Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Brinell Hardness Test

Cargado por

innocentsoulDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Brinell Hardness Test

Cargado por

innocentsoulCopyright:

Formatos disponibles

Experiment no 1

TA B L E O F C ON TE N TS

Objective ......................................................................................................................................... 3

Need To Know About ...................................................................................................................... 2

Introduction..................................................................................................................................... 2

What Is Hardness?........................................................................................................................... 2

Material Science .............................................................................................................................. 3

Scratch Hardness ............................................................................................................................. 3

Indentation Hardness ...................................................................................................................... 3

Rebound Hardness .......................................................................................................................... 3

How To Measure Hardness? ........................................................................................................... 4

Hardness Measurement Method .................................................................................................... 4

Brinell Hardness Test....................................................................................................................... 4

Standards......................................................................................................................................... 5

Brinell Test Method......................................................................................................................... 5

Application ...................................................................................................................................... 7

Strength ........................................................................................................................................... 7

Weaknesses ..................................................................................................................................... 7

Limitations ....................................................................................................................................... 7

Errors in Hardness Testing .............................................................................................................. 8

References ....................................................................................................................................... 8

Department of Industrial and Manufacturing Engineering

1 University of Engineering and Technology, Lahore

Experiment no 1

Testing of Materials

Brinell Hardness Test

OB JE CT IV E

Measurement of Hardness of Carbon Steel using Brinell Hardness Test.

NE E D T O KN OW A B O UT

(1) To understand what hardness is, and how it can be used to indicate some properties of

materials

(2) To conduct typical engineering hardness tests and be able to recognize commonly used

hardness scales and numbers

(3) To be able to understand the correlation between hardness numbers and the properties of

materials

(4) To learn the advantages and limitations of the common hardness test methods

Experimental Condition:

Temperature: 25oC

Load (P) =3000kg

Indenter Diameter (D) = 10mm

IN TR O DU CT I ON

It is a common practice to test most materials before they are accepted for processing, and

before they are put into service to determine whether or not they meet the specifications required. One

of these tests is hardness. The Rockwell, Brinell and durometer machines are those most commonly

used for this purpose.

W HA T IS HA R D N ES S ?

The Metals Handbook defines hardness as "Resistance of metal to plastic deformation, usually by

indentation. However, the term may also refer to stiffness or temper or to resistance to scratching,

Department of Industrial and Manufacturing Engineering

2 University of Engineering and Technology, Lahore

Experiment no 1

abrasion, or cutting. It is the property of a metal, which gives the ability to resist being permanently,

deformed (bent, broken, or have its shape changed), when a load is applied. The greater the hardness of

the metal, the greater resistance it has to deformation.

In materials science, there are three principal operational definitions of hardness:

Scratch hardness: Resistance to fracture or plastic (permanent) deformation due to

friction from a sharp object

Indentation hardness: Resistance to plastic (permanent) deformation due to a

constant load from a sharp object

Rebound hardness: Height of the bounce of an object dropped on the material,

related to elasticity.

The equation based definition of hardness is the pressure applied over the projected contact area

between the indenter and the material being tested. As a result hardness values are typically reported in

units of pressure

MA T E RIA L S C I EN CE

Hardness is a characteristic of a solid material expressing its resistance to permanent

deformation. Hardness can be measured on the Mohr’s scale or various other scales. Some of the other

scales used for indentation hardness in engineering—Rockwell, Vickers, and Brinell—can be compared

using practical conversion tables.

S CRA T C H HA R DN ES S

In mineralogy, hardness commonly refers to a material's ability to penetrate softer materials. An

object made of a hard material will scratch an object made of a softer material. Scratch hardness is

usually measured on the Mohr’s scale of mineral hardness. One tool to make this measurement is the

sclerometer.

Pure diamond is the hardest readily-available natural mineral substance and will scratch any

other natural material. Diamond is therefore used to cut other diamonds; in particular, higher-grade

diamonds are used to cut lower-grade diamonds.

IN D EN TA T I O N HA R DN ES S

Indentation hardness tests are primarily used in engineering and metallurgy fields. The tests

work on the basic premise of measuring the critical dimensions of an indentation left by a specifically

dimensioned and loaded indenter.

RE B OU N D HA R DN ES S

Also known as dynamic hardness, rebound hardness measures the height of the "bounce" of a

diamond-tipped hammer dropped from a fixed height onto a material. The device used to take this

measurement is known as a scleroscope.

Department of Industrial and Manufacturing Engineering

3 University of Engineering and Technology, Lahore

Experiment no 1

Two scales that measures rebound hardness are the Leeb rebound hardness test and Bennett

hardness scale.

H OW T O M EA S U R E HA R DN ES S ?

Moh’s scale of hardness

The Moh’s scale of hardness characterizes the scratch resistance of various minerals through the

ability of a harder material to scratch a softer material.

Moh’s Hardness Mineral Absolute Hardness

1 Talc 1

2 Gypsum 3

3 Calcite 9

7 Quartz 100

10 Diamond 1600

HA RD N ES S M EA S UR E M EN T M ET H O D

There are three types of tests used with accuracy by the metals industry; they are the Rockwell

hardness test, the Brinell hardness test, and the Vickers hardness test. The way the three of these

hardness tests measure a metal's hardness is to determine the metal's resistance to the penetration of a

non-deformable ball or cone. The tests determine the depth or area which such a ball or cone will sink

into the metal, under a given load, within a specific period of time.

The followings are the most common hardness test methods used in today`s technology:

1. Rockwell hardness test

2. Brinell hardness

3. Vickers

4. Knoop hardness

5. Shore

BR IN E L L HA R DN ES S T ES T

The Brinell hardness test method consists of indenting the

test material with a 10 mm diameter hardened steel or carbide

ball subjected to a load of 3000 kg. For softer materials the load

can be reduced to 1500 kg or 500 kg to avoid excessive

indentation. The full load is normally applied for 10 to 15 seconds

Department of Industrial and Manufacturing Engineering

4 University of Engineering and Technology, Lahore

Experiment no 1

in the case of iron and steel and for at least 30 seconds in the case of other metals. The diameter of the

indentation left in the test material is measured with a low powered microscope. The Brinell harness

number is calculated by dividing the load applied by the surface area of the indentation.

Brinell testing is typically done on iron and steel castings using a 3000Kg test force and a 10mm

diameter carbide ball. Aluminum and other softer alloys are frequently tested using a 500Kg test force

and a 10 or 5mm carbide ball. Therefore the typical range of Brinell testing is 500 to 3000kg with 5 or

10mm carbide balls.

S TA N DA R DS

Brinell Test methods are defined in the following standards:

ASTM E10

ISO 6506

Brinell Hardness numbers

Materials Hardness

Aluminium 15 HBS 10/100

Copper 35 HBS 10/100

Mild Steel 120 HB

Stainless Steel 200 HB

Glass 1550 HB

Hardened Tool Steel 1500-1900HB

BR IN E L L T ES T M E T H OD

All Brinell tests use a carbide ball indenter. The test procedure is as follows:

The indenter of Diameter (D) 10mm is pressed into the sample by an accurately

controlled test force.

The force of 3000kg is maintained for a specific dwell time, normally 15 - 30 seconds.

After the dwell time is complete, the indenter is removed leaving a round indent in

the sample.

The size of the indent is determined optically by measuring two diagonals of the

round indent using either a portable microscope or one that is integrated with the load

application device.

Department of Industrial and Manufacturing Engineering

5 University of Engineering and Technology, Lahore

Experiment no 1

The Brinell hardness number is a function of the

test force divided by the curved surface area of the indent.

The indentation is considered to be spherical with a radius

equal to half the diameter of the ball. The average of the two

diagonals is used in the following formula to calculate the

Brinell hardness:

Where:

P = applied force (kgf)

D = diameter of indenter (mm)

d = diameter of indentation (mm)

The diameter of the impression is the average of two readings at right angles and the use of a

Brinell hardness number table can simplify the determination of the Brinell hardness. A well structured

Brinell hardness number reveals the test

conditions, and looks like this, "75 HBW

10/3000/30" which means that a Brinell

Hardness of 75 was obtained using a 10mm

diameter hardened steel with a 3000 kilogram

load applied for a period of 30 seconds and

the W indicates that a carbide ball was used.

On tests of extremely hard metals a tungsten

carbide ball is substituted for the steel ball.

The Brinell number, which normally

ranges from HB 50 to HB 750 for metals, will

increase as the sample gets harder. Tables are

available to make the calculation simple. A

typical Brinell hardness is specified as follows:

356HBW

Where 356 is the calculated hardness

and the W indicates that a carbide ball was

used. Note- Previous standards allowed a steel ball and had an S designation. Steel balls are no longer

allowed.

Department of Industrial and Manufacturing Engineering

6 University of Engineering and Technology, Lahore

Experiment no 1

RE S U LTS F O R M I LD S TE E L

Center line for the notch Brinnel Hardness Test

Readings

part d (mm) number (BHN)

1 3.25 117

2 3.20 121

3 3.20 121

Average 119.7

A PP L ICA TI O N

Because of the wide test force and Indenter diameter range the Brinell test can be used on

almost any metallic material.

S TR E N GT H

One scale covers the entire hardness range, although comparable results can only be obtained if

the ball size and test force relationship is the same.

A wide range of test forces and ball sizes to suit every application.

Nondestructive, sample can normally be reused.

Compared to the other hardness test methods, the Brinell ball makes the deepest and widest

indentation, so the test averages the hardness over a wider amount of material, which will more

accurately account for multiple grain structures and any irregularities in the uniformity of the

material.

W EA KN ES S ES

The main drawback of the Brinell test is the need to optically measure the indent size. This

requires that the test point be finished well enough to make an accurate measurement.

Slow testing can take 30 seconds, not counting the sample preparation time.

LI M ITA TI O NS

However, because of the large ball diameter the test cannot be used to determine the hardness

variations in a welded joint for which the Vickers test is preferred.

Very hard metals, over 450BHN may also cause the ball to deform resulting in an inaccurate

reading. To overcome this limitation a tungsten carbide ball is used instead of the hardened steel

ball but there is also a hardness limit of 600BHN with this indenter.

The oxide layer should be remove from the sample by using sand paper or grinders otherwise it

Department of Industrial and Manufacturing Engineering

7 University of Engineering and Technology, Lahore

Experiment no 1

would cause variation in hardness number.

We cannot perform this operation on a very thin sheet of metal usually having thickness less

than 10mm.For this we need to pile few sheets accurately without any impurity or oxide layer.

ER R ORS NI HA RD N ES S T ES TI N G

There are many factors that can affect the accuracy of the hardness test. Some of these such as

flatness and surface finish have already been mentioned above but it is worth re-emphasizing the

point that flatness is most important - a maximum angle of approximately ± 1° would be

regarded as acceptable.

To achieve the required flatness tolerance and surface finish surface grinding or machining may

be necessary. The correct load must be applied and to achieve this there must be no friction in

the loading system otherwise the impression will be smaller than expected - regular maintenance

and calibration of the machine is therefore essential. The Brinell ball will deform over a period of

time and inaccurate readings will result. This deterioration will be accelerated if a large

proportion of the work is on hard materials. The length of time that the load is applied is

important and must be controlled.

The specimen dimensions are important - if the test piece is too thin the hardness of the

specimen table will affect the result. As a rule of thumb the specimen thickness should be ten

times the depth of the impression for the Brinell test and twice that of the Vickers diagonal.

Similarly, if the impression is too close to the specimen edge then low hardness values will be

recorded - again as a rule the impression should be some 4 to 5 times the impression diameter

from any free edge.

The specimen table should be rigidly supported and must be in good condition - burrs or raised

edges beneath the sample will give low readings. Impact loading must be avoided. It is very easy

to force the indenter into the specimen surface when raising the table into position. This can

strain the equipment and damage the indenter. Operator training is crucial and regular validation

or calibration is essential if hardness rest results are to be accurate and reproducible

RE F ER E NC ES

1. ^ ASTM E10 - 08 Standa rd Test Method for Bri nell Ha rdness of Metallic Ma terials

2. ^ ISO 6506-1:2005 Metallic ma terials - Bri nell ha rdness tes t - Pa rt 1: Tes t method

3. http://en.wikipedia.org/wiki/Mohs_scale_of_mineral_hardness

4. http://en.wikipedia.org/wiki/Brinell_hardness_test

5. http://www.scribd.com/doc/18004150/Hardness-Report?autodown=pdf

6. “Technical Metallurgy” by Cliffe (page 150 – 154)

7. “Material, Their Nature, Fabrication and Properties” by Sergal (page 143 – 145, 71 –72)

8. “Metallurgy for Engineers” by Rollesan (page 15)

Department of Industrial and Manufacturing Engineering

8 University of Engineering and Technology, Lahore

También podría gustarte

- Brinell Hardness Test (New)Documento8 páginasBrinell Hardness Test (New)innocentsoul100% (2)

- Hardness Test SubmitDocumento8 páginasHardness Test Submitonkod1Aún no hay calificaciones

- Lab ReportDocumento21 páginasLab ReportMuhammad YasirAún no hay calificaciones

- Hardness TestDocumento8 páginasHardness TestFakhrul MuizzAún no hay calificaciones

- Rockwell hardness test explainedDocumento9 páginasRockwell hardness test explainedMahrukh JavedAún no hay calificaciones

- Hardness TestDocumento20 páginasHardness TestJake Tee Hon YiAún no hay calificaciones

- Hardness ReportDocumento11 páginasHardness Reportcheyaya100% (8)

- Hardness Testing of Metallic MaterialsDocumento4 páginasHardness Testing of Metallic MaterialsAshan Marambe100% (1)

- Material Hardness Lab ReportDocumento6 páginasMaterial Hardness Lab ReportSam SweeneyAún no hay calificaciones

- Lab ReportDocumento7 páginasLab ReportSrinivas Duvvuri100% (1)

- Brinell Hardness Testing PresentationDocumento17 páginasBrinell Hardness Testing PresentationAldi Zuldiansyah100% (1)

- Thermo CalibrationDocumento10 páginasThermo CalibrationAngelo De AsisAún no hay calificaciones

- Rockwell Hardness Testing of Metallic Materials Lab ReportDocumento5 páginasRockwell Hardness Testing of Metallic Materials Lab ReportEmıły WınıfredAún no hay calificaciones

- Charpy Impact TestDocumento4 páginasCharpy Impact TestChinmay Deo80% (5)

- Rockwell Hardness TestDocumento4 páginasRockwell Hardness TestAsifIqbal100% (2)

- Complete Tensile Test On MS BarDocumento9 páginasComplete Tensile Test On MS Barafzal taiAún no hay calificaciones

- Lab 7 Fracture Ductile To Brittle TransitionDocumento4 páginasLab 7 Fracture Ductile To Brittle TransitionTommy MilesAún no hay calificaciones

- Vicker's Hardness TestDocumento9 páginasVicker's Hardness Testinnocentsoul75% (4)

- Brinell Hardness Test Compares Steel and AluminumDocumento7 páginasBrinell Hardness Test Compares Steel and AluminumabdulazizAún no hay calificaciones

- Engineering Materials Lab ReportDocumento18 páginasEngineering Materials Lab ReportAhmad Fakhrie ShahAún no hay calificaciones

- Bending Test (Report) eDocumento14 páginasBending Test (Report) eWesam Maleh100% (1)

- Charpy Impact TestDocumento2 páginasCharpy Impact TestGanim Shed100% (1)

- Engineering Materials - Hardness TestingDocumento5 páginasEngineering Materials - Hardness TestingrandomkillerAún no hay calificaciones

- Hardness Test: Department of Mechanical & Manufacturing Engineering Faculty of Engineering, University of Putra MalaysiaDocumento5 páginasHardness Test: Department of Mechanical & Manufacturing Engineering Faculty of Engineering, University of Putra MalaysiaNurul Siddiqah Whakiddin100% (1)

- Brunel Hardness TestDocumento8 páginasBrunel Hardness TestSalam AlbaradieAún no hay calificaciones

- By David Grossi: Engineering Materials Mech 207Documento5 páginasBy David Grossi: Engineering Materials Mech 207Ashish Gandhi100% (1)

- Vicker HardnessDocumento3 páginasVicker HardnessEhsanulhaq786100% (1)

- Brinell Hardness ReportDocumento3 páginasBrinell Hardness ReportjaibalayyaAún no hay calificaciones

- Impact TestDocumento8 páginasImpact TestRashid Mehmood100% (1)

- Tensile Test Report: Mechanical Properties of Mild Steel, Copper and AluminiumDocumento18 páginasTensile Test Report: Mechanical Properties of Mild Steel, Copper and AluminiumHafsa KhanAún no hay calificaciones

- Hardness Testing Methods GuideDocumento33 páginasHardness Testing Methods Guideamol1321Aún no hay calificaciones

- Clad MeasurementDocumento6 páginasClad MeasurementSunny SaparAún no hay calificaciones

- Hardness Test A4Documento9 páginasHardness Test A4aisyah mohamad othmanAún no hay calificaciones

- Hardness TestDocumento8 páginasHardness TestEmanuel Calvin100% (1)

- Experiment No. 1 Brinell Hardness Test IntroductionDocumento4 páginasExperiment No. 1 Brinell Hardness Test IntroductionAhmad AbdAún no hay calificaciones

- Rockwell Hardness Test MethodDocumento5 páginasRockwell Hardness Test MethodAnonymous gFcnQ4goAún no hay calificaciones

- Rockwell Hardness TestDocumento7 páginasRockwell Hardness TestMostafizur Rahman Sobuj100% (1)

- Hardness TestDocumento12 páginasHardness TestLola MeerazAún no hay calificaciones

- Tensile TestDocumento9 páginasTensile TestMohamed Reeza100% (1)

- Exp-1 Tension Test PDFDocumento8 páginasExp-1 Tension Test PDFHanamant HunashikattiAún no hay calificaciones

- Complete Lab Sand CastingDocumento23 páginasComplete Lab Sand CastingMuhd MuzafarAún no hay calificaciones

- 10 Torsion TestDocumento16 páginas10 Torsion Testfrankjono75% (4)

- Hardness Test Lab ReportDocumento6 páginasHardness Test Lab ReportFakhri Arif100% (1)

- Vickers Hardness Test: Measuring Material HardnessDocumento2 páginasVickers Hardness Test: Measuring Material HardnessMohsin Qazi100% (1)

- Objectives: Experiment: Fatigue TestingDocumento8 páginasObjectives: Experiment: Fatigue TestingShruti Raveendran100% (1)

- Brinell TestDocumento4 páginasBrinell TestashprakAún no hay calificaciones

- Your Name: Ulises Jose Corona Name of The Course: MAE2160 Materials Science Lab Date: Report DateDocumento7 páginasYour Name: Ulises Jose Corona Name of The Course: MAE2160 Materials Science Lab Date: Report DateUlises Corona100% (4)

- Non-Destructive Testing Methods GuideDocumento148 páginasNon-Destructive Testing Methods GuidejksankarAún no hay calificaciones

- NDT AcceptanceDocumento62 páginasNDT Acceptancebommakanti srinivasAún no hay calificaciones

- Microstructure Exam SteelDocumento8 páginasMicrostructure Exam SteelYun Jian100% (1)

- Impact Test Measures Material Toughness in 40 CharactersDocumento5 páginasImpact Test Measures Material Toughness in 40 CharactersKamal JayarajAún no hay calificaciones

- Ultrasonic Testing of Ferritic Steel Welds Under 40 CharactersDocumento1 páginaUltrasonic Testing of Ferritic Steel Welds Under 40 Characterssdmkl85Aún no hay calificaciones

- Vickers Hardness Test Machine GuideDocumento2 páginasVickers Hardness Test Machine GuideurwakhanAún no hay calificaciones

- Hardness TestDocumento15 páginasHardness TestAnand KvAún no hay calificaciones

- Lab 3Documento25 páginasLab 3Andrew KuwaitAún no hay calificaciones

- HardnessDocumento24 páginasHardnessmvdaulkar100% (1)

- MSE 528: Microhardness Hardness Measurements: ObjectivesDocumento11 páginasMSE 528: Microhardness Hardness Measurements: ObjectivesMuhammad QusyairiAún no hay calificaciones

- HardnessDocumento23 páginasHardnesskdalavadi3905Aún no hay calificaciones

- Determination of the Mechanical and Technological Properties of MetalsDe EverandDetermination of the Mechanical and Technological Properties of MetalsAún no hay calificaciones

- L&M pumps maintenance guideDocumento23 páginasL&M pumps maintenance guideinnocentsoulAún no hay calificaciones

- Bridge Design Using STAADDocumento38 páginasBridge Design Using STAADpheron200390% (10)

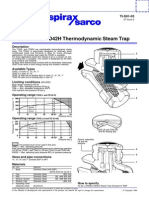

- TD42L and TD42H Thermodynamic Steam Trap: DescriptionDocumento2 páginasTD42L and TD42H Thermodynamic Steam Trap: DescriptioninnocentsoulAún no hay calificaciones

- TD42L and TD42H Thermodynamic Steam Trap: DescriptionDocumento2 páginasTD42L and TD42H Thermodynamic Steam Trap: DescriptioninnocentsoulAún no hay calificaciones

- Animation Production FacilityDocumento17 páginasAnimation Production FacilityFaizan AhmedAún no hay calificaciones

- Biomass PPT 1-09Documento12 páginasBiomass PPT 1-09necdetdalgicAún no hay calificaciones

- Spirax Sarco Ball Float PDFDocumento12 páginasSpirax Sarco Ball Float PDFchanayireAún no hay calificaciones

- Application For Employment at WASADocumento2 páginasApplication For Employment at WASAJade Al BoodoosinghAún no hay calificaciones

- Bac Riggingvx Rvxv06enDocumento12 páginasBac Riggingvx Rvxv06eninnocentsoulAún no hay calificaciones

- Sem2011 Prelist 20110111Documento4 páginasSem2011 Prelist 20110111innocentsoulAún no hay calificaciones

- 06 Probability DistributionDocumento19 páginas06 Probability DistributioninnocentsoulAún no hay calificaciones

- Cutting Tool Design Knowledge Capture June '02 - Bailey, Roy, Harris and Tanner PDFDocumento19 páginasCutting Tool Design Knowledge Capture June '02 - Bailey, Roy, Harris and Tanner PDFdkundankumarAún no hay calificaciones

- Rockwell Hardness TestDocumento12 páginasRockwell Hardness Testinnocentsoul100% (1)

- POM As Competitive Weapon1Documento43 páginasPOM As Competitive Weapon1innocentsoulAún no hay calificaciones

- How To Improve Your VocabularyDocumento8 páginasHow To Improve Your VocabularyinnocentsoulAún no hay calificaciones

- Cs504 Help MeterialDocumento9 páginasCs504 Help MeterialinnocentsoulAún no hay calificaciones

- PresentationDocumento3 páginasPresentationinnocentsoulAún no hay calificaciones

- Vicker's Hardness TestDocumento9 páginasVicker's Hardness Testinnocentsoul75% (4)

- IT General Controls QuestionnaireDocumento6 páginasIT General Controls Questionnairewktso0% (1)

- Accessibility by Design Handbook Syf41 42Documento60 páginasAccessibility by Design Handbook Syf41 42Ats ByAún no hay calificaciones

- Evaluation and Application of Characteristic Values Based On Eurocode 7 Design MethodologyDocumento5 páginasEvaluation and Application of Characteristic Values Based On Eurocode 7 Design MethodologySeng SiongAún no hay calificaciones

- Data Sheet For Actuators For On-Off Valves: OctoberDocumento13 páginasData Sheet For Actuators For On-Off Valves: OctoberFershaalAún no hay calificaciones

- Steam Tank Pressure & QualityDocumento5 páginasSteam Tank Pressure & QualityAri Reza KAún no hay calificaciones

- Petronas License NorimaxDocumento4 páginasPetronas License NorimaxSalman FarisiAún no hay calificaciones

- Writing A Parser From Wire To WindowDocumento43 páginasWriting A Parser From Wire To WindowJonah H. HarrisAún no hay calificaciones

- Insulating Firebrick (IFB)Documento2 páginasInsulating Firebrick (IFB)rickidenesAún no hay calificaciones

- Amortiguador Pala 7495Documento2 páginasAmortiguador Pala 7495milenko Cortes100% (1)

- Ebook Oracle E-Business Suite R12 Step by Step InstallationDocumento57 páginasEbook Oracle E-Business Suite R12 Step by Step InstallationOraERPAún no hay calificaciones

- Snapdragon 730 Mobile Platform Product BriefDocumento2 páginasSnapdragon 730 Mobile Platform Product Briefaswin acpAún no hay calificaciones

- Materials System SpecificationDocumento10 páginasMaterials System SpecificationMudabbir Hussain100% (1)

- Sennheiser Open-Aire HD-414 HeadphoneDocumento2 páginasSennheiser Open-Aire HD-414 HeadphonePilisi CsabaAún no hay calificaciones

- Using A System Cost Analysis ToDocumento11 páginasUsing A System Cost Analysis Tosaa6383Aún no hay calificaciones

- Summative - Chemical ReactionDocumento2 páginasSummative - Chemical ReactionRosalie Tilos Orito67% (3)

- 3 PatentsDocumento4 páginas3 PatentsNaresh GollapalliAún no hay calificaciones

- Digital Fiberoptic Sensor: FS-N SeriesDocumento28 páginasDigital Fiberoptic Sensor: FS-N SeriesOlger Garcia FalconesAún no hay calificaciones

- En LV Power Supplies For High Altitude Applications Application NoteDocumento7 páginasEn LV Power Supplies For High Altitude Applications Application Notejoe blowAún no hay calificaciones

- PMP SLD 5th EdDocumento170 páginasPMP SLD 5th EdSohail Khan100% (1)

- VK Report PDFDocumento21 páginasVK Report PDFumeshAún no hay calificaciones

- B GcubeDocumento2 páginasB GcubeSumedha SwayansidhaAún no hay calificaciones

- Kelayakan Investasi Instalasi Sea Water Reverse Osmosis (Swro) Di Kawasan Wisata Pantai Kenjeran SurabayaDocumento9 páginasKelayakan Investasi Instalasi Sea Water Reverse Osmosis (Swro) Di Kawasan Wisata Pantai Kenjeran SurabayaKang SudikAún no hay calificaciones

- ECE Board HistoryDocumento2 páginasECE Board HistoryPats Renato CarmonaAún no hay calificaciones

- Sis 2.0Documento34 páginasSis 2.0Weslin Carlos Ramirez CamizanAún no hay calificaciones

- PRACTICAL RESERVOIR MONITORING AND WATERFLOODINGDocumento51 páginasPRACTICAL RESERVOIR MONITORING AND WATERFLOODINGDuddi Dennisuk100% (3)

- Types 1098-EGR and 1098H-EGR Pressure Reducing RegulatorsDocumento44 páginasTypes 1098-EGR and 1098H-EGR Pressure Reducing RegulatorsToto TotoroAún no hay calificaciones

- Learnings from penetration testing a university websiteDocumento3 páginasLearnings from penetration testing a university websiteLovepreetSidhu100% (1)

- Sap Abap Resume Online - RamanaDocumento3 páginasSap Abap Resume Online - RamanaraamanAún no hay calificaciones

- Handbook PDFDocumento37 páginasHandbook PDFJuan Dela CruzAún no hay calificaciones

- One, Two, Rotational Kinematics (Review)Documento3 páginasOne, Two, Rotational Kinematics (Review)Music LastAún no hay calificaciones