Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Retaining Wall Design

Cargado por

ruytguerra0 calificaciones0% encontró este documento útil (0 votos)

18 vistas168 páginasDerechos de autor

© © All Rights Reserved

Formatos disponibles

XLS, PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

© All Rights Reserved

Formatos disponibles

Descargue como XLS, PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

18 vistas168 páginasRetaining Wall Design

Cargado por

ruytguerraCopyright:

© All Rights Reserved

Formatos disponibles

Descargue como XLS, PDF, TXT o lea en línea desde Scribd

Está en la página 1de 168

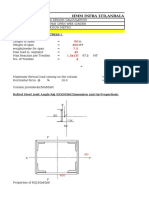

INPUT DATAS

INPUT GRADE OF CONCRETE fck 25 N/mm2

INPUT GRADE OF STEEL f y 415 N/mm2

INPUT ANGLE OF REPOSE OF SOIL 30 DEG

INPUT BULK DENSITY OF SOIL Ws 18 KN/m3

INPUT SOIL SAFE BEARING CAPACITY SBC 150 KN/m2

INPUT ANGLE OF SURCHARGE OF FILL C 10 DEG

INPUT COEFFT OF FRICTION 0.45

COS C 0.985

COS 0.866

COEFFT OF ACTIVE PRESSURE Ka 0.350 0.334

COEFFT OF PASSIVE PRESSURE Kp 2.859

INPUT HEIGHT OF FILLING H 3.00 mtr

MIN DEPTH OF FDN h 0.93 mtr

INPUT PROVIDE DEPTH OF FDN D h/4= 0.75 1.20 mtr 1.20

TOTAL HT OF WALL Ht=H+D 4.20 mtr

CONST 0.098

Toe Length TL 0.75 mtr 0.75

Heel Length HL 2.60 mtr

CALCULATED BASE WIDTH B(MIN) Bm 2.23 mtr

INPUT PROVIDE BASE WIDTH B B 3.75 mtr 3.75

INPUT SURCHARGE ps ps 2.00 KN/m

BASE SLAB THICK D(MIN) 350 280 mm 210

INPUT PROVIDE BASE SLAB THICK D 280 mm 0

WALL THICK AT BOTTOM T(MIN) 420 350 mm 280

INPUT PROVIDE WALL THICK AT BOTTOM T1 400 mm 400

INPUT PROVIDE WALL THICK AT TOP T2 200 mm 0

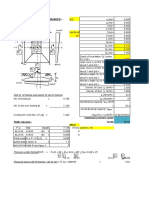

CHECK FOR BEARING PRESSURE

WT OF BASE SLAB/FOOTING W1 26.25 KN/m

WT OF STEM/ WALL RECTANGLE PART W2 19.60 KN/m

WT OF STEM/ WALL TRIANGLE PART W3 9.80 KN/m

WT OF REAR SOIL OVER HEEL W4 184.19 KN/m

WT/ AXIAL LOAD FROM COLUMN W5 0.00 KN/m

TOTAL STABILISING VERTICAL FORCE W 239.84 KN/m

HORIZONTAL EARTH PRESSURE Ph 48.37 KN/m

HORIZONTAL SURCHARGE Ps 15.37 KN/m

TOTAL HORIZONTAL PRESSURE V 63.73 KN/m

DISTANCE OF W1 FROM TOE FRONT TIP X1 X1 1.88 mtr

DISTANCE OF W2 FROM TOE FRONT TIP X2 0.85 mtr

DISTANCE OF W3 FROM TOE FRONT TIP X3 0.63 mtr

DISTANCE OF W3 FROM TOE FRONT TIP X4 2.66 mtr

DISTANCE OF W3 FROM TOE FRONT TIP X5 0.85 mtr

HT OF HORT FORCE Y1 FROM TOE TOP Y1 1.31 mtr

(WHERE WATER TABLE IS BELOW BASE OF FOOTING)

(Ex 15.1 RCC by BC Punmia & Ex 12.1 Vazrani and Ratwani)

RCC RETAINING WALL(CANTILEVERTYPE) MAX 6.0 MTR HEIGHT INCL COLUMN LOAD IN LINE

HT OF SUR FORCE Y2 FROM TOE TOP Y2 1.96 mtr

DIST OF VERT REACTION FROM TOE FRONT TIP 2.34 mtr

CALCULATION OF PRESSURE

REACTION OF FORCES 248.17 KN

DIST OF REACTION FROM TOE X 1.89 m

ECCENTRICITY e FROM CETRE OF BASE SLAB 0.01 m

PRESSURE AT TOE TIP Pmax 0 65.29 KN/m2 150

PRESSURE AT HEEL TIP Pmax 0 62.62 KN/m2 150

PRESSURE AT TOE FACE OF VER STEM 64.76 KN/m2

PRESSURE AT HEEL FACE OF VER STEM 64.47 KN/m2

FOS AGAINST OVERTURNING 6.34

FOS AGAINST SLIDING 1.69

DESIGN OF SHEAR KEY

INPUT PERMISSIBLE SHEAR STRESS Tc 0.33 N/mm2

THICKNESS OFKEY 0 mm 0

DEPTH OF KEY 0.00 m

KEY REINFORCEMENT 0 mm2

INPUT PROVIDE DIA OF STEEL BAR 10 mm

SPACING OF BARS 0 mm

DESIGN OF BASE SLAB

DESIGN OF TOE SLAB

EFFECTIVE DEPTH OF TOE d 205 mm

SPAN OF TOE L1 0.75 m

WT OF FOOTING W4 7.00 KN/m

MAX BM AT BASE OF TOE Mt 24.48 KN-m

SHEAR FORCE Vmax 47.44 KN

DESIGN OF TOE SLAB TO RESIST BENDING MOMENT

Grade of Concrete M 25

Grade of Steel Fe 415

Base width 1.0 Mtr

Max BM Mx 24.48 KN-M

BM = (Const*fck) bd^2 3.444 bd^2

Calculated Eff Depth of Slab 84 mm 195

RESULT Adopt Effective Depth d 200 mm

INPUT Use Dia of Slab rft 10 mm

Adopt Cover for Slab 75 mm

Over all Depth of Base Slab D 280 mm

Width of Slab considered for Cal 1000 mm

Grade of Concrete M 25

Grade of Steel Fe 415

a= 0.87 *(fy^2/fck) 5993.43

b= -0.87 fy -361.05

c= m= Mu/(bd^2) 0.61

m= Mu/(bd^2) p %= (-b- sqrt(b^2-4ac))/2a At

0.61 0.175 350 Sqmm

Min area of Tension Steel Ao=0.85*bd/fy 410 Sqmm

OR INCREASE WIDTH OF FDN

Min Area of Steel 0.15 % (Temp Rft) 420 Sqmm

Max area of Tensile Steel = 0.04 bD 11200 Sqmm

Provide Area of Tension Steel 420 Sqmm

Area of One Bar 78.57 Sqmm 10

RESULT Spacing of Main Bars 180 mm 10

Min Area of Steel 0.12 % 336 Sqmm

Check for Min rft OK

Temp rft 0.15 % of gross area will be provided in the longitudinal direction

420 Sqmm

INPUT Use 10 mm Dia bars as distribution Rft

Area of One Bar 78.57 Sqmm 10

RESULT Spacing of Distribution Bars 180 mm 10

DESIGN/ CHECK FOR TOE SLAB TO RESIST SHEAR

Grade of Concrete M 25

Effective Depth 200 mm

Over allDepth of Slab 280 mm

Dia of Shear rft 10 mm

Area of One Bar 78.57 Sqmm

Spacing of Bars 180 mm

Max Shear Force wL/2 47.44 KN

Percentage of Tensile Steel 100At/2bd = 0.22 %

(at the end, alternate bar are bent up)

Design Shear Strength 0.344 N/ Sqmm

Calculated k Value

INPUT For 280 mm thick slab, k=

Permissible Max Shear Stress 0.344 N/ Sqmm

Nominal Shear stress Vu/bd 0.24 N/ Sqmm

Shear Check Safe

DESIGN OF HEELSLAB

SPAN OF HEEL L2 2.60 M

PRESSURE AT HEEL Wp 63.55 KN/m2

WT OF SOIL OVER HEEL W5 70.56 KN/m

WT OF HEEL W6 7.00 KN/m

MAX BM AT HEEL Mh 47.36 KN-m

SHEAR FORCE Vmax 50.44 KN

DESIGN OF HEEL SLAB TO RESIST BENDING MOMENT

Grade of Concrete M 25

Grade of Steel Fe 415

Base width 1.0 Mtr

Max BM Mx 47.36 KN-M

BM = (Const*fck) bd^2 3.444 bd^2

Calculated Eff Depth of Slab 117 mm 195

RESULT Adopt Effective Depth d 200 mm

INPUT Use Dia of Slab rft 12 mm

Adopt Cover for Slab 75 mm

Over all Depth of Base Slab D 280 mm

Width of Slab considered for Cal 1000 mm

Grade of Concrete M 25

Grade of Steel Fe 415

a= 0.87 *(fy^2/fck) 5993.43

b= -0.87 fy -361.05

c= m= Mu/(bd^2) 1.18

m= Mu/(bd^2) p %= (-b- sqrt(b^2-4ac))/2a At

1.18 0.348 697 Sqmm

Min area of Tension Steel Ao=0.85*bd/fy 410 Sqmm

Min Area of Steel 0.15 % (Temp Rft) 420 Sqmm

Max area of Tensile Steel = 0.04 bD 11200 Sqmm

Provide Area of Tension Steel 697 Sqmm

Area of One Bar 113.14 Sqmm 12

RESULT Spacing of Main Bars 160 mm 12

Min Area of Steel 0.12 % 336 Sqmm

Check for Min rft OK

Temp rft 0.15 % of gross area will be provided in the longitudinal direction

420 Sqmm

INPUT Use 12 mm Dia bars as distribution Rft

Area of One Bar 113.14 Sqmm 12

RESULT Spacing of Distribution Bars 260 mm 12

DESIGN/ CHECK FOR HEEL SLAB TO RESIST SHEAR

Grade of Concrete M 25

Effective Depth 200 mm

Over allDepth of Slab 280 mm

Dia of Shear rft 12 mm

Area of One Bar 113.14 Sqmm

Spacing of Bars 160 mm

Max Shear Force wL/2 50.44 KN

Percentage of Tensile Steel 100At/2bd = 0.35 %

(at the end, alternate bar are bent up)

Design Shear Strength 0.423 N/ Sqmm

Calculated k Value

INPUT For 280 mm thick slab, k=

Permissible Max Shear Stress 0.423 N/ Sqmm

Nominal Shear stress Vu/bd 0.25 N/ Sqmm

Shear Check Safe

DESIGN OF STEM WALL

SPAN OF WALL L3 3.80 M

MAX BM AT BOTTOM OF WALL Mw 116.46 KN-m

SHEAR FORCE Vmax 63.73 KN

DESIGN OF STEM WALL TO RESIST BENDING MOMENT

Grade of Concrete M 25

Grade of Steel Fe 415

Base width 1.0 Mtr

Max BM Mx 116.46 KN-M

BM = (Const*fck) bd^2 3.444 bd^2

Calculated Eff Depth of Slab 184 mm 313

RESULT Adopt Effective Depth d 320 mm

INPUT Use Dia of Stem Wall rft 12 mm

Adopt Cover for Stem wall 75 mm

Over all Depth of Base Slab D 400 mm

Width of Slab considered for Cal 1000 mm

Grade of Concrete M 25

Grade of Steel Fe 415

a= 0.87 *(fy^2/fck) 5993.43

b= -0.87 fy -361.05

c= m= Mu/(bd^2) 1.14

m= Mu/(bd^2) p %= (-b- sqrt(b^2-4ac))/2a At

1.14 0.333 1068 Sqmm

Min area of Tension Steel Ao=0.85*bd/fy 655 Sqmm

Min Area of Steel 0.15 % (Temp Rft) 600 Sqmm

Max area of Tensile Steel = 0.04 bD 16000 Sqmm

Provide Area of Tension Steel 1068 Sqmm

Area of One Bar 113.14 Sqmm 12

RESULT Spacing of Main Bars 100 mm 12

Min Area of Steel 0.12 % 480 Sqmm

Check for Min rft OK

Temp rft 0.15 % of gross area will be provided in the longitudinal direction

600 Sqmm

INPUT Use 12 mm Dia bars as distribution Rft

Area of One Bar 113.14 Sqmm 12

RESULT Spacing of Distribution Bars 180 mm 12

CURTAILMENT REINFORCEMENT

DEPTH FROM TOP OF EMBANKMENT 2.1 Mtr

AREA OF REINFORCEMENT 534 Sqmm

Use Dia of Stem Wall rft 12 mm 20

Area of One Bar 113.14 Sqmm

Spacing of Distribution Bars 200 mm 12

DISTRIBUTION STEEL

DEPTH FROM TOP OF EMBANKMENT 2.1 Mtr

AREA OF REINFORCEMENT 600 Sqmm

Use Dia of Stem Wall rft 12 mm 16

Area of One Bar 113.14 Sqmm

Spacing of Distribution Bars 180 mm 12

DESIGN/ CHECK FOR STEM WALL TO RESIST SHEAR

Grade of Concrete M 25

Effective Depth 320 mm

Over allDepth of Slab 400 mm

Dia of Shear rft 12 mm

Area of One Bar 113.14 Sqmm

Spacing of Bars 100 mm

Max Shear Force wL/2 63.73 KN

Percentage of Tensile Steel 100At/2bd = 0.35 %

(at the end, alternate bar are bent up)

Design Shear Strength 0.423 N/ Sqmm

Calculated k Value

INPUT For 400 mm thick slab, k=

Permissible Max Shear Stress 0.423 N/ Sqmm

Nominal Shear stress Vu/bd 0.20 N/ Sqmm

Shear Check Safe

Soil Ws KN/Sqm Rg Mean Fr bet soil & wall

Sand 17-20 25-35 30 0.55 29

Medium Clay 16-18 14-28 21 0.4 22

Soft Clay 15-17 4-16 10 0.33 18

Ka= Cos C((Cos C- Sqrt(Cos C^2-Cos ^2))/(Cos C+ Sqrt(Cos C^2-Cos ^2))) = ((1-SIN())/(1+SIN())^2

1/ka

h=SBC/Ws*(1-sin /1+sin )^2

DEPTH=H/4 AND NOT LESS THAN MIN DEPTH/ 1.00Mtr DEPTH OF FDN

Ht=H+DEPTH

= 1- q0/(2H) =TOE WIDTH/BASE WIDTH

Bm

B- Bm-T1

H*(Sqrt((1-sino/1+sino)/(1-k * (3*k+1)))*H Vaz Rat Page 437

GENERALLY B=Ht/3 AND NOT LESS THAN B(MIN)

GIVE VALUE=0 IF THERE IS NO SURCHARGE

D=Ht/12 to Ht/20

BASE SLAB THICKNESS

T=Ht/10 to H/15 H=

WALL THICKNESS AT BOT 3000

Th at Top T2 = T1/2 WALL THICKNESS AT TOP

W1=B*D*25

W2=(T1)*(H-D)*25

W3=(T2-T1)/2*(H-D)*25

W4=ALPHA*B*(Ht-D)*Ws+Ps*ALPHA* EXIST. GL

AXIAL LOAD FROM COLUMN IN LINE WITH RETAING WALL

W=W1+W2+W3+W4

P1=Ka*Ws*Ht*Ht/2

Ps=ps*Ht NAME FORCE LVR ARM MOM @ Toe h=

W1 26.25 1.88 49.22

X1=B/2 W2 19.60 0.85 16.66

ALPHA*B+T1/2 W3 9.80 0.63 6.22

ALPHA*B+T1+(T2-T1)/3 W4 184.19 2.66 489.76 1200

X3=B-ALPHA*B/2 W5 0.00 0.85 0.00 D=

W 239.84 2.34 561.86 280

Y1=Ht/3 Ph 48.37 1.31 63.20

(WHERE WATER TABLE IS BELOW BASE OF FOOTING)

(Ex 15.1 RCC by BC Punmia & Ex 12.1 Vazrani and Ratwani)

RCC RETAINING WALL(CANTILEVERTYPE) MAX 6.0 MTR HEIGHT INCL COLUMN LOAD IN LINE

Y2=Ht/2 Pv 15.37 1.96 30.12

W1*X1+W2*X2+W3*X3/(V ) V 63.73 1.46 93.32 10 # @

R 248.17 1.89 468.54 180 mm c/c

R=V*V+H*H

X=(W1*X1+W2*X2+W3*X3+Ph*Y1+Ps*Y2)/R 10 # @

e=X-B/2 (- SIGN FOR RESULTANT FORCE AWAY TO HEAL SIDE OF STEM SLAB) CHECK Pmax < SBC 180 mm c/c

Pmax=W/B(1+6*e/B) CHECK Pmin>O (TO RESIST VERTICAL UP PR)

Pmin=W/B(1-6*e/B)

CHECK FOS>1.5

CHECK FOS>1.5

FOS=(W1*X1+W2*X2+W3*X3)/(P*Y1+Ps*Y2)

FOS=u*W/(Ph+Ps)

ALL DIMENSIONS ARE IN MILLIMETRES

FROM IS 456 TABLE FOR M25= 0.29/MM2 FOR M30=0.29N/MM2

THICKNESS OF KEY=(P+Ps)*1.5/Tc SHEAR KEY THICK

Max Shear Stress

Grade of Concrete M 25

Max SS N/Sqmm 3.1

fck 25

Design Shear Strength

d=D-COVER 100 As/bd SS N/Sqmm

L1=B-B2-T 0.20 14.51 0.331

W4=D*25

Mt=(W4+Pmax)*L1*L1/2

V=(Pmax*(L1-d))*1.5

Max Depth of Nutral Axis

fy Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm

250 0.53 d H=

415 0.48 d 3.00

500 0.46 d

550 0.44 d

Limiting Moment of resistance MR = Const * b*d^2 N mm

Const= 0.36*fck*Xm(1-0.42*Xm)

Concrete M Fe 250 Fe 415 Fe 500 Fe 550

15 2.229 2.067 1.991 1.949 EXIST. GL

20 2.972 2.755 2.655 2.598

25 3.715 3.444 3.318 3.248

30 4.458 4.133 3.982 3.897

35 5.201 4.822 4.645 4.547 h=

1.20

Steel

TOE

750

0.75

D=

0.28

mm Dia

SBC 65.29

mm Dia 150

mm Dia bars as distribution Rft

mm Dia

mm Dia

Max Shear Stress

Grade of Concrete M 25

Max SS N/Sqmm 3.1

fck 25

Design Shear Strength

100 As bd SS N/Sqmm

0.22 13.30 0.344

N/ Sqmm

1.00 Value of K

1.00 Ds >300 275 250 225 200 175 <151

k 1.00 1.05 1.10 1.15 1.20 1.25 1.30

N/ Sqmm

* Shear rft be provided in a slab deeper than 200 mm

HL

Wp=(P2+P4)/2

W5=Ws*(Ht-D)

W6=25*D

Mh=Wp+W5+W6)*L2*L2

V=(Pheel*(L2-d))*1.5

3.75

Max Depth of Nutral Axis

fy Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm

250 0.53 d

415 0.48 d

500 0.46 d

550 0.44 d

Limiting Moment of resistance MR = Const * b*d^2 N mm

Const= 0.36*fck*Xm(1-0.42*Xm)

Concrete M Fe 250 Fe 415 Fe 500 Fe 550

15 2.229 2.067 1.991 1.949

20 2.972 2.755 2.655 2.598

25 3.715 3.444 3.318 3.248

30 4.458 4.133 3.982 3.897

35 5.201 4.822 4.645 4.547

mm Dia

mm Dia

mm Dia bars as distribution Rft

mm Dia

mm Dia

Max Shear Stress

Grade of Concrete M 25

Max SS N/Sqmm 3.1

fck 25

Steel

Design Shear Strength

100 As bd SS N/Sqmm

0.35 8.21 0.423

N/ Sqmm

1.00 Value of K

1.00 Ds >300 275 250 225 200 175 <151

k 1.00 1.05 1.10 1.15 1.20 1.25 1.30

N/ Sqmm

* Shear rft be provided in a slab deeper than 200 mm

L3=Ht-D

Mw=Ph* Ht/3+Ps*Ht/2 L3*L3+PsL3*L3/2

V=(Pheel*(L2-d))*1.5

Max Depth of Nutral Axis

fy Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm

250 0.53 d

415 0.48 d

500 0.46 d

550 0.44 d

Limiting Moment of resistance MR = Const * b*d^2 N mm

Const= 0.36*fck*Xm(1-0.42*Xm)

Concrete M Fe 250 Fe 415 Fe 500 Fe 550

15 2.229 2.067 1.991 1.949

20 2.972 2.755 2.655 2.598

25 3.715 3.444 3.318 3.248

30 4.458 4.133 3.982 3.897

35 5.201 4.822 4.645 4.547

mm Dia

mm Dia

Steel

mm Dia bars as distribution Rft

mm Dia

mm Dia

mm Dia

mm Dia

Max Shear Stress

Grade of Concrete M 25

Max SS N/Sqmm 3.1

fck 25

Design Shear Strength

100 As bd SS N/Sqmm

0.35 8.21 0.423

N/ Sqmm

1.00 Value of K

1.00 Ds >300 275 250 225 200 175 <151

k 1.00 1.05 1.10 1.15 1.20 1.25 1.30

N/ Sqmm

* Shear rft be provided in a slab deeper than 200 mm

2 KN/M SURCHARGE

MADE UP GL MADE UP GL

t= 200

ANGLE OF SURCHARGE C

12 # @

200 mm c/c

EARTH FILLING SIDE

12 # @

180 mm c/c

12 # @

100 mm c/c

12 # @

1960 100 mm c/c

12 # @

180 mm c/c

12 # @

160 mm c/c

(TO RESIST VERTICAL DOWN PRESSURE)

528

12 # @

0.00 260 mm c/c

10 # @

0 mm c/c

0

(TO RESIST VERTICAL UP PR)

T=

400

B= 3750

ALL DIMENSIONS ARE IN MILLIMETRES

2 KN/M SURCHARGE

MADE UP GL MADE UP GL

W5

0.00

t= 0.20

ANGLE OF SURCHARGE C

EARTH FILLING SIDE

Ps

15.37

Ph

48.37

W2

19.60

W3 W4

9.80 184.19

R

0.01

0.40

2600

TOE

750

HEEL

0.75 2.60

W1

26.25

64.76 64.47 62.62

3.75

(Ex 14.1 Dhayaratnam& Ex 19.3 AK Jain)

INPUT DATAS

INPUT GRADE OF CONCRETE fck 25 N/mm2

INPUT GRADE OF STEEL f y 415 N/mm2

INPUT ANGLE OF REPOSE OF SOIL 35 DEG

INPUT BULK DENSITY OF SOIL Ws 17 KN/m2

INPUT SOIL SAFE BEARING CAPACITY SBC 200 KN/m2

INPUT ANGLE OF SURCHARGE OF FILL C 0 DEG

INPUT COEFFT OF FRICTION 0.45

COS C 1

COS 0.819

COEFFT OF ACTIVE PRESSURE Ka 0.271

COEFFT OF PASSIVE PRESSURE Kp 3.687

INPUT HEIGHT OF FILLING H 3 mtr

MIN DEPTH OF FDN h 0.87 mtr

INPUT PROVIDE DEPTH OF FDN D h/4= 0.75 1.80 mtr 1.80

TOTAL HT OF WALL Ht=H+D 4.80 mtr

CONST (Select FACTOR b from the range ) = 0.740 0.740 0.851

CALCULATED BASE WIDTH B(MIN) 2.00 mtr

INPUT PROVIDE BASE WIDTH B 4.60 mtr 4.60

INPUT SURCHARGE ps 0 KN/m

BASE SLAB THICK D(MIN) 320 mm

INPUT PROVIDE BASE SLAB THICK D 320 mm 0

WALL THICK AT BOTTOM T(MIN) 400 mm

INPUT PROVIDE WALL THICK AT BOTTOM T1 400 mm 0

INPUT PROVIDE WALL THICK AT TOP T2 200 mm 0

CHECK FOR BEARING PRESSURE

WT OF BASE SLAB/FOOTING W1 36.80 KN/m

WT OF STEM/ WALL W2 33.60 KN/m

WT OF REAR SOIL OVER HEEL W3 259.18 KN/m

TOTAL STABILISING VERTICAL FORCE V 329.58 KN/m

HORIZONTAL EARTH PRESSURE Ph 46.27 KN/m

HORIZONTAL SURCHARGE Ps 0.00 KN/m

TOTAL HORIZONTAL PRESSURE 46.27 KN/m

DISTANCE OF W1 FROM TOE FRONT TIP X1 2.30 mtr

DISTANCE OF W2 FROM TOE FRONT TIP X2 1.00 mtr

DISTANCE OF W3 FROM TOE FRONT TIP X3 2.90 mtr

HT OF HORT FORCE Y1 FROM TOE TOP 1.49 mtr

HT OF SUR FORCE Y2 FROM TOE TOP 2.24 mtr

DIST OF VERT REACTION FROM TOE FRONT TIP 2.64 mtr

RCC RETAINING WALL(CANTILEVERTYPE) MAX 6.0 MTR HEIGHT AND CLOLUMNS IN LINE

(WHERE WATER TABLE IS BELOW BASE OF FOOTING)

CALCULATION OF PRESSURE

REACTION OF FORCES 332.82 KN

DIST OF REACTION FROM TOE X 2.40 m

ECCENTRICITY e 0.10 m

PRESSURE AT TOE TIP Pmax 81.42 KN/m2

PRESSURE AT HEEL TIP Pmax 61.88 KN/m2

PRESSURE AT TOE FACE OF VER STEM 78.03 KN/m2

FOS AGAINST OVERTURNING 12.58

FOS AGAINST SLIDING 3.21

IF FOS<1.5 PROVIDE SHEAR KEY

OR INCREASE WIDTH OF FDN

DESIGN OF SHEAR KEY

INPUT PERMISSIBLE SHEAR STRESS Tc 0.33 N/mm2

THICKNESS OFKEY 1000 mm 1000

DEPTH OF KEY 0.00 m

KEY REINFORCEMENT 1200 mm2

INPUT PROVIDE DIA OF STEEL BAR 16 mm

SPACING OF BARS 160 mm

DESIGN OF BASE SLAB

DESIGN OF TOE SLAB

EFFECTIVE DEPTH OF TOE d 245 mm

SPAN OF TOE L1 0.80 m

WT OF FOOTING W4 8.00 KN/m

MAX BM AT BASE OF TOE Mt 34.16 KN-m

SHEAR FORCE Vmax 59.37 KN

DESIGN OF TOE SLAB TO RESIST BENDING MOMENT

Grade of Concrete M 25

Grade of Steel Fe 415

Base width 1.0 Mtr

Max BM Mx 34.16 KN-M

BM = (Const*fck) bd^2 3.444 bd^2

Calculated Eff Depth of Slab 100 mm 232

RESULT Adopt Effective Depth d 240 mm

INPUT Use Dia of Slab rft 16 mm

Adopt Cover for Slab 75 mm

Over all Depth of Base Slab D 325 mm

Width of Slab considered for Cal 1000 mm

Grade of Concrete M 25

Grade of Steel Fe 415

a= 0.87 *(fy^2/fck) 5993.43

b= -0.87 fy -361.05

c= m= Mu/(bd^2) 0.59

m= Mu/(bd^2) p %= (-b- sqrt(b^2-4ac))/2a At

0.59 0.169 406 Sqmm

Min area of Tension Steel Ao=0.85*bd/fy 491.57 Sqmm

Max area of Tensile Steel = 0.04 bD 13000 Sqmm

Provide Area of Tension Steel 492 Sqmm

Area of One Bar 201.14 Sqmm 16

RESULT Spacing of Main Bars 400 mm 16

Min Area of Steel 0.12 % 390 Sqmm

Check for Min rft OK

Temp rft 0.15 % of gross area will be provided in the longitudinal direction

487.5 Sqmm

INPUT Use 16 mm Dia bars as distribution Rft

Area of One Bar 201.14 Sqmm 16

RESULT Spacing of Distribution Bars 410 mm 16

DESIGN/ CHECK FOR TOE SLAB TO RESIST SHEAR

Grade of Concrete M 25

Effective Depth 240 mm

Over allDepth of Slab 325 mm

Dia of Shear rft 16 mm

Area of One Bar 201.14 Sqmm

Spacing of Bars 400 mm

Max Shear Force wL/2 59.37 KN

Percentage of Tensile Steel 100At/2bd = 0.21 %

(at the end, alternate bar are bent up)

Design Shear Strength 0.338 N/ Sqmm

Calculated k Value

INPUT For 325 mm thick slab, k=

Permissible Max Shear Stress 0.338 N/ Sqmm

Nominal Shear stress Vu/bd 0.25 N/ Sqmm

Shear Check Safe

DESIGN OF HEELSLAB

SPAN OF HEEL L2 3.40 M

PRESSURE AT HEEL Wp 76 KN/m2

WT OF SOIL OVER HEEL W5 76 KN/m

WT OF HEEL W6 8 KN/m

MAX BM AT HEEL Mh 266 KN-m

SHEAR FORCE Vmax 218.22 KN

DESIGN OF HEEL SLAB TO RESIST BENDING MOMENT

Grade of Concrete M 25

Grade of Steel Fe 415

Base width 1.0 Mtr

Max BM Mx 266.33 KN-M

BM = (Const*fck) bd^2 3.444 bd^2

Calculated Eff Depth of Slab 278 mm 232

RESULT Adopt Effective Depth d 280 mm

INPUT Use Dia of Slab rft 16 mm

Adopt Cover for Slab 75 mm

Over all Depth of Base Slab D 365 mm

Width of Slab considered for Cal 1000 mm

Grade of Concrete M 25

Grade of Steel Fe 415

a= 0.87 *(fy^2/fck) 5993.43

b= -0.87 fy -361.05

c= m= Mu/(bd^2) 3.40

m= Mu/(bd^2) p %= (-b- sqrt(b^2-4ac))/2a At

3.40 1.167 3268 Sqmm

Min area of Tension Steel Ao=0.85*bd/fy 573.49 Sqmm

Max area of Tensile Steel = 0.04 bD 14600 Sqmm

Provide Area of Tension Steel 3268 Sqmm

Area of One Bar 201.14 Sqmm 16

RESULT Spacing of Main Bars 60 mm 16

Min Area of Steel 0.12 % 438 Sqmm

Check for Min rft OK

Temp rft 0.15 % of gross area will be provided in the longitudinal direction

547.5 Sqmm

INPUT Use 16 mm Dia bars as distribution Rft

Area of One Bar 201.14 Sqmm 16

RESULT Spacing of Distribution Bars 360 mm 16

DESIGN/ CHECK FOR HEEL SLAB TO RESIST SHEAR

Grade of Concrete M 25

Effective Depth 280 mm

Over allDepth of Slab 365 mm

Dia of Shear rft 16 mm

Area of One Bar 201.14 Sqmm

Spacing of Bars 60 mm

Max Shear Force wL/2 218.22 KN

Percentage of Tensile Steel 100At/2bd = 1.20 %

(at the end, alternate bar are bent up)

Design Shear Strength 0.685 N/ Sqmm

Calculated k Value

INPUT For 365 mm thick slab, k=

Permissible Max Shear Stress 0.685 N/ Sqmm

Nominal Shear stress Vu/bd 0.78 N/ Sqmm

Shear Check Un safe

DESIGN OF STEM WALL

SPAN OF WALL L3 4.40 M

MAX BM AT BOTTOM OF WALL Mw 103.63 KN-m

SHEAR FORCE Vmax 46.27 KN

DESIGN OF STEM WALL TO RESIST BENDING MOMENT

Grade of Concrete M 25

Grade of Steel Fe 415

Base width 1.0 Mtr

Max BM Mx 103.63 KN-M

BM = (Const*fck) bd^2 3.444 bd^2

Calculated Eff Depth of Slab 173 mm 309

RESULT Adopt Effective Depth d 310 mm

INPUT Use Dia of Stem Wall rft 16 mm

Adopt Cover for Stem wall 75 mm

Over all Depth of Base Slab D 395 mm

Width of Slab considered for Cal 1000 mm

Grade of Concrete M 25

Grade of Steel Fe 415

a= 0.87 *(fy^2/fck) 5993.43

b= -0.87 fy -361.05

c= m= Mu/(bd^2) 1.08

m= Mu/(bd^2) p %= (-b- sqrt(b^2-4ac))/2a At

1.08 0.315 978 Sqmm

Min area of Tension Steel Ao=0.85*bd/fy 634.94 Sqmm

Max area of Tensile Steel = 0.04 bD 15800 Sqmm

Provide Area of Tension Steel 978 Sqmm

Area of One Bar 201.14 Sqmm 16

RESULT Spacing of Main Bars 200 mm 16

Min Area of Steel 0.12 % 474 Sqmm

Check for Min rft OK

Temp rft 0.15 % of gross area will be provided in the longitudinal direction

592.5 Sqmm

INPUT Use 16 mm Dia bars as distribution Rft

Area of One Bar 201.14 Sqmm 16

RESULT Spacing of Distribution Bars 330 mm 16

CURTAILMENT REINFORCEMENT

DEPTH FROM TOP OF EMBANKMENT 2.4 Mtr

AREA OF REINFORCEMENT 489 Sqmm

Use Dia of Stem Wall rft 16 mm 20

Area of One Bar 201.14 Sqmm

Spacing of Distribution Bars 400 mm 16

DISTRIBUTION STEEL

DEPTH FROM TOP OF EMBANKMENT 2.4 Mtr

AREA OF REINFORCEMENT 592.5 Sqmm

Use Dia of Stem Wall rft 16 mm 16

Area of One Bar 201.14 Sqmm

Spacing of Distribution Bars 330 mm 16

DESIGN/ CHECK FOR STEM WALL TO RESIST SHEAR

Grade of Concrete M 25

Effective Depth 310 mm

Over allDepth of Slab 395 mm

Dia of Shear rft 16 mm

Area of One Bar 201.14 Sqmm

Spacing of Bars 200 mm

Max Shear Force wL/2 46.27 KN

Percentage of Tensile Steel 100At/2bd = 0.32 %

(at the end, alternate bar are bent up)

Design Shear Strength 0.408 N/ Sqmm

Calculated k Value

INPUT For 395 mm thick slab, k=

Permissible Max Shear Stress 0.408 N/ Sqmm

Nominal Shear stress Vu/bd 0.15 N/ Sqmm

Shear Check Safe

(Ex 14.1 Dhayaratnam& Ex 19.3 AK Jain)

Soil Ws KN/Sqm Rg Mean Fr bet soil & wall

Sand 17-20 25-35 30 0.55 29

Medium Clay 16-18 14-28 21 0.4 22

Soft Clay 15-17 4-16 10 0.33 18

Ka= Cos C((Cos C- Sqrt(Cos C^2-Cos ^2))/(Cos C+ Sqrt(Cos C^2-Cos ^2))) = ((1-SIN())/(1+SIN())^2

h=SBC/Ws*(1-sin /1+sin )^2

DEPTH=H/4 AND NOT LESS THAN MIN DEPTH/ 1.00Mtr DEPTH OF FDN

Ht=H+DEPTH

=0.36*(SQRT(1+(3.4*SBC)/(Ws*Ht))-1) TO 0.45*(SQRT(1+(3*SBC)/(Ws*Ht))-1 =HEEL WIDTH/BASE WIDTH

B=0.5*Ht*SQRT(Ka/((1-0.55*))

GENERALLY B=Ht/3 AND NOT LESS THAN B(MIN)

GIVE VALUE=0 IF THERE IS NO SURCHARGE

D=Ht/12 to Ht/20

BASE SLAB THICKNESS

T=Ht/10 to H/15 H=

WALL THICKNESS AT BOT 3000

Th at Top T2 = T1/2 WALL THICKNESS AT TOP

W1=B*D*25

W2=(T1+T2)/2*(H-D)*25

W3=ALPHA*B*(Ht-D)*Ws+Ps*ALPHA*

W=W1+W2+W3 EXIST. GL

P1=Ka*Ws*Ht*Ht/2

Ps=ps*Ht

h=

X1=B/2

X2=B-ALPHA*B-T1/2

X3=B-ALPHA*B/2 1800

Y1=Ht/3 D=

Y2=Ht/2 320

W1*X1+W2*X2+W3*X3/(V )

RCC RETAINING WALL(CANTILEVERTYPE) MAX 6.0 MTR HEIGHT AND CLOLUMNS IN LINE

(WHERE WATER TABLE IS BELOW BASE OF FOOTING)

16 # @

R=V*V+H*H 410 mm c/c

X=(W1*X1+W2*X2+W3*X3+Ph*Y1+Ps*Y2)/R

e=X-B/2 16 # @

Pmax=W/B(1-6*e/B) CHECK Pmax < SBC 400 mm c/c

Pmin=W/B(1-6*e/B) CHECK Pmin>O (TO RESIST VERTICAL UP PR)

FOS=(W1*X1+W2*X2+W3*X3)/(P*Y1+Ps*Y2) CHECK FOS>1.5

FOS=u*W/(Ph+Ps) CHECK FOS>1.5

ALL DIMENSIONS ARE IN MILLIMETRES

FROM IS 456 TABLE FOR M25= 0.29/MM2 FOR M30=0.29N/MM2

THICKNESS OF KEY=(P+Ps)*1.5/Tc SHEAR KEY THICK

Max Shear Stress

Grade of Concrete M 25

Max SS N/Sqmm 3.1

fck 25

Design Shear Strength

d=D-COVER 100 As/bd SS N/Sqmm

L1=B-B2-T 0.20 14.51 0.331

W4=D*25

Mt=(W4+Pmax)*L1*L1/2

V=(Pmax*(L1-d))*1.5

Max Depth of Nutral Axis

fy Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm

250 0.53 d

415 0.48 d

500 0.46 d

550 0.44 d

Limiting Moment of resistance MR = Const * b*d^2 N mm

Const= 0.36*fck*Xm(1-0.42*Xm)

Concrete M Fe 250 Fe 415 Fe 500 Fe 550

15 2.229 2.067 1.991 1.949

20 2.972 2.755 2.655 2.598

25 3.715 3.444 3.318 3.248

30 4.458 4.133 3.982 3.897

35 5.201 4.822 4.645 4.547

800

Steel

mm Dia

mm Dia

mm Dia bars as distribution Rft

mm Dia

mm Dia

Max Shear Stress

Grade of Concrete M 25

Max SS N/Sqmm 3.1

fck 25

Design Shear Strength

100 As bd SS N/Sqmm

0.21 13.85 0.338

N/ Sqmm

1.00 Value of K

1.00 Ds >300 275 250 225 200 175 <151

k 1.00 1.05 1.10 1.15 1.20 1.25 1.30

N/ Sqmm

* Shear rft be provided in a slab deeper than 200 mm

L2=ALPHA*B

Wp=Pmin+(Pmax-Pmin)*alpha

W5=Ws*(Ht-D)

W6=25*D

Mh=Wp+W5+W6)*L2*L2

V=(Pheel*(L2-d))*1.5

Max Depth of Nutral Axis

fy Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm

250 0.53 d

415 0.48 d

500 0.46 d

550 0.44 d

Limiting Moment of resistance MR = Const * b*d^2 N mm

Const= 0.36*fck*Xm(1-0.42*Xm)

Concrete M Fe 250 Fe 415 Fe 500 Fe 550

15 2.229 2.067 1.991 1.949

20 2.972 2.755 2.655 2.598

25 3.715 3.444 3.318 3.248

30 4.458 4.133 3.982 3.897

35 5.201 4.822 4.645 4.547

mm Dia

mm Dia

mm Dia bars as distribution Rft

mm Dia

mm Dia

Max Shear Stress

Grade of Concrete M 25

Max SS N/Sqmm 3.1

fck 25

Design Shear Strength

100 As bd SS N/Sqmm

Steel

1.20 2.42 0.685

N/ Sqmm

1.00 Value of K

1.00 Ds >300 275 250 225 200 175 <151

k 1.00 1.05 1.10 1.15 1.20 1.25 1.30

N/ Sqmm

* Shear rft be provided in a slab deeper than 200 mm

L3=Ht-D

Mw=Ph* Ht/3+Ps*Ht/2 L3*L3+PsL3*L3/2

V=(Pheel*(L2-d))*1.5

Max Depth of Nutral Axis

fy Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm

250 0.53 d

415 0.48 d

500 0.46 d

550 0.44 d

Limiting Moment of resistance MR = Const * b*d^2 N mm

Const= 0.36*fck*Xm(1-0.42*Xm)

Concrete M Fe 250 Fe 415 Fe 500 Fe 550

15 2.229 2.067 1.991 1.949

20 2.972 2.755 2.655 2.598

25 3.715 3.444 3.318 3.248

30 4.458 4.133 3.982 3.897

35 5.201 4.822 4.645 4.547

mm Dia

mm Dia

Steel

mm Dia bars as distribution Rft

mm Dia

mm Dia

mm Dia

mm Dia

Max Shear Stress

Grade of Concrete M 25

Max SS N/Sqmm 3.1

fck 25

Design Shear Strength

100 As bd SS N/Sqmm

0.32 8.95 0.408

N/ Sqmm

1.00 Value of K

1.00 Ds >300 275 250 225 200 175 <151

k 1.00 1.05 1.10 1.15 1.20 1.25 1.30

N/ Sqmm

* Shear rft be provided in a slab deeper than 200 mm

0 KN/M SURCHARGE

MADE UP GL MADE UP GL

t= 200

ANGLE OF SURCHARGE C

16 # @

400 mm c/c

EARTH FILLING SIDE

16 # @

330 mm c/c

16 # @

200 mm c/c

16 # @

2240 200 mm c/c

16 # @

330 mm c/c

16 # @

60 mm c/c

(TO RESIST VERTICAL DOWN PRESSURE)

704

16 # @

0.00 360 mm c/c

16 # @

160 mm c/c

1000

(TO RESIST VERTICAL UP PR)

T=

400

B= 4600

ALL DIMENSIONS ARE IN MILLIMETRES

800 3400

INPUT DATAS

INPUT GRADE OF CONCRETE fck 25 N/mm2

INPUT GRADE OF STEEL f y 415 N/mm2

INPUT ANGLE OF REPOSE OF SOIL 30 DEG

INPUT BULK DENSITY OF SOIL Ws 16 KN/m3

INPUT SOIL SAFE BEARING CAPACITY SBC 200 KN/m2

INPUT ANGLE OF SURCHARGE OF FILL C 15 DEG

INPUT CLEAR SPACING OF COUNTERFORT L 3.24 3.00 mtr 3.00

INPUT THICKNESS OF COUNTERFORT Tc 0.30 mtr 0.30

C/C SPACING OF COUNTERFORT Lc 3.30 mtr

INPUT BASE WIDTH OF FRONT COUNTERFORT B2 1.25 mtr

INPUT HT OF FRONT COUNTERFORT ABOVE BASE SLAB 3.00 mtr

INPUT COEFFT OF FRICTION 0.6

COS C 0.966

COS 0.866

COEFFT OF ACTIVE PRESSURE Ka 0.373 0.334

COEFFT OF PASSIVE PRESSURE Kp 2.680

INPUT HEIGHT OF FILLING H 6.00 mtr

MIN DEPTH OF FDN h 1.39 mtr

INPUT PROVIDE DEPTH OF FDN D h/4= 1.5 1.50 mtr 1.50

TOTAL HT OF WALL Ht=H+D 7.50 mtr

CONST 0.242

Toe Length TL 0.90 1.25 mtr 1.25

Heel Length HL 3.25 mtr

CALCULATED BASE WIDTH B(MIN) Bm 3.72 mtr

INPUT PROVIDE BASE WIDTH B B 4.75 mtr 4.75

BASE WIDTH OF REAR COUNTERFORT B1 3.25 mtr

INPUT SURCHARGE ps ps 2.00 KN/m

BASE SLAB THICK D(MIN) 409 mm

INPUT PROVIDE BASE SLAB THICK D 409 mm 400

WALL THICK AT BOTTOM T(MIN) 250 mm

INPUT PROVIDE WALL THICK AT BOTTOM T1 250 mm 0

INPUT PROVIDE WALL THICK AT TOP T2 250 250 mm 0

CHECK FOR BEARING PRESSURE

WT OF BASE SLAB/FOOTING W1 48.53 KN/m

WT OF STEM/ WALL RECTANGLE PART W2 44.32 KN/m

WT OF STEM/ WALL TRIANGLE PART W3 0.00 KN/m

WT OF REAR SOIL OVER HEEL W4 371.05 KN/m

WT/ AXIAL LOAD FROM COLUMN W5 0.00 KN/m

TOTAL STABILISING VERTICAL FORCE W 463.90 KN/m

HORIZONTAL EARTH PRESSURE Ph 150.12 KN/m

HORIZONTAL SURCHARGE Ps 50.29 KN/m

(WHERE WATER TABLE IS BELOW BASE OF FOOTING)

(Ex 15.4 RCC by BC Punmia & Ex 12.5 Vazrani and Ratwani)

RCC COUNTERFORT RETAINING WALL (HT ABOVE 6 MTR) INCL COLUMN LOAD IN LINE

TOTAL HORIZONTAL PRESSURE V 200.41 KN/m

DISTANCE OF W1 FROM TOE FRONT TIP X1 X1 2.38 mtr

DISTANCE OF W2 FROM TOE FRONT TIP X2 1.38 mtr

DISTANCE OF W3 FROM TOE FRONT TIP X3 1.40 mtr

DISTANCE OF W3 FROM TOE FRONT TIP X4 3.33 mtr

DISTANCE OF W3 FROM TOE FRONT TIP X5 1.38 mtr

HT OF HORT FORCE Y1 FROM TOE TOP Y1 2.36 mtr

HT OF SUR FORCE Y2 FROM TOE TOP Y2 3.55 mtr

DIST OF VERT REACTION FROM TOE FRONT TIP 3.04 mtr

CALCULATION OF PRESSURE

REACTION OF FORCES 505.34 KN

DIST OF REACTION FROM TOE X 1.74 m

ECCENTRICITY e FROM CETRE OF BASE SLAB -0.64 m

PRESSURE AT TOE TIP Pmax 0 18.78 KN/m2 200

PRESSURE AT HEEL TIP Pmax 0 176.54 KN/m2 200

PRESSURE AT TOE FACE OF VER STEM 60.30 KN/m2

PRESSURE AT HEEL FACE OF VER STEM 68.60 KN/m2

FOS AGAINST OVERTURNING 2.75

FOS AGAINST SLIDING 1.39

DESIGN OF SHEAR KEY

INPUT PERMISSIBLE SHEAR STRESS Tc 0.33 N/mm2

THICKNESS OFKEY 910 mm 0

DEPTH OF KEY 0.00 m

KEY REINFORCEMENT 1092 mm2

INPUT PROVIDE DIA OF STEEL BAR 10 mm

SPACING OF BARS 70 mm

DESIGN OF BASE SLAB

DESIGN OF TOE SLAB

EFFECTIVE DEPTH OF TOE d 334 mm

SPAN OF TOE L1 1.25 m

WT OF FOOTING W4 10.22 KN/m

MAX BM AT BASE OF TOE BOTTOM NEAR COUNTERFORT EDGE Mt 56.34 KN-m

SHEAR FORCE Vmax 154.35 KN

DESIGN OF TOE SLAB TO RESIST BENDING MOMENT

Grade of Concrete M 25

Grade of Steel Fe 415

Base width 1.0 Mtr

Max BM Mx 56.34 KN-M

BM = (Const*fck) bd^2 3.444 bd^2

Calculated Eff Depth of Slab 128 mm 324

RESULT Adopt Effective Depth d 330 mm

INPUT Use Dia of Slab rft 10 mm

Adopt Cover for Slab 75 mm

Over all Depth of Base Slab D 410 mm

Width of Slab considered for Cal 1000 mm

Grade of Concrete M 25

OR INCREASE WIDTH OF FDN

Grade of Steel Fe 415

a= 0.87 *(fy^2/fck) 5993.43

b= -0.87 fy -361.05

c= m= Mu/(bd^2) 0.52

m= Mu/(bd^2) p %= (-b- sqrt(b^2-4ac))/2a At

0.52 0.147 485 Sqmm

Min area of Tension Steel Ao=0.85*bd/fy 675.90 Sqmm

Max area of Tensile Steel = 0.04 bD 16400 Sqmm

Provide Area of Tension Steel 676 Sqmm

Area of One Bar 78.57 Sqmm 10

RESULT Spacing of Main Bars 110 mm 10

Min Area of Steel 0.12 % 492 Sqmm

Check for Min rft OK

Temp rft 0.15 % of gross area will be provided in the longitudinal direction

615 Sqmm

INPUT Use 10 mm Dia bars as distribution Rft

Area of One Bar 78.57 Sqmm 10

RESULT Spacing of Distribution Bars 120 mm 10

DESIGN/ CHECK FOR TOE SLAB TO RESIST SHEAR

Grade of Concrete M 25

Effective Depth 330 mm

Over allDepth of Slab 410 mm

Dia of Shear rft 10 mm

Area of One Bar 78.57 Sqmm

Spacing of Bars 110 mm

Max Shear Force wL/2 154.35 KN

Percentage of Tensile Steel 100At/2bd = 0.22 %

(at the end, alternate bar are bent up)

Design Shear Strength 0.342 N/ Sqmm

Calculated k Value

INPUT For 410 mm thick slab, k=

Permissible Max Shear Stress 0.342 N/ Sqmm

Nominal Shear stress Vu/bd 0.47 N/ Sqmm

Shear Check Un safe

Design of Stirrups

Grade of Concrete M 25

Grade of Steel Fe 415

Effective Depth of Beam 330 mm

Over all Depth of Beam 410 mm

Width of Beam 1000 mm

Max Shear Force wl/2 Vu 154.35 KN

Strength of Shear rft Vus=Vu-Tc bd 41336 N

INPUT Dia of Shear rft 12 mm

Area of One Bar 113.14 Sqmm

INPUT No of legged vertical stirrups 4 Nos

Area of Vertical Stirrup Rft Asv 452.57 mm

RESULT Spacing of Shear rft x=0.87 fy Asv d/ Vus 1300 mm 420

Check for Spacing OK Min Spacing is 100 mm for placing of Concrete, Max 450 mm

Min Area of Shear rft 0.4 b x /fy 404.82 Sqmm

Check for min Shear rft Area OK If NOT OK then Increase the size of Rft oa more No of Legs

DESIGN OF HEELSLAB

SPAN OF HEEL L2 3.25 M

PRESSURE AT HEEL Wp 68.60 KN/m2

WT OF SOIL OVER HEEL W4 113.46 KN/m

WT OF HEEL W1a 10.22 KN/m

MAX BM AT HEEL TOP at Counterfort Mh 61.96 KN-m

SHEAR FORCE Vmax 123.92 KN

DESIGN OF HEEL SLAB TO RESIST BENDING MOMENT

Grade of Concrete M 25

Grade of Steel Fe 415

Base width 1.0 Mtr

Max BM Mx 61.96 KN-M

BM = (Const*fck) bd^2 3.444 bd^2

Calculated Eff Depth of Slab 134 mm 324

RESULT Adopt Effective Depth d 330 mm

INPUT Use Dia of Slab rft 12 mm

Adopt Cover for Slab 75 mm

Over all Depth of Base Slab D 410 mm

Width of Slab considered for Cal 1000 mm

Grade of Concrete M 25

Grade of Steel Fe 415

a= 0.87 *(fy^2/fck) 5993.43

b= -0.87 fy -361.05

c= m= Mu/(bd^2) 0.57

m= Mu/(bd^2) p %= (-b- sqrt(b^2-4ac))/2a At

0.57 0.162 535 Sqmm

Min area of Tension Steel Ao=0.85*bd/fy 675.90 Sqmm

Max area of Tensile Steel = 0.04 bD 16400 Sqmm

Provide Area of Tension Steel 676 Sqmm

Area of One Bar 113.14 Sqmm 12

RESULT Spacing of Main Bars 160 mm 12

Min Area of Steel 0.12 % 492 Sqmm

Check for Min rft OK

Temp rft 0.15 % of gross area will be provided in the longitudinal direction

615 Sqmm

INPUT Use 12 mm Dia bars as distribution Rft

Area of One Bar 113.14 Sqmm 12

RESULT Spacing of Distribution Bars 180 mm 12

DESIGN/ CHECK FOR HEEL SLAB TO RESIST SHEAR

Grade of Concrete M 25

Effective Depth 330 mm

Over allDepth of Slab 410 mm

Dia of Shear rft 12 mm

Area of One Bar 113.14 Sqmm

Spacing of Bars 160 mm

Max Shear Force wL/2 123.92 KN

Percentage of Tensile Steel 100At/2bd = 0.21 %

(at the end, alternate bar are bent up)

Design Shear Strength 0.341 N/ Sqmm

Calculated k Value

INPUT For 410 mm thick slab, k=

Permissible Max Shear Stress 0.341 N/ Sqmm

Nominal Shear stress Vu/bd 0.38 N/ Sqmm

Shear Check Un safe

Design of Stirrups

Grade of Concrete M 25

Grade of Steel Fe 415

Effective Depth of Beam 330 mm

Over all Depth of Beam 410 mm

Width of Beam 1000 mm

Max Shear Force wl/2 Vu 123.92 KN

Strength of Shear rft Vus=Vu-Tc bd 11399 N

INPUT Dia of Shear rft 10 mm

Area of One Bar 78.57 Sqmm

INPUT No of legged vertical stirrups 2 Nos

Area of Vertical Stirrup Rft Asv 157.14 mm

RESULT Spacing of Shear rft x=0.87 fy Asv d/ Vus 1640 mm 420

Check for Spacing OK Min Spacing is 100 mm for placing of Concrete, Max 450 mm

Min Area of Shear rft 0.4 b x /fy 404.82 Sqmm

Check for min Shear rft Area NOT OK If NOT OK then Increase the size of Rft oa more No of Legs

DESIGN OF STEM WALL

SPAN / HT OF STEM WALL L3 7.09 M

HORIZONTAL PRESSURE ON STEM WALL Ph 40.90 KN/m2

CLEAR SPACING OF COUNTERFORT L L 3.00 M

MAX BM AT BOTTOM OF WALL Mw Mw 46.01 KN-m

SHEAR FORCE Vmax V 61.35 KN

DESIGN OF STEM WALL TO RESIST BENDING MOMENT

Grade of Concrete M 25

Grade of Steel Fe 415

Base width 1.0 Mtr

Max BM Mx 46.01 KN-M

BM = (Const*fck) bd^2 3.444 bd^2

Calculated Eff Depth of Slab 116 mm 200

RESULT Adopt Effective Depth d 200 mm

INPUT Use Dia of Stem Wall rft 12 mm

Adopt Cover for Stem wall 40 mm

Over all Depth of Base Slab D 245 mm

Width of Slab considered for Cal 1000 mm

Grade of Concrete M 25

Grade of Steel Fe 415

a= 0.87 *(fy^2/fck) 5993.43

b= -0.87 fy -361.05

c= m= Mu/(bd^2) 1.15

m= Mu/(bd^2) p %= (-b- sqrt(b^2-4ac))/2a At

1.15 0.337 675 Sqmm

Min area of Tension Steel Ao=0.85*bd/fy 409.64 Sqmm

Max area of Tensile Steel = 0.04 bD 9800 Sqmm

Provide Area of Tension Steel 675 Sqmm

Area of One Bar 113.14 Sqmm 12

RESULT Spacing of Main Bars 160 mm 12

Min Area of Steel 0.12 % 294 Sqmm

Check for Min rft OK

Temp rft 0.15 % of gross area will be provided in the longitudinal direction

367.5 Sqmm

INPUT Use 12 mm Dia bars as distribution Rft

Area of One Bar 113.14 Sqmm 12

RESULT Spacing of Distribution Bars 300 mm 12

CURTAILMENT REINFORCEMENT

DEPTH FROM TOP OF EMBANKMENT 3.75 Mtr

AREA OF REINFORCEMENT 337.5 Sqmm

Use Dia of Stem Wall rft 12 mm 20

Area of One Bar 113.14 Sqmm

Spacing of Distribution Bars 320 mm 12

DISTRIBUTION STEEL

DEPTH FROM TOP OF EMBANKMENT 3.75 Mtr

AREA OF REINFORCEMENT 367.5 Sqmm

Use Dia of Stem Wall rft 12 mm 16

Area of One Bar 113.14 Sqmm

Spacing of Distribution Bars 300 mm 12

DESIGN/ CHECK FOR STEM WALL TO RESIST SHEAR

Grade of Concrete M 25

Effective Depth 200 mm

Over allDepth of Slab 245 mm

Dia of Shear rft 12 mm

Area of One Bar 113.14 Sqmm

Spacing of Bars 160 mm

Max Shear Force wL/2 61.35 KN

Percentage of Tensile Steel 100At/2bd = 0.35 %

(at the end, alternate bar are bent up)

Design Shear Strength 0.423 N/ Sqmm

Calculated k Value

INPUT For 245 mm thick slab, k=

Permissible Max Shear Stress 0.466 N/ Sqmm

Nominal Shear stress Vu/bd 0.31 N/ Sqmm

Shear Check Safe

DESIGN OF FRONT COUNTER FORT (OVER TOE) TO RESIST BENDING MOMENT

Length of Front Counter Fort 1.25 Mtr

Earth Pressure at tip of Counter Fort w1 18.78 KN/Sqm

Earth Pressure at Stem of Counter Fort w3 60.30 KN/Sqm

Ht of Front Counterfort Above Base Slab 3.00 Mtr

C/C dist between Counter Fort 3.30 Mtr

Max BM due to Earth Pressure 101.94 KN M 84.10 101.94

Max SF due to Earth Pressure 163.11 KN

Grade of Concrete M 25

Grade of Steel Fe 415

Base width 0.3 Mtr

Max BM Mx 101.94 N-MM

BM = (Const*fck) bd^2 3.444 bd^2

Calculated Eff Depth of Slab 314 mm

RESULT Adopt Effective Depth d 320 mm

INPUT Use Dia of Slab rft 16 mm

Adopt Cover for Slab 50 mm

Over all Depth of Base Slab D 380 mm

Width of Slab considered for Cal 300 mm

Grade of Concrete M 25

Grade of Steel Fe 415

a= 0.87 *(fy^2/fck) 5993.43

b= -0.87 fy -361.05

c= m= Mu/(bd^2) 3.32

m= Mu/(bd^2) p %= (-b- sqrt(b^2-4ac))/2a At

3.32 1.132 1087 Sqmm

Min area of Tension Steel Ao=0.85*bd/fy 196.63 Sqmm

Max area of Tensile Steel = 0.04 bD 4560 Sqmm

Provide Area of Tension Steel 1087 Sqmm

Area of One Bar 201.14 Sqmm 16

RESULT No of Main Bars 6 Nos 16

Min Area of Steel 0.12 % 456 Sqmm

Check for Min rft OK

Temp rft 0.15 % of gross area will be provided in the longitudinal direction

570 Sqmm

INPUT Use 16 mm Dia bars as distribution Rft

Area of One Bar 201.14 Sqmm 16

RESULT Spacing of Distribution Bars 350 mm 16

INPUT Provided Depth of Front Counter Fort 1250 mm 1250

Shear Force at d away from Stem

DESIGN/ CHECK FOR FRONT COUNTER FORT WALL TO RESIST SHEAR

Grade of Concrete M 25

Effective Depth 320 mm

Over allDepth of Slab 380 mm

Dia of Shear rft 16 mm

Area of One Bar 201.14 Sqmm

No of Bars 6 Nos

Max Shear Force wL/2 163.11 KN

Percentage of Tensile Steel 100At/2bd = 1.26 %

(at the end, alternate bar are bent up)

Design Shear Strength 0.697 N/ Sqmm

Calculated k Value

INPUT For 380 mm thick slab, k=

Permissible Max Shear Stress 0.697 N/ Sqmm

Nominal Shear stress Vu/bd 0.51 N/ Sqmm

Shear Check Safe

Provide 10 mm dia 2 legged stirrup at 200 C/C to connect with stem

DESIGN OF REAR COUNTER FORT (OVER HEEL) TO RESIST BENDING MOMENT

Height of Front Counter Fort 7.50 Mtr

Base Widh of Front Counter Fort 3.25 Mtr

Inclination of Counter Fort = 0.4089 Radian 23.43 Degree

Ht of Earth Filling Above GL 7.09 Mtr

Max BM = wh^3*(1-sin)/(1+sin)*3/6 950.96 KN m

SF/HorizThrust wh^2*(1-sin)/(1+sin)*3/2 402.30 KN

Effective depth d= h*sin -cover 2,902 mm

Grade of Concrete M 25

Grade of Steel Fe 415

Base width 0.3 Mtr

Max BM Mx 950.96 N-MM

BM = (Const*fck) bd^2 3.444 bd^2

Calculated Eff Depth of Slab 959 mm 1200

RESULT Adopt Effective Depth d 1200 mm

INPUT Use Dia of Slab rft 20 mm

Adopt Cover for Slab 50 mm

Over all Depth of Base Slab D 1260 mm

Width of Slab considered for Cal 300 mm

Grade of Concrete M 25

Grade of Steel Fe 415

a= 0.87 *(fy^2/fck) 5993.43

b= -0.87 fy -361.05

c= m= Mu/(bd^2) 2.20

m= Mu/(bd^2) p %= (-b- sqrt(b^2-4ac))/2a At

2.20 0.688 2479 Sqmm

Sqmm

Provide Area of Tension Steel 2479 Sqmm

Area of One Bar 314.29 Sqmm 20

RESULT No of Main Bars 8 Nos 20

Min Area of Steel 0.12 % 1512 Sqmm

Temp rft 0.15 % of gross area will be provided in the longitudinal direction

1890 Sqmm

INPUT Use 16 mm Dia bars as distribution Rft

Area of One Bar 201.14 Sqmm 16

RESULT Spacing of Distribution Bars 110 mm 16

DESIGN/ CHECK FOR REAR COUNTER FORT WALL TO RESIST SHEAR

SF/HorizThrust wh^2*(1-sin)/(1+sin)*3/2 402.30 KN

Net SF= F-M*tan /d' 87.21 KN

Grade of Concrete M 25

Effective Depth 1200 mm

Over allDepth of Slab 1260 mm

Dia of Shear rft 20 mm

Area of One Bar 314.29 Sqmm

No of Bars 8 Nos

Max Shear Force wL/2 87.21 KN

Percentage of Tensile Steel 100At/2bd = 0.70 %

(at the end, alternate bar are bent up)

Design Shear Strength 0.559 N/ Sqmm

Calculated k Value

INPUT For 1260 mm thick slab, k=

Permissible Max Shear Stress 0.559 N/ Sqmm

Nominal Shear stress Vu/bd 0.07 N/ Sqmm

Shear Check Safe

Provide 10 mm dia 2 legged stirrup at 200 C/C to connect with stem

Soil Ws KN/Sqm Rg Mean Fr bet soil & wall

Sand 17-20 25-35 30 0.55 29

Medium Clay 16-18 14-28 21 0.4 22

Soft Clay 15-17 4-16 10 0.33 18

D=22*(H/)^(1/4)

T= H/10

B1=(B-Tc)/2

H=

0

Ka= Cos C((Cos C- Sqrt(Cos C^2-Cos ^2))/(Cos C+ Sqrt(Cos C^2-Cos ^2))) = ((1-SIN())/(1+SIN())^2

1/ka

h=SBC/Ws*(1-sin /1+sin )^2

DEPTH=H/4 AND NOT LESS THAN MIN DEPTH/ 1.00Mtr DEPTH OF FDN EXIST. GL

Ht=H+DEPTH

= 1- q0/(2H) =TOE WIDTH/BASE WIDTH

Bm h=

B- Bm-T1

H*(Sqrt((1-sino/1+sino)/(1-k * (3*k+1)))*H Vaz Rat Page 437

B1=(B-Tc)/2, Alpha*B,F32) #VALUE!

GIVE VALUE=0 IF THERE IS NO SURCHARGE D=

0

D=40*L*H^0.5+80

BASE SLAB THICKNESS

T=Ht/10 to H/15 0 # @

WALL THICKNESS AT BOT 0 mm c/c

Th at Top T2 = T1 /2 WALL THICKNESS AT TOP

25 # @

0 mm c/c

W1=B*D*25 (TO RESIST VERTICAL UP PR)

W2=(T1)*(H-D)*25

W3=(T2-T1)/2*(H-D)*25

W4=ALPHA*B*(Ht-D)*Ws+Ps*ALPHA*

AXIAL LOAD FROM COLUMN IN LINE WITH RETAING WALL

W=W1+W2+W3+W4

P1=Ka*Ws*Ht*Ht/2 NAME FORCE LVR ARM MOM @ Toe ALL DIMENSIONS ARE IN MILLIMETRES

Ps=ps*Ht W1 48.53 2.38 115.25

GENERALLY B=0.5H TO 0.6H AND NOT LESS THAN B(MIN) REF PUNMIA PP 857

(WHERE WATER TABLE IS BELOW BASE OF FOOTING)

(Ex 15.4 RCC by BC Punmia & Ex 12.5 Vazrani and Ratwani)

RCC COUNTERFORT RETAINING WALL (HT ABOVE 6 MTR) INCL COLUMN LOAD IN LINE

#VALUE!

W2 44.32 1.38 60.94

X1=B/2 W3 0.00 1.40 0.00

ALPHA*B+T1/2 W4 371.05 3.33 1234.04

ALPHA*B+T1+(T2-T1)/3 W5 0.00 1.38 0.00

X3=B-ALPHA*B/2 W 463.90 3.04 1410.22

Ph 150.12 2.36 354.86

Y1=Ht/3 Ps 50.29 3.55 178.30

Y2=Ht/2 V 200.41 2.66 533.16

W1*X1+W2*X2+W3*X3/(V ) R 505.34 1.74 877.06

R=V*V+H*H

X=(W1*X1+W2*X2+W3*X3+Ph*Y1+Ps*Y2)/R

e=X-B/2 (- SIGN FOR RESULTANT FORCE AWAY TO HEAL SIDE OF STEM SLAB) CHECK Pmax < SBC

Pmax=W/B(1+6*e/B) CHECK Pmin>O

Pmin=W/B(1-6*e/B)

CHECK FOS>1.5

CHECK FOS>1.5

FOS=(W1*X1+W2*X2+W3*X3)/(P*Y1+Ps*Y2)

FOS=u*W/(Ph+Ps)

FROM IS 456 TABLE FOR M25= 0.29/MM2 FOR M30=0.29N/MM2

THICKNESS OF KEY=(P+Ps)*1.5/Tc SHEAR KEY THICK

Max Shear Stress

Grade of Concrete M 25

Max SS N/Sqmm 3.1

fck 25

Design Shear Strength

d=D-COVER 100 As/bd SS N/Sqmm

L1=B-B2-T 0.20 14.51 0.331

W4=D*25

Mt=(W4+Pmax)*L1*L1/2

V=(Pmax*(L1-d))*1.5

Max Depth of Nutral Axis

fy Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm

250 0.53 d H=

415 0.48 d 6.00

500 0.46 d

550 0.44 d

Limiting Moment of resistance MR = Const * b*d^2 N mm

Const= 0.36*fck*Xm(1-0.42*Xm)

Concrete M Fe 250 Fe 415 Fe 500 Fe 550

Steel

15 2.229 2.067 1.991 1.949 EXIST. GL

20 2.972 2.755 2.655 2.598

25 3.715 3.444 3.318 3.248

30 4.458 4.133 3.982 3.897

35 5.201 4.822 4.645 4.547 h=

1.50

D=

0.41

mm Dia

SBC 18.78

mm Dia 200

mm Dia bars as distribution Rft

mm Dia

mm Dia

Max Shear Stress

Grade of Concrete M 25

Max SS N/Sqmm 3.1

fck 25

Design Shear Strength

100 As bd SS N/Sqmm

0.22 13.41 0.342

N/ Sqmm

1.00 Value of K

1.00 Ds >300 275 250 225 200 175 <151

k 1.00 1.05 1.10 1.15 1.20 1.25 1.30

N/ Sqmm

* Shear rft be provided in a slab deeper than 200 mm

1.25

4.75

TOE

12 mm Dia 4 Legs

Min Spacing is 100 mm for placing of Concrete, Max 450 mm

If NOT OK then Increase the size of Rft oa more No of Legs

HL

Wp=(P2+P4)/2

W5=Ws*(Ht-D)

W6=25*D

Mh=Wp+W5+W6)*L2*L2

V=Pheel/2*clear width of counterfort*1.5

Max Depth of Nutral Axis

fy Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm

250 0.53 d

415 0.48 d

500 0.46 d

550 0.44 d

Limiting Moment of resistance MR = Const * b*d^2 N mm

Const= 0.36*fck*Xm(1-0.42*Xm)

Concrete M Fe 250 Fe 415 Fe 500 Fe 550

15 2.229 2.067 1.991 1.949

20 2.972 2.755 2.655 2.598

25 3.715 3.444 3.318 3.248

30 4.458 4.133 3.982 3.897

35 5.201 4.822 4.645 4.547

Steel

mm Dia

mm Dia

mm Dia bars as distribution Rft

mm Dia

mm Dia

Max Shear Stress

Grade of Concrete M 25

Max SS N/Sqmm 3.1

fck 25

Design Shear Strength

100 As bd SS N/Sqmm

0.21 13.55 0.341

N/ Sqmm

1.00 Value of K

1.00 Ds >300 275 250 225 200 175 <151

k 1.00 1.05 1.10 1.15 1.20 1.25 1.30

N/ Sqmm

* Shear rft be provided in a slab deeper than 200 mm

10 mm Dia 2 Legs

Min Spacing is 100 mm for placing of Concrete, Max 450 mm

If NOT OK then Increase the size of Rft oa more No of Legs

L3=Ht-D

Ka ** H *Cos c

Mw=Ph* L^2/8

V=Ph*L/2

Max Depth of Nutral Axis

fy Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm

250 0.53 d

415 0.48 d

500 0.46 d

550 0.44 d

Limiting Moment of resistance MR = Const * b*d^2 N mm

Const= 0.36*fck*Xm(1-0.42*Xm)

Concrete M Fe 250 Fe 415 Fe 500 Fe 550

15 2.229 2.067 1.991 1.949

20 2.972 2.755 2.655 2.598

25 3.715 3.444 3.318 3.248

30 4.458 4.133 3.982 3.897

35 5.201 4.822 4.645 4.547

mm Dia

mm Dia

Steel

mm Dia bars as distribution Rft

mm Dia

mm Dia

mm Dia

mm Dia

Max Shear Stress

Grade of Concrete M 25

Max SS N/Sqmm 3.1

fck 25

Design Shear Strength

100 As bd SS N/Sqmm

0.35 8.21 0.423

N/ Sqmm

1.10 Value of K

1.10 Ds >300 275 250 225 200 175 <151

k 1.00 1.05 1.10 1.15 1.20 1.25 1.30

N/ Sqmm

* Shear rft be provided in a slab deeper than 200 mm

Max Depth of Nutral Axis

fy Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm

250 0.53 d

415 0.48 d

500 0.46 d

550 0.44 d

Limiting Moment of resistance MR = Const * b*d^2 N mm

Const= 0.36*fck*Xm(1-0.42*Xm)

Concrete M Fe 250 Fe 415 Fe 500 Fe 550

15 2.229 2.067 1.991 1.949

20 2.972 2.755 2.655 2.598

25 3.715 3.444 3.318 3.248

30 4.458 4.133 3.982 3.897

35 5.201 4.822 4.645 4.547

mm Dia

mm Dia

mm Dia bars as distribution Rft

mm Dia

Steel

mm Dia

Max Shear Stress

Grade of Concrete M 25

Max SS N/Sqmm 3.1

fck 25

Design Shear Strength

100 As bd SS N/Sqmm

1.26 2.31 0.697

N/ Sqmm

1.00 Value of K

1.00 Ds >300 275 250 225 200 175 <151

k 1.00 1.05 1.10 1.15 1.20 1.25 1.30

N/ Sqmm

* Shear rft be provided in a slab deeper than 200 mm

Max Depth of Nutral Axis

fy Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm

250 0.53 d

415 0.48 d

500 0.46 d

550 0.44 d

Limiting Moment of resistance MR = Const * b*d^2 N mm

Const= 0.36*fck*Xm(1-0.42*Xm)

Concrete M Fe 250 Fe 415 Fe 500 Fe 550

Steel

15 2.229 2.067 1.991 1.949

20 2.972 2.755 2.655 2.598

25 3.715 3.444 3.318 3.248

30 4.458 4.133 3.982 3.897

35 5.201 4.822 4.645 4.547

mm Dia

mm Dia

mm Dia bars as distribution Rft

mm Dia

mm Dia

Max Shear Stress

Grade of Concrete M 25

Max SS N/Sqmm 3.1

fck 25

Design Shear Strength

100 As bd SS N/Sqmm

0.70 4.16 0.559

N/ Sqmm

1.00 Value of K

1.00 Ds >300 275 250 225 200 175 <151

k 1.00 1.05 1.10 1.15 1.20 1.25 1.30

N/ Sqmm

* Shear rft be provided in a slab deeper than 200 mm

mm KN/M SURCHARGE

MADE UP GL MADE UP GL

t= 0

ANGLE OF SURCHARGE C

0 # @

0 mm c/c

EARTH FILLING SIDE

0 # @

0 mm c/c

0 # @

0 mm c/c

0 # @

#VALUE! 0 mm c/c

0 # @

0 mm c/c

0 # @

0 mm c/c

(TO RESIST VERTICAL DOWN PRESSURE)

0

0 # @

mm 0 mm c/c

mm # @

Sqmm mm c/c

0

(TO RESIST VERTICAL UP PR)

T=

0

B= #VALUE!

ALL DIMENSIONS ARE IN MILLIMETRES

#VALUE! #VALUE!

2.00 KN/M SURCHARGE

MADE UP GL MADE UP GL

W5

0.00

t= 250

ANGLE OF SURCHARGE C

EARTH FILLING SIDE

Ps

50.29

Ph

150.12

W2

44.32

W3 W4

0.00 371.05

R

ecc=

-0.64

0.25

W1

48.53

60.30 68.60 176.54

HEEL

1.25 3.25

4.75

TOE

0 KN/M SURCHARGE

MADE UP GL MADE UP GL

t= 0

ANGLE OF SURCHARGE C

0 # @

0 mm c/c

EARTH FILLING SIDE

H=

0 0 # @

0 mm c/c

0 # @

0 mm c/c

0 # @

EXIST. GL 0 0 mm c/c

0 # @

0 mm c/c

0 # @

h= 0 mm c/c

(TO RESIST VERTICAL DOWN PRESSURE)

0

D= 0

0

0 # @ 0 # @

0 mm c/c 0.00 0 mm c/c

0 # @

0 # @ 0 mm c/c

0 mm c/c 0

(TO RESIST VERTICAL UP PR)

T=

0

B= 0

ALL DIMENSIONS ARE IN MILLIMETRES

0 0

MADE UP GL

(TO RESIST VERTICAL DOWN PRESSURE)

COUNTERFORT RCC RETAINING WALL

(Ex 14.5 Dhayaratnam, Ex 12.4 Vazirani and Ratwani)

INPUT DATAS

INPUT GRADE OF CONCRETE fck 25 N/mm2

INPUT GRADE OF STEEL f y 415 N/mm2

INPUT ANGLE OF REPOSE OF SOIL 30 DEG

INPUT BULK DENSITY OF SOIL Ws 20 KN/m2

INPUT SOIL SAFE BEARING CAPACITY SBC 200 KN/m2

INPUT ANGLE OF SURCHARGE OF FILL C 0 DEG

INPUT CLEAR SPACING OF COUNTERFORT L 3.00 mtr

INPUT THICKNESS OF COUNTERFORT Tc 0.30 mtr

C/C SPACING OF COUNTERFORT Lc 3.30 mtr

INPUT BASE WIDTH OF FRONT COUNTERFORT B2 2.30 mtr

INPUT HT OF FRONT COUNTERFORT ABOVE BASE SLAB 3.00 mtr

INPUT COEFF OF FRICTION 0.55

COS C 1

COS 0.866

COEFFT Of ACTIVE PRESSURE Ka 0.334

COEFFT Of PASSIVE PRESSURE Kp 2.998

INPUT HEIGHT OF FILLING H 7.5 mtr

MIN DEPTH OF FDN h 1.11 mtr

INPUT PROVIDE DEPTH OF FDN D 1.50 mtr

TOTAL HT OF WALL Ht=H+D 9.00 mtr

CONST (Select FACTOR b from the range ) = 0.427 0.427

CALCULATED BASE WIDTH B(MIN) 5.00 mtr

INPUT PROVIDE BASE WIDTH B 5.00 mtr

BASE WIDTH OF REAR COUNTERFORT B1 2.40 mtr

INPUT SURCHARGE ps 0 KN/m

BASE SLAB THICK D(MIN) 450 mm

INPUT PROVIDE BASE SLAB THICK D 450 mm

WALL THICK AT BOTTOM T(MIN) 300 mm

INPUT PROVIDE WALL THICK AT BOTTOM T1 300 mm

INPUT PROVIDE WALL THICK AT TOP T2 150 mm

CHECK FOR BEARING PRESSURE

WT OF BASE SLAB/FOOTING W1 185.63 KN

WT OF STEM/ WALL W2 158.71 KN

WT OF REAR COUNTERFORT Wcf1 76.95 KN

WT OF FRONT COUNTERFORT Wcf2 25.88 KN

WT OF REAR SOIL OVER HEEL W3 1231.20 KN

TOTAL STABILISING VERTICAL FORCE V OVER C/C CF DIST 1678.36 KN

HORIZONTAL EARTH PRESSURE Ph 731.47 KN

HORIZONTAL SURCHARGE Ps 0.00 KN

TOTAL HORIZONTAL PRESSURE 731.47

DISTANCE OF W1 FROM TOE TIP X1 2.50 mtr

DISTANCE OF W2 FROM TOE TIP X2 2.45 mtr

DISTANCE OF Wcf1 FROM TOE TIP Xcf1 3.40 mtr

DISTANCE OF Wcf2 FROM TOE TIP Xcf2 1.53 mtr

DISTANCE OF W3 FROM TOE TIP X3 3.40 mtr

TOTAL MOMENT DUE TO VERT FORCE @ TOE TIP 5340.29 KN-mtr

DIST OF RESULTANT VERT FORCE FROM TOE TIP 3.18 mtr

HORIZONTAL EARTH PRESSURE Ph 731.47 KN

HORIZONTAL SURCHARGE Ps 0.00 KN

TOTAL HORIZONTAL PRESSURE 731.47

VERT HT OF HORT FORCE Y1 ABOVE BASE SLAB 2.85 mtr

VERT HT OF SUR FORCE Y2 ABOVE BASE SLAB 4.28 mtr

TOTAL MOMENT DUE TO HORI FORCE @ WALL BOTTOM 2084.70 KN-mtr

NET MOMENT ABOUT TOE 3255.59 KN-mtr

CALCULATION OF EARTH PRESSURE

Co eff = (base*c/c butress dist/2) FOR p1 8.25

Co eff = (base*c/c butress dist/2) FOR p2 8.25

DIST FROM TIP OF TOE FOR SOIL REACTION P1 1.67

DIST FROM TIP OF TOE FOR SOIL REACTION P2 3.33

NET SOIL REACTION CO EFF 8.25

NET MOMENT DUE TO SOIL REACTION CO EFF 13.75

SOIL PRESSURE P1 236.77

SOIL PRESSURE P2 33.33

SOIL PRESSURE P3 206.78

SOIL PRESSURE P4 210.24

DIST OF RESULTANT VERT FORCE FROM TOE TIP 3.18 mtr

CALCULATION OF EARTH PRESSURE

RESULTANT FORCES R=SQRT(H^2+V^2) 1830.83 KN

DIST OF RESULTANT FORCE FROM TOE TIP X 1.78 m

ECCENTRICITY e 0.72 m

` MAX PRESSURE Pmax (P1) 128.42 KN/m2

MIN PRESSURE Pmin(P2) 75.02 KN/m2

PRESSURE BELOW LEFT SIDE OF STEM WALL P3 94.48 KN/m2

PRESSURE BELOW RIGHT SIDE OF STEM WALL P4 92.23 KN/m2

FOS AGAINST OVERTURNING 2.56

FOS AGAINST SLIDING 1.26

IF FOS<1.5 PROVIDE SHEAR KEY

OR INCREASE WIDTH OF FDN

DESIGN OF SHEAR KEY

INPUT PERMISSIBLE SHEAR STRESS Tc 0.33 N/mm2

THICKNESS OFKEY 1110 mm

DEPTH OF KEY 1.05 m

KEY REINFORCEMENT 1332 mm2

INPUT PROVIDE DIA OF STEEL BAR 10 mm

SPACING OF BARS 50 mm

For Toe Slab For Heel Slab For Stem Wall

Length L= 3.00 3.00 3.00

Height h= 2.30 2.40 8.55

h/L ratio 0.767 0.800 2.850

Constants 1 2

For Toe Slab Copy Values from Table -0.054 -0.044

For Heel Slab Copy Values from Table -0.053 -0.051

For Stem Wall Copy Values from Table

CRITICAL MOMENTS IN TOE, HEAL AND THE STEM WALL SLABS (IN KN-M/M)

DUE TO W W*L^2

(KN-M) (KN-M/M)

TOE SLAB (MOMENT CAUSING TENSION ON THE BOTTOM FASE IS CONSIDERED AS POSSITIVE)

UDL -128.42 -1155.75

TRIANGLE 53.40 480.57

TOTAL

HEEL SLAB (MOMENT CAUSING TENSION ON THE BOTTOM FASE IS CONSIDERED AS POSSITIVE)

UDL -100.65 -905.86

TRIANGLE 75.02 675.18

TOTAL

VERTICAL WALL SLAB

TRIANGLE 57.03 513.31

DESIGN OF TOE SLAB

EFFECTIVE DEPTH OF TOE d 375 mm

SPAN OF TOE L1 1.85 m

WT OF FOOTING W4 11.25 KN/m

MAX BM AT BASE OF TOE Mt 90.15 KN-m

SHEAR FORCE Vmax 259.23 KN

DESIGN OF TOE SLAB TO RESIST BENDING MOMENT

Grade of Concrete M 25

Grade of Steel Fe 415

Base width 1.0 Mtr

Max BM Mx 90.15 KN-M

BM = (Const*fck) bd^2 3.444 bd^2

Calculated Eff Depth of Slab 162 mm

RESULT Adopt Effective Depth d 370 mm

INPUT Use Dia of Slab rft 12 mm

Adopt Cover for Slab 75 mm

Over all Depth of Base Slab D 450 mm

Width of Slab considered for Cal 1000 mm

Grade of Concrete M 25

Grade of Steel Fe 415

a= 0.87 *(fy^2/fck) 5993.43

b= -0.87 fy -361.05

c= m= Mu/(bd^2) 0.66

m= Mu/(bd^2) p %= (-b- sqrt(b^2-4ac))/2a At

0.66 0.188 697 Sqmm

Min area of Tension Steel Ao=0.85*bd/fy 757.83 Sqmm

Max area of Tensile Steel = 0.04 bD 18000 Sqmm

Provide Area of Tension Steel 758 Sqmm

Area of One Bar 113.14 Sqmm

RESULT Spacing of Main Bars 150 mm

Min Area of Steel 0.12 % 540 Sqmm

Check for Min rft OK

Temp rft 0.15 % of gross area will be provided in the longitudinal direction

675 Sqmm

INPUT Use 12 mm Dia bars as distribution Rft

Area of One Bar 113.14 Sqmm

RESULT Spacing of Distribution Bars 170 mm

DESIGN/ CHECK FOR TOE SLAB TO RESIST SHEAR

Grade of Concrete M 25

Effective Depth 370 mm

Over allDepth of Slab 450 mm

Dia of Shear rft 12 mm

Area of One Bar 113.14 Sqmm

Spacing of Bars 150 mm

Max Shear Force wL/2 259.23 KN

Percentage of Tensile Steel 100At/2bd = 0.20

(at the end, alternate bar are bent up)

Design Shear Strength 0.334

Calculated k Value

INPUT For 450 mm thick slab, k=

Permissible Max Shear Stress 0.334

Nominal Shear stress Vu/bd 0.70

Shear Check Un safe

DESIGN OF HEELSLAB

SPAN OF HEEL L2 2.13 M

PRESSURE AT HEEL Wp 98 KN/m2

WT OF SOIL OVER HEEL W5 171 KN/m

WT OF HEEL W6 11 KN/m

MAX BM AT HEEL Mh 73 KN-m

SHEAR FORCE Vmax 223.47 KN

DESIGN OF HEEL SLAB TO RESIST BENDING MOMENT

Grade of Concrete M 25

Grade of Steel Fe 415

Base width 1.0 Mtr

Max BM Mx 73.37 KN-M

BM = (Const*fck) bd^2 3.444 bd^2

Calculated Eff Depth of Slab 146 mm

RESULT Adopt Effective Depth d 400 mm

INPUT Use Dia of Slab rft 12 mm

Adopt Cover for Slab 50 mm

Over all Depth of Base Slab D 455 mm

Width of Slab considered for Cal 1000 mm

Grade of Concrete M 25

Grade of Steel Fe 415

a= 0.87 *(fy^2/fck) 5993.43

b= -0.87 fy -361.05

c= m= Mu/(bd^2) 0.46

m= Mu/(bd^2) p %= (-b- sqrt(b^2-4ac))/2a At

0.46 0.130 520 Sqmm

Min area of Tension Steel Ao=0.85*bd/fy 819.28 Sqmm

Max area of Tensile Steel = 0.04 bD 18200 Sqmm

Provide Area of Tension Steel 819 Sqmm

Area of One Bar 113.14 Sqmm

RESULT Spacing of Main Bars 140 mm

Min Area of Steel 0.12 % 546 Sqmm

Check for Min rft OK

Temp rft 0.15 % of gross area will be provided in the longitudinal direction

682.5 Sqmm

INPUT Use 12 mm Dia bars as distribution Rft

Area of One Bar 113.14 Sqmm

RESULT Spacing of Distribution Bars 170 mm

DESIGN/ CHECK FOR HEEL SLAB TO RESIST SHEAR

Grade of Concrete M 25

Effective Depth 400 mm

Over allDepth of Slab 455 mm

Dia of Shear rft 12 mm

Area of One Bar 113.14 Sqmm

Spacing of Bars 140 mm

Max Shear Force wL/2 223.47 KN

Percentage of Tensile Steel 100At/2bd = 0.20

(at the end, alternate bar are bent up)

Design Shear Strength 0.332

Calculated k Value

INPUT For 455 mm thick slab, k=

Permissible Max Shear Stress 0.332

Nominal Shear stress Vu/bd 0.56

Shear Check Un safe

DESIGN OF STEM WALL

SPAN OF WALL L3 8.70 M

MAX BM AT BOTTOM OF WALL Mw 20.53 KN-m

SHEAR FORCE Vmax 731.47 KN

DESIGN OF STEM WALL TO RESIST BENDING MOMENT

Grade of Concrete M 25

Grade of Steel Fe 415

Base width 1.0 Mtr

Max BM Mx 20.53 KN-M

BM = (Const*fck) bd^2 3.444 bd^2

Calculated Eff Depth of Stem 77 mm

RESULT Adopt Effective Depth d 600 mm

INPUT Use Dia of Stem rft 12 mm

Adopt Cover for Stem 50 mm

Over all Depth of Stem D 655 mm

Width of Stem considered for Cal 1000 mm

Grade of Concrete M 25

Grade of Steel Fe 415

a= 0.87 *(fy^2/fck) 5993.43

b= -0.87 fy -361.05

c= m= Mu/(bd^2) 0.06

m= Mu/(bd^2) p %= (-b- sqrt(b^2-4ac))/2a At

0.06 0.016 96 Sqmm

Min area of Tension Steel Ao=0.85*bd/fy 1228.92 Sqmm

Max area of Tensile Steel = 0.04 bD 26200 Sqmm

Provide Area of Tension Steel 1229 Sqmm

Area of One Bar 113.14 Sqmm

RESULT Spacing of Main Bars 90 mm

Min Area of Steel 0.12 % 786 Sqmm

Check for Min rft OK

Temp rft 0.15 % of gross area will be provided in the longitudinal direction

982.5 Sqmm

INPUT Use 8 mm Dia bars as distribution Rft

Area of One Bar 50.29 Sqmm

RESULT Spacing of Distribution Bars 50 mm

DESIGN/ CHECK FOR STEM WALL TO RESIST SHEAR

Grade of Concrete M 25

Effective Depth 600 mm

Over all Depth of Stem 655 mm

Dia of Shear rft 12 mm

Area of One Bar 113.14 Sqmm

Spacing of Bars 90 mm

Max Shear Force wL/2 731.47 KN

Percentage of Tensile Steel 100At/2bd = 0.20

(at the end, alternate bar are bent up)

Design Shear Strength 0.334

Calculated k Value

INPUT For 655 mm thick slab, k=

Permissible Max Shear Stress 0.334

Nominal Shear stress Vu/bd 1.22

Shear Check Un safe

DESIGN OF FRONT COUNTER FORT TO RESIST BENDING MOMENT

Length of Front Counter Fort 2.3 Mtr

Earth Pressure at tip of Counter Fort w1 182 KN/Sqm

Earth Pressure at Stem of Counter Fort w3 82.7 KN/Sqm

Ht of Front Counterfort Above Base Slab 1.05 Mtr

C/C dist between Counter Fort 3.30 Mtr

Max BM due to Earth Pressure 1299.67 KN M

Grade of Concrete M 25

Grade of Steel Fe 415

Base width 0.3 Mtr

Max BM Mx 1299.67 N-MM

BM = (Const*fck) bd^2 3.444 bd^2

Calculated Eff Depth of Slab 1122 mm

RESULT Adopt Effective Depth d 1130 mm

INPUT Use Dia of Slab rft 25 mm

Adopt Cover for Slab 50 mm

Over all Depth of Base Slab D 1195 mm

Width of Slab considered for Cal 300 mm

Grade of Concrete M 25

Grade of Steel Fe 415

a= 0.87 *(fy^2/fck) 5993.43

b= -0.87 fy -361.05

c= m= Mu/(bd^2) 3.39

m= Mu/(bd^2) p %= (-b- sqrt(b^2-4ac))/2a At

3.39 1.165 3950 Sqmm

Min area of Tension Steel Ao=0.85*bd/fy 694.34 Sqmm

Max area of Tensile Steel = 0.04 bD 14340 Sqmm

Provide Area of Tension Steel 3950 Sqmm

Area of One Bar 491.07 Sqmm

RESULT No of Main Bars 9 Nos

Min Area of Steel 0.12 % 1434 Sqmm

Check for Min rft OK

Temp rft 0.15 % of gross area will be provided in the longitudinal direction

1792.5 Sqmm

INPUT Use 16 mm Dia bars as distribution Rft

Area of One Bar 201.14 Sqmm

RESULT Spacing of Distribution Bars 110 mm

INPUT Provided Depth of Front Counter Fort 1250 mm 1250

Shear Force at d away from Stem

DESIGN/ CHECK FOR REAR COUNTER FORT WALL TO RESIST SHEAR

SF/HorizThrust 1004.54 KN

Net SF= F-M*tan /d' 479.47 KN

Grade of Concrete M 25

Effective Depth 1130 mm

Over allDepth of Slab 1195 mm

Dia of Shear rft 25 mm

Area of One Bar 491.07 Sqmm

No of Bars 9 Nos

Max Shear Force wL/2 479.47 KN

Percentage of Tensile Steel 100At/2bd = 1.30

(at the end, alternate bar are bent up)

Design Shear Strength 0.707

Calculated k Value

INPUT For 1195 mm thick slab, k=

Permissible Max Shear Stress 0.707

Nominal Shear stress Vu/bd 0.42

Shear Check Safe

Provide 10 mm dia 2 legged stirrup at 200 C/C to connect with stem

DESIGN OF REAR COUNTER FORT TO RESIST BENDING MOMENT

Height of Front Counter Fort 9.00 Mtr

Base Widh of Front Counter Fort 2.30 Mtr

Inclination of Counter Fort = 0.2502 Radian 14.34

Ht of Earth Filling Above GL 7.5 Mtr

Max BM = wh^3*(1-sin)/(1+sin)*3/6 1406.27 KN m

SF/HorizThrust wh^2*(1-sin)/(1+sin)*3/2 562.51 KN

Grade of Concrete M 25

Grade of Steel Fe 415

Base width 0.3 Mtr

Max BM Mx 1406.27 N-MM

BM = (Const*fck) bd^2 3.444 bd^2

Calculated Eff Depth of Slab 1167 mm

RESULT Adopt Effective Depth d 1170 mm

INPUT Use Dia of Slab rft 25 mm

Adopt Cover for Slab 50 mm

Over all Depth of Base Slab D 1235 mm

Width of Slab considered for Cal 300 mm

Grade of Concrete M 25

Grade of Steel Fe 415

a= 0.87 *(fy^2/fck) 5993.43

b= -0.87 fy -361.05

c= m= Mu/(bd^2) 3.42

m= Mu/(bd^2) p %= (-b- sqrt(b^2-4ac))/2a At

3.42 1.179 4140 Sqmm

Sqmm

Provide Area of Tension Steel 4140 Sqmm

Area of One Bar 491.07 Sqmm

RESULT No of Main Bars 9 Nos

Min Area of Steel 0.12 % 1482 Sqmm

Temp rft 0.15 % of gross area will be provided in the longitudinal direction

1852.5 Sqmm

INPUT Use 16 mm Dia bars as distribution Rft

Area of One Bar 201.14 Sqmm

RESULT Spacing of Distribution Bars 110 mm

DESIGN/ CHECK FOR REAR COUNTER FORT WALL TO RESIST SHEAR

SF/HorizThrust wh^2*(1-sin)/(1+sin)*3/2 562.51 KN

Net SF= F-M*tan /d' 264.91 KN

Grade of Concrete M 25

Effective Depth 1170 mm

Over allDepth of Slab 1235 mm

Dia of Shear rft 25 mm

Area of One Bar 491.07 Sqmm

No of Bars 9 Nos

Max Shear Force wL/2 264.91 KN

Percentage of Tensile Steel 100At/2bd = 1.26

(at the end, alternate bar are bent up)

Design Shear Strength 0.698

Calculated k Value

INPUT For 1235 mm thick slab, k=

Permissible Max Shear Stress 0.698

Nominal Shear stress Vu/bd 0.23

Shear Check Safe

Provide 10 mm dia 2 legged stirrup at 200 C/C to connect with stem

COUNTERFORT RCC RETAINING WALL

(Ex 14.5 Dhayaratnam, Ex 12.4 Vazirani and Ratwani)

Soil Ws KN/Sqm Rg Mean Fr bet soil & wall

Sand 17-20 25-35 30 0.55 29

Medium Clay 16-18 14-28 21 0.4 22

Soft Clay 15-17 4-16 10 0.33 18

0.3 T= H/10

B1=(B-Tc)/2

Ka= Cos C((Cos C- Sqrt(Cos C^2-Cos ^2))/(Cos C+ Sqrt(Cos C^2-Cos ^2)))

h=SBC/Ws*(1-sin /1+sin )^2

1.20 DEPTH=H/3 AND NOT LESS THAN MIN DEPTH/ 1.20Mtr DEPTH OF FDN

Ht=H+DEPTH

0.487 =0.36*(SQRT(1+(3.4*SBC)/(Ws*Ht))-1) TO 0.45*(SQRT(1+(3*SBC)/(Ws*Ht))-1 =HEEL WIDTH/BASE WIDTH

B=0.5*Ht*SQRT(Ka/((1-0.55*))

3.00 GENERALLY B=Ht/3 AND NOT LESS THAN B(MIN)

2.40 B1=(B-Tc)/2, Alpha*B,F32)

GIVE VALUE=0 IF THERE IS NO SURCHARGE

T=Ht/20 to H/30

200 BASE SLAB THICKNESS

T=Ht/30 to H/40

250 WALL THICKNESS AT BOT

125 Th at Top T2 = T1/2 WALL THICKNESS AT TOP

W1=B*D*Lc*25

W2=(T1+T2)/2*(H-D)*Lc*25

Wcf1= Hcf*Tc*B1*25/2

Wcf2= Hcf*Tc*B2*25/2

W3=ALPHA*B*(Ht-D)*Ws+Ps*ALPHA*

3.30 W=W1+W2+W3

P1=Ka*Ws*Ht*Ht/2*L

Ps=ps*Ht*L

Th=Ph+Ps

X1=B/2

X2=Bcf2+T1/2

Xcf1=B2+T1+B1/3

Xcf2=B2*2/3

X3=B2+T1+B1/3

Mh=(W1*X1+W2*X2+W3*X3+Wcf1*XCF1+Wcf2*Xcf2+Ph*Y1+Ps*Y2)

=M/W

P1=Ka*Ws*Ht*Ht/2*L

Ps=ps*Ht*L

Th=Ph+Ps

Y1=Ht/3

Y2=Ht/2

Mv=P1*Y1+P2*Y2

M=Mh-Mv

R=SQRT(V*V+H*H)

X=(W1*X1+W2*X2+W3*X3+Wcf1*XCF1+Wcf2*Xcf2+Ph*Y1+Ps*Y2)/R

e=X-B/2

Pmax=W/B(1+6*e/B) CHECK Pmax < SBC

Pmin=W/B(1-6*e/B) CHECK Pmin>O

FOS=(W1*X1+W2*X2+W3*X3)/(P*Y1+Ps*Y2) CHECK FOS>1.5

FOS=u*W/(Ph+Ps) CHECK FOS>1.5

Max Shear Stress

Grade of Concrete M 25

SHEAR KEY THICK Max SS N/Sqmm 3.1 THICKNESS OF KEY=(P+Ps)*1.5/Tc

fck 25

Design Shear Strength

100 As/bd SS N/Sqmm

0.20 14.51 0.331

3 4 1 2 3 4

0.021 -0.078 -0.026 -0.017 0.008 0.000

0.025 -0.081 -0.020 -0.021 0.010 0.000

-0.029 -0.040 0.021 0.000

CRITICAL MOMENTS IN TOE, HEAL AND THE STEM WALL SLABS (IN KN-M/M)

AT BASE

1 or 1 M1 2 or 2 M2 3 or 3 M3 4 or 4 M4

TOE SLAB (MOMENT CAUSING TENSION ON THE BOTTOM FASE IS CONSIDERED AS POSSITIVE)

-0.054 62.41 -0.044 50.85 0.021 -24.27 -0.078 90.15

-0.026 -12.49 -0.017 -8.17 0.008 3.84 0.000 0.00

49.92 42.68 -20.43 90.15

HEEL SLAB (MOMENT CAUSING TENSION ON THE BOTTOM FASE IS CONSIDERED AS POSSITIVE)

-0.053 48.01 -0.051 46.20 0.025 -22.65 -0.081 73.37

-0.020 -13.50 -0.021 -14.18 0.010 6.75 0.000 0.00

34.51 32.02 -15.89 73.37

-0.029 -14.89 -0.040 -20.53 0.021 10.78 0.000 0.00

14.89 20.53 10.78 0.00

d=D-COVER

L1=B-B2-T

W4=D*25

Mt=(W4+Pmax)*L1*L1/2

V=(Pmax*(L1-d))*1.5

Max Depth of Nutral Axis

fy Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm

250 0.53 d

369 415 0.48 d

500 0.46 d

550 0.44 d

Limiting Moment of resistance MR = Const * b*d^2 N mm

Const= 0.36*fck*Xm(1-0.42*Xm)

MIDDLE HT TOP MIDDLE POINT

Concrete M Fe 250 Fe 415 Fe 500 Fe 550

15 2.229 2.067 1.991 1.949

20 2.972 2.755 2.655 2.598

25 3.715 3.444 3.318 3.248

30 4.458 4.133 3.982 3.897

35 5.201 4.822 4.645 4.547

12 mm Dia

12 mm Dia

mm Dia bars as distribution Rft

12 mm Dia

12 mm Dia

Max Shear Stress

Grade of Concrete M 25

Max SS N/Sqmm 3.1

fck 25

Design Shear Strength

100 As bd SS N/Sqmm

0.20 14.24 0.334

%

N/ Sqmm

Calculated k Value 1.00 Value of K

mm thick slab, k= 1.00 Ds >300 275 250 225 200 175

k 1.00 1.05 1.10 1.15 1.20 1.25

N/ Sqmm

* Shear rft be provided in a slab deeper than 200 mm

N/ Sqmm

Steel

L2=ALPHA*B

Wp=Pmin+(Pmax-Pmin)*alpha

W5=Ws*(Ht-D)

W6=25*D

Mh=Wp+W5+W6)*L2*L2

V=(Pheel*(L2-d))*1.5

Max Depth of Nutral Axis

fy Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm

250 0.53 d

394 415 0.48 d

500 0.46 d

550 0.44 d

Limiting Moment of resistance MR = Const * b*d^2 N mm

Const= 0.36*fck*Xm(1-0.42*Xm)

Concrete M Fe 250 Fe 415 Fe 500 Fe 550

15 2.229 2.067 1.991 1.949

20 2.972 2.755 2.655 2.598

25 3.715 3.444 3.318 3.248

30 4.458 4.133 3.982 3.897

35 5.201 4.822 4.645 4.547

12 mm Dia

12 mm Dia

mm Dia bars as distribution Rft

Steel

12 mm Dia

12 mm Dia

Max Shear Stress

Grade of Concrete M 25

Max SS N/Sqmm 3.1

fck 25

Design Shear Strength

100 As bd SS N/Sqmm

0.20 14.37 0.332

%

N/ Sqmm

Calculated k Value 1.00 Value of K

mm thick slab, k= 1.00 Ds >300 275 250 225 200 175

k 1.00 1.05 1.10 1.15 1.20 1.25

N/ Sqmm

* Shear rft be provided in a slab deeper than 200 mm

N/ Sqmm

L3=Ht-D

Mw=KaWs L3*L3+PsL3*L3/2

V=(Pheel*(L2-d))*1.5

Max Depth of Nutral Axis

fy Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm

250 0.53 d

600 415 0.48 d

500 0.46 d

550 0.44 d

Limiting Moment of resistance MR = Const * b*d^2 N mm

Const= 0.36*fck*Xm(1-0.42*Xm)

Concrete M Fe 250 Fe 415 Fe 500 Fe 550

15 2.229 2.067 1.991 1.949

20 2.972 2.755 2.655 2.598

25 3.715 3.444 3.318 3.248

30 4.458 4.133 3.982 3.897

35 5.201 4.822 4.645 4.547

Steel

12 mm Dia

12 mm Dia

mm Dia bars as distribution Rft

8 mm Dia

8 mm Dia

Max Shear Stress

Grade of Concrete M 25

Max SS N/Sqmm 3.1

fck 25

Design Shear Strength

100 As bd SS N/Sqmm

0.20 14.17 0.334

%

N/ Sqmm

Calculated k Value 1.00 Value of K

mm thick slab, k= 1.00 Ds >300 275 250 225 200 175

k 1.00 1.05 1.10 1.15 1.20 1.25

N/ Sqmm

* Shear rft be provided in a slab deeper than 200 mm

N/ Sqmm

Max Depth of Nutral Axis

fy Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm

250 0.53 d

415 0.48 d

500 0.46 d

550 0.44 d

Limiting Moment of resistance MR = Const * b*d^2 N mm

Const= 0.36*fck*Xm(1-0.42*Xm)

Concrete M Fe 250 Fe 415 Fe 500 Fe 550

15 2.229 2.067 1.991 1.949

20 2.972 2.755 2.655 2.598

25 3.715 3.444 3.318 3.248

30 4.458 4.133 3.982 3.897

35 5.201 4.822 4.645 4.547

25 mm Dia

25 mm Dia

mm Dia bars as distribution Rft

16 mm Dia

16 mm Dia

Steel

Max Shear Stress

Grade of Concrete M 25

Max SS N/Sqmm 3.1

fck 25

Design Shear Strength

100 As bd SS N/Sqmm

1.30 2.23 0.707

%

N/ Sqmm

Calculated k Value 1.00 Value of K

mm thick slab, k= 1.00 Ds >300 275 250 225 200 175

k 1.00 1.05 1.10 1.15 1.20 1.25

N/ Sqmm

* Shear rft be provided in a slab deeper than 200 mm

N/ Sqmm

Degree

Max Depth of Nutral Axis

fy Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm

250 0.53 d

0 415 0.48 d

500 0.46 d

550 0.44 d

Limiting Moment of resistance MR = Const * b*d^2 N mm

Const= 0.36*fck*Xm(1-0.42*Xm)

Concrete M Fe 250 Fe 415 Fe 500 Fe 550

15 2.229 2.067 1.991 1.949

20 2.972 2.755 2.655 2.598