Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Asme B16.25

Cargado por

william_m080 calificaciones0% encontró este documento útil (0 votos)

1K vistas22 páginasTítulo original

ASME B16.25

Derechos de autor

© Attribution Non-Commercial (BY-NC)

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Attribution Non-Commercial (BY-NC)

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

1K vistas22 páginasAsme B16.25

Cargado por

william_m08Copyright:

Attribution Non-Commercial (BY-NC)

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 22

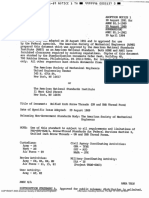

STD-ASHE Bbb-25-ENGL 1997 MM 0759670 OS8bab T13 Mi

CN ee EL

(Revision of ASME B16.25-1992)

Te a

ea ee ee ee

G)

(XS the american Sra

ate icons

STD-ASME Blb-25-ENGL 1997 MM 0759670 OS80b87 527 Ml

& The American Society of

r@ Mechanical Engineers

AN AMERICAN NATIONAL STANDARD

BUTTWELDING ENDS

ASME B16.25-1997

(vision of ASME B16.25-1082)

Copyright by the American Society Of Mechanical Engineers

Non Feb 08 11:59:15 2007

STD-ASME Blb-25-ENGL 1997 MM O759b70 OS80b88 Abb Ml

Date of Issuance: May 30, 1997

The 1997 edition of this Standard is being issued with an automatic addenda

subscription service. The use of an addenda allows revisions made in

response to public review comments or committee actions to be published

as necessary; revisions published in addenda will become effective 6 months

after the Date of Issuance of the addenda. The next edition of this Standard

is scheduled for publication in 2002.

ASME issues written replies to inquiries concerning interpretations of

technical aspects of this Standard. The interpretations will be included with

the above addenda service. Interpretations are not part of the addenda to

the Standard.

‘ASME is the registered trademark of The American Society of Mechanical Engineers.

‘This code or standard was developed under procedures acuredited as meeting the criteria for

‘American National Standards. The Consensus Cammittae that approved the code or standard

‘was balanced to assure that Inaividuais trom competent and concerned interests have had an

‘opportunity to participate. The proposed code or standard was made available for public review

‘and comment which provides an opportunity for additional publicinput fram industry, academia,

regulatory agencies, end the publie-ata

"ASME does not “approve,” "rate," or “endorta” any item, construction, propristary device,

or activity,

[ASME dose not tako ony position with reapect tothe validity of any patent rights asserted in

‘connection with any items mentioned inthis document and does not undertake to insure anyon

utilizing a standard against lability for infringement of any applicable Letters Patent, nor assume

such liability. Usere of a coda or ctandaed aro axprosaly advised thot the determination of

‘he validity of any such patent rights, and the risk of the infringement of such rights is entirely

their own roaponsibilty

Participation hy federal agency representative(s) or parsonis) affiliated with industry ie not to

be interpreted as government of industry endorsement ofthis code of standard.

ASME accepts responeibility for only those interpretations isauedin accordance with governing

ASME procedures and nolicias which preclude the issuance of interpretations by individual

No part of this document may be repreduced in any form,

In an electronic retrieval system or otherwise,

without the prior written permission of the publisher

The American Society of Mechanical Enginoore

‘345 East 47th Street. New York, NY. 10017

Copyright © 1997 by

THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

Al Rights Reserved

Printed in USA,

Copyright by the American Society Of Mechanical Engineers

Mon Feb 08 11:59:16 2007

STD-ASME B1b-25-ENGL 1997 MM O759670 OS80b85 772 a

FOREWORD

(This Foreword is not part of ASME B16.25-1907.)

In July 1953, the American Welding Society presented a proposal on Welding End

Preparation to Sectional Committee B16 of the American Standards Association (ASA),

with the recommendation that it be considered as a candidate American Standard, The

proposal was expanded to include welding preparation for anges and valves covered by

ASA BI65, Steel Pipe Flanges and Flanged Fitings, and for fittings covered by ASA.

B16.9, Buttwelding Fittings. Consideration was also given to Pipe Fabrication Institute

Stanciard FS-1

The third draft reviewed by Subcommittee 3, Subgroup 6 (now Subcommittee F) of the

BIG Sectional Committee was forwarded to the Committee, to the cosponsor organizations,

and then to ASA for approval. Final approval was given on September 14. 1955, with the

designation ASA B16.25-1955,

Revisions were developed as need for clarification and improvement became known, and

‘were approved as ASA B16,25-1958 and ASA B16.25-1964, After ASA reorganized as

the American National Standards Institute (ANSI) and the Sectional Committee became

‘American National Standards Committee B16, a further revision was approved as ANSI

B16.25-1972

Subcommittee F immediately began work on a major expansion end updating of the

standard, adding illustrations and requirements for welding cnd configurations applicable to

fa number of specific circumstances, including cast stecl and alloy valves. When a draft

hhad been developed that overcame the many problems and conflicting demands, the Standards

Committee, cosecretariat organizations, and ANSI concurred in approval of ANSI B16.25

1979 on July 18, 1979.

In 1982, American National Standards Committee B16 was reorganized as an ASME

Committee operating under procedures accredited by ANSI. In the 1986 edition, inch

dimensions were established as the standard and numerous changes in text and format were

wade. Notes for illustrations were also clarified. Following approval by the Standards

Committee and ASME, approval as American National Standard was given hy ANSI on

October 8. 1986, with the new designation ASME/ANSI BI6.25-1986.

In 1992, the subcommittee revised the requirements for the preparation of the inside

diameter of welding end. The references in Annex B were also updated. After public review

and approval by ASME, this edition was approved by ANSI on October 26, 1992, with

the new designation ASME B16.25-1992.

In this 1997 Edition, metric dimensions were added as an independent but equal standard

to the inch units. Ad Annex was also added to reference quality system requirements.

Following approval by the Standards Committee and ASME, this revision to the 1992

edition of B16.25 way approved as an American National Standard by ANSI on April 17,

1997, with the new designation ASME B16.25-1997.

Requests for interpretation or suggestions for revision shoukd be sent to Ue: Secretary,

BIG Committee, The American Society of Mechanical Engineers, United Engi Center,

345 East 47th Street, New York, NY 10017.

Copyright by the American Society Of Mechanical Engineers

Mon Feb 08 11:59:16 2007

STD-ASNE Blb-25-ENGL 1997 MM O75970 OS80b90 414 mm

ASME B16 COMMITTEE

Standardization of Valves, Flanges, F

Gaskets

gs, and

(The following isthe roster of the Committee atthe time of approval ofthis Standard.)

OFFICERS

W.N. MeLean, Chair

R.A. Schmidt, Vioe Chair

K Giciora, Secretary

COMMITTEE PERSONNEL

W, Balls, Consultant, Columbus, Ohio

R. R. Brodin, Fichor Controle International, Inc, Marshalltown, iowa

K. Ciciora, ASME. New Yort, New York

M.A. Clark, NIBCO, Ine, Elkhart, Indiana

{A Cohen, Copper Development Assaciation, New Vork, New York

W. ©. Farrel, Jr, Consultant, Birmingham, Alabama

DA. Frikken, Monsonto Co, St. Louis, Missouri

M.W. Garland, Frick Company, Wayneshoro, Pennsylvania

4... Inch, Mueller Refrigeration Products Co. Hartsville, Tennessee

G. A. Jolly, Vogt Valve Co., Louievill, Kentucky

W. G, Knecht. Consultant, Willamsport, Pennsylvania

R, Kovater, The William Powell C., Cincinnati, Ohio

W.N. MeLaan, Newco Valvas, Palos Park, Ilinois

LA. Schmit, Ladish Co, Russelivte, Arkensas

W. M. Stephan, Floxitali, Inc, Ponnsaukon, Now Jersey

1. F, Stroud. Ductile Iron Pipe Research Association, Birmingham, Alabama

LE, White, Richard E, White & Associates, South Bend, Indiane

A. Williams, Southern Company Services, Birmingham, Alabama

‘Dow Chemical Co., Freeport, Texas

7 Union Carbide Corp., South Charleston, West Vieginia

PERSONNEL OF SUBCOMMITTEE F — STEEL THREADED

AND WELDING FITTINGS

PR, Benavides, Tubs Forgings of America, Portland, Orogon

G.A. Cuctlo, Capitol Manufacturing Co., Crowley, Louisiana

LU, D'Ura0, Secretary, ASME, New York, New Vor

D.R.Frikkan, Monsanto Co. St Louis, Missouri

LE, Johnson, Consuitant, Gibsonia, Pennsylvania

G.A Jolly, Chair, Vogt Vaivo Co., Louisville, Kentucky

R.C. Lafferty, Penna Machine Works. nc.. Astoner. Pennsylvania

H. Monroe, Consultant, Birmingham, Alabama

W. Muir, Consultant, Simcoe, Ontario, Canada

A. Schmidt, Ladish Co., Russelvile, Arkansas

‘A. Wills, Dow Chemical Co,, Froeport, Texas

B.

D

R

L

Copyright by the American Society Of Mechanical Engineers

Mon Feb 08 11:59:17 2007

STD-ASME BLb-25-ENGL 1997 MM O7S9670 OS80b51 350 mm

CONTENTS

Foreword cee

Committee Roster v

1 Scope : 1

2 Transition Contours ..........-.. cece Td

3 Welding Bovel Design .........cscecseeeseeses 1

4 Proparation of Inside Diameter of Welding End 5

5 Tolerances coe 6

Figures

1 Maximum Envelope for Welding End Transitions... 2

2 Weld Bevels for Wall Thickness Not Over 22 mm (088 in.) son... 3

3 Weld Bevel Details for Wall Thickness Over 22 mm (0.88 in.) 4

4 Weld Bevel Demils for GTAW Root Pass (Wall Thickness Over

3 mm (0.12 in.) w 10 mm (0.38 in), Inclusive] 5

5 Weld Bevel Details for GTAW Root Pass [Wall Thickness Over

10 mm (0.38 in) to 25 mm (1.0 in), Inclusive) »... 6

6 Weld Bevel Details for GTAW Root Pass

[Wall Thickness Over 25 mm (1.0 in) s.-see-+ 1

Table

Hl Dimensions of Welding Ends ......-+ ce 8

Annexes

A Inch Table ose... u

B Quality System Program 15

c References voces 0

SPECIAL NOTE:

‘The interpretations t0 ASME B16.25 are included in this Edition uy a separate section for the user's convenience

This section, however, is not part of the Standard,

Copyright by the American Society Of Mechanical Engineers

Non Feb 08 11:59:18 2007

STD-ASME B1b-25-ENGL 1997 MM O759670 OS80b92 257 a

ASME 816.25-1997

BUTTWELDING ENDS

1 SCOPE

1.1 General

This Standard covers the preparation of buttwelding

‘ends of piping components to be joined into a piping

system by welding. It includes requirements for welding

bevels, for extemal and intemal shaping of heavy

wall components, and for preparation of internal ends

(including dimensions and tolerances). Coverage in-

cludes preparation for joints with the following:

(a) no backing rings;

(6) split or noncontinuous backing rings:

(6) solid or continuous backing rings:

(a) consumabie insert rings:

(e) gas tungsten arc welding (GTAW) of the root

pass.

Deiails of preparation for any backing ring must be

specified in ordering the component.

12 Application

‘This Standard applies to any metallic materials for

which a welding procedure ean be satisfactorily quali-

fied, but does not prescribe specific welding processes

for procedures. Unless otherwise specified by the pur-

chaser, it does not apply to welding ends conforming

to ASME BI65, BI6.9, or B16.28.

1.3 Standard Units

The values stated in either metric or inch units are

to be regarded separately as standard, Within the text,

the inch units are shown in parentheses. The values

stated in each system are not exact equivalents; therefore

cach system must be used independently of the other.

Combining values from the two systems may result in

nonconformance with the Standard

1.4 Referenced Standards

Standards and specifications adopted by reference in

this Standard are shown in Annex C, which is part of

this Standard. It is not considered practical to identify

the specific edition of each standard and specification

in the individual references; instead the specific edition

is identified in Annex C. An end preparation made in

Copyright by the American Society Of Mechanical Engineers

Non Feb 08 11:59:18 2007

conformance to this Standard in all other respects, will

bbe considered to be in conformance to the Standard

even though the edition reference may be changed in

f subsequent addendum to or revision of the Standard,

1.8 Quality Systems

Nonmandatory requirements relating to the manufac.

turer's Quality System Program are described in

Annex B.

1.6 Convention

For the purpose of determining conformance with

this Standard, the convention for Axing significant digits

where limits, maximum or minimum values, are speci-

fied shall be “rounding off” as defined in ASTM

Practice E 29. This requires that an observed oF calcu-

lated value shall be rounded off to the nearest unit in

the last right-hand digit used for expressing the limit.

Decimal values and tolerances do not imply a particular

method of measurement.

2 TRANSITION CONTOURS

Figure | delineates the maximum envelope in which

transitions from welding bevel to the outer surface of

the component and from the root face to the inner

surface of the component must lie. Except as specified

in Note (5) to Fig. 1 and as otherwise specified by

the purchaser, the exact contour within this envelope

is the manufacturer's option, providing it maintains the

specified minimum wall thickness, has no slopes steeper

than those indicated for the respective regions, and

includes the proper surface for backing rings if specified

3 WELDING BEVEL DESIGN

3.1 Bevels for Other Than GTAW Root Pass

(a) Components having nominal wall thicknesses of

3 mm (0.12 in.) and less shall have ends cut square

or slightly chamfered.

(2) Components having nominal wall thicknesses

over 3 mm (0.12 in) to 22 mm (0.88 in) inclusive

shall have single angle bevels as illustrated in Fig. 2.

STD-ASME BUb-25-ENGL 1997 MM 0759670 OS80L93 123 mm

ASME 816.25-1997 BUTTWELDING ENDS

= 15 tein

Outside

= -5

Note (9

Outside

agus 20.05 tin

45.deg mo AFA 20.98 fin

20 dog max (31

a

SJl_-

! Meir Note)

1 tomt Lae Minimum 19tmn

|

Z

et Of

Note (1

Component or Fiting

zZ

Maximum stope 13

Trae

Were) Rave 20.08 fig tNote (5

—-—-4

Trside

Zinn Hansition region

notes:

(31 The vatve oF tpg Is whenever ofthe following is appleabe:

(a) the minimum ordered wall thcknase ofthe pipe

{8} 0.79 times the nominal wal thickness of pipe ordered to a pipe schedule wal ilckness that has an under-clerance of 12.5%

{eh the minimum ordered wal thickness of the eylindical welding and of acompnnent oe fiting fr the thinner ofthe twa) when the

Jpintia between two componente

(2) The maximum inckness at ne end of tne component is

(a) the groatar of fin + mm (0.16 in} or 1 18tmn whan orderad on minimum walt babes

AG) the greater of (rn + mm (0.16 n} or 1 10tNom when ordered on a nominal wall Bass

(31 Weta bevel shown (for ilutration only,

(4) The weld reinforcement permitted by applicable code may lie outside the maximum envelooe

(51 where anstions using maximum slope do not intersect Inside or ausige surface, as shown by phantom outlines, maximum slopes

shown or aerate a0 shal be Used

FIG. 1. MAXIMUM ENVELOPE FOR WELDING END TRANSITIONS

Copyright by the American Society Of Mechanical Engineers

Non Feb 08 11:53:19 2007

STD-ASME Bbh.2@5-ENGL 1997 MM 0759670 0580694 ObT mi

BUTTWELDING ENDS

a5 78 009 225 009

Me

Note 1 10308

F 008000

St

(a) Welding End Data for Joint Without Backing Ring

375 dea 225 600,

[Note (2h

18.08

+ {0.08 10.08)

odes

lt .

[el Welding End Detait or Joint Using Continuous

Rectangular Backing Ring

Fig. 1 Yor aetals.

() See Section 5 for tolorances ather than those given in thas sketches

33105) min (10010 -o)

‘maximum envelope for trenaitons from welding bev

ASME B16.25-1997

TTT 78 dog 25 deg

\

x

f 'séstoen

soe oa | Lf t

--2I Sos mn |

(6) Welding End Dati for Joint Using Spit

‘Rectangular Becking Ring

375 deg 225 doo

16308

£00200

TAF leans. |

ato)

stg max wordimin |

(aye

19 End Detal for Joint Using Continuous

"Tapered Backing Ring

1 root 220 into body f component.

notes:

{i} Imeral surface may be as-formed or machined for dimension @ at root face. Contour within the envelope shalt be in gocordence

with Section 2

{2} Intersections shouldbe slightly rounded.

FIG. 2 WELD BEVELS FOR WALL THICKNESS NOT OVER 22 mm (0.88 in.)

Copyright by the American Society Of Mechanical Engineers

Non Feb 08 11:59:20 2007

STD/ASME BLb-25-ENGL 159597 MM 075970 OS80b95 TTL Mi

ASME B16.25-1997 BUTTWELDING ENDS

a tay cto Hq tee ae

u 4 ~

N \

SS

S

- iNew 2

375 dey 22.8 dog W7 deg 223 deg

1075 000)

19208 18.08

Sa text .

(908200, (075 20.06) ct 2000

(Noten

:

r a

---J i

(a) Welding End Detal for Joint Wout Backing Ring

-- roaeg 2106

5 eg 21.809

ost

{05 soon,

sa deg mak

026-0

== 7 1305/min © “oor 0) ‘vooie-0

Seay mex 1022) min |

{1 Weising End Data fr Joint Using Continuous ( Walding End Deal for Joint Using Continuous

Rectangular Backing Png "apered Backing Ring

‘oeNenAL NOTES

{G1 Broken lines denote maximum envelope for trensitions trom welding groove and rot fs

Se0Fig. 1107

(0) See Sections for tolerances otnerinan those given in tese sketes.

(c) Purehase order must speify contour of ay backing ring to Be used

() Linear elmensions aro in ritimeters wits incn values In parentheses.

into bosly of components

NOTES:

{MP Internal eurtaco may bo ae formed or machined for dimension Bat root face. Contour within the envolope ahal bo in accordance

vwitn Section 2

(2) Intersections should be sightly rounded,

FIG. 3 WELD BEVEL DETAILS FOR WALL THICKNESS OVER 22 mm (0.88

Copyright by the American Society Of Mechanical Engineers

Non Feb 08 11:59:20 2007

STD-ASME Bbb-25-ENGL 1997 MM O759b70 OS80b5b 932 Ml

BUTTWELDING ENDS

(©) Components having nominal wall thicknesses

‘greater than 22 mm (0.88 in.) shall have compound

angle bevels as illustrated in Fig. 3.

3.2 Bevele for GTAW Root Pass

(a) Components having nominal wall thicknesses of

3 mm (0.12 in.) and less shall have ends cut square

or slightly chamfered.

(2) Components having nominal wall

over 3 mm (0.12 in.) to 10 mm (0.38 in)

shall have 37% deg + 2% deg bevels or slightly

concave bevels. See Fig. 4.

(c) Components having nominal wall thicknesses

over 10 mm (0.38 in) to 25 mm (1.0 in) inclusive

shall have bevels as shown in Fig. 5.

(d) Components having nominal wall thicknesses

greater than 25 mm (1.0 in.) shall have bevels as

shown in Fig. 6

4 PREPARATION OF INSIDE DIAMETER OF

WELDING END

4.1 General

Preparation of the inside diameter at the end of @

component shall be in accordance with one of the

following, as specified by the purchaser.

(a) Components to be welded without backing rings

shall meet the requirements of the standard or specifica-

tion for the component

() Components to be welded using split or noncon-

tinuous backing rings shall be contoured with a cylindri-

cal surface at the end as shown in Fig. 2, sketch (b)

and Fig. 3, sketch (b). If the backing ring contour fs

‘other than rectangular, details must be furnished by

the purchaser.

(C) Components 10 be welded using solid or continu

cous backing rings shall be contoured with a cylindrical

oor tapered surlave al the end as specified by the

purchaser. End preparation is illustrated in Fig, 2, sketch

() and Fig. 3, sketch (c) for rectangular ends and in

Fig. 2, sketch (4) and Fig. 3, sketch (4) for tapered ends.

(d) Components to be welded using consumable

insert rings or GTAW root pass shall be contoured

with a eylindrical surface at the end as shown in Figs

4,5, and 6,

42 Dimension C

Values for dimension C shown in Fig. 2, sketches

(©) and (A); Fig. 3, sketches (c) and (d); and Figs. 5

Copyright by the American Society Of Mechanical Engineers

Mon Feb 05 11:53:21 2007

‘ASME B16.25-1997

375.09 223 609

18:08

(0.08 10.00)

(GENERAL NOTES:

applies for gas tunasten arc welding (GTAW) ot

oot pate where nominal wal thicknass is over

‘mm (0.12 in) to 10 mm (0.38 in.) inclusive,

(b) Linesr dimensions are in milimetera with inch valuas in

parentheses.

FIG. 4 WELD BEVEL DETAILS FOR GTAW

ROOT PASS

[Wall Thickness Over 3 mm (0.12 in.)

to 10 mm (0.38 in), Inclusive]

and 6 are tabulated in Table 1 for DIN 65 through 900

(NPS 2% through 36),

Dimensions for other sizes and/or wall thicknesses

can be determined by te following formulas.

C= A= 0.79 = 1.754 ~ 0.25 mm

= 0031 - 1.95

= 04010 i.)

where

nominal O.D. of pipe (see column 3 in

Tables {and Al, taken from ASME

B36.10M)

0.79

(0.031) = minus tolerance on O.D. of pipe. mm

(in), as covered by ASTM specifications

having the more restrictive requirements

such as A 106, A 335, ete

minimal wall of 87/4% of nominal walt

(permited by ASTM specification having

the more restrictive requirements such as

A 106, A 335, etc.) multiplied by 2 t0

convert into terms of diameter

nominal wall thickness of pipe, aun (in.)

us =

STD-ASME BLb-25-ENGL 1997 MM 0759470 OS80b97 479 ml

ASME 816.25-1997 BUTTWELDING ENDS

ay eg 28 ang

TT Beg 225 409 7

4 \

N N

0102000)

NG SS

S

sioxsin

ine

Nee aot

an 4 " {0.078 20.016)

‘oo70s000)

wan mad oy

seg max

ian 1025-102 b voas- 02

--4 40.19) in | (ew-000 --4 510.19) min. (40,010 ~ 0.040)

Wea es

cenena nores

(a) This detail applies fr gas tungsten are welding (GTAW) ofthe root pase whero nominal wal thicknece le over 10 mm (0.38 In 10

251mm { 101) inclusive.

(0) Broken lines denote maximum envelope for ransitions trom welding groove and land into bedy of component. See Fig. for deta

{6} S2e Section 6 for tolerances other than those given in these sketches.

(@) Linear aimensions are in ilimeters with inch values in parentheses,

NOTE:

(9) Inside corners should be lightly rounded.

FIG. 5 WELD BEVEL DETAILS FOR GTAW ROOT PASS

[Wall Thickness Over 10 mm (0.38 in.) to 25 mm (1.0 in}, Inclusive]

025 5 TOLERANCES (See Figs. 2. 3. 5. and 6)

(0.010) = plus machining tolerance on Bore C.

mm (in) 5.1 Dimension 8

43 Exceptio Values for the LD. at the welding end [see dimension

(a) For pipe or tubing varying from the ASTM A

106 and A 335 types, having different wall thickness

andloe outside diameter tolerances (such as forged

and bored pipe), the foregoing formulas may be

inapplicable.

(0) For components in smaller sizes and lower sched-

tule numbers, it may be necessary to deposit weld metal

on the inside diameter or use thicker wall materials in

‘order to machine the backing ring while maintaining

required wall thickness. This condition may also arise

when using material whose nominal dimensions indicate

sutficient metal but whose actual inside diameter (LD.),

considering tolerances, is large enough to require addi-

tional metal

Copyright by the American Society Of Mechanical Engineers

Mon Feb 08 11:59:22 2007

B, Fig. 2, sketches (a) and (b); and Fig. 3, sketches:

(@) and (b)} shall be as specified in the applicable

standard or specification for the component.

6.2 Welding Bevels, Root Face, and

ension C

Values of welding bevels, root face, and dimension

€ shall be as indicated in Figs. 2, 3, 4, 5, and 6.

Large diameter pipe and fitings with a relatively

thin wall have a tendency to spring out-of-round after

removal from the machining fixture. Por this reason,

the measured diameters may vary with orientation. A

tolerance of +0.25 mm (40.010 in.) shall apply to the

average diameter

STD-ASME Bbb-25-ENGL 1997 MM 0759670 O580b98 705 Mi

BUTTWELDING ENDS

10deo 21 de0

20 00g 225000

re1w25

{078 t0 100)

30.099 max

“" 1025-102

rc 110.18) min {:0.010- 0.040)

4 |

Types

GENERAL NOTES:

(@) This detall applic for gas tungsten arc welding (GTAW of root pass wheve unin wall

(0) Broken ines denote maximum envelope Tor transitions trom welding groove and land into Body of component, See Fig fo

ASME B16.25-1997

10deg +1 deg

20 veg 229.009

191025

10.76 to 4.00)

[Note

30 dog max

025-102

| ee bo

510.19) min

lckness sg

nan 25 mm (1.99),

{c} See Section 5 for tolerances other than thoes given in these eketchoe,

(W) Liner dimensions are in ili

Nore:

(9) Ina commore shouldbe lightly rounded.

swith Inch values In parenneses,

FIG. 6 WELD BEVEL DETAILS FOR GTAW ROOT PASS

[Wall Thickness Over 25 mm (

5.3 Dimension A

Dimension A is the nominal outside diameter of the

component at the welding end.

5.3.1 Valves (Column 4 of Tables 1 and A1)

Nominal Sie Tolerance

5 DN 125 (NPS 9) #24 mem (OU 1m) -ON mm (O03 in)

> DN 150 (NPS 6) +40 mm (0.6 in) -0.8 mm (0.03 in)

9.3.2 Other Components. Dimension A values

for other components shall be as specified in the

applicable standaid or specification for dhe component

Copyright by the American Society Of Mechanical Engineers

Mon Feb 08 11:59:22 2007

in

5.4 Wall Thickness

‘The maximum thickness, fags at the end of the

component is:

(a) greater of fais + 4 mm (0.16 in.) or LIS

when ordered on a minimum wall basis:

(0) greater Of fin + 4 MM (0.16 iN.) OF 1.10 tom

when ordered on a nominal wall basis (see Fig. 1).

‘The minimum thickness, tyiq. shall be as spectfied

inthe applicable standard or specification for the compo-

nent (see Figs. 2, 3, 5, and 6).

STD-ASME BIb-25-ENGL 1997 MM O759670 OS80L99 4) mt

ASME 816.25-1997

‘TABLE 1 DIMENSIONS OF WELDING ENDS

{See Figs. 1 to 6, Inclusive)

SUTTWELDING ENDS

‘OD. at Welding Ends

Wrought or

Nominal Schedule Fabricated Cast Steet

No. Components, Valves,

(DN Note (1H) AlNote (1 A Note (it a Note (3). t

5 40 730 8 625 6293 516

20 730 B 39 59.69 7o1

160 730 % 5a 55.28 953

Xxs 730 8 4 4743 1402

0 0 seo a a 7a28 6.49

80 883 3 735 7453 7.62

160 889 ot 665 60.20 11.13

XxS 289 a 585 6119 1828

%0 0 1018 105 80 9052 574

80 1018 105 355 85.42 8.08

100 40 143 7 102 10272 6.02

20 a3 mw rT 828 36

20 143 7 2 9378 1113

160 143 n7 75 89.65 139

XxS. 43 u7 80 83.30 Wrz

v5 0 1413 144 18 12880 655

80 1413 144 122 12358 953

120 1413 14a ns ma04 1230

160 1413 184 1095 nza7 1588

xs 1413 144 103 10692 19.05

150 40 1683 mm 134 15482 mm

0 1602 m 1465 149.06 1097

vo 1683 m 140 14229, 1427

160 1003 wm, 132 13531 1828

XxS 1683 m 14s 1288s 21.95

200 40 219.41 229 203 203.75 8.18

50 2191 223 1985 200.02 1031

80 2191 223 1935 195.84 1270

100 219.1 223 189 r9188 16.09

aw zit zs wz 165.11 18.28

140 219 223 178 renee 2082

XxS, 2191 223 1745 va36 22

160 213.1 23 M3 W779 2301

280 40 2730 278 2545 285.74 927

60 2730 278 2475 249.74 1270

0 270 28 202 24586 16.09

100 2730 278 2365 240.01 18.26

120 2730 278 230 pasa ana

v0 2720 28 22 27781 26.0

160 2730 278 26 22135 28.58

‘200 sto ama 29 205 06.08 953

wv 2238 229 303 300.72 oat

xs. 3238 329 2985, 300.58 1270

60 ana 29 295 99779 wa7r

(Wotes follow at end of rable)

Copyright by the American Society Of Mechanical Engineers

Non Feb 08 11:53:23 2007

(Table 1 continues on next page)

STD-ASME Blb-25-ENGL 1997 MM 0759670 OS80700 193 ml

AUTTWELDING ENDS ASME 81625-1997

TABLE 1 DIMENSIONS OF WELDING ENDS (CONT‘D)

(See Figs. 1 to 6. Inclusive)

‘OD. at Welding Ends

Wrought oF

Nominal ‘Schedule Fabricated Cact Steat

Pipe Size ‘No. Components. valves.

(OND {ote (1 ‘A (Note (1) AlNote (2) 8 {Note (3H) '

300 80 2200 29 209 202.17 17.43

100 aa 229 rat 235.28 rad

0 3238 323 23 27831 25.40

140 3238, 329 2555 272.78 22.58

160 aaa 379 257 268.48 3332

380 sto 2556 362 3385 saree 93

40 3556 362 335 335.08 113

xs. 355.6 382 330 mana 1270

60 3556 362 255 22815 15.09

80 3555 362 3175 32122 13.05

100 3556 382 308 312.88 23.83

120 3556 362 300 305.93 2718

140 3386 382 22 239.00 3175

160 3556 362 284 292.07 3571

400 STO 406.4 a3 3875, 308.68 953

40 406.4 a3 281 ant 270

wo 405.4 413 373 37621 16.66

80 406.4 413 2635 Bers 21a

100 408.4 413 354 359.53 26.13

120 408.4 413 3445 351.18 30.96

140 406.4 a3 238 paves 3653

160 406.4 4x3 3255 335.50 40.49

450 sto 4872 464 aan 430.48 953

xs. 497.2 404 482 433.98 12.70

0 4572 464 4285 aa119 waz

0 4572 464 419 422.82 19.05

80 4572 404 409.5 41445 2383

100 487.2 464 3985 40478 23.38

10 a2 a8 3819 395.03 3433,

+40 472 aca 378 386.77 2o67

160 4572 464 366.5 376.99 45.24

500 sto 508.0 516 429 190.28 953

XS 508.0 516 482.5 484.74 1270

0 508.0 516 478 400.55 1508

60 508.0 516 487 470.88 2062

v0 uso 516 4555 6113 28.19

100 508.0 516 43 450.02 3254

120 508.0 516 a 440 79 3.10

180 508.0 516 419 429.17 4435,

160 508.0 516 408 410.48 5001

550 sto 5588 507 539 541.08 983

xs. 5588 567 rey 52684 1270

60 5588 567 514 518.86 ne

80 558.8 567 501 507.75 2058

{Notes follow at end of table) (Table 1 continues on next page)

Copyright by the American Society Of Mechanical Engineers

Non Feb 08 11:53:23 2007

STD-ASME BLb-25-ENGL 1997 MM 0759670 580702 0°T a

[ASME 816.25-1997 BUTTWELDING ENOS

TABLE 1 DIMENSIONS OF WELDING ENDS (CONT'D)

(See Figs. 1 to 6, inclusive)

(0.0. at Welding Ends

Wrought or

Nominal Schedule Fabricated Cast Steel

Pipe Size ‘No. Components, Valves,

(ON [Note (1H) ‘A (Note (1 A [Note fit s E tNote (3H ‘

550 100 5508 se7 4935 496.69 3499

10 55aa 567 416 485.52 4128

140 9388 867 403 avast 47.63

160 5508 887 4505 463.30 5.08

200 sto 609.6 619 5905 591.88 953

xs 600.6 619 584 505.34 1270

30 609.5 619 381 583.53 1az7

40 609.6 619 5785, 577.97 1748

60 600.8 a9 560.5 565.49 2461

80 609.8 ei9 5475 554.38 30.96

100 600.8 619 522 540.49 38.89

120 6096 619 5178 528.08 46.02

140 6096 619 505 51631 9237

160 6006 619 00.5 50437 50.54

650 0 660.4 670 6455 645.50 792

2 8604 670 635 sata 70

700 0 ma ma 6955 696.30 792

20 m2 mi 686 687.94 1270

30 ma 7m 0795 982.37 15.88

750 0 7820 ™m 746 747.30 192

20 782.0 mm 7368 738.74 1270

a0 7820 ™ nn ma 1588

300 10 ene 25 797 797.90 792

20 8128 5 715 789.54 1270

30 8128 25 781 78397 1588

0 8128 5 mm 781.17 17.43

80 0 asa 76 24a 249.70 792

20 853.6 876 838 340.34 1270

30 8636 876 sz 834.77 15.88

0 9526 276 ae 231.97 Wa

300 10 oa 927 8985 999.50 792

20 oa ou 0 291.14 270

30 sna 927 282.5 995.57 15.88

0 ona 927 8765 280.02 19.05

GENERAL NOTES:

(a) Dimensions are in milimeters.

{} Seo Section 6 for tolerances

Notes:

(1 Leter designations signty

(@) STD = standard wall thickness

(b) XS = extra-strong wall thickness

(@) XXS = douthie extra strong wall thickness

(2) The diameters listed are not requirements. They are provided for the convenience of the user.

&) Internal machining for continuous Backina rings for ses DN 50 and smal isnot contemplated, Se para. 42 for C

Jimension for sizes not Hit

Copyright by the American Society Of Mechanical Engineers

Mon Feb 08 11:59:24 2007

STD-ASME BLb-25-ENGL 1997 MM 0759670 OS80702 Thb ml

BUTTWELDING ENDS. ASME 816,25-1997

ANNEX A

INCH TABLE

(This Annex is an integral part of ASME 816.25 and Is placed after the main text for convenience.)

‘This Annex provides a table of the standard inch

ddimensious for fittings

Copyright by the American Society Of Mechanical Engineers

Non Feb 08 11:53:25 2007

STD-ASHE Blb-25-ENGL 1997 MM O759670 0580703 972 a

ASME 818:25-199/ BUTTWELDING ENDS

TABLE A1_ DIMENSIONS OF WELDING ENDS

(See Figs. 1 to 6, inclusive)

‘OD. at Welding Ends

‘Wrought or

Nominal ‘Schedule Fabricated Cast Steat

Pipe Size ‘No. Components, Valves,

wes) [Note (11 A [Noto (1) AlNote (21) 8 Note (3h) t

Bn 40 298 2.96 2.489 2478 0.203

80 288 296 2303 2.351 0276

180 288 296 2125 278 0375

XxS, 268 2.98 wm 1368 0882

3 40 350 3.59 3.088 3.081 0218

80 250 359 2.900 2934 0300

160 350 339 2624 2692 0.438,

XXS 350 250 2.00 2409 0.600

3% 40 400 412 3598 3.504 0228

80 4.00 an 3.364 3.402 0318

4 40 450 482 4.026 ose 0.237

20 450 462 3.826 3.869 0.337

120 450 42 3824 092 case

160 450 462 3.438 3.530 0.531

Xxs 450 462 2157 3779 a

5 a0 556 560 087 5.070 0.268

80 5.56 569 4313, 4.366 0375

120 5.56 5.09 4500 4087 0.500

160 5.55 569 Petry aaa 0.6825

XxS, 5.58 5.09 4083 4.209 0.750

6 aw 682 678 6.085 6.094 0.280

°0 682 378 5781 5.828 0.432

120 682 678 5501 5.600 0562

160 6s2 678 5.187 5.326 org

2xs 662 678 4807 5072 0.364

8 40 862 378 7.981 8.020 0.322

0 262 878 7a13 7.973 0.406

80 882 378 7825 7708 0.500

100 362 378 7437 73a 0534

170 ae? a7” 7187 T08 ona

140 62 378 7.001 7183 oz

Xxs 362 878 8.875 7.053 0.875

160 362 378 6813 6.998 0.906

10 0 10.75 10.98 10.020 too70 0.385

60 10.75 10.98 9.750 9.834 0.300

20 1075 1098 962 9670 soa

100 10.75 10.98 9312 9.451 ong

120 1075 10.98 9.082 9.232 oss

M0 10.78 10.94 8750 8.959 1.000

160 10.75 ws 500 740 1125

2 sto 1275 1297 12.000 12.052 ms

49 1215 1297 vgs nig 0.08

xs. 1275 1297 14.750 a836 0.500

60 1275 1297 11626 1175 0582

(Notas follow at and of table! (Table A} continuse on next page)

Copyright by the American Society Of Mechanical Engineers

Non Feb 08 11:53:25 2007

STD-ASME B1L.2S-ENGL 1997 MM 0759670 0580704 835 mm

BUTTWELDING ENDS ASME B16.25-1997

TABLE A1 DIMENSIONS OF WELDING ENDS (CONT'D)

(See Figs. 1 to 6, inclusive)

OD. ot Welding Ends

Wrought or

Nominal Schedule Fabrieatad Cast Staal

Pipe size ‘No. Components, Valve

NPs) (Note (1H) A Note (1) A Note (211 8 Note (301 t

2 0 12.75 1297 nara 11.608 oa

100 1275 1237 11.982 n232 oss

120 1275 1297 10.750 10.959 1.000

vo 1275 1297 10.500 10.740 1.195

160 1275 237 wo.126 wo.ais 1312

1“ sto 1400 1425 13250 13303 0.375

0 14.00 1425 13.124 13.192 0.438

xs. 14.00 1425 13.000 13.088 0.500

60 14.00 1435 1812 a0 nse

80 14.00 1425 12.500 12.046 0.750

100 14.00 1426 yaaa wae 0938

v0 14.00 1812 ye048 1.034

140 1400 11.500 wm 1.250

160 14.00 ants an4g8 1406

6 sto 16.00 16.25 15.250 15.03 0.275

40 16.00 16.25 15.000 15.084 0500

© 16.00 19.25 s4.988 saan 0.656

80 16.00 16.25 waa 1442 ose

"00 16.00 1625 13.938 vats ust

120 16.00 16.25 13.562 13.826 1219

140 16.00 16.28 13.108 13.442 1438

160 16.00 16.25 w812 13.170 1594

8 sto 18.00 1828 7.250 7.303 0375

XS 13.00 1828 7.000 7084 9500

ra 1800 1878 16878 16975, 0562

60 18.00 1828 16.500 16.890 0.750

80 18.00 1928 16.124 16318 0.998

100 18.00 1828 15.688, 15.936, 1.158

120 18.00 1328 15250 15553, 1375

140 12.00 1828 14876 15.225 1562

160 18.00 1828 16.038, 14892 1781

2 stD 20.00 2031 19.250 19.303 om

xs. 20.00 2031 19.000 19.084 0.500

40 20.00 2031 18812 18.920 0504

ey 2000 20:31 ware 13538 oi

80 2000 2031 17538, 19.155 1.03

100 20.00 2031 ae v7 1281

120 20.00 2031 17.000 1338 say

140 20.00 2031 18.500, 16.096 1.750

160 20.00 2031 16.062 16513, 11963

2 sto 22.00 2208 21.260 21903 0278

xs, 22.00 234 21.000 21.088 0500

60 22.00 2234 20.250 20.428 0875

80 22.00 234 19.750 19.990 1.128

(Notes follow at ond of table) (Table At continues on next page)

Copyright by the American Society Of Mechanical Engineers

Non Feb 08 11:53:25 2007

STD-ASME BLL-25-ENGL 1997 MM O759b70 OS80705 775

ASME 816.25-1997 BUTTWELOING ENDS

TABLE A1 DIMENSIONS OF WELDING ENDS (CONT‘D)

{See Figs. 1 to 6, Inclusive)

(OD. at Welding Ends

Wrought o

Nominal Schedule Fabricated Cast Steet

Pipe size ‘No. components, Valves,

(NPs) Note (1H, ‘A Note (1 A Note (it a CINote (3), t

2 100 22.00 22.34 19.250 19553, 1375

120 22.00 2234 18.750 ra15 1625

140 22.00 22.34 18.250 18678 1875

160 22.00 2234 17.750 18.240 2175

m4 sto 24.00 2438 23.260 23.308 0375

xs. 24.00 2038 anon panes 0500

so 24.00 24.38 22876 22975 0.562

40 24.00 24.38 22.624 22.755 0.888

fa 2aon 2428 22.062 22.283 0.963

20 24.00 2438 21562 21826 ans

100 24.00 2438 20.938 21280 1531

20 2400 2438 20376 20.788 agi

140 24.00 24.30 19.876 20.350 2.082

160 2400 2038 war 19.857 2384

26 0 26.00 2628 25.376 25.413 0212

2 2600 838 25.000 25.086 os

23 10 2800 7338 27.396 2ra13 oan

2 zau0 28.38 27.000 27.084 0.509

20 2800 2038 26.760 26.965 0.625

30 10 30.00 30:38 29376 20.813 osi2

20 30.00, 30.8 29.000 29.088 0.500

30 30.00 3038 28.750 73.865 0.625

2 0 200 2750 31978 a1a13 oan

2 3200 3250 31.000 31.088 0.300

30 32.00 2250 30.760 30.865 0.525

40 32.00 3250 30.628 30.755 0.88

u 0 3400 3080 33.376 aan 0212

2 3400 3450 33.000 33.088 0.300

20 2400 2450 32.760 22.965 0.626

0 3400 3450 32.628 32.785 0.688

36 10 36.00 2660 38.276 35.413 0312

20 3600 3650 ‘35.000 5.088 ou

20 38.00 3650 34.750 34.865 0625

49 3600 2650 ‘38.500 2a 646 0750

GENERAL NOTES:

{@) Dimoncione aro in inches.

(0) Sea Section 5 for tolerances,

Notes:

(1) Lottor designations signify:

(a) STD = standard wall thickness

(6) XS = exra-strong wall thickness

(6) XXS = double extra strong wall thickness

(2) The diamatars listed are not raquiremants. They are provided for the eanvenience af the user.

(3) Internal mechining for continuous becking rings for sizes NPS 2 and smaller ia not contemplated. See para. 42 for C

dimension for sizes not listed.

u

Copyright by the American Society Of Mechanical Engineers

Mon Feb 08 11:59:26 2007

STD-ASME BLb-25-ENGL 1997 MM 0759670 OS8070L LO mm

ANNEX B

QUALITY SYSTEM PROGRAM

(This is a nonmandatory part of ASME B16.25 and is included for information anly.)

“The products manufactured in accordance with ASME.

816.25 shall be produced under a quality system pro-

gram following te principles of an appropriate standard

from the ISO 9000 series.’ A determination of the

need fr rexistation and/or cetfication of the product

The eres is also available from the American National Stands

Instiate (ANSI and the American Socitay for Quality Contol

(ASOC) as American Nacional Standards that are dented by a

prefs “Q" replacing the prefix 90." Each sanded of the series

listed under references

Copyright by the American Society Of Mechanical Engineers

Mon Feb 08 11:59:26 2007

vanufacturer’s quality system program by an indepen-

dent organization shall be the responsibility of the

‘manufacturer. The detailed documentation demonstra-

ting program compliance shall be available 10 the

purchaser at the manufacturer's facility. A writen sum-

‘mary description of the program utilized by the product

manufacturer shall be available to the purchaser upon

request. The product manufacturer is defined as the

entity whose name or trademark appears on the product

in accordance with the marking or identification require-

ments of ASME 16.25.

STD-ASME Blb-2S-ENGL 1997 MM O759670 O580707 Sua Ml

BUTTWELDING ENDS.

ASME 816.25-1097

ANNEX C

REFERENCES

{This Annex is on integral part of ASME 616.26 and ie placod aftor the main text for convenience.)

‘The following is alist of standards and specifications

referenced in this Standard showing the year of approval

ASME Publications (Approved as American National

Standards)

ASME BI6,5-1988, Pipe Flanges and Flanged Fi

ASME B16,9-1993, Factory-Made Wrought Stee! Butt-

wolding Fittings

ASME B16.28-1994, Wrought Steel Buttwelding Short

Radius Elbows and Returns

ANSVASME B36,10M-1985, Welded and Seamless

Wrought Steel Pipe

ASTM Publications

ASTM E 29-93, Standard Practice for Using Significant

Digits in Test Data to Determine Conformance With

Specifications

ASTM A 106-94, Specification for Seamless Carbon

Steel Pipe for High-Temperature Service

ASTM A 335/A 335M-94, Specification for Seaunless

Ferrtic Ally Steel Pipe for High-Temperature Service

150 Publications

ISO 9000-1: 1994: Quality Management and Quality

Assurance Standards — Part 1: Guidelines for Selection

and Use

Copyright by the American Society Of Mechanical Engineers

Non Feb 08 11:59:27 2007

ISO 9000-2: 1993: Quality Management and Quality

‘Assurance Standards — Part ?: Generic Guidelines for

the Application of ISO 9001, ISO 9002. and ISO 9003

ISO 90003-1991: Quality Management and Quality

Assurance Standards — Part 3: Guidelines for the

Application of ISO 9001 to the Development, Supply

and Maintenance of Software

10 9001: 1994: Quality Systems — Model for Quality

Assurance in Design, Development, Production, Installa-

tion, and Servicing

10 9002: 1994: Quality Systems — Model for Quality

Assurance in Production and Servicing

1S 9003: 1994: Quality Systems — Model for Quality

‘Assurance in Pinal Inspection and Test

Publications appearing above which have been ap-

proved as American National Standards may also be

obtained from:

ANSI

American National Standards Institute, Inc

IL West 42nd Suet, New York, New York 10036

180

ISO Cenual Secretariat

Case Postale 56

CH-I211 GENEVA 20

Switzerland

También podría gustarte

- Asme B16.22Documento26 páginasAsme B16.22Tien Pham100% (2)

- Asme B16.47-2011Documento120 páginasAsme B16.47-2011Asad100% (4)

- Aws c4.4 c4.4m 2004 Recommended Practices For Heat Shaping and Straightening With Oxyfuel Gas HeatingDocumento53 páginasAws c4.4 c4.4m 2004 Recommended Practices For Heat Shaping and Straightening With Oxyfuel Gas HeatingKara White0% (1)

- ASME ANSI B16.11 Forged Fittings Socket Welding and ThreadedDocumento33 páginasASME ANSI B16.11 Forged Fittings Socket Welding and ThreadedpaulamuisesAún no hay calificaciones

- User Design Spec - Rev1Documento5 páginasUser Design Spec - Rev1John NashAún no hay calificaciones

- Guide For Welding Ferritic/Austenitic Duplex Stainless Steel Piping and TubingDocumento29 páginasGuide For Welding Ferritic/Austenitic Duplex Stainless Steel Piping and Tubingarnoldbatista55100% (2)

- Nozzle LoadsDocumento8 páginasNozzle LoadsGovindan KrishnamoorthybashyamAún no hay calificaciones

- Pfi-Es-16 (2001)Documento7 páginasPfi-Es-16 (2001)jothishAún no hay calificaciones

- ASTM A 516 - A 516M Pressure Vessel PlateDocumento4 páginasASTM A 516 - A 516M Pressure Vessel PlatebonnicoAún no hay calificaciones

- ASME B16.47 Flanges and Dimensions ChartDocumento18 páginasASME B16.47 Flanges and Dimensions ChartSaifulla Baig67% (3)

- Stainless Steel Pipe: ASME B36.19M-2004Documento14 páginasStainless Steel Pipe: ASME B36.19M-2004shakeelahmadjsr100% (1)

- AWS D10 4 86R Recommended Practices PDFDocumento44 páginasAWS D10 4 86R Recommended Practices PDFwi100% (1)

- Asme B 31.3Documento343 páginasAsme B 31.3xaviereduardo67% (3)

- API 5l Pipe SpecificationsDocumento16 páginasAPI 5l Pipe SpecificationsAhmed Hamdy Hussein50% (2)

- b16 47Documento65 páginasb16 47Gustavo FamaAún no hay calificaciones

- Astm A733 Niples PDFDocumento4 páginasAstm A733 Niples PDFyesAún no hay calificaciones

- Aws D10.9Documento73 páginasAws D10.9scrib93420Aún no hay calificaciones

- Aws A5.14 A5.14m (1997) PDFDocumento30 páginasAws A5.14 A5.14m (1997) PDFnaspauzan100% (2)

- Asme B16.11 2005Documento30 páginasAsme B16.11 2005Starla Hill100% (4)

- MSS SP-97Documento15 páginasMSS SP-97ali karar100% (2)

- Metal-Korea Flange Material SpecificationsDocumento6 páginasMetal-Korea Flange Material SpecificationsarferrafAún no hay calificaciones

- Pfi Es-24Documento10 páginasPfi Es-24kingstonAún no hay calificaciones

- ASTM F1545 Plastic Lined Pipe 0803 PDFDocumento6 páginasASTM F1545 Plastic Lined Pipe 0803 PDFdavi rodriguesAún no hay calificaciones

- Asme B 31.3Documento343 páginasAsme B 31.3Erwin Del Aguila100% (3)

- Asme Section Ii A Sa-29 Sa-29m PDFDocumento26 páginasAsme Section Ii A Sa-29 Sa-29m PDFHyunjong MoonAún no hay calificaciones

- API 5L Pipe Specifications and GradesDocumento14 páginasAPI 5L Pipe Specifications and GradesMY RELAX0% (1)

- Aws D10.18 2018Documento38 páginasAws D10.18 2018Vinodth KumarAún no hay calificaciones

- Iso 5752 1982Documento13 páginasIso 5752 1982Madheswaran Dharmapuri100% (1)

- STP PT 007 PDFDocumento46 páginasSTP PT 007 PDFRafael Cossolino100% (1)

- Pfi-Es-22 (1999)Documento4 páginasPfi-Es-22 (1999)jothish100% (5)

- Asme B31.3 - 2012Documento10 páginasAsme B31.3 - 2012Angel Cuya0% (2)

- Pfi-Es-3 (2000) PDFDocumento4 páginasPfi-Es-3 (2000) PDFBarnum Pebble Darrel100% (1)

- Class 3000 Steel Pipe Unions Socket Welding and Threaded: MSS SP-83-2006Documento12 páginasClass 3000 Steel Pipe Unions Socket Welding and Threaded: MSS SP-83-2006ISRAEL PORTILLOAún no hay calificaciones

- B16 10Documento39 páginasB16 10Nila GamaAún no hay calificaciones

- SWPS Aws B2.1-8-212-2001Documento19 páginasSWPS Aws B2.1-8-212-2001dietersima100% (4)

- Ansi B16 - 5Documento157 páginasAnsi B16 - 5Felipe SandovalAún no hay calificaciones

- ASME IX - 2019 - Addenda - ChangesDocumento7 páginasASME IX - 2019 - Addenda - ChangeszaheerAún no hay calificaciones

- Guide For Welding Duplex & SDSS MaterialsDocumento37 páginasGuide For Welding Duplex & SDSS MaterialsKUMAR100% (3)

- Electric-Fusion-Welded Austenitic Chromium-Nickel Stainless Steel Pipe For High-Temperature Service and General ApplicationsDocumento9 páginasElectric-Fusion-Welded Austenitic Chromium-Nickel Stainless Steel Pipe For High-Temperature Service and General ApplicationsbiancogallazziAún no hay calificaciones

- Aws B1.10Documento41 páginasAws B1.10Tam Huynh Thanh100% (1)

- Norma AWSDocumento17 páginasNorma AWSFRANCISCO TORRES100% (2)

- Astm A105Documento5 páginasAstm A105ahmad0% (1)

- ASME-B16.20a-2009-Metallic Gaskets For Pipe FlangesDocumento65 páginasASME-B16.20a-2009-Metallic Gaskets For Pipe FlangesCarlos Gutierrez100% (3)

- Asme B1.1Documento177 páginasAsme B1.1Santosh Shetty100% (4)

- Asme Y14.13mDocumento27 páginasAsme Y14.13mAmin Alisadeghi100% (2)

- Asme B16.21Documento21 páginasAsme B16.21Denis Gonzales VasquezAún no hay calificaciones

- Asme A13.1Documento13 páginasAsme A13.1Adilson GabuAún no hay calificaciones

- Asme B1.20.5 PDFDocumento66 páginasAsme B1.20.5 PDFBala Murugan100% (1)

- Asme B1.20.1Documento32 páginasAsme B1.20.1Michael Tayactac100% (1)

- Asme B1.20.1 PDFDocumento32 páginasAsme B1.20.1 PDFAkram DriraAún no hay calificaciones

- ASME PTC 10 - Compressors and ExhaustersDocumento191 páginasASME PTC 10 - Compressors and ExhaustersAndreea FloreaAún no hay calificaciones

- ASME PTC 06 - 1985 - Report For Evaluation of Measurement Uncertainty in Performace Test of Steam TurbinesDocumento86 páginasASME PTC 06 - 1985 - Report For Evaluation of Measurement Uncertainty in Performace Test of Steam TurbinesJunwoo KimAún no hay calificaciones

- Asme B31.8Documento244 páginasAsme B31.8diegoAún no hay calificaciones

- Asme B1.1 - 1989Documento177 páginasAsme B1.1 - 1989Kevin AlmeidaAún no hay calificaciones

- Asme B16.50 2001Documento24 páginasAsme B16.50 2001tamnahaviAún no hay calificaciones

- Asme A13.1Documento13 páginasAsme A13.1oscar rdzAún no hay calificaciones

- Thu Jul 24 11:52:57 2003Documento13 páginasThu Jul 24 11:52:57 2003Dwi Ananto RaharjoAún no hay calificaciones

- ASME PTC 3.1 - 1979 Diesel - Burner FuelDocumento83 páginasASME PTC 3.1 - 1979 Diesel - Burner FuelKristianAún no hay calificaciones

- Ansi36 19Documento13 páginasAnsi36 19Yamini ShindeAún no hay calificaciones

- Astm c172-99 Sampling Freshly Mix Concrete PDFDocumento3 páginasAstm c172-99 Sampling Freshly Mix Concrete PDFVíctor M Fernández JiménezAún no hay calificaciones

- Astm ADocumento32 páginasAstm AKhaled FatnassiAún no hay calificaciones

- C 0150Documento7 páginasC 0150william_m08Aún no hay calificaciones

- Malleable Iron Flanges, Pipe Fittings, and Valve Parts For Railroad, Marine, and Other Heavy Duty Service at Temperatures Up To 650°F (345°C)Documento2 páginasMalleable Iron Flanges, Pipe Fittings, and Valve Parts For Railroad, Marine, and Other Heavy Duty Service at Temperatures Up To 650°F (345°C)william_m08Aún no hay calificaciones

- Astm A139Documento6 páginasAstm A139william_m08100% (1)

- Flat-Rolled Electrical Steels For Magnetic ApplicationsDocumento4 páginasFlat-Rolled Electrical Steels For Magnetic Applicationswilliam_m08Aún no hay calificaciones

- Seamless Ferritic Alloy-Steel Pipe For High-Temperature ServiceDocumento8 páginasSeamless Ferritic Alloy-Steel Pipe For High-Temperature ServiceSofiaJabadanEspulgarAún no hay calificaciones

- A336A336Documento7 páginasA336A336Andres Camilo BenitezAún no hay calificaciones

- MSS SP 83 01 Class 3000 Steel Pipe Unions Socket Welding and Threaded.Documento12 páginasMSS SP 83 01 Class 3000 Steel Pipe Unions Socket Welding and Threaded.william_m08Aún no hay calificaciones

- Astm A328Documento2 páginasAstm A328william_m08100% (1)

- Teacher's Printable Activities for Top Notch ExtensionDocumento3 páginasTeacher's Printable Activities for Top Notch ExtensionCristina SoaresAún no hay calificaciones

- Rotina ExplosaoDocumento1 páginaRotina Explosaowilliam_m08Aún no hay calificaciones

- A 479 PDFDocumento8 páginasA 479 PDFwilliam_m08Aún no hay calificaciones

- A 447Documento4 páginasA 447william_m08Aún no hay calificaciones

- Dear MarinaDocumento1 páginaDear Marinawilliam_m08Aún no hay calificaciones