Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Belt Grinder Plans V 1

Cargado por

josklxDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Belt Grinder Plans V 1

Cargado por

josklxCopyright:

Formatos disponibles

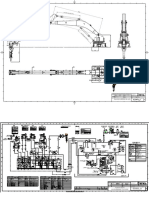

Belt Grinder -Backbone make one

weld together, 4 places

x 2" flat bar

cut a 1/16" x clearance slot the entire length on the inside of the x 2" flat bar tap -20

x 2" flat bar

2.030"

x 2" flat bar

0.530"

x 2" flat bar

file = BeltGrinder1.vsd Created 10/08/2011 Version 10/08/2011

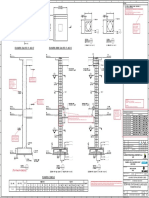

Belt Grinder -Bearing Plate make one

Bearing Plate, 3/8" f;at bar. weld the Backbone to the Bearing Plate

take appropriate steps so that after welding this angle is precisely 90 degrees since it affects belt tracking

drill appropriate pattern to mount two pillow block bearings to the plate

6.000"

7.000"

file = BeltGrinder1.vsd Created 10/08/2011 Version 10/08/2011

Belt Grinder -Tracking Arm Bracket make one

take appropriate steps so that after welding this angle is precisely 90 degrees since it affects belt tracking

drill 0.500" 0.750" weld x 2" flat bar to the frame to form the tracking arm bracket

6.500"

file = BeltGrinder1.vsd Created 10/08/2011 Version 10/08/2011

Belt Grinder -Pedistal make one

1-1/2" square tubing with 3/16" or 1/4" wall

drill and tap square tubing -20, then weld nut over the hole to increase the number of threads weld 1" x 0.250" wall DOM tubing to square tubing.

2.000" 8.000" 33.000"

Belt Grinder -Backbone and Pedistal Assembly make one

weld Backbone to Pedistal

Belt Grinder -Stand make one

10.000"

1- square tubing with 3/16" or wall

electrical switch box

1" square bar

18.000"

10.000"

10.000"

10.000"

file = BeltGrinder1.vsd Created 10/08/2011 Version 10/08/2011

Belt Grinder -Tracking Adjustment Block make one

x 4" flat bar

drill 0.250", 2 places 1.000" 1.000" 1.000" 1.000"

0.500" 0.750"

3.000"

tap 3/8-24

3.500"

file = BeltGrinder1.vsd Created 10/08/2011 Version 10/08/2011

Belt Grinder -Tracking Adjustment Lever make one

drill 0.500" tap -20

weld 1/2" x 1- flat bar to Tracking Adjustment Block

1.500" 8.000"

file = BeltGrinder1.vsd Created 10/08/2011 Version 10/08/2011

Belt Grinder -Tracking Adjustment Arm make one

1.125" x 2" flat bar, 2 places drill 0.250" 0.250" weld two pieces together

tap -13

1.500"

3.000"

1.000"

1.000"

file = BeltGrinder1.vsd Created 10/08/2011 Version 10/08/2011

Belt Grinder -Vertical Platen Frame make one

3/8" x 6" flat bar

tap -13, 3 places 3/8" radius, drill 0.750" Tap 3/8-16, 4 places

1/4" radius, drill 0.500"

drill 0.500"

1.250" 2.250"

3.875" 4.250" 5.000" 5.750"

0.750" 1.125" 1.500" 1.750" 2.250" 3.000" 4.000" 6.000"

file = BeltGrinder1.vsd Created 10/08/2011 Version 10/08/2011

Belt Grinder -Tool Rest make one

2.500" cut away this area

3" angle iron with wall

0.750"

0.750" tap -13 then weld a nut over the hole to increase the number of threads

file = BeltGrinder1.vsd Created 10/08/2011 Version 10/08/2011

Belt Grinder -Tool Rest Support Arm make one

round end, 2 places

square bar, 4 places, welded together drill 0.500"

0.750"

2.500" 8.750"

9.500"

file = BeltGrinder1.vsd Created 10/08/2011 Version 10/08/2011

Belt Grinder -Vertical Platen Extension Arm make one

x 2" flat bar tap -13, 2 places

2.500" 21.000"

file = BeltGrinder1.vsd Created 10/08/2011 Version 10/08/2011

Belt Grinder -Platen Clamp make one

3/8" x 1- flat bar drill 0.500", 2 places

2.500"

4.000"

file = BeltGrinder1.vsd Created 10/08/2011 Version 10/08/2011

Belt Grinder -Motor Mount make one

drill 0.375". 4 places 1.750" 0.750"

2.250"

7.000"

x 1" flat bar, 4 places

drill 0.500", 2 places

1.000"

4.875"

6.875"

file = BeltGrinder1.vsd Created 10/08/2011 Version 10/08/2011

Belt Grinder -Vertical Platten Bracket make two

tap -20 and countersink

1.000"

1.50"

1.000"

5.000"

file = BeltGrinder1.vsd Created 10/08/2011 Version 10/08/2011

Belt Grinder -Vertical Platten make one

countersink all the way through, 2 places

6.000"

x 2" flat bar of stainless steel or other wear resistant material 4.250"

1.750"

1.000"

file = BeltGrinder1.vsd Created 10/08/2011 Version 10/08/2011

1.000"

También podría gustarte

- Bob Engnath Knife PatternsDocumento43 páginasBob Engnath Knife Patternsherpaderpadood100% (13)

- Fazendo Canivete PDFDocumento112 páginasFazendo Canivete PDFsibalde67% (3)

- Micro-Lathe Plans (Popular Mechanics)Documento4 páginasMicro-Lathe Plans (Popular Mechanics)sjdarkman1930100% (13)

- Cnc-Build 2x4 CNC Plasma Free PlansDocumento6 páginasCnc-Build 2x4 CNC Plasma Free PlansAxels_Man_Cave73% (11)

- BG-272 Belt Grinder Bill of Materials - R1Documento7 páginasBG-272 Belt Grinder Bill of Materials - R1Leandro Bueno100% (1)

- DavonDocumento1601 páginasDavonPalyyAún no hay calificaciones

- Water Filtration System - Method StatementDocumento7 páginasWater Filtration System - Method Statementsunil_v575% (4)

- Bolt Together 2 X 72 Belt GrinderDocumento27 páginasBolt Together 2 X 72 Belt GrindervianaufgAún no hay calificaciones

- DIY 2x72 Belt Grinder For Knife MakingDocumento4 páginasDIY 2x72 Belt Grinder For Knife MakingJamespagan0% (1)

- Knife Making ProcessDocumento18 páginasKnife Making ProcessPinjaman Peribadi67% (3)

- CNC Plasma 5x10Documento76 páginasCNC Plasma 5x10uguraydemirAún no hay calificaciones

- Blacksmith Knife TutorialDocumento18 páginasBlacksmith Knife TutorialAndre Balen100% (2)

- Make Your Own Bowie KnifeDocumento5 páginasMake Your Own Bowie Knifegoodsharer100% (1)

- Propane Burner DesignDocumento34 páginasPropane Burner DesignCary Brief50% (2)

- Tricking Out HF 9x20 LatheDocumento48 páginasTricking Out HF 9x20 LatheCliff Miller100% (2)

- Lift Table DIY PlansDocumento10 páginasLift Table DIY PlansDrchipbr0% (1)

- Bandmill PlanDocumento14 páginasBandmill Planpaulh1965100% (1)

- Fuji Xerox cp105b Service Manual PDFDocumento2 páginasFuji Xerox cp105b Service Manual PDFSyaf RoniAún no hay calificaciones

- Alien Legacy-Manual PDFDocumento93 páginasAlien Legacy-Manual PDFMark BallingerAún no hay calificaciones

- Fertilizer Industry Wastewater TreatmentDocumento1 páginaFertilizer Industry Wastewater TreatmentAnmol UpadhyayAún no hay calificaciones

- Grinder PlansDocumento21 páginasGrinder Plansmanometro80% (5)

- Grinder PlansDocumento17 páginasGrinder PlansRobert Steven Ciaccio100% (1)

- Knife Grinder - PlansDocumento21 páginasKnife Grinder - PlansRodney SmithAún no hay calificaciones

- How To Make Your Own Belt SanderDocumento34 páginasHow To Make Your Own Belt Sanderpizzolatto100% (7)

- RGR Grinder PDF Plans by Daniel RotblattDocumento18 páginasRGR Grinder PDF Plans by Daniel RotblattFettahAbderrahmaneAún no hay calificaciones

- Sheet Metal Cutter Plan - Metalworking Plans - CraftsmanspaceDocumento17 páginasSheet Metal Cutter Plan - Metalworking Plans - Craftsmanspacear02nbs100% (1)

- Precision PressDocumento4 páginasPrecision PressFrenchwolf420Aún no hay calificaciones

- Backstand EnglishDocumento7 páginasBackstand Englishdennis52100% (1)

- Micro Machine Shop Mods EtcDocumento488 páginasMicro Machine Shop Mods Etcsbarnett38@100% (4)

- 34 Knife DesignDocumento10 páginas34 Knife Designsalenka71100% (1)

- Wooden Knife Handle and SheathDocumento10 páginasWooden Knife Handle and SheathMehmet Emre Bastopcu100% (2)

- Crossbow PlansDocumento4 páginasCrossbow Planssuperscribed75% (4)

- Preview Thread CuttingDocumento21 páginasPreview Thread CuttingAnonymous mKdAfWif33% (3)

- Emco Unimat Lathe AccessoriesDocumento1 páginaEmco Unimat Lathe Accessoriesjose garofanoAún no hay calificaciones

- Building: LatheDocumento60 páginasBuilding: LathePierre799es86% (7)

- Making Folding Knives by Harold Hoffman (Action Book Publishers)Documento78 páginasMaking Folding Knives by Harold Hoffman (Action Book Publishers)vbamain100% (3)

- Step-By-Step Knifemaking by David Boye Hunting Knives Sheaths Etching Metal Grinding How ToDocumento266 páginasStep-By-Step Knifemaking by David Boye Hunting Knives Sheaths Etching Metal Grinding How ToHaze Long100% (5)

- MotorBoys MembersOnly PlanBookDocumento113 páginasMotorBoys MembersOnly PlanBookriofeliz100% (1)

- How To Run A Lathe 1928Documento148 páginasHow To Run A Lathe 1928John Watson50% (2)

- A Small Bench Lathe Made of PipeDocumento2 páginasA Small Bench Lathe Made of PipeCicero Milan100% (3)

- MD Profiler Instruction ManualDocumento11 páginasMD Profiler Instruction ManualTatiana Trenogina100% (1)

- S&W Model 10Documento4 páginasS&W Model 102506223Aún no hay calificaciones

- Lost-Wax Bronzes by Robyn ErbeDocumento66 páginasLost-Wax Bronzes by Robyn Erbebr0nzeyAún no hay calificaciones

- Crossbow Construction 1999Documento5 páginasCrossbow Construction 1999Jerico Lausin100% (1)

- Rust Bluing TutorialDocumento9 páginasRust Bluing TutorialStefan BadicaAún no hay calificaciones

- The Hand Forged Knife - Karl Schroen - 1984 (S)Documento75 páginasThe Hand Forged Knife - Karl Schroen - 1984 (S)Alessandro Urenda100% (6)

- Custom Knifemaking 10 Projects... Tim McCreight PDF (S)Documento219 páginasCustom Knifemaking 10 Projects... Tim McCreight PDF (S)preceptiveinquirer87% (15)

- BlowbackDocumento29 páginasBlowbackposejdon40100% (1)

- 101 Knife Designs - Practical Knives For Daily Use - Carter, Murray PDFDocumento272 páginas101 Knife Designs - Practical Knives For Daily Use - Carter, Murray PDFJd Diaz100% (2)

- Steel: It's Selection, Annealing, Hardening and TemperingDocumento440 páginasSteel: It's Selection, Annealing, Hardening and TemperingArtisan Ideas83% (6)

- Belt Sander 0001Documento5 páginasBelt Sander 0001wienslaw5804Aún no hay calificaciones

- Flour Mill Instruction SheetDocumento13 páginasFlour Mill Instruction SheetM Indra RahmansyahAún no hay calificaciones

- Abrasives: Rotary Files & RaspsDocumento25 páginasAbrasives: Rotary Files & RaspsalejandroAún no hay calificaciones

- Modern Plant Stand PlanDocumento6 páginasModern Plant Stand PlanJorge NavarroAún no hay calificaciones

- Tricking Out Asian 9x20 LatheDocumento48 páginasTricking Out Asian 9x20 Lathearanicki8587Aún no hay calificaciones

- Easy BioGrindDocumento16 páginasEasy BioGrindRenzo DlgAún no hay calificaciones

- Coil Winder Rev 3-19-11Documento17 páginasCoil Winder Rev 3-19-11dougforbes000Aún no hay calificaciones

- Coil WinderDocumento15 páginasCoil Winderkokomore100% (1)

- Notes, Parts List & Drawings: Easy DIY Biomass GrinderDocumento16 páginasNotes, Parts List & Drawings: Easy DIY Biomass GrinderCalfos SaririAún no hay calificaciones

- Farm Equipment Welding PlansDocumento100 páginasFarm Equipment Welding Plansb0beiii100% (4)

- Traditional Picnic TableDocumento13 páginasTraditional Picnic TableRyan Samuel C. CervasAún no hay calificaciones

- Frame Jig Assembly GuideDocumento12 páginasFrame Jig Assembly GuideMalcolm DiamondAún no hay calificaciones

- Frame Saw Manual 1902Documento111 páginasFrame Saw Manual 1902wolf143Aún no hay calificaciones

- Dowel Maker InstructionDocumento12 páginasDowel Maker InstructionKeanu ReavesAún no hay calificaciones

- Voice Recognition Using MatlabDocumento10 páginasVoice Recognition Using MatlabSneha Muralidharan100% (1)

- 327101-BJ81-C-RCC-0007 Rev.00 - Client MarkupDocumento1 página327101-BJ81-C-RCC-0007 Rev.00 - Client MarkupGokulprabhuAún no hay calificaciones

- Taglio Sez Circ 2Documento3 páginasTaglio Sez Circ 2mariorossi_4Aún no hay calificaciones

- UL FM Vertical Indicator Post Maintenance and Operation Manual - Fire Protection - Models 5400 & 5450Documento7 páginasUL FM Vertical Indicator Post Maintenance and Operation Manual - Fire Protection - Models 5400 & 5450Juan Jose Teodoro AguilarAún no hay calificaciones

- VP422 HDTV10A Service Manual PDFDocumento25 páginasVP422 HDTV10A Service Manual PDFDan Prewitt0% (1)

- Building Applied Natural Language GenerationDocumento32 páginasBuilding Applied Natural Language Generationrat86Aún no hay calificaciones

- M3 Hull Plate Nesting - SP1Documento50 páginasM3 Hull Plate Nesting - SP1Bùi Công Lộc100% (1)

- Quadrosense - ManualDocumento22 páginasQuadrosense - ManualdannraduAún no hay calificaciones

- d1 - Evaluation - Justify Content Designs and Formats - FinalDocumento5 páginasd1 - Evaluation - Justify Content Designs and Formats - Finalapi-466034593Aún no hay calificaciones

- QA QC: ApproachDocumento3 páginasQA QC: ApproachSherif EltoukhiAún no hay calificaciones

- Tak Company Profile - 1Documento28 páginasTak Company Profile - 1zacky100% (1)

- Pipe Welding ProceduresDocumento257 páginasPipe Welding ProceduresKhaeril Anwar100% (1)

- VW-Audi Airbag Reset Tool User ManualDocumento14 páginasVW-Audi Airbag Reset Tool User ManualgermantronikAún no hay calificaciones

- Project Management Resume ExampleDocumento2 páginasProject Management Resume ExampleGuino VargasAún no hay calificaciones

- iQ-WEBX 6 2 3 Installation Guide INT EN - 001RDocumento51 páginasiQ-WEBX 6 2 3 Installation Guide INT EN - 001RDoug KolkowAún no hay calificaciones

- pLINES Datasheet FP V2.22Documento2 páginaspLINES Datasheet FP V2.22TrinhDinhLoc0% (1)

- Bcgroup GeniusDocumento9 páginasBcgroup GeniusNenad JovanovicAún no hay calificaciones

- Business Plan: Syeda Zurriat & Aimen RabbaniDocumento11 páginasBusiness Plan: Syeda Zurriat & Aimen RabbanizaraaAún no hay calificaciones

- Mathalino: E N W S G S V V V V V W W W D Γ Γ Γ Γ Γ Γ Γ Γ Ll Pl Li Pi GiDocumento8 páginasMathalino: E N W S G S V V V V V W W W D Γ Γ Γ Γ Γ Γ Γ Γ Ll Pl Li Pi GiLovely Joy ArdanielAún no hay calificaciones

- HSD Area Security GuardDocumento2 páginasHSD Area Security GuardSavita matAún no hay calificaciones

- Automobile Manufacturing Process (17403) : Chapter 1. ForgingDocumento87 páginasAutomobile Manufacturing Process (17403) : Chapter 1. ForgingPramod DhaigudeAún no hay calificaciones

- Gad Ad2 J10k1020c27a 200a201Documento1 páginaGad Ad2 J10k1020c27a 200a201AbdulAún no hay calificaciones

- 023 POL902.00 CB1Q3934en 01 ModBusDocumento4 páginas023 POL902.00 CB1Q3934en 01 ModBusEvandroRodriguesAún no hay calificaciones

- 3 Drill StringDocumento43 páginas3 Drill StringShabaz HazharAún no hay calificaciones

- Modeling Complex Zo For Op AmpsDocumento28 páginasModeling Complex Zo For Op Ampswalid OUNISAún no hay calificaciones