Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Inspection Sheet 1

Cargado por

shashi_spmDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Inspection Sheet 1

Cargado por

shashi_spmCopyright:

Formatos disponibles

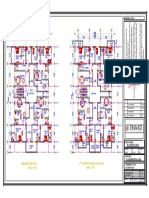

S.NO Drawing No.

1 W.O.1304-Platform at EL +1400

2 W.O.1304-Platform at EL +2400

4 W.O.1304-Platform at EL +3900

5 W.O.1304-Platform at EL +4900

6 W.O.1304-Platform at EL +5300

7 W.O.1304-Platform at EL +5950-I

8 W.O.1304-Platform at EL +5950-II

9 W.O.1303-Platform at EL +6150_a

10 W.O.1304-Platform at EL +6650

11 W.O.1303-Platform at EL +6650_a

12 W.O.1303-Platform at EL +8750 & 9600_a

13 W.O.1303-Platform at EL +8950_a

14 W.O.1303-Platform at EL +10100_a

15 W.O.1303-Platform at EL +12960_a

16 W.O.1303-Platform at EL +15670_a

17 W.O.1303-Platform at EL +16000_a

18 W.O.1304-Platform at EL +16500

19 W.O.1303-Platform at EL +17800_a

20 W.O.1303-Platform at EL +18380_a

21 W.O.1304-Platform at EL +19750

PLATEFORM INSPECTION REPORT

DESCRIPTION TIE MEMBER ANGLE CLIT(tie member)

PLATFORM AT EL. +1400

PLATFORM AT EL. +2400

PLATFORM AT EL. +3900

PLATFORM AT EL. +4900

PLATFORM AT EL. +5300

PLATFORM AT EL. +5950

PLATFORM AT EL. +5950

PLATFORM AT EL. +6150

PLATFORM AT EL. +6650

PLATFORM AT EL. +6650

PLATFORM AT EL. +8750 & 9600

PLATFORM AT EL. +8950

PLATFORM AT EL. +10100

PLATFORM AT EL. +12960

PLATFORM AT EL. +15670

PLATFORM AT EL. +16000

PLATFORM AT EL. +16500

PLATFORM AT EL. +17800

PLATFORM AT EL. +18380

PLATFORM AT EL. +19750

PLATEFORM INSPECTION REPORT

WELDING CHIPPING BRACING(as per drwng) RAILING TOE GUARD

PLATEFORM INSPECTION REPORT

CHEQURED/GRITTING PAINTING REMARKS

plateform extended for staircase lvl+2400 to

lvl+5300

LVL 3900 IS EXTEND FOR DUSTCOLLECTOR

PANEL ROOM

ISMB 400 FROM X2 TO X6 CHANGE TO

&K1 TO X2 ISMB 300 CHANGE TO & plateform

extended for waste sand hopper chute

Extend for head pulley mounting of bc-102

column k11 not required .plateform not

extended to k11

LVL 6650 modified INTO 6800 because of pipe

line and purlin (REF DRAWING NO )

Plateform extended for staircase from

plateform lvl+ 6150 to lvl+ 8950

Extended for gas train

PLATEFORM INSPECTION REPORT

S.NO COLUMN LEVEL +

LVL+ 6000

LVL+ 9500

LVL+ 15450

2 X1 TO X2

3 K1 TO X2 LVL+ 15450

LVL+ 15450

LVL+ 21880

LVL+ 15450

LVL+ 21880

LVL+ 6000

LVL+ 11500

LVL+ 15450

7 X5 TO X6

LVL+ 6000

LVL+ 11500

LVL+ 15450

LVL+ 11500

LVL+ 15450

10 X6 TO X7 LVL+ 21880

11 K7 TO X7 LVL+ 15450

LVL+ 15450

LVL+ 21880

LVL+ 6000

LVL+ 9500

LVL+ 15450

LVL+ 6000

LVL+ 9500

LVL+ 15450

8

9

12

13

14

K6 TO X6

X6 TO K7

X7 TO X8

X1 TO X5

X5 TO OLD PLANT

TIE BEAM BETWEEN COLUMNS

X1 TO K1

X2 TO X3

X3 TO X4

X5 TO K6

1

4

5

6

NO. OF TIE beam (as per drawing) ACTUAL CROSS BRACING ANGLE CLIT

1 NOS

1 NOS

1 NOS

1 NOS

1 NOS

1 NOS 1 NOS

1 NOS

1 NOS 1 NOS

1 NOS

1 NOS

1 NOS

1 NOS

1 NOS

1 NOS

1 NOS

1 NOS

1 NOS

1 NOS

1 NOS 1 NOS

1 NOS

1 NOS

1 NOS

1 NOS

1 NOS

1 NOS

1 NOS

1 NOS

1 NOS

TIE BEAM BETWEEN COLUMNS

WELDING PAINTING REMARKS

TIE BEAM BETWEEN COLUMNS

S.NO ITEM WELDING BOLTING LINER SENSOR PAINTING Remarks

1 RETURN SAND HOPPER 1(H.S)

2 RETURN SAND HOPPER 2(H.S)

3 RETURN SAND HOPPER 3(H.S)

4 RETURN SAND HOPPER 4(H.S)

5 WASTE SAND HOPPER

6 N-GIRDER

7 ST- COLUMNS

HOPPER /N-GIRDER

S.NO HOPPER DEFLECTION (mm)

10 up side

20 up side

20 up side

0 up side

20 up side

10 up side

5 up side

10 up side

20 up side

10 up side

25 up side

10 up side

5 up side

5 up side

5 up side

8 up side

10 up side

8 up side

10 up side

20 up side

20 up side

15 up side

25 up side

5 up side

15 up side

20 up side

20 up side

10 up side

15 up side

15 up side

1

5

Hopper pannel report

Return sand hopper (4)

Return sand hopper (3)

Return sand hopper (2)

Return sand hopper (1)

waste sand hopper

4

3

2

Bottom

Centre

Bottom

Centre

Centre

Bottom

Centre

Bottom

Centre

Bottom

Remarks

Dimension is taken from

1st,3rd,5th vertical channel from

hill side .

Dimension is taken from

1st,3rd,5th vertical channel from

return sand hopper side .

Hopper pannel report

S.NO Check points BC-102 BC-103 BC-112 BC-1 BC-2 BC-5.1 BC-5.2 BC-5.3 BC-5.4 BC-6 BC-7

1 Leveling of conveyor done?

2 Idler Bracket and idler fixed?

3 Return idler bracket and return idler fixed?

4 Snub pulley fixed?

5 Skirt board fixed?

6 Skirting rubber?

7 Grouting runway welded?

8 V-scrapper rubber?

9 Top cover fixed?

10 Rear plate?

11 Discharge Chute fixed?

12 Discharge Hood fixed?

13 Discharge Chute welded?

14 V-plough cylinder fixed?

15 V-plough chute fixed?

16 V- plough rubber fixed?

17 Secondary scraper installed?

18 Primary scrapper installed?

19 Discharge Inspection door fixed?

20 Inspection door handdle fixed?

21 Tail end cover fixed?

22 Safety guard fixed?

23 motor coupling bolt tighten?

24 Gear box oil filled?

25 Hold back pin fixed?

26 Plummer block greasing?

27 Gear motor pad welded?

28 Pull cord installed?

29 Read sensor installed?

Check List for belt conveyors

También podría gustarte

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Btech Leather PDFDocumento22 páginasBtech Leather PDFshashi_spmAún no hay calificaciones

- Subject Description Form: Subject Code Subject Title Credit Value Level Pre-requisite/Co-requisite/Exclusion ObjectivesDocumento2 páginasSubject Description Form: Subject Code Subject Title Credit Value Level Pre-requisite/Co-requisite/Exclusion Objectivesshashi_spmAún no hay calificaciones

- Loramendi Machine Startupstop ChecklistDocumento5 páginasLoramendi Machine Startupstop Checklistshashi_spmAún no hay calificaciones

- Cycle Time (Machinewise)Documento1 páginaCycle Time (Machinewise)shashi_spmAún no hay calificaciones

- Ravinder Kabir ResignationDocumento1 páginaRavinder Kabir Resignationshashi_spmAún no hay calificaciones

- Sachidanand: Carreer ObjecvtiveDocumento2 páginasSachidanand: Carreer Objecvtiveshashi_spmAún no hay calificaciones

- Secret Behind Calculation of Machine Time in SAMDocumento2 páginasSecret Behind Calculation of Machine Time in SAMshashi_spmAún no hay calificaciones

- Module 1 ProjectDocumento14 páginasModule 1 Projectshashi_spmAún no hay calificaciones

- Sandeep Kumar: Carreer ObjecvtiveDocumento3 páginasSandeep Kumar: Carreer Objecvtiveshashi_spmAún no hay calificaciones

- Operation Core Cycle Time (Sec) : Summarry-Eicher 6 Bore BlockDocumento4 páginasOperation Core Cycle Time (Sec) : Summarry-Eicher 6 Bore Blockshashi_spmAún no hay calificaciones

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- UTasker On Preemptive RTOSDocumento2 páginasUTasker On Preemptive RTOSGabi MihailaAún no hay calificaciones

- IStructE CM Exam Report 2012Documento17 páginasIStructE CM Exam Report 2012aAún no hay calificaciones

- Drafting Module 10 Ab 2nd QDocumento20 páginasDrafting Module 10 Ab 2nd QKC JaymalinAún no hay calificaciones

- Mini Project AbstractDocumento4 páginasMini Project Abstractabiswal0% (1)

- Technical Drawing StandardsDocumento20 páginasTechnical Drawing StandardsGeorge Maliaris57% (14)

- Shortnote LabDocumento22 páginasShortnote LabSamiAún no hay calificaciones

- Method Statement For Temporary OpeningDocumento1 páginaMethod Statement For Temporary Openingvaibhav_sparshAún no hay calificaciones

- Heat Load CalculationDocumento3 páginasHeat Load Calculationapi-3728508100% (2)

- Variable Speed Drives: Smart Ideas For Your BusinessDocumento2 páginasVariable Speed Drives: Smart Ideas For Your BusinessSamiYousifAún no hay calificaciones

- LED Solutions Catalogue 2011Documento537 páginasLED Solutions Catalogue 2011stewart_douglas574Aún no hay calificaciones

- Channel and Bolt Fixings: For The Construction IndustryDocumento16 páginasChannel and Bolt Fixings: For The Construction IndustryHany IbrahimAún no hay calificaciones

- Ccna4 7.5.1Documento5 páginasCcna4 7.5.1Mark ManingasAún no hay calificaciones

- Vero Beach Real Estate Ad - DSRE 08112013Documento8 páginasVero Beach Real Estate Ad - DSRE 08112013Sorensen RealtorsAún no hay calificaciones

- Usb ClearDocumento8 páginasUsb ClearDanielsYautibugAún no hay calificaciones

- Geotechnical Analysis of Deep Foundation For Nakheel Tower Using 3D Finite Element ModellingDocumento4 páginasGeotechnical Analysis of Deep Foundation For Nakheel Tower Using 3D Finite Element ModellingAtiq R RafiAún no hay calificaciones

- Example Copy of ETS Service Catalog TemplateDocumento13 páginasExample Copy of ETS Service Catalog TemplateSatish KumarAún no hay calificaciones

- CMS Implementation PlanDocumento16 páginasCMS Implementation PlanpranaypaiAún no hay calificaciones

- Silabus ArcGIS Server TutorialsDocumento2 páginasSilabus ArcGIS Server Tutorialswilly filkosima100% (1)

- How To Identify - Determine The Maximum JVM Heap Size - My NotesDocumento3 páginasHow To Identify - Determine The Maximum JVM Heap Size - My NotesSuresh SaiAún no hay calificaciones

- 04 Reference SpecificationDocumento672 páginas04 Reference SpecificationLin DavidAún no hay calificaciones

- Guide To Smoke Extraction in BuildingsDocumento76 páginasGuide To Smoke Extraction in BuildingsKc Hon100% (2)

- Azen Axial Fan Catalogue1Documento14 páginasAzen Axial Fan Catalogue1Isaac GuijarroAún no hay calificaciones

- Log ForwarderDocumento26 páginasLog ForwarderguitarbaseproAún no hay calificaciones

- NHL-2342N Datasheet VolktekDocumento3 páginasNHL-2342N Datasheet VolktekeravadheshAún no hay calificaciones

- D C B A D C B A: Ground Floor Plan SCALE 1:100 1 3 Architectural Floor Plan SCALE 1:100Documento1 páginaD C B A D C B A: Ground Floor Plan SCALE 1:100 1 3 Architectural Floor Plan SCALE 1:100Ahmed Daahir AdenAún no hay calificaciones

- Order Management Technical TOI READYDocumento25 páginasOrder Management Technical TOI READYGyan SharmaAún no hay calificaciones

- Building A SQL Server Test LabDocumento18 páginasBuilding A SQL Server Test LabFazal Ur Rehman ShahAún no hay calificaciones

- TM N6 C2A SUI 25042017 (002) - Arch 0523Documento75 páginasTM N6 C2A SUI 25042017 (002) - Arch 0523leo penaflorAún no hay calificaciones

- CLT USA-Chapter-3 0Documento35 páginasCLT USA-Chapter-3 0Adam BartonAún no hay calificaciones

- RC17 Column1Documento20 páginasRC17 Column1lavyAún no hay calificaciones