VSS in primary sludge to soluble short chain carbon (SCC) to feed

Bio-P organisms.

METHOD

- Contact primary sludge with anaerobic biomass that is grown at a long enough

SRT to promote hydrolyzation and acid formation, but not so long as to allow

methane formation.

- Research carried out at UBC indicates very strongly that an SRT between 5

and 10 days with an HRT between 10 and 15 hours provides maximum

conversion to VFA, and at the same time does not permit methanogens to

grown.

PROCESS OPTIONS

1. "Active" Primary Fsermenter

- deep sludge blanket with recycle of thickened sludge to inlet.

- must be able to maintain a deep enough sludge blanket to get the desired 5 d

SRT.

Sludge Blanket

PE

Q

RS

Recycle

Waste

2. Complete Mix Fermenter

- covered, stirred tank with solids recovery and recycle in PC.

- obtain high enough TSS concentration in fermenter to achieve 5 d SRT.

3. Complete Mix Fermenter with Dedicated Thickener

- easy to regulate both SRT and HRT.

PC

PE

Q

RS

Recycle

Waste

PC

PE

PS

Recycle

Waste

VFA

4. Static Fermenter

- carry high enough sludge blanket to achieve desired SRT.

Waste

PC

PE

Q

RS

VFA

Ferm.

PS

- must be able to estimate mass of solids in Fermenter, and know mass/d of

solids in PS, so that ~ 5 d SRT can be maintained.

OPERATING RESULTS

1. Loss of TSS

- well designed and operated fermenter will solubilize 40% to 60% of the PS

TSS. Both VSS and FSS are reduced.

- hence solids load to digesters is dramatically reduced, with design life of

existing digesters being substantially extended.

- but, total gas (methane) production will be reduced, perhaps up to 30% if all

PS is fermented.

2. Soluble COD Gain in Supernatant

- operating results elsewhere have shown that for every kg of TSS

hydrolyzed, about 0.25 kg. of COD

5

is formed.

3. VFA Production

- operating results show that 60% to 70% of COD

5

will be in the form of VFA.

COD

5

and VFA in Static Fermenter Supernatant

0

0 5 15 10 20

concentration

GOLD BAR SCENARIO

If fermenter 50% of produced primary sludge at average loading conditions for 310

ML/d design average flow:

primary solids to fermenter ~ 20,000 kg/d with 60% TSS loss,

COD

5

= 20,000 (0.6) (0.25)

= 3000 kg/d

VFA produced = 3000 (0.65) = 1950 kg/d

VFA addition to PE = 1950

310

= 6.3 mg/L

También podría gustarte

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Pages From Californijska Cijev 9Documento1 páginaPages From Californijska Cijev 9selmir_9Aún no hay calificaciones

- Pages From Californijska CijevDocumento9 páginasPages From Californijska Cijevselmir_9Aún no hay calificaciones

- Pages From Californijska Cijev 6Documento1 páginaPages From Californijska Cijev 6selmir_9Aún no hay calificaciones

- Pages From Californijska Cijev 7Documento1 páginaPages From Californijska Cijev 7selmir_9Aún no hay calificaciones

- Pages From Californijska Cijev 8Documento1 páginaPages From Californijska Cijev 8selmir_9Aún no hay calificaciones

- Pages From Californijska Cijev 4Documento1 páginaPages From Californijska Cijev 4selmir_9Aún no hay calificaciones

- Pages From Californijska Cijev 3Documento1 páginaPages From Californijska Cijev 3selmir_9Aún no hay calificaciones

- Pages From Californijska Cijev 9Documento1 páginaPages From Californijska Cijev 9selmir_9Aún no hay calificaciones

- Pages From Californijska Cijev 7Documento1 páginaPages From Californijska Cijev 7selmir_9Aún no hay calificaciones

- Pages From Grundfosliterature-3065923 3Documento1 páginaPages From Grundfosliterature-3065923 3selmir_9Aún no hay calificaciones

- Pages From Californijska Cijev 6Documento1 páginaPages From Californijska Cijev 6selmir_9Aún no hay calificaciones

- Pages From Californijska Cijev 8Documento1 páginaPages From Californijska Cijev 8selmir_9Aún no hay calificaciones

- Pages From Californijska Cijev 5Documento1 páginaPages From Californijska Cijev 5selmir_9Aún no hay calificaciones

- Pages From Californijska Cijev 1Documento1 páginaPages From Californijska Cijev 1selmir_9Aún no hay calificaciones

- Pole Spacing ToolDocumento2 páginasPole Spacing Toolselmir_9Aún no hay calificaciones

- Pages From Californijska Cijev 1Documento1 páginaPages From Californijska Cijev 1selmir_9Aún no hay calificaciones

- English (GB) Installation and Operating Instructions: 2. ApplicationsDocumento1 páginaEnglish (GB) Installation and Operating Instructions: 2. Applicationsselmir_9Aún no hay calificaciones

- BS EN 858-1-2002 Separator Systems For Light Liquids (1) 1 PDFDocumento1 páginaBS EN 858-1-2002 Separator Systems For Light Liquids (1) 1 PDFselmir_929% (7)

- Pages From Grundfosliterature-3065923 5Documento1 páginaPages From Grundfosliterature-3065923 5selmir_9Aún no hay calificaciones

- EC-Grounding Bonding and Overcurrent Protection-D01-M03 (Part 1)Documento21 páginasEC-Grounding Bonding and Overcurrent Protection-D01-M03 (Part 1)selmir_9Aún no hay calificaciones

- Pages From Grundfosliterature-3065923 1Documento1 páginaPages From Grundfosliterature-3065923 1selmir_9Aún no hay calificaciones

- Pages From Grundfosliterature-3065923 4Documento1 páginaPages From Grundfosliterature-3065923 4selmir_9Aún no hay calificaciones

- 14 20gravelsand 20I 200,4-0,8 20 20PDS 20eDocumento1 página14 20gravelsand 20I 200,4-0,8 20 20PDS 20eselmir_9Aún no hay calificaciones

- Multifunction Valve 50 HZ: Company Name: Created By: Phone: DateDocumento2 páginasMultifunction Valve 50 HZ: Company Name: Created By: Phone: Dateselmir_9Aún no hay calificaciones

- Sched 40 Concentric Reducers - Carbon Steel-2Documento3 páginasSched 40 Concentric Reducers - Carbon Steel-2selmir_9Aún no hay calificaciones

- IEE tutorial workshop on Earthing & Bonding techniquesDocumento51 páginasIEE tutorial workshop on Earthing & Bonding techniquestgkenny873491% (35)

- The Comparison of Wafer Check Valve and Flange Swing Check Valve - Made in China Check ValvesDocumento1 páginaThe Comparison of Wafer Check Valve and Flange Swing Check Valve - Made in China Check Valvesselmir_9Aún no hay calificaciones

- Irlr8726Pbf Irlu8726Pbf: ApplicationsDocumento11 páginasIrlr8726Pbf Irlu8726Pbf: Applicationsselmir_9Aún no hay calificaciones

- BS en 858-2-2003 Separator Systems For Light Liquids (3) 4Documento1 páginaBS en 858-2-2003 Separator Systems For Light Liquids (3) 4selmir_9Aún no hay calificaciones

- BS en 858-2-2003 Separator Systems For Light Liquids (3) 12Documento1 páginaBS en 858-2-2003 Separator Systems For Light Liquids (3) 12selmir_9Aún no hay calificaciones

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- FTJ Series Product Guide PDFDocumento12 páginasFTJ Series Product Guide PDFJhon SendokAún no hay calificaciones

- Device Code ListDocumento383 páginasDevice Code ListBach BuiAún no hay calificaciones

- 128 Salicylic Rohdia MSDSDocumento13 páginas128 Salicylic Rohdia MSDSWike Wingtias ArnesaAún no hay calificaciones

- Pump JTN B1Documento8 páginasPump JTN B1Patricia J ÁngelesAún no hay calificaciones

- Astm 2Documento5 páginasAstm 2carlos salinasAún no hay calificaciones

- Practice Quiz Diffraction 1Documento2 páginasPractice Quiz Diffraction 1pauljkt1Aún no hay calificaciones

- Deep Cryogenic Treatment of A D2 Cold-Work Tool Steel PDFDocumento4 páginasDeep Cryogenic Treatment of A D2 Cold-Work Tool Steel PDFBinh Thanh LeAún no hay calificaciones

- 2013 12 Handbok Fittings ENG WebDocumento72 páginas2013 12 Handbok Fittings ENG WebVictor BiacoloAún no hay calificaciones

- Maximum Equivalent Stress Safety ToolDocumento2 páginasMaximum Equivalent Stress Safety ToolDonfack BertrandAún no hay calificaciones

- Non-Destructive Pressure Detection in Sealed Containers Using Strain MeasurementDocumento7 páginasNon-Destructive Pressure Detection in Sealed Containers Using Strain MeasurementstevensurandomAún no hay calificaciones

- Non Hydrocarbon GasesDocumento3 páginasNon Hydrocarbon GasesFrancelino A. X. ConceicaoAún no hay calificaciones

- 0808231109005091Documento2 páginas0808231109005091tinitnthesaiyanAún no hay calificaciones

- Cold Lime Soda Softening ProcessDocumento10 páginasCold Lime Soda Softening ProcessSaurabh JadhavAún no hay calificaciones

- Vapor-Phase Hydrogen Peroxide Resistance of Environmental IsolatesDocumento5 páginasVapor-Phase Hydrogen Peroxide Resistance of Environmental IsolatesMohamed FetouhAún no hay calificaciones

- Inorganic NotesDocumento4 páginasInorganic NotesMr. XAún no hay calificaciones

- Lipids Classification and FunctionsDocumento4 páginasLipids Classification and FunctionsThalia PacamalanAún no hay calificaciones

- Ats 2 (Csir Net) PDFDocumento17 páginasAts 2 (Csir Net) PDFAayushi VermaAún no hay calificaciones

- Lecture Planner - Chemistry PDF OnlyDocumento1 páginaLecture Planner - Chemistry PDF OnlyJai ChandAún no hay calificaciones

- Physics I ProblemsDocumento1 páginaPhysics I ProblemsbosschellenAún no hay calificaciones

- Case Studies in Boiler FailuresDocumento14 páginasCase Studies in Boiler Failuresparthi2006576880% (5)

- Fuel Oil AnalysisDocumento6 páginasFuel Oil AnalysisPawan BeniwalAún no hay calificaciones

- Material Properties of EPDM, NBR, and FPM Rubber Seals - Technical - Resources - BLUCHERDocumento3 páginasMaterial Properties of EPDM, NBR, and FPM Rubber Seals - Technical - Resources - BLUCHERManish Pareek100% (1)

- Capacitive Sensors: Measuring Levels, Displacements & MoreDocumento19 páginasCapacitive Sensors: Measuring Levels, Displacements & MoreAdarsh RajAún no hay calificaciones

- Syllabus:-Biomolecules, Cell: The Unit of Life, Structural Organisation in AnimalsDocumento9 páginasSyllabus:-Biomolecules, Cell: The Unit of Life, Structural Organisation in AnimalsEXCEPTIONAL FOCUSAún no hay calificaciones

- Fluid Mechanics: Properties, Viscosity and ApplicationsDocumento77 páginasFluid Mechanics: Properties, Viscosity and ApplicationsvijaynieAún no hay calificaciones

- O Level Physics 2023-2025 ATP TipsDocumento7 páginasO Level Physics 2023-2025 ATP TipsAmy WolmesAún no hay calificaciones

- Shear Friction MattockDocumento10 páginasShear Friction MattockSisina Anish100% (1)

- Antimicrobial Silver Nanoparticle Bacterial Cellulose Wound DressingDocumento9 páginasAntimicrobial Silver Nanoparticle Bacterial Cellulose Wound Dressingfranciscrick69Aún no hay calificaciones

- Nuclear Protective TextilesDocumento34 páginasNuclear Protective TextilesVikas SinghAún no hay calificaciones