Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Metals 082305 PDF

Cargado por

Adam JensenTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Metals 082305 PDF

Cargado por

Adam JensenCopyright:

Formatos disponibles

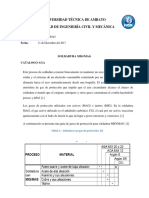

Flowformed Materials

MATERIAL

CATEGORY

Unalloyed

Near Alpha

Alpha-Beta

Alpha-Beta

Near Alpha

Near Alpha

Near Alpha

Beta

Beta

Beta

Austenitic

MATERIAL

Titanium Grade 2

Titanium Grade 9 (Ti 3Al-2.5V)

Ti Grade 5 (Ti 6AL-4V)

Ti Grade 23 (Ti 6Al-4V ELI)

TITANIUM

Titanium 6Al-2Sn-4Zr-2Mo

ATI 425 (Ti 4AL-2.5V)

ATI 425 (Ti 4AL-2.5V)

Titanium Beta C

Titanium Beta C

Ttianium 15-3

304 Stainless

316 Stainless

Nitronic 50

Non-Magnetic

P550

STAINLESS STEEL

Precipitation Hardening

15-5 PH Stainless

17-4 PH Stainless

17-7 PH Stainless

Custom 465

Duplex

Super Duplex 918

Inconel 718

Inconel 718

Waspaloy

NICKEL BASED ALLOY

Nickel 201

Monel 400

Inconel 625

Inconel 825

Chromium-Molybdenum 4130 Steel

4130 Steel

4140 Steel

Nickel-Chromium-Moly.

4340 Steel

STEEL ALLOY

8620 Steel

9310 Steel

Ferritic-Chromium-Alum. Incoloy MA956

Chromium-Vanadium

CRV 6150H Mod.

HF1

Maraging Steel T-250

Maraging Steel C-250

HIGH STRENGTH

Maraging Steel C-300

STEELALLOY

Maraging Steel C-350

Aermet 100

MULTIPHASE ALLOY

MP35N

MAGNESIUM

Magnesium AZ80A

Aluminum 3003

ALUMINUM ALLOY

Aluminum 6061-T9

Aluminum 6061

Aluminum 7075-T6

Zircaloy 4

Zirconium 702, Com. Pure

REFRACTORY ALLOY

Niobium

Columbium 103

Tantalum

Tantalum 10% Tungsten

PRECIOUS METAL

Silver

Copper - Oxygen Free

COPPER BASED ALLOY

Copper Beryllium

Cartridge Brass

Toughmet 3 AT110

BEARING STEEL

52100 Steel

TOOL STEEL

M50 Steel

SPECIFICATION

AMS 4942C

AMS 4944E

AMS 4928P

AMS 4930D

AMS 4975

AMS 4958

AMS 4958

AMS 4914A

AMS 5647G

AMS 5653B

AMS 5764C

Schoeller-Bleck.

AMS 5659F

AMS 5528F

AMS 5643M

UNS S46500

UNS S39277

AMS 5662J

AMS 5662J

AMS 5706J

ASTM B 160

AMS 4675

AMS 5581

ASTM 163

AMS 6350

AMS 6350

AMS 6362

AMS 6414

AMS 6274L

AMS 6260M

UNS S67956

MSRR 6914

AMS 6519A

AMS 6512

AMS 6514D

MIL-S-46850 IV

AMS 6352

AMS 5844

ASTM B107M

AMS 4067H

AMS A 22771

AMS A 22771

AMS QQ A200/11

ASTM B351

ASTM B658

ASTM B394

AMS 7852

AMS 7849

AMS 7846

99.95%

ASTM B42

UNS C17200

UNS C26000

ASTM B 505

ASTM A 295

ASTM A 600

NOMINAL CHEMISTRIES

99.8 Ti

94.5 Ti

90 Ti

90 Ti

86 Ti

92 Ti

92 Ti

75 Ti

75 Ti

76 Ti

19Cr

17Cr

22Cr

19Cr

15Cr

17Cr

17Cr

12Cr

25Cr

52.5Ni

52.5Ni

57 Ni

99Ni

66Ni

61Ni

42Ni

.3C

.3C

.4C

.4C

.2C

.13C

20Cr

.45C

1C

18.5Ni

7.5Co

8.8Co

12Co

13.4Co

35Co

91 Mg

98Al

98 Al

98 Al

90 Al

98.5Zr

99.2Zr

100Nb

90Nb

100Ta

90Ta

99Ag

99.9Cu

98Cu

70 Cu

77Cu

1C

.85C

3Al

6Al

6Al

6Al

4Al

4Al

3Al

3Al

15V

1Mn

1Mn

12.5Ni

19Mn

5Ni

4Ni

7Ni

11Ni

7Ni

19Cr

19Cr

19.5Cr

32Cu

21.5Cr

21.5Cr

.8Cr

.8Cr

.95Cr

.8Cr

.5Cr

1.2Cr

4.5Al

1.4Cr

1.75Mn

3Mo

4.8Mo

4.8Mo

4.8Mo

1.2Mo

35Ni

8.5Al

1Mn

.6 Si

.6 Si

5.5Zn

1.4Sn

2.5V

4V

4V

2Sn

2.5V

2.5V

8V

8V

3Al

10Ni

2.5Mo

.5Mo

3.5Cu

4Cu

3.5Mo

5Nb

5Nb

13Co

9Mo

3Mo

.5Mn

.5Mn

.85Mn

1.83Ni

.55Ni

3.2Ni

.5Ti

.7Mn

.85Si

1.4Ti

18.5Ni

18.5Ni

18.5Ni

11Ni

20Cr

6Zn

1Cu

.2Cu

.2Cu

2.5 Mg

.2Fe

(ELI)

4Zr

1.5Fe

1.5Fe

6Cr

6Cr

3Cr

.5Si

12Ni

2Mo

4Zr

4Zr

3Sn

4Mo

4Mo

.5Si

.6N

.06C

3Mo

3Mo

4Mo

3Ti

2.5Fe

.2Mo

.2Mo

.2Mo

.25Mo

.2Mo

.12Mo

.05C

.3Si

.2Cr

.25Si

.25Si

.25Si

.7Mn .23Si

.5Y

.4Ti

.73Ti

1.4Ti

3Cr

10Mo

1Si

1.6Cu

.1Cr

.12O

10Hf

10W

1.4Ni

28.5Zn

15Ni

.35Mn

4Cr

MATERIAL CONDITION

.4Pb

.3Be

8Sn

.25Si

.35Mn

1.45Cr

4.5Mo 1V

As Flowformed

As Flowformed

As Flowformed

As Flowformed

As Flowformed

As Flowformed

Flowformed & Aged

As Flowformed

FF, Anneal & Aged

As Flowformed

As Flowformed

As Flowformed

As Flowformed

As Flowformed

Flowofrmed & Aged

As Flowformed

As Flowformed

Flowformed & Aged

As Flowformed

FF, Anneal & Aged

As Flowformed

As Flowformed

As Flowformed

As Flowformed

As Flowformed

As Flowformed

As Flowformed

Rc 37 & Flowformed

As Flowformed

Rc 32 & Flowformed

As Flowformed & HT

As Flowofremd & HT

As Flowformed

As Flowformed

As Flowformed & HT

Flowformed & Aged

Flowformed & Aged

Flowformed & Aged

Flowformed & Aged

Flowformed & Aged

As Flowformed

As Flowformed

As Flowformed

T4 & then Flowform

T6 & then Flowform

W, Flowformed & Aged

FF & Stress Relieved

FF & Stress Relieved

Flowofrmed & Annealed

As Flowformed

Flowformed & Annealed

Flowformed & Annealed

As Flowformed

As Flowformed

As Flowformed

As Flowformed

As Flowformed & HT

As Flowformed & HT

As Flowformed & HT

Materials can be post flowformed heat treated differently to alter the mechanical properties from what is shown on the matrix.

.2% YIELD

KSI

110

130

158

163

140

147

175

154

143

189

166

165

165

212

196

153

150

247

198

189

200

130

82

108

130

130

130

185

126

154

81

83

156

187

142

286

275

295

382

250

251

26

20

47

54

77

35

49

20

84

25

70

33

50

190

65

110

UTS,

KSI

124

159

193

186

150

181

180

192

154

206

181

178

178

238

198

185

185

258

232

220

240

185

88

121

150

164

157

212

138

192

108

132

177

203

164

292

280

306

389

270

270

37

25

51

57

86

60

71

35

102

40

90

35

70

215

80

125

ELONG. HARDNESS DENSITY

%

~ RC

LBS/CU"

24

25

0.163

14

35

0.162

14

41

0.162

16

40

0.162

14

32

0.164

14

40

0.162

11

40

0.162

5

41

0.174

14

34

0.174

6

43

0.172

16

34

0.287

15

34

0.287

14

39

0.285

13

45

0.285

10

42

0.282

13

40

0.281

12

40

0.281

10

50

0.283

11

45

0.283

21

46

0.296

10

48

0.296

23

40

0.296

10

18

0.321

17

24

0.318

14

33

0.294

12

34

0.294

14

35

0.284

9

39

0.284

24

30

0.284

15

41

0.284

25

28

0.284

18

27

0.284

6

39

0.262

14

43

0.284

17

32

0.282

5

54

0.289

7

54

0.289

8

55

0.289

3

60+

0.289

11

53

0.285

13

51

0.304

12

0.064

12

0.098

18

0.098

14

0.098

14

0.102

20

0.237

33

0.235

20

0.311

5

0.32

50

0.602

30

0.602

20

0.379

15

0.322

10

44

0.302

10

0.308

10

30

0.323

64

0.282

64

0.288

También podría gustarte

- Tabla de Equivalencia Astm-din-EnDocumento1 páginaTabla de Equivalencia Astm-din-EnxgiorgAún no hay calificaciones

- Corespondente OtelDocumento8 páginasCorespondente Otelsimo96Aún no hay calificaciones

- INSO Fundicion - FoundryDocumento6 páginasINSO Fundicion - Foundryluisx10Aún no hay calificaciones

- ValenciasDocumento1 páginaValenciasbrujula24Aún no hay calificaciones

- Norton DiseñodeMáquinasApéndiceEDocumento8 páginasNorton DiseñodeMáquinasApéndiceEJonathan MendozaAún no hay calificaciones

- OERLIKON - Catálogo General.Documento510 páginasOERLIKON - Catálogo General.Victor Quispe Cosme100% (1)

- Tablas MaterialesDocumento2 páginasTablas MaterialesDouglas E Rivero100% (1)

- Catálogo General de Consumibles para SoldaduraDocumento490 páginasCatálogo General de Consumibles para SoldaduraVictor RodriguesAún no hay calificaciones

- Trabajo Clasificacion Aceros y Fundiciones Segun NormasDocumento11 páginasTrabajo Clasificacion Aceros y Fundiciones Segun NormasPedroAún no hay calificaciones

- Tabla Dureza BulonesDocumento16 páginasTabla Dureza Bulonesfbenitez738Aún no hay calificaciones

- Equivalencias Acero Normas InternacionalesDocumento3 páginasEquivalencias Acero Normas InternacionalesASTRIDCHAún no hay calificaciones

- Apuntes de Identificación de AcerosDocumento1 páginaApuntes de Identificación de Acerosmarco31416Aún no hay calificaciones

- Tabla Equivalencias de Aceros BiltraDocumento4 páginasTabla Equivalencias de Aceros BiltraLUIS BISIERAún no hay calificaciones

- Tabla de Aceros PDFDocumento4 páginasTabla de Aceros PDFMiguel Angel Cejas VillodresAún no hay calificaciones

- Normas y aleaciones de cobre, latón y bronceDocumento1 páginaNormas y aleaciones de cobre, latón y bronceFernando ChavezAún no hay calificaciones

- Metales SoldablesDocumento8 páginasMetales SoldablesTattys Rose100% (1)

- Diccionario de Fórmulas QuímicasDocumento42 páginasDiccionario de Fórmulas QuímicasMiguel André Salinas RevillaAún no hay calificaciones

- Especificaciones AstmDocumento8 páginasEspecificaciones Astmrambo1978Aún no hay calificaciones

- Compuerta API EspDocumento5 páginasCompuerta API EspSQUALO_122Aún no hay calificaciones

- Silo - Tips Valvulas de Compuerta Clase 150Documento5 páginasSilo - Tips Valvulas de Compuerta Clase 150jackmarko castillo rosalesAún no hay calificaciones

- Valvulas Compuerta Api Esp PDFDocumento5 páginasValvulas Compuerta Api Esp PDFJR RZAún no hay calificaciones

- Catalgo de Tornillo y TuercasDocumento131 páginasCatalgo de Tornillo y TuercasAdrian Franco MolinaAún no hay calificaciones

- Ti 6Al-4V (Grade 5)Documento3 páginasTi 6Al-4V (Grade 5)Gregory Alberto Artavia SalazarAún no hay calificaciones

- Calidad 4Documento103 páginasCalidad 4Julia CuellarAún no hay calificaciones

- Catalogo Tecnico Esparragos y BulonesDocumento131 páginasCatalogo Tecnico Esparragos y BulonesDamian LeonardoAún no hay calificaciones

- ASTM A515 Grado 60Documento8 páginasASTM A515 Grado 60guidin89Aún no hay calificaciones

- Tropicalização MateriaisDocumento3 páginasTropicalização MateriaisEvandro Cesário da SilvaAún no hay calificaciones

- Manual de TornillosDocumento6 páginasManual de TornillosMarcos SuárezAún no hay calificaciones

- Ingeniería de procesos siderúrgicos: La experiencia de AHMSADe EverandIngeniería de procesos siderúrgicos: La experiencia de AHMSAAún no hay calificaciones

- Bladesmithing: Secretos del tratamiento térmico de la forja de cuchillosDe EverandBladesmithing: Secretos del tratamiento térmico de la forja de cuchillosAún no hay calificaciones

- Oficios Artísticos. Forja: Las técnicas de la forja explicadas paso a pasoDe EverandOficios Artísticos. Forja: Las técnicas de la forja explicadas paso a pasoCalificación: 5 de 5 estrellas5/5 (1)

- Bladesmithing; Cuchillería a partir de chatarra: Cómo fabricar cuchillos con ballestas, cables, clavos de vías férreas y limasDe EverandBladesmithing; Cuchillería a partir de chatarra: Cómo fabricar cuchillos con ballestas, cables, clavos de vías férreas y limasAún no hay calificaciones

- Reparación de elementos metálicos. TMVL0309De EverandReparación de elementos metálicos. TMVL0309Calificación: 5 de 5 estrellas5/5 (1)

- Quiz 4 - Estática - MEC 151 - 2022-2Documento1 páginaQuiz 4 - Estática - MEC 151 - 2022-2Adam JensenAún no hay calificaciones

- Quiz 1 - Estática - MEC 151 - 2022-1Documento1 páginaQuiz 1 - Estática - MEC 151 - 2022-1Adam JensenAún no hay calificaciones

- Quiz 3 - Estática - MEC 151 - 2022-2Documento1 páginaQuiz 3 - Estática - MEC 151 - 2022-2Adam JensenAún no hay calificaciones

- Descargar PDF SSRDocumento4 páginasDescargar PDF SSRAdam JensenAún no hay calificaciones

- Ayudantia Elementos de MaquinasDocumento9 páginasAyudantia Elementos de MaquinasAdam JensenAún no hay calificaciones

- BasesDocumento37 páginasBasesAdam JensenAún no hay calificaciones

- ParalelizacionDocumento3 páginasParalelizacionAdam JensenAún no hay calificaciones

- Curso Particulasmagneticas2014 PDFDocumento138 páginasCurso Particulasmagneticas2014 PDFAdam JensenAún no hay calificaciones

- Proyecto DEMDocumento10 páginasProyecto DEMAdam JensenAún no hay calificaciones

- Implementación Centro MecatrónicaDocumento5 páginasImplementación Centro MecatrónicaAdam JensenAún no hay calificaciones

- Ruedas DentadasDocumento105 páginasRuedas DentadasAdam JensenAún no hay calificaciones

- Metodo de InteracionDocumento5 páginasMetodo de InteracionAdam JensenAún no hay calificaciones

- Plano General Pescante 500 (KG)Documento1 páginaPlano General Pescante 500 (KG)Adam JensenAún no hay calificaciones

- IMM280 - Ayudatia 12 S1-2015Documento5 páginasIMM280 - Ayudatia 12 S1-2015Adam JensenAún no hay calificaciones

- PernosDocumento6 páginasPernosAdam JensenAún no hay calificaciones

- Chile Productos Rodamientos, Unidades y Soportes Rodamientos de Bolas Rodamientos Rígidos de Bolas Rodamientos Rígidos de Una Hilera de BolasDocumento1 páginaChile Productos Rodamientos, Unidades y Soportes Rodamientos de Bolas Rodamientos Rígidos de Bolas Rodamientos Rígidos de Una Hilera de BolasAdam JensenAún no hay calificaciones

- IMM280 - Ayudatia 1 S1-2015Documento11 páginasIMM280 - Ayudatia 1 S1-2015Adam JensenAún no hay calificaciones

- IMM280 - Ayudatia 1 S2-2015Documento6 páginasIMM280 - Ayudatia 1 S2-2015IKAR053Aún no hay calificaciones

- Vibraciones MecanicasDocumento12 páginasVibraciones MecanicasNelson Oróstica LafferteAún no hay calificaciones

- IMM280 - Ayudatia 8 S1-2015Documento5 páginasIMM280 - Ayudatia 8 S1-2015Adam JensenAún no hay calificaciones

- Reglamento SEIADocumento47 páginasReglamento SEIAAdam JensenAún no hay calificaciones

- IWM255 - Ayudatia 1Documento1 páginaIWM255 - Ayudatia 1Adam JensenAún no hay calificaciones

- Ayu 1MEC 2Documento1 páginaAyu 1MEC 2Adam JensenAún no hay calificaciones

- Calculo de EjesDocumento6 páginasCalculo de EjesAdam JensenAún no hay calificaciones

- Tarea1 MecDocumento2 páginasTarea1 MecAdam JensenAún no hay calificaciones

- Cálculo de Columna 80 TN (HEB 160)Documento2 páginasCálculo de Columna 80 TN (HEB 160)Adam JensenAún no hay calificaciones

- Ayu 2Documento1 páginaAyu 2Adam JensenAún no hay calificaciones

- 10 TurbomaquinasDocumento29 páginas10 TurbomaquinasAngel Farro100% (2)

- Catalogo de Gatos de BotellaDocumento1 páginaCatalogo de Gatos de BotellaAdam JensenAún no hay calificaciones

- Aleaciones de AluminioDocumento20 páginasAleaciones de AluminioJani Sepulveda100% (1)

- ParedonesDocumento11 páginasParedonesAlex Yoel LunaAún no hay calificaciones

- NitruradoDocumento2 páginasNitruradoOscar Luna MayoAún no hay calificaciones

- Soldadura Mig Mag Jimenez GabrielDocumento16 páginasSoldadura Mig Mag Jimenez GabrielCristian Ramirez RodasAún no hay calificaciones

- Carta Color Winds or NewtonDocumento9 páginasCarta Color Winds or Newtonmartin50% (2)

- Irrigante Alcalino de Hipoclorito de Sodio y Sus Interacciones QuímicasDocumento6 páginasIrrigante Alcalino de Hipoclorito de Sodio y Sus Interacciones QuímicasMarco VegaAún no hay calificaciones

- Definición y clasificación de agregados para uso en morteros y hormigonesDocumento16 páginasDefinición y clasificación de agregados para uso en morteros y hormigonesAle Mejia Hernandez67% (9)

- VMS Cord. OccDocumento51 páginasVMS Cord. OccDavidAún no hay calificaciones

- Tema 3 Fisica y QuimicaDocumento4 páginasTema 3 Fisica y Quimicamariajesus0921Aún no hay calificaciones

- HeterociclosDocumento4 páginasHeterociclosGabrielaAún no hay calificaciones

- Tierras Raras IiDocumento44 páginasTierras Raras IiCarlos VizcarraAún no hay calificaciones

- Outokumpu El BrocalDocumento4 páginasOutokumpu El BrocalCarmen Tinco ValdezAún no hay calificaciones

- Atracciones termales en ChurínDocumento5 páginasAtracciones termales en ChurínJulio Cesar MamaniAún no hay calificaciones

- ConceDocumento13 páginasConcesergioAún no hay calificaciones

- Informe #7 (Complejometría)Documento4 páginasInforme #7 (Complejometría)Rodrigo CárdenasAún no hay calificaciones

- CDR Chile 10 08 2020Documento68 páginasCDR Chile 10 08 2020IsvanRobinHuaylascoArredondoAún no hay calificaciones

- Tablas de Secciones y Tipos de Aleaciones para de Conductores Cobre y AluminioDocumento11 páginasTablas de Secciones y Tipos de Aleaciones para de Conductores Cobre y AluminioWalterAún no hay calificaciones

- Pin TurasDocumento1 páginaPin TurasErick ValdezAún no hay calificaciones

- Concepto Tabla PeriódicaDocumento24 páginasConcepto Tabla PeriódicaernestolavAún no hay calificaciones

- Construccion IIDocumento59 páginasConstruccion IISheylla Vanessa Barrantes AlbercaAún no hay calificaciones

- Guia de Alcoholes y FenolesDocumento3 páginasGuia de Alcoholes y FenolesPaulo Alejandro Araos Brito100% (1)

- Lixiviacion de Minerales de OroDocumento2 páginasLixiviacion de Minerales de OroCarolay Chavez CallupeAún no hay calificaciones

- Guia Calor y TemperaturaDocumento4 páginasGuia Calor y TemperaturaJosé Ignacio Gaona MellaAún no hay calificaciones

- 3era Participación 12 - 03 - 21 - Problemas Resueltos Del Proceso ElectrometalúrgicoDocumento28 páginas3era Participación 12 - 03 - 21 - Problemas Resueltos Del Proceso ElectrometalúrgicoJhon WilliamsAún no hay calificaciones

- La Falla de CaltepecDocumento27 páginasLa Falla de Caltepecraul218810Aún no hay calificaciones

- DacitaDocumento7 páginasDacitaAlan Cuno ValerianoAún no hay calificaciones

- Qui 125 Guia de Ayudantia 1° Sem 2013Documento42 páginasQui 125 Guia de Ayudantia 1° Sem 2013Adriana ToroAún no hay calificaciones

- Practica 1 - Quimica IIDocumento5 páginasPractica 1 - Quimica IIAhtziri CardenasAún no hay calificaciones

- Soldadura SanitariaDocumento3 páginasSoldadura Sanitariaanon_307120162100% (3)

- Ejercicios RESUELTOS Del Tema 5 (Reacciones de Transferencia de Electrones)Documento7 páginasEjercicios RESUELTOS Del Tema 5 (Reacciones de Transferencia de Electrones)Rafa VilchezAún no hay calificaciones