Documentos de Académico

Documentos de Profesional

Documentos de Cultura

HIRARC

Cargado por

Adrian IlieDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

HIRARC

Cargado por

Adrian IlieCopyright:

Formatos disponibles

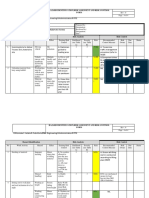

MUDAJAYA CORPORATION BERHAD

Department 10 Damansara Height Personnel participated & consulted:

OSH TASK RISK ASSESSMENT

Assessors name Prepared by:

Doc No. Ref Code / Rev

Reviewed by:

Approved by:

Area Activity

Name Preliminaries Works - Site Clearing

Designation

1) 2) 3)

Legal Compliance

Name: Signature: Date:

Name: Signature: Date:

Name: Signature: Date:

Hazard Identification

Risk Assessment Applicable OSH Leg/Reg/COP (in addition to OSHA Sec 15, FM(SHW) reg) Significant Hazard? (Y/N)

No.

Sub-Activity

Condition of assessment

Hazards

Consequences

Existing Control Measures (ECM)

F C, PC, NC

Risk Rating

Control Determination of control hierarchy: 1. Elimination of hazards Risk 2. Substitution Categ. 3. Engineering 4. Administrative 5. Personal Protective Equipment (PPE) 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide Barricade to Excavate Area. 4. Appoint a Traffic Controller.

Struck /crushed by machine/Collision

Body injuries / fatality

OSHA Act Sec 15. FM (BOWEC)(Safety)

Enggineering & Admin. Control - Safety awareness -Barrier, Traffic Control, Training, Briefing & Monitoring

Potential contact with underground power line

Body injuries / fatality

OSHA Act Sec 15. Enggineering, Admin. FM (BOWEC) (Electrical Hazard) Control & PPE - Safety Reg 16. 1986 Electricity Supply awareness Act 1990 Electricity Reg. and Isolation, Briefing, Monitoring rules 1994 and appropriate PPE

12

II

1. All workers must be inducted before commencing work. 2. All workers must use proper P.P.E 3. To provide competent super visor to supervise the activity full time. 4. To organize Tool Box talk/meeting every time want to start work. 5. To provide Clearance Marking as per TNB requirement.

Exposure to noise

Chronic hearing problem

OSHA Act Sec 15 FM (Noise Exposure) Reg. 1989.

Admin. Control & PPE Safety awareness -Ear plug/muff & initial noise monitoring

1. All workers must be inducted before commencing work. 2. All workers must use proper P.P.E 3. To provide competent super visor to supervise the activity full time. 4. To organize Tool Box talk/meeting every time want to start work.

Excavation Of Earth (Excavator, Back Hoe and Dump Truck)

R/W

Enggineering & Admin. Inhalation of heavy smoke / OSHA Sec 15, Control - Safety awareness Chronic health problem exhaust fume FM (BOWEC) Reg 11 & 14. 1986 -Face mask, Servicing, Toolbox Talk, Monitoring 1. OSHA Act Sect 15, 2. FMA Sect. 22. 3. Prevention And Control Of Infectious Diseases Act and Regulation OSHA Sec 15, FM (Mineral Dust) Reg. 1989

1. All workers must used proper PPE at work site. 2. Un-good condition of machinery need to be check and repair as posible. 3. Toolbox Talk before start work.

Mosquito/ insect bites

Dengue/ skin rash/dermatitis

Eliminationcontrol

Pest

1. Appoint pest control to clear all insect/ mosquito as shown in Prevention And Control Of Infectious Diseases Act and Regulation

Inhalation of dust

Irritation of respiratory tract

Engineering, admin control & PPE Water sprinkling/Browser, Dust mask and training Engineering, Admin Control Provided proper access/egress, training/information Admin. Control work practice Safe

1. Provide water sprinkler/ browser to prevent flying dust. supply face mask to worker which involved

2.

Slippery & poor access/egress

Slip, trip & fall - body injuries

OSHA Sec 15, FM (SHW) & (BOWEC)

Operation in unsafe mode

Body injuries / fatality

OSHA Sec 15 & 24

1. Stop work. 2.Terminate if necessary 1. Provive Shelter for workers cooling body from direct sun. 2. Brief workers to drink a lot of plain water. 3. Advise workers to use a appropriate cloth due to hot weather.

Heat stress

Fatigue/ skin rash

OSHA Sec 15 & 24, FMA Sect. 23

Engineering, admin control & PPE Shelter, Briefing & Protective clothing

12

II

Exposure to welding fume

Irritation of respiratory tract

OSHA Sec 15 & 24, FM (BOWEC)(Safety) Reg 14. OSHA Sec 15, FMA Sec 11 & (BOWEC) Reg 15 OSHA Sec 15, FMA Sec 11 & (BOWEC) Reg 15

Admin control & PPE Training, Briefing & Face mask Admin control & PPE Training, Briefing & Face Shield Admin control & PPE Training, Briefing, Protective clothing, hand glove & face shield

Exposed to UV & IR ray

permanent eye damage

Exposure to welding spark

Skin burn

Installation of Hoarding (Welding Set, Power Tool/Drill)

NR/W

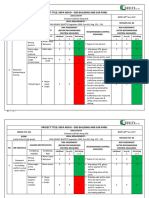

Hazard Identification

Risk Assessment Applicable OSH Leg/Reg/COP (in addition to OSHA Sec 15, FM(SHW) reg) Legal Compliance F C, PC, NC L S Significant Hazard? (Y/N)

No.

Sub-Activity

Condition of assessment

Hazards

Consequences

Existing Control Measures (ECM)

Risk Rating

Electrocution Installation of Hoarding (Welding Set, Power Tool/Drill)

Fatality /body injuries

OSHA Sec 15, FM (BOWEC)(SAFETY) Reg. 16

Admin control & PPE Training, Briefing, Protective clothing & hand glove.

12

Control Determination of control hierarchy: 1. Elimination of hazards Risk 2. Substitution Categ. 3. Engineering 4. Administrative 5. Personal Protective Equipment (PPE) 1. Only the competent permitted to carrying out work. 2. PPE equipment that suitable to be used while working. 3. Supervise and provide briefing before start work. 4. II Obtain Working Permit from MCB. 5. All workers must be inducted before commencing of work. 6. All workers must be briefing before start work. 1. All moving part of the machine must be fully guarded. 2. All workers must be inducted before commencing of work. 3. All workers must be briefing before start work. 4. Proper PPE must be worn while working. 5. Provide training to workers which involved.

NR/W Exposure to sharp object Hand Injuries OSHA Sec 15, FMA Sec. 24 Engineering, admin control & PPE Guarded, briefing and Protective clothing Admin control & PPE Training, Briefing, Protective clothing & hand glove. Engineering, admin control & PPE Shelter, Briefing & Protective clothing C 1 3 2 N 6 I

Flying of particles

Eye or body injuries

OSHA Sec 15, FMA Sec. 24

Heat stress

Fatigue

OSHA Sec 15 & 24, FMA Sect. 23 1. OSHA Act Sect 15, 2. FMA Sect. 22. 3. Prevention And Control Of Infectious Diseases Act and Regulation

12

II

1. Provive Shelter for workers cooling body from direct sun. 2. Brief workers to drink a lot of plain water. 3. Advise workers to use a appropriate cloth due to hot weather.

Mosquito/ insect bites

Dengue/ skin rash/dermatitis

Eliminationcontrol

Pest

1. Appoint pest control to clear all insect/ mosquito as shown in Prevention And Control Of Infectious Diseases Act and Regulation

Struck /crushed by machine/Collision

Body injuries / fatality

OSHA Act Sec 15. FM (BOWEC)(Safety)

Enggineering & Admin. Control - Safety awareness -Barrier, Traffic Control, Training, Briefing & Monitoring

1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide Barricade to Excavate Area. 4. Appoint a Traffic Controller.

Mosquito/ insect bites

Dengue/ skin rash/dermatitis

1. OSHA Act Sect 15, 2. FMA Sect. 22. 3. Prevention And Control Of Infectious Diseases Act and Regulation OSHA Sec 15, FM (Mineral Dust) Reg. 1989

Eliminationcontrol

Pest

1. Appoint pest control to clear all insect/ mosquito as shown in Prevention And Control Of Infectious Diseases Act and Regulation

Inhalation of dust/Concrette Dust

Irritation of respiratory tract

Engineering, admin control & PPE Water sprinkling/Browser, Dust mask and training

1. Provide water sprinkler/ browser to prevent flying dust. supply face mask to worker which involved

2.

Silt Trap/Wash Trough (Excavator, Back Hoe, Welding Set, Cutting Machine/grinder)

Potential contact with underground power line NR/W

Body injuries / fatality

Enggineering, Admin. OSHA Act Sec 15. FM (BOWEC) (Electrical Hazard) Control & PPE - Safety Reg 16. 1986 Electricity Supply awareness Act 1990 Electricity Reg. and Isolation, Briefing, Monitoring rules 1994 and appropriate PPE OSHASec 15, FMA (BOWEC)

12

II

1. All workers must be inducted before commencing work. 2. All workers must use proper P.P.E 3. To provide competent super visor to supervise the activity full time. 4. To organize Tool Box talk/meeting every time want to start work. 5. To provide Clearance Marking as per TNB requirement. 6. Permit To Work.

Fall into excavated trench

Body injuries

Engineering,Admin controlGuardrail/Barrier, monitoring

Inhalation of dust

Irritation of respiratory tract

OSHA Sec 15, FM (Mineral Dust) Reg. 1989

Engineering, admin control & PPE Water sprinkling/Browser, Dust mask and training Admin control & PPE Training, Briefing, Protective clothing & hand glove.

1. Provide water sprinkler/ browser to prevent flying dust. supply face mask to worker which involved

2.

Electrocution

Fatality /body injuries

OSHA Sec 15, FM (BOWEC)(SAFETY) Reg. 16

1. Only the competent permitted to carrying out work. 2. PPE equipment that suitable to be used while working. 3. Supervise and provide briefing before start work. 4. Obtain Working Permit from MCB. 5. All workers must be inducted before commencing of work. 6. All

Heat stress

Fatigue

OSHA Sec 15 & 24, FMA Sect. 23

Engineering, admin control & PPE Shelter, Briefing & Protective clothing

Hazard Identification

Risk Assessment Applicable OSH Leg/Reg/COP (in addition to OSHA Sec 15, FM(SHW) reg) Legal Compliance F C, PC, NC L S Significant Hazard? (Y/N)

No.

Sub-Activity

Condition of assessment

Hazards

Consequences

Existing Control Measures (ECM)

Risk Rating

Control Determination of control hierarchy: 1. Elimination of hazards Risk 2. Substitution Categ. 3. Engineering 4. Administrative 5. Personal Protective Equipment (PPE) 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide Barricade to Excavate Area. 4. Appoint a Traffic Controller.

Struck /crushed by machine/Collision

Body injuries / fatality

OSHA Act Sec 15. FM (BOWEC)(Safety)

Enggineering & Admin. Control - Safety awareness -Barrier, Traffic Control, Training, Briefing & Monitoring

12

II

Potential contact with underground power line

Body injuries / fatality

Enggineering, Admin. OSHA Act Sec 15. FM (BOWEC) (Electrical Hazard) Control & PPE - Safety Reg 16. 1986 Electricity Supply awareness Act 1990 Electricity Reg. and Isolation, Briefing, Monitoring rules 1994 and appropriate PPE

12

II

1. All workers must be inducted before commencing work. 2. All workers must use proper P.P.E 3. To provide competent super visor to supervise the activity full time. 4. To organize Tool Box talk/meeting every time want to start work. 5. To provide Clearance Marking as per TNB requirement. 6. Permit To Work.

Enggineering & Admin. Inhalation of heavy smoke / OSHA Sec 15, Control - Safety awareness Chronic health problem exhaust fume FM (BOWEC) Reg 11 & 14. 1986 -Face mask, Servicing, Toolbox Talk, Monitoring

1. All workers must used proper PPE at work site. 2. Un-good condition of machinery need to be check and repair as posible. 3. Toolbox Talk before start work.

Manual handling

Sprains, strains & backache Irritation of respiratory tract

OSHA Act 15, FMA Sec. 12 OSHA Sec 15 & 24, FM (BOWEC)(Safety) Reg 14. OSHA Sec 15 & 24

Admin. Control safe lifting procedure Admin control & PPE Training, Briefing & Face mask Admin. Control work practice Safe

Exposure to welding fume

Operation in unsafe mode

Body injuries / fatality

1. Stop work. 2.Terminate if necessary 1. Provive Shelter for workers cooling body from direct sun. 2. Brief workers to drink a lot of plain water. 3. Advise workers to use a appropriate cloth due to hot weather.

Stream Diversion (Excavator, Back Hoe, Welding Set & Cutting Machine)

Heat stress R/W

Fatigue/ skin rash

OSHA Sec 15 & 24, FMA Sect. 23

Engineering, admin control & PPE Shelter, Briefing & Protective clothing

12

II

Confined Space

Harzadous Atmosphere

OSHA Sect 15. ICOP 2010 (Industrial Code Of Practice)

Engineering, admin control & PPE Guidelines in Industrial Code Of Practice 2010 (ICOP)

12

II

Detail Requirement: 1. Permit System. 2. Permit to Work. 3. Isolation Requirement. 4.Requirement to Ensure Safety of Atmosphere. 5. Entry Into Hazardous Atmosphere. 6. Rescue and Emergency Services. 7.Health Requirements of Person Working in Confined Space. 8. Training. 9. Additional Precautions During Occupancy of Confined Space. 10. Record Keeping.

Fall into excavated trench

Body injuries

OSHA Sec 15, FMA (BOWEC)

Engineering,Admin controlGuardrail/Barrier, monitoring

Soil collapse into trench/Cave in

Body injuries / fatality

OSHA Act 15, FM (BOWEC) Reg 116,117 & 118 OSHA Sec 15, FMA Sec 11 & (BOWEC) Reg 15

Engineering controlShoring/ safe work practice, Supervising Admin control & PPE Training, Briefing & Face Shield Admin control & PPE Training, Briefing, Protective clothing, hand glove & face shield

12

II

1. Permit To Work Required before excavation. Supervise at all potential area in full time. Briefing/Toolbox Talk before start work. 4. Training.

2. 3.

Exposed to UV & IR ray

Permanent eye damage

Exposure to welding spark

Skin burn

OSHA Sec 15, FMA Sec 11 & (BOWEC) Reg 15

Hazard Identification

Risk Assessment Applicable OSH Leg/Reg/COP (in addition to OSHA Sec 15, FM(SHW) reg) Legal Compliance F C, PC, NC L S Significant Hazard? (Y/N)

No.

Sub-Activity

Condition of assessment

Hazards

Consequences

Existing Control Measures (ECM)

Risk Rating

Control Determination of control hierarchy: 1. Elimination of hazards Risk 2. Substitution Categ. 3. Engineering 4. Administrative 5. Personal Protective Equipment (PPE) 1. Permit to Work Required for Hot Job. 2. Monitoring and analyze the potential of hazard. 3. Briefing/Toolbox Talk before start work. 4. Competent/Training.

Electrocution

Fatality /body injuries

OSHA Sec 15, FM (BOWEC)(SAFETY) Reg. 16

Admin control & PPE Training, Briefing, Protective clothing & hand glove.

12

II

Struck /crushed by machine/Collision

Body injuries / fatality

OSHA Act Sec 15. FM (BOWEC)(Safety)

Enggineering & Admin. Control - Safety awareness -Barrier, Traffic Control, Training, Briefing & Monitoring

1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide Barricade to Excavate Area. 4. Appoint a Traffic Controller.

Potential contact with underground power line

Body injuries / fatality

Enggineering, Admin. OSHA Act Sec 15. FM (BOWEC) (Electrical Hazard) Control & PPE - Safety Reg 16. 1986 Electricity Supply awareness Act 1990 Electricity Reg. and Isolation, Briefing, Monitoring rules 1994 and appropriate PPE

12

II

1. All workers must be inducted before commencing work. 2. All workers must use proper P.P.E 3. To provide competent super visor to supervise the activity full time. 4. To organize Tool Box talk/meeting every time want to start work. 5. To provide Clearance Marking as per TNB requirement. 6. Permit To Work.

Exposure to noise

Chronic hearing problem

OSHA Act Sec 15 FM (Noise Exposure) Reg. 1989.

Admin. Control & PPE Safety awareness -Ear plug/muff & initial noise monitoring

1. All workers must be inducted before commencing work. 2. All workers must use proper P.P.E 3. To provide competent super visor to supervise the activity full time. 4. To organize Tool Box talk/meeting every time want to start work.

Earth Work - (Excavator, Back Hoe, Back Pusher, Roller Compactor, Dump Truck)

R/W Enggineering & Admin. Inhalation of heavy smoke / OSHA Sec 15, Control - Safety awareness Chronic health problem exhaust fume FM (BOWEC) Reg 11 & 14. 1986 -Face mask, Servicing, Toolbox Talk, Monitoring C 1 3 2 N 6 I 1. All workers must used proper PPE at work site. 2. Un-good condition of machinery need to be check and repair as posible. 3. Toolbox Talk before start work.

Inhalation of dust/Concrette Dust

Irritation of respiratory tract

OSHA Sec 15, FM (Mineral Dust) Reg. 1989

Engineering, admin control & PPE Water sprinkling/Browser, Dust mask and training Admin. Control work practice Safe

1. Provide water sprinkler/ browser to prevent flying dust. supply face mask to worker which involved

2.

Operation in unsafe mode

Body injuries / fatality

OSHA Sec 15 & 24

1. Stop work. 2.Terminate if necessary 1. Provive Shelter for workers cooling body from direct sun. 2. Brief workers to drink a lot of plain water. 3. Advise workers to use a appropriate cloth due to hot weather.

Heat stress

Fatigue/ skin rash

OSHA Sec 15 & 24, FMA Sect. 23

Engineering, admin control & PPE Shelter, Briefing & Protective clothing Engineering, Admin Control Provided proper access/egress, training/information Admin control & PPE Training, Briefing & Face Shield Admin control & PPE Training, Briefing, Protective clothing, hand glove & face shield

12

II

Slippery & poor access/egress

Slip, trip & fall - body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Exposed to UV & IR ray

permanent eye damage

OSHA Sec 15, FMA Sec 11 & (BOWEC) Reg 15 OSHA Sec 15, FMA Sec 11 & (BOWEC) Reg 15

Exposure to welding spark

Skin burn

Electrocution

Fatality /body injuries

OSHA Sec 15, FM (BOWEC)(SAFETY) Reg. 16

Admin control & PPE Training, Briefing, Protective clothing & hand glove.

12

II

1. Permit to Work Required for Hot Job. 2. Monitoring and analyze the potential of hazard. 3. Briefing/Toolbox Talk before start work. 4. Kompetent/Training.

Hazard Identification

Risk Assessment Applicable OSH Leg/Reg/COP (in addition to OSHA Sec 15, FM(SHW) reg) Legal Compliance F C, PC, NC Admin control & PPE Training, Briefing & Face mask L S Significant Hazard? (Y/N)

No.

Sub-Activity

Condition of assessment

Hazards

Consequences

Existing Control Measures (ECM)

Risk Rating

Control Determination of control hierarchy: 1. Elimination of hazards Risk 2. Substitution Categ. 3. Engineering 4. Administrative 5. Personal Protective Equipment (PPE) I

Exposure to welding fume

Irritation of respiratory tract

OSHA Sec 15 & 24, FM (BOWEC)(Safety) Reg 14.

Confined Space

Harzadous Atmosphere

OSHA Sect 15. ICOP 2010 (Industrial Code Of Practice)

Engineering, admin control & PPE Guidelines in Industrial Code Of Practice 2010 (ICOP)

12

II

Detail Requirement: 1. Permit System. 2. Permit to Work. 3. Isolation Requirement. 4.Requirement to Ensure Safety of Atmosphere. 5. Entry Into Hazardous Atmosphere. 6. Rescue and Emergency Services. 7.Health Requirements of Person Working in Confined Space. 8. Training. 9. Additional Precautions During Occupancy of Confined Space. 10. Record Keeping.

Minor fire accident/ Contact with Hot Part

Skin burn

OSHA Sec 15 & 24 FMA (BOWEC)

Admin Control & PPE Briefing,Protective clothing, hand glove & face shield

12

II

1. Permit To Work Required for Hot Job. 2. Flashback Arrestor is compulsory. 3. Briefing/Toolbox Talk before start work. 4. Competent/Training. 1. Permit Ro Work Required for Hot Job. 2. Flashback Arrestor is compulsory. 3. Briefing/Toolbox Talk before start work. 4. Competent/Training.

Leakage of oxy-acetylene hose- fire or explosion

Fatality /body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Engineering & Admin. Control - Flash Back Arrestor, Training, Briefing & Hot work permit Engineering, admin control & PPE Water sprinkling/Browser, Dust mask and training Admin control & PPE Training, Briefing, Protective clothing & hand glove. Admin. Control Training, Briefing, Job Rotation & Safe work practice Admin. Control Training, Briefing, Job Rotation & Safe work practice Admin. Control & PPE Safety awareness -Ear plug/muff & initial noise monitoring Admin. Control Training, Briefing, Job Rotation & Safe work practice Engineering, admin control & PPE Guarded, briefing and Protective clothing

Inhalation of dust/Concrette Dust

Irritation of respiratory tract

OSHA Sec 15, FM (Mineral Dust) Reg. 1989

1. Provide water sprinkler/ browser to prevent flying dust. supply face mask to worker which involved

2.

Flying of particles

Eye or body injuries

OSHA Sec 15, FMA Sec. 24

Body vibration

Body injuries

OSHA Sec 15 FMA (BOWEC)

Ergonomic- awkward position & repetitive motion

Body strain

Info from: DOSH,Niosh, CROSH, CCOHS, Miosh & etc

Box Culvert and Sump (Excavator/Back Hoe, Mobile Crane, Hacker, Oxy-Cutting, Cutting Machine/Grinder)

Exposure to noise R/W

Chronic hearing problem

OSHA Act Sec 15 FM (Noise Exposure) Reg. 1989.

1. All workers must be inducted before commencing work. 2. All workers must use proper P.P.E 3. To provide competent super visor to supervise the activity full time. 4. To organize Tool Box talk/meeting every time want to start work.

Hand-arm vibration

Carpal tunnel syndrome

OSHA Sec 15 FMA (BOWEC)

Exposure to sharp object

Hand Injuries

OSHA Sec 15, FMA Sec. 24

1. All moving part of the machine must be fully guarded. 2. All workers must be inducted before commencing of work. 3. All workers must be briefing before start work. 4. Proper PPE must be worn while working. 5. Provide training to workers which involved. 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide Barricade to Excavate Area. 4. Appoint a signalman with a good communication to operator.

Falling of materials

Fatality /body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Admin control & PPE Training, Briefing, Signalman, Safe Work Practice & Safety Helmet

12

II

Hazard Identification

Risk Assessment Applicable OSH Leg/Reg/COP (in addition to OSHA Sec 15, FM(SHW) reg) Legal Compliance F C, PC, NC L S Significant Hazard? (Y/N)

No.

Sub-Activity

Condition of assessment

Hazards

Consequences

Existing Control Measures (ECM)

Risk Rating

Control Determination of control hierarchy: 1. Elimination of hazards Risk 2. Substitution Categ. 3. Engineering 4. Administrative 5. Personal Protective Equipment (PPE) 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Competent/license operator only can operate machine 4. Appoint a signalman with a good communication to operator. 5. Supervise by the experience person.

Toppling of crane

Fatality /body injuries

OSHA Sec 15 FMA (BOWEC)

Admin. Control - Safe working load/procedure

Slippery & poor access/egress

Slip, trip & fall - body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Engineering, Admin Control Provided proper access/egress, training/information Engin. & Admin control Mechanical guard, Safe Work Practice training & Briefing

Operation of Power Tools

Hand injuries/Body Injury

OSHA Sec 15, FM (BOWEC)

1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Training workers only can operate machine. 4. Supervise by the experience person.

Heat stress

Fatigue/ skin rash

OSHA Sec 15 & 24, FMA Sect. 23

Engineering, admin control & PPE Shelter, Briefing & Protective clothing Engineering controlShoring/ safe work practice, Supervising Admin control & PPE Training, Briefing, Protective clothing & hand glove. Engineering, admin control & PPE Water sprinkling/Browser, Dust mask and training Admin Control & PPE Briefing,Protective clothing, hand glove & face shield

Soil collapse into trench/Cave in

Body injuries / fatality

OSHA Act 15, FM (BOWEC) Reg 116,117 & 118 OSHA Sec 15, FMA Sec. 24

12

II

1. Permit To Work Required before excavation. Supervise at all potential area in full time. Briefing/Toolbox Talk before start work. 4. Training.

2. 3.

Flying of particles

Eye or body injuries

Inhalation of dust/Concrette Dust

Irritation of respiratory tract

OSHA Sec 15, FM (Mineral Dust) Reg. 1989

Minor fire accident/ Contact with Hot Part

Skin burn

OSHA Sec 15 & 24 FMA (BOWEC)

1. Permit To Work Required before excavation. Supervise at all potential area in full time. Briefing/Toolbox Talk before start work. 4. Training.

2. 3.

Exposure to sharp object

Hand Injuries

OSHA Sec 15, FMA Sec. 24

Engineering, admin control & PPE Guarded, briefing and Protective clothing

1. All moving part of the machine must be fully guarded. 2. All workers must be inducted before commencing of work. 3. All workers must be briefing before start work. 4. Proper PPE must be worn while working. 5. Provide training to workers which involved. 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide Barricade to Excavate Area. 4. Appoint a signalman with a good communication to license machine operator. 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Competent/license operator only can operate machine 4. Appoint a signalman with a good communication to operator. 5. Supervise by the experience person. 1. Stop work. 2.Terminate if necessary

Falling of material

Body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Admin control & PPE Training, Briefing, Signalman, Safe Work Practice & Safety Helmet

Toppling of crane

Body injuries / fatality

OSHA Sec 15 FMA (BOWEC)

Admin. Control - Safe working load/procedure

12

II

Piling Works - (Jack-In Machine, Mobile Crane, Welding Set, Generator, Drop Hammer)

Operation in unsafe mode R/W

Body injuries / fatality

OSHA Sec 15 & 24

Admin. Control work practice

Safe

Hazard Identification

Risk Assessment Applicable OSH Leg/Reg/COP (in addition to OSHA Sec 15, FM(SHW) reg) Legal Compliance F C, PC, NC L S Significant Hazard? (Y/N)

No. 7

Sub-Activity Piling Works - (Jack-In Machine, Mobile Crane, Welding Set, Generator, Drop Hammer)

Condition of assessment R/W

Hazards

Consequences

Existing Control Measures (ECM)

Risk Rating

Control Determination of control hierarchy: 1. Elimination of hazards Risk 2. Substitution Categ. 3. Engineering 4. Administrative 5. Personal Protective Equipment (PPE) 1. All workers must be inducted before commencing work. 2. All workers must use proper P.P.E 3. To provide competent super visor to supervise the activity full time. 4. To organize Tool Box talk/meeting every time want to start work. 1. Permit Ro Work Required for Hot Job. 2. Monitoring and analyze the potential of hazard. 3. Briefing/Toolbox Talk before start work. 4. Kompetent/Training.

Exposure to noise

Chronic hearing problem

OSHA Act Sec 15 FM (Noise Exposure) Reg. 1989.

Admin. Control & PPE Safety awareness -Ear plug/muff & initial noise monitoring

Electrocution

Fatality /body injuries

OSHA Sec 15, FM (BOWEC)(SAFETY) Reg. 16

Admin control & PPE Training, Briefing, Protective clothing & hand glove.

12

II

Heat stress

Fatigue/ skin rash

OSHA Sec 15 & 24, FMA Sect. 23

Engineering, admin control & PPE Shelter, Briefing & Protective clothing

Heat stress Load Test - (Mobile Crane, Jack-In Machine)

Fatigue/ skin rash

OSHA Sec 15 & 24, FMA Sect. 23

Engineering, admin control & PPE Shelter, Briefing & Protective clothing

NR/W Struck /crushed by machine/Collision OSHA Act Sec 15. FM (BOWEC)(Safety) Enggineering & Admin. Control - Safety awareness -Barrier, Traffic Control, Training, Briefing & Monitoring 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide Barricade to Excavate Area. 4. Appoint a Traffic Controller.

Body injuries / fatality

MUDAJAYA CORPORATION BERHAD

Department 10 Damansara Height Personnel participated & consulted:

OSH TASK RISK ASSESSMENT

Assessors name Prepared by:

Doc No. Ref Code / Rev

Reviewed by:

Approved by:

Area Activity

Name Building Works

Hazard Identification

Designation

1) 2) 3)

Risk Assessment Legal Compliance

Name: Signature: Date:

Name: Signature: Date:

Name: Signature: Date:

No.

Sub-Activity

Condition of assessment

Hazards

Consequences

Applicable OSH Leg/Reg/COP (in addition to OSHA Sec 15, FM(SHW) reg)

Existing Control Measures (ECM)

F C, PC, NC

Significant Hazard? (Y/N)

Risk Rating

Control Determination of control hierarchy: 1. Elimination of hazards Risk 2. Substitution Categ. 3. Engineering 4. Administrative 5. Personal Protective Equipment (PPE) 1. Erected by competent/training person only. 2. PE Design required for any scaffold erected more than 15 meters. 3. Inspection and supervising of competent person every time before its to be used. 4. Record keeping. 5. Ensure the material is in good condition/serviceable 1. Erected by competent/training person only. 2. Safety Harness/belt, lifelines & necessary precaution. 3. Briefing/toolbox talk before commencing work. Supervise by competent person. 5. Safe Work Practice.

Collapse of Structure

Body injuries / fatality

OSHA Sec 15. FM (BOWEC) (Scaffold) Part 10 Reg 72-98

Enggin. & Admin. Control Safety awareness, Competent, PE Design, Training, Briefing & Monitoring

12

II

Falling from Height

Body injuries / fatality

Osha Sec. 15 & 24 FM (SHW) Reg 12, 32 & (Scaffold) Pt 10 Reg 72-98

Engin. & Admin Control Walking Platform, Safety Harness /belt, Training & Briefing

12

II

4.

Falling of construction material from height

Fatality /body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Admin control & PPE Training, Briefing, Signalman, Safe Work Practice & Safety Helmet Engineering, Admin Control Provided proper access/egress, training/information

12

II

1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide Toe Board to Open Edge. 4. Barrier working area to prevent any invasion. 5. Monitoring of work and working area. 1. Ensure all workers aware about a safe work practice & procedure. 2. Briefing before start work. 3. immediately replace unserviceable or damage equipment. 4. safety belt or lifelines required for working at height 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Stop work immediatly. 1. Electrical Hand Tool must be in good condition. 2. Monitoring and analyze the potential of hazard. 3. Briefing/Toolbox Talk before start work. 4. Competent/Training. 1. Scaffold must be check and assessed every week and after heavy rain or wind, (Refer Checklist) 2. Record keeping. 3. Immediate action fo any consequences to the structure or scaffold condition. 4. PE Design Required for scaffold erected 15 meter and above

Slippery & poor access/egress 1 Scaffolding NR/W

Slip, trip & fall - body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Lightning

Body injuries / fatality

OSHA Act Sec 15. FMA Sec 23

Admin Control Safe work practice & Briefing.

Electrocution

Fatality /body injuries

OSHA Sec 15, FM (BOWEC) Reg. 16

Admin control & PPE Training, Briefing, Protective clothing & hand glove.

Wind/Rain

Structure Collapse/ disturbed/budge

OSHA Sec 15. FM (BOWEC) (Scaffold) Part 10 Reg 72-98

Admin. Control work practice

Safe

12

II

Heat Stress

Fatigue

OSHA Sec 15 & 24, FMA Sect. 23

Engineering, admin control & PPE Shelter, Briefing & Protective clothing

Collapse

Body injuries / fatality

OSHA Sec 15. FM (BOWEC) (Scaffold) Part 10 Reg 72-98

Enggin. & Admin. Control Safety awareness, Competent, PE Design, Training, Briefing & Monitoring

12

II

1. Erected by competent/training person only. 2. PE Design required for any scaffold erected more than 15 meters. 3. Inspection and supervising of competent person every time before its to be used. 4. Record keeping. 5. Ensure the material is in good condition/serviceable 1. Erected by competent/training person only. 2. Safety Harness/belt, lifelines & necessary precaution. 3. Briefing/toolbox talk before commencing work. Supervise by competent person. 5. Safe Work Practice.

Falling from Height

Body injuries / fatality

Osha Sec. 15 & 24 FM (SHW) Reg 12, 32 & (Scaffold) Pt 10 Reg 72-98

Engin. & Admin Control Walking Platform, Safety Harness /belt, Training & Briefing

12

II

4.

Hazard Identification Applicable OSH Leg/Reg/COP (in addition to OSHA Sec 15, FM(SHW) reg)

Risk Assessment Legal Compliance F C, PC, NC L S Significant Hazard? (Y/N)

No.

Sub-Activity

Condition of assessment

Hazards

Consequences

Existing Control Measures (ECM)

Risk Rating

Control Determination of control hierarchy: 1. Elimination of hazards Risk 2. Substitution Categ. 3. Engineering 4. Administrative 5. Personal Protective Equipment (PPE) 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide Toe Board to Open Edge. 4. Barrier working area to prevent any invasion. 5. Monitoring of work and working area. 1. Ensure all workers aware about a safe work practice & procedure. 2. Briefing before start work. 3. immediately replace unserviceable or damage equipment. 4. safety belt or lifelines required for working at height 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Stop work immediatly. 1. Electrical Hand Tool must be in good condition. 2. Monitoring and analyze the potential of hazard. 3. Briefing/Toolbox Talk before start work. 4. Competent/Training. 1. Scaffold must be check and assessed condition every week and after heavy rain or wind, (Refer Checklist) 2. Record keeping. 3. Immediate action for any consequences to the structure or scaffold condition.

Falling of construction material from height

Fatality /body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Admin control & PPE Training, Briefing, Signalman, Safe Work Practice & Safety Helmet

12

II

Working Platform

NR/W

Slippery & poor access/egress

Slip, trip & fall - body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Engineering, Admin Control Provided proper access/egress, training/information

Lightning

Body injuries / fatality

OSHA Sec 15. FMA Sec 23

Admin Control Safe work practice & Briefing.

Electrocution

Fatality /body injuries

OSHA Sec 15, FM (BOWEC) Reg. 16

Admin control & PPE Training, Briefing, Protective clothing & hand glove.

Wind/Rain

Structure Collapse/ disturbed/budge

OSHA Sec 15. FM (BOWEC) (Scaffold) Part 10 Reg 72-98

Admin. Control work practice

Safe

12

II

Heat Stress

Fatigue

OSHA Sec 15 & 24, FMA Sect. 23

Engineering, admin control & PPE Shelter, Briefing & Protective clothing

Collapse of Structure

Body injuries / fatality

OSHA Sec 15. FM (BOWEC) (Scaffold) Part 10 Reg 72-98

Enggin. & Admin. Control Safety awareness, Competent, PE Design, Training, Briefing & Monitoring

1. Only a good condition of ladder allowed to be used. 2. Mantain of good keeping of ladder condition. 3. Immediate change any damages with serviceable one. 4. Ensure the material is in good condition/serviceable 1. Erected by competent/training person only. 2. Hard Barrier/Guard rail. 3. Briefing/toolbox talk before commencing work. Supervise by competent person. 5. Safe Work Practice. 6. Ensure the material is in good condition/serviceable

Ladder

NR/W Falling from Height Body injuries / fatality

Osha Sec. 15 & 24 FM (SHW) Reg 12, 32 & (Scaffold) Pt 10 Reg 72-98

Engin. & Admin Control Walking Platform, Safety Harness /belt, Training & Briefing

12

II

4.

Slippery & poor access/egress

Slip, trip & fall - body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Engineering, Admin Control Provided proper access/egress, training/information

Caught in moving parts of machines

Body injuries

OSHA Sec 15 & 24 FMA sec 15,20

Engin, Admin Control & PPE Guard rail, Safe work practice, Training & Briefing.

1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Guarding machine/moving part.

Ergonomic- awkward position & repetitive motion

Body strain

Admin. Control Info from: DOSH,Niosh, CROSH, Training, Briefing, Job Rotation CCOHS, Miosh & etc & Safe work practice Enggineering & Admin. Control - Safety awareness -Face mask, Servicing, Toolbox Talk, Monitoring

Concrette Mixer

R/W Inhalation of heavy smoke / exhaust fume Chronic health problem OSHA Sec 15, FM (BOWEC) Reg 11 & 14. 1986

1. All workers must used proper PPE at work site. 2. Un-good condition of machinery need to be check and repair as posible. 3. Briefing before start work.

Hazard Identification 4 No. Concrette Mixer Sub-Activity R/W Condition of assessment Applicable OSH Leg/Reg/COP (in addition to OSHA Sec 15, FM(SHW) reg)

Risk Assessment Legal Compliance F C, PC, NC L S Significant Hazard? (Y/N)

Hazards

Consequences

Existing Control Measures (ECM)

Risk Rating

Control Determination of control hierarchy: 1. Elimination of hazards Risk 2. Substitution Categ. 3. Engineering 4. Administrative 5. Personal Protective Equipment (PPE) 1. All workers must be inducted before commencing work. 2. All workers must use proper P.P.E 3. To provide competent super visor to supervise the activity full time. 4. Briefing before start work.

Exposure to noise

Chronic hearing problem

OSHA Act Sec 15 FM (Noise Exposure) Reg. 1989.

Admin. Control & PPE Safety awareness -Ear plug/muff & initial noise monitoring

Electrocution

Fatality /body injuries

OSHA Sec 15, FM (BOWEC) Reg. 16

Admin control & PPE Training, Briefing, Protective clothing & hand glove.

1. Electrical Hand Tool must be in good condition. 2. Monitoring and analyze the potential of hazard. 3. Briefing/Toolbox Talk before start work. 4. Competent/Training. 1. All workers must used proper PPE at work site. 2. Un-good condition of machinery need to be check and repair as posible. 3. Briefing before start work.

Inhalation of heavy smoke / exhaust fume

Chronic health problem

OSHA Sec 15, FM (BOWEC) Reg 11 & 14. 1986

Enggineering & Admin. Control - Safety awareness -Face mask, Servicing, Toolbox Talk, Monitoring

Air Compressor

NR/W

Struck by pressure hoses

Body injuries

OSHA Sec 15. FMA Reg 4 & 118

Enggineering & Admin. Control - Safety awareness -Barrier, Traffic Control, Training, Briefing & Monitoring

1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards.

Unfit/ unsafe machine

Body injuries / fatality

FM - Rules (Boiler and Compressor) 1970 & FMA (Notification,Cert of Fitness & Insp.) Reg.1970

Admin Control - Only machine with fitness certified must be used.

12

II

1. All Air compressor must have c ertificate of fitness from DOSH and display at the compressor. 2. Maintenance and servicing as schedule. 3. Record Keeping.

Exposure to noise

Chronic hearing problem

OSHA Act Sec 15 FM (Noise Exposure) Reg. 1989.

Admin. Control & PPE Safety awareness -Ear plug/muff & initial noise monitoring

1. All workers must be inducted before commencing work. 2. All workers must use proper P.P.E 3. To provide competent super visor to supervise the activity. 4. Briefing before start work.

Electrocution

Fatality /body injuries

OSHA Sec 15, FM (BOWEC) Reg. 16

Admin control & PPE Training, Briefing, Protective clothing & hand glove.

12

II

1. General check before used and the machine must be in good condition. 2. Monitoring and analyze the potential of hazard. 3. Monthly check/maintenance must in schedule. 4. Record Keeping.

Exposed hot surface

Skin burn

OSHA Sec 15 & 24 FMA (BOWEC)

Admin Control & PPE Briefing,Protective clothing, hand glove & face shield

Generator

NR/W Inhalation of heavy smoke / exhaust fume Chronic health problem OSHA Sec 15, FM (BOWEC) Reg 11 & 14. 1986

Enggineering & Admin. Control - Safety awareness -Face mask, Servicing, Toolbox Talk, Monitoring

1. Placement generator in open area and suitable. 2. Un-good condition of machinery need to be check and repair as posible. 3. Maintenance must be done as schedule. 4. Record Keeping.

Exposure to noise

Chronic hearing problem

OSHA Act Sec 15 FM (Noise Exposure) Reg. 1989.

Admin. Control & PPE Safety awareness -Ear plug/muff & initial noise monitoring

Caught in moving parts of machines

Body injuries / fatality

OSHA Sec 15 & 24 FMA sec 15,20

Engin, Admin Control & PPE Guard rail, Safe work practice, Training & Briefing.

12

II

1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Guarding machine/moving part.

Bending Machine

R/W

Hazard Identification Applicable OSH Leg/Reg/COP (in addition to OSHA Sec 15, FM(SHW) reg)

Risk Assessment Legal Compliance F C, PC, NC L S Significant Hazard? (Y/N)

No.

Sub-Activity

Condition of assessment

Hazards

Consequences

Existing Control Measures (ECM)

Risk Rating

Control Determination of control hierarchy: 1. Elimination of hazards Risk 2. Substitution Categ. 3. Engineering 4. Administrative 5. Personal Protective Equipment (PPE) 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Guarding machine/moving part.

Operation of Power Tools

Hand injuries/Body Injury

OSHA Sec 15, FM (BOWEC)

Engin. & Admin control Mechanical guard, Safe Work Practice training & Briefing

Bending Machine

R/W Inhalation of heavy smoke / exhaust fume Chronic health problem OSHA Sec 15, FM (BOWEC) Reg 11 & 14. 1986

Enggineering & Admin. Control - Safety awareness -Face mask, Servicing, Toolbox Talk, Monitoring

1. Placement machine in open area and suitable. 2. Un-good condition of machinery need to be check and repair as posible. 3. Maintenance must be done as schedule.

Ergonomic- awkward position & repetitive motion

Body strain

Admin. Control Info from: DOSH,Niosh, CROSH, Training, Briefing, Job Rotation CCOHS, Miosh & etc & Safe work practice Admin. Control & PPE Safety awareness -Ear plug/muff & initial noise monitoring

Exposure to noise

Chronic hearing problem

OSHA Act Sec 15 FM (Noise Exposure) Reg. 1989.

Operation of Power Tools

Hand injuries/Body Injury

OSHA Sec 15, FM (BOWEC)

Engin. & Admin control Mechanical guard, Safe Work Practice training & Briefing

1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Guarding machine/moving part.

Inhalation of heavy smoke / exhaust fume

Chronic health problem

OSHA Sec 15, FM (BOWEC) Reg 11 & 14. 1986

Enggineering & Admin. Control - Safety awareness -Face mask, Servicing, Toolbox Talk, Monitoring

1. All workers must used proper PPE at work site. 2. Un-good condition of machinery need to be check and repair as posible. 3. Toolbox Talk before start work. 4. Place the machine in a good ventilation area.

Flying of particles and cutting disc 8 Cutting Machine R/W

Eye or body injuries

OSHA Sec 15, FMA Sec. 24

Admin control & PPE Training, Briefing, Protective clothing & hand glove.

Inhalation of dust

Irritation of respiratory tract

OSHA Sec 15, FM (Mineral Dust) Reg. 1989

Engineering, admin control & PPE Water sprinkling/Browser, Dust mask and training

1. Provide water sprinkler/ browser to prevent flying dust. supply face mask to worker which involved

2.

Ergonomic- awkward position & repetitive motion

Body strain

Admin. Control Info from: DOSH,Niosh, CROSH, Training, Briefing, Job Rotation CCOHS, Miosh & etc & Safe work practice

I 1. All workers must used proper PPE at work site. 2. Un-good condition of machinery need to be check and repair as posible. 3. Toolbox Talk before start work. 4. stationed machine in open area to prevent sound wave that repeat

Exposure to noise

Chronic hearing problem

OSHA Act Sec 15 FM (Noise Exposure) Reg. 1989.

Admin. Control & PPE Safety awareness -Ear plug/muff & initial noise monitoring

Toppling

Fatality /body injuries

OSHA Sec 15 FM (BOWEC) Reg 6, 58, 118

Admin. Control - Safe working load/procedure

12

II

1. Operator must be inducted before commencing of work. 2. Competent/license operator only can operate machine 3. Appoint a signalman with a good communication to operator. 4. Supervise by the experience person.

Mobile Crane

R/W

Hazard Identification Applicable OSH Leg/Reg/COP (in addition to OSHA Sec 15, FM(SHW) reg)

Risk Assessment Legal Compliance F C, PC, NC L S Significant Hazard? (Y/N)

No.

Sub-Activity

Condition of assessment

Hazards

Consequences

Existing Control Measures (ECM)

Risk Rating

Control Determination of control hierarchy: 1. Elimination of hazards Risk 2. Substitution Categ. 3. Engineering 4. Administrative 5. Personal Protective Equipment (PPE) 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Avoid to be under loading material. 4. Appoint a signalman with a good communication to operator.

Falling of materials

Fatality /body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Admin control & PPE Training, Briefing, Signalman, Safe Work Practice & Safety Helmet

12

II

Mobile Crane

R/W Struck /crushed by machine/Collision Body injuries / fatality OSHA Act Sec 15. FM (BOWEC)(Safety)

Enggineering & Admin. Control - Safety awareness -Barrier, Traffic Control, Training, Briefing & Monitoring Admin Control & PPE Briefing, monitoring, Safe Work Practice, hand glove & Safety Boot

1. Operator must be inducted before commencing of work. 2. Competent/license operator only can operate machine 3. Appoint a signalman with a good communication to operator. 4. Supervise by the experience person.

Electrocution (Working near power sources)

Fatality /body injuries

OSHA Sec 15, FMA (BOWEC)

12

II

1. Safe work practice/procedure must be follow 2. Monitoring and analyze the potential of hazard. 3. Briefing/Toolbox Talk before start work. 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Stop work immediatly. 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide Barricade to Excavate Area. 4. Appoint a Traffic Controller. 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide Barricade to Excavate Area. 4. Appoint a signalman with a good communication to operator. 1. Stop work. 2.Terminate if necessary

Lightning

Body injuries / fatality

OSHA Sec 15. FMA Sec 23

Admin Control Safe work practice & Briefing.

Struck /crushed by machine/Collision

Body injuries / fatality

OSHA Act Sec 15. FM (BOWEC)(Safety)

Enggineering & Admin. Control - Safety awareness -Barrier, Traffic Control, Training, Briefing & Monitoring

12

II

Falling of materials

Fatality /body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Admin control & PPE Training, Briefing, Signalman, Safe Work Practice & Safety Helmet

Operation in unsafe mode

Body injuries / fatality

OSHA Sec 15 & 24

Admin. Control work practice

Safe

10

Excavator / Back Hoe

R/W

Fall into excavated trench

Body injuries

OSHA Sec 15, FMA (BOWEC)

Engineering,Admin controlGuardrail/Barrier, monitoring

Potential contact with underground power line

Body injuries / fatality

OSHA Act Sec 15. FM (BOWEC) (Electrical Hazard) Reg 16. 1986 Electricity Supply Act 1990 Electricity Reg. and rules 1994

Enggineering, Admin. Control & PPE - Safety awareness Isolation, Briefing, Monitoring and appropriate PPE Admin Control & PPE Briefing, monitoring, Safe Work Practice, hand glove & Safety Boot

12

II

1. All workers must be inducted before commencing work. 2. All workers must use proper P.P.E 3. To provide competent super visor to supervise the activity full time. 4. To organize Tool Box talk/meeting every time want to start work. 5. To provide Clearance Marking as per TNB requirement. 6. Permit To Work. 1. Safe work practice/procedure must be follow 2. Monitoring and analyze the potential of hazard. 3. Briefing/Toolbox Talk before start work. 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Stop work immediatly.

Electrocution (Working near power sources)

Fatality /body injuries

OSHA Sec 15, FMA (BOWEC)

12

II

Lightning

Body injuries / fatality

OSHA Sec 15. FMA Sec 23

Admin Control Safe work practice & Briefing.

Hazard Identification Applicable OSH Leg/Reg/COP (in addition to OSHA Sec 15, FM(SHW) reg)

Risk Assessment Legal Compliance F C, PC, NC L S Significant Hazard? (Y/N)

No.

Sub-Activity

Condition of assessment

Hazards

Consequences

Existing Control Measures (ECM)

Risk Rating

Control Determination of control hierarchy: 1. Elimination of hazards Risk 2. Substitution Categ. 3. Engineering 4. Administrative 5. Personal Protective Equipment (PPE) 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Arrange flow of traffic 4. Appoint a Traffic Controller.

Struck /crushed by machine/Collision

Body injuries / fatality

OSHA Act Sec 15. FM (BOWEC)(Safety)

Enggineering & Admin. Control - Safety awareness -Barrier, Traffic Control, Training, Briefing & Monitoring

Fall into excavated trench

Body injuries

OSHA Sec 15, FMA (BOWEC)

Engineering,Admin controlGuardrail/Barrier, monitoring

11

Lorry / Dump Truck

NR/W

Struck /crushed by machine/Collision

Body injuries / fatality

OSHA Act Sec 15. FM (BOWEC)(Safety)

Enggineering & Admin. Control - Safety awareness -Barrier, Traffic Control, Training, Briefing & Monitoring

12

II

1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide Barricade to Excavate Area. 4. Appoint a Traffic Controller.

Inhalation of heavy smoke / exhaust fume

Chronic health problem

OSHA Sec 15, FM (BOWEC) Reg 11 & 14. 1986

Enggineering & Admin. Control - Safety awareness -Face mask, Servicing, Toolbox Talk, Monitoring

1. All workers must used proper PPE at work site. 2. Un-good condition of machinery need to be check and repair as posible. 3. Toolbox Talk before start work. 4. Place the machine in a good ventilation area.

Falling of materials

Body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Admin control & PPE Training, Briefing, Signalman, Safe Work Practice & Safety Helmet

1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Appoint a Traffic Controller.

Struck /crushed by machine/Collision

Body injuries / fatality

OSHA Act Sec 15. FM (BOWEC)(Safety)

Enggineering & Admin. Control - Safety awareness -Barrier, Traffic Control, Training, Briefing & Monitoring

12

II

1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide Barricade to working Area. 4. Appoint a Traffic Controller. 1. All workers must be inducted before commencing work. 2. All workers must use proper P.P.E 3. Noise monitoring 4. Briefing before start work.

12

Roller / Roller Compactor

NR/W Exposure to noise Chronic hearing problem

OSHA Act Sec 15 FM (Noise Exposure) Reg. 1989.

Admin. Control & PPE Safety awareness -Ear plug/muff & initial noise monitoring Admin. Control Training, Briefing, Job Rotation & Safe work practice

Body Vibration

Body Injuries/ Health Impact

OSHA Sec 15 FMA (BOWEC)

1. Operator must be inducted before start work. 2. Work monitoring in a potential area.

Exposure to noise

Chronic hearing problem

OSHA Act Sec 15 FM (Noise Exposure) Reg. 1989.

Admin. Control & PPE Safety awareness -Ear plug/muff & initial noise monitoring

1. All workers must be inducted before commencing work. 2. All workers must use proper P.P.E 3. To provide competent super visor to supervise the activity full time. 4. To organize Tool Box talk/meeting every time want to start work. 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide guard to moving part if necessary. 4. Supervise the work

Caught in moving parts of machines

Body injuries / fatality

OSHA Sec 15 & 24 FMA sec 15,20

Engin, Admin Control & PPE Guard rail, Safe work practice, Training & Briefing.

13

Power Tool

NR/W Body Vibration

Body Injuries/ Health Impact

OSHA Sec 15 FMA (BOWEC)

Admin. Control Training, Briefing, Job Rotation & Safe work practice

1. Workers must be inducted before start work. 2. Work monitoring and supervising. 3. Workers must have a good health and fit to work.

Hazard Identification Applicable OSH Leg/Reg/COP (in addition to OSHA Sec 15, FM(SHW) reg)

Risk Assessment Legal Compliance F C, PC, NC L S Significant Hazard? (Y/N)

13 No.

Power Tool Sub-Activity

NR/W of Condition assessment

Hazards

Consequences

Existing Control Measures (ECM)

Risk Rating

Control Determination of control hierarchy: 1. Elimination of hazards Risk 2. Substitution Categ. 3. Engineering 4. Administrative 5. Personal Protective Equipment (PPE)

Hand-arm vibration

Carpal tunnel syndrome

OSHA Sec 15 FMA (BOWEC)

Admin. Control Training, Briefing, Job Rotation & Safe work practice

Electrocution

Fatality /body injuries

OSHA Sec 15, FM (BOWEC) Reg. 16

Admin control & PPE Training, Briefing, Protective clothing & hand glove.

12

II

1. Electrical Hand Tool must be in good condition. 2. Monitoring and analyze the potential of hazard. 3. Briefing/Toolbox Talk before start work. 4. Competent/Training.

Exposure to noise

Chronic hearing problem

OSHA Sec 15 FM (Noise Exposure) Reg. 1989.

Admin. Control & PPE Safety awareness -Ear plug/muff & initial noise monitoring

1. All workers must be inducted before commencing work. 2. All workers must use proper P.P.E 3. To provide competent super visor to supervise the activity. 4. Briefing before start work.

Flying of particles

Eye or body injuries

OSHA Sec 15, FMA Sec. 24

Admin control & PPE Training, Briefing, Protective clothing & hand glove.

Exposure to sharp object 14 Drill / Grinder NR/W Operation in unsafe mode

Hand Injuries

OSHA Sec 15, FMA Sec. 24

Engineering, admin control & PPE Guarded, briefing and Protective clothing Admin. Control work practice Safe

1. All moving part of the machine must be fully guarded. 2. All workers must be inducted before commencing of work. 3. All workers must be briefing before start work. 4. Proper PPE must be worn while working. 5. Provide training to workers which involved. 1. Stop work. 2.Terminate if necessary 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide guard to moving part if necessary. 4. Supervise the work 1. Electrical Hand Tool must be in good condition. 2. Monitoring and analyze the potential of hazard. 3. Briefing/Toolbox Talk before start work. 4. Competent/Training.

Body injuries / fatality

OSHA Sec 15 & 24

Caught in moving parts of machines

Body injuries

OSHA Sec 15 & 24 FMA sec 15,20

Engin, Admin Control & PPE Machine Guard, Safe work practice, Training & Briefing.

Electrocution

Fatality /body injuries

OSHA Sec 15, FM (BOWEC) Reg. 16

Admin control & PPE Training, Briefing, Protective clothing & hand glove.

12

II

Exposure to noise

Chronic hearing problem

OSHA Sec 15 FM (Noise Exposure) Reg. 1989.

Admin. Control & PPE Safety awareness -Ear plug/muff & initial noise monitoring

1. All workers must be inducted before commencing work. 2. All workers must use proper P.P.E 3. To provide competent super visor to supervise the activity. 4. Briefing before start work.

Caught in moving parts of machines 15 Jack Hammer / Hacker NR/W

Body injuries

OSHA Sec 15 & 24 FMA sec 15,20

Engin, Admin Control & PPE Machine Guard, Safe work practice, Training & Briefing.

1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide guard to moving part if necessary. 4. Supervise the work 1. Electrical Hand Tool must be in good condition. 2. Monitoring and analyze the potential of hazard. 3. Briefing/Toolbox Talk before start work. 4. Competent/Training. 1. Electrical Hand Tool must be in good condition. 2. Workers must be inducted before start work. 3. Work monitoring and supervising. 4. Workers must have a good health and fit to work. 5. Competent/Training.

Electrocution

Fatality /body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Admin control & PPE Training, Briefing, Protective clothing & hand glove.

Body vibration

Body injuries

OSHA Sec 15 FMA (BOWEC)

Admin. Control Training, Briefing, Job Rotation & Safe work practice

Hazard Identification Applicable OSH Leg/Reg/COP (in addition to OSHA Sec 15, FM(SHW) reg)

Risk Assessment Legal Compliance F C, PC, NC L S Significant Hazard? (Y/N)

No.

Sub-Activity

Condition of assessment

Hazards

Consequences

Existing Control Measures (ECM)

Risk Rating

Control Determination of control hierarchy: 1. Elimination of hazards Risk 2. Substitution Categ. 3. Engineering 4. Administrative 5. Personal Protective Equipment (PPE) 1. Cartridge must be stored in proper place and secure. 2. The cartridge must have a bucket c/w standby fire extinguisher. 3. Only the hose with flash back arreator allowed to be used. 4. Only the competent workers can operate the welding. 5. Working permit needed before start work. 6. Safety briefing and workplace monitoring by supervisor in charge 1. Electrical Hand Tool must be in good condition. 2. Monitoring and analyze the potential of hazard. 3. Briefing/Toolbox Talk before start work. 4. Competent/Training.

Leakage of oxy-acetylene hose- fire or explosion

Fatality /body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Engineering & Admin. Control - Flash Back Arrestor, Training, Briefing & Hot work permit

12

II

16

Electrocution

Fatality /body injuries

OSHA Sec 15, FM (BOWEC) Reg. 16

Admin control & PPE Training, Briefing, Protective clothing & hand glove. Admin control & PPE Training, Briefing & Face Shield Engineering, admin control & PPE Shelter, Briefing & Protective clothing

12

II

Exposed to UV & IR ray Welding - (Electric/Gases) R/W Heat Stress

permanent eye damage

OSHA Sec 15, FMA Sec 11 & (BOWEC) Reg 15

Fatigue/ skin rash

OSHA Sec 15 & 24, FMA Sect. 23

Exposure to welding fume

Irritation of respiratory tract

OSHA Sec 15 & 24, FM (BOWEC)(Safety) Reg 14.

Admin control & PPE Training, Briefing & Face mask

1. All workers must used proper PPE at work site. 2. Un-good condition of equipment need to be check and repair as posible. 3. Toolbox Talk before start work.

Exposure to welding spark

Skin burn

OSHA Sec 15, FMA Sec 11 & (BOWEC) Reg 15

Admin control & PPE Training, Briefing, Protective clothing, hand glove & face shield

Falling of materials

Fatality /body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Admin control & PPE Training, Briefing, Signalman, Safe Work Practice & Safety Helmet

12

II

1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide Barricade to Excavate Area. 4. Appoint a signalman with a good communication to operator. 1. Permit To Work Required before excavation. 2. Supervise at all potential area in full time. 3. Briefing/Toolbox Talk before start work. 4. Trenching system required. 5. Training.

Soil collapse into trench/Cave in

Body injuries / fatality

OSHA Act 15, FM (BOWEC) Reg 116,117 & 118

Engineering control- Shoring/ safe work practice, Supervising

12

II

R/W Inhalation of dust/Concrette Dust Irritation of respiratory tract OSHA Sec 15 & 24 FM (Mineral Dust) Reg. 1989

Engineering, admin control & PPE Water sprinkling/Browser, Dust mask and training Engineering, Admin Control Provided proper access/egress, training/information

1. Provide water sprinkler/ browser to prevent flying dust. supply face mask to worker which involved

2.

17 Construction of Main Drains

Slippery & poor access/egress

Slip, trip & fall - body injuries

OSHA Sec 15, FMA 1967

Ergonomic- awkward position & repetitive motion

Body strain

Admin. Control Info from: DOSH,Niosh, CROSH, Training, Briefing, Job Rotation CCOHS, Miosh & etc & Safe work practice

NR/W

Lightning

Body injuries / fatality

OSHA Sec 15. FMA Sec 23

Admin Control Safe work practice & Briefing.

1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Stop work immediatly.

Hazard Identification Applicable OSH Leg/Reg/COP (in addition to OSHA Sec 15, FM(SHW) reg)

Risk Assessment Legal Compliance F C, PC, NC L S Significant Hazard? (Y/N)

No.

Sub-Activity

Condition of assessment

Hazards

Consequences

Existing Control Measures (ECM)

Risk Rating

Control Determination of control hierarchy: 1. Elimination of hazards Risk 2. Substitution Categ. 3. Engineering 4. Administrative 5. Personal Protective Equipment (PPE)

R/W

Heat Stress

Fatigue/ skin rash

OSHA Sec 15 & 24, FMA Sect. 23

Engineering, admin control & PPE Shelter, Briefing & Protective clothing

Falling from Height

Body injuries / fatality

Osha Sec. 15 & 24 FMA (BOWEC)

Engin. & Admin Control Walking Platform, Safety Harness /belt, Training & Briefing

12

II

1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide training & safe work practice. 4. Monitoring and supervise the works.. 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide training & safe work practice. 4. Monitoring and supervise the works.. 1. Supervise & monitoring at all potential area. 2. Briefing/Toolbox Talk before start work. 3. Training & Safe work Practice. 4. Analyze works expose to hazards.

Falling of construction material from height 18 Wall R/W

Fatality /body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Admin control & PPE Training, Briefing, Signalman, Safe Work Practice & Safety Helmet

Wall Collapse

Body injuries / fatality

OSHA Sec 15 & 24 FMA (BOWEC)

Admin control & PPE Training, Briefing,safe Work Practice & Safety Helmet

Ergonomic- awkward position & repetitive motion

Body strain

Admin. Control Info from: DOSH,Niosh, CROSH, Training, Briefing, Job Rotation CCOHS, Miosh & etc & Safe work practice

Falling from Height

Body injuries / fatality

OSHA Sec 15 & 24 FMA (BOWEC)

Engin. & Admin Control Walking Platform, Safety Harness /belt, Training & Briefing Engin, Admin Control & PPE Safe guard, Safe work practice, Training & Briefing.

12

II

1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide training & safe work practice. 4. Monitoring and supervise the works.. 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Guarding machine/moving part.

Entanglement by rotating saw

Body injuries / fatality

OSHA Sec 15 & 24 FMA sec 15,20

12

II

Inhalation of wood dust

Irritation of respiratory tract

OSHA Sec 15, FM (Mineral Dust) Reg. 1989

Admin Control & PPE Dust mask and training

Flying of nails/ objects

Eye or body injuries

OSHA Sec 15, FMA Sec. 24

Admin control & PPE Training, Briefing, Protective clothing

Failure of formwork/ temporary platform 19 Formwork R/W

Body injuries / fatality

OSHA Sec 15. FM (BOWEC) (Scaffold) Part 10 Reg 72-98

Enggin. & Admin. Control Safety awareness, Competent, PE Design, Training, Briefing & Monitoring

12

II

1. Erected by competent/training person only. 2. PE Design required for any scaffold erected more than 15 meters. 3. Inspection and supervising of competent person every time before its to be used. 4. Record keeping. 5. Ensure the material is in good condition/serviceable

Protruding nails, starter bar & sharp objects

Body injuries

OSHA Sec 15 & 24 FMA 1967

Engineering control -house keeping

Struck or pinch by hammer

Hand Injuries

OSHA Sec 15, FMA Sec. 24

Admin control & PPE Briefing, Hand Glove and Protective clothing

19

Formwork

R/W

Hazard Identification Applicable OSH Leg/Reg/COP (in addition to OSHA Sec 15, FM(SHW) reg)

Risk Assessment Legal Compliance F C, PC, NC L S Significant Hazard? (Y/N)

No.

Sub-Activity

Condition of assessment

Hazards

Consequences

Existing Control Measures (ECM)

Risk Rating

Control Determination of control hierarchy: 1. Elimination of hazards Risk 2. Substitution Categ. 3. Engineering 4. Administrative 5. Personal Protective Equipment (PPE) 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide training & safe work practice. 4. Monitoring and supervise the works..

Falling of construction material from height

Fatality /body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Admin control & PPE Training, Briefing, Signalman, Safe Work Practice & Safety Helmet

12

II

Collapse/Failure of formwork/ temporary platform

Body injuries / fatality

OSHA Sec 15 & 24 FMA (BOWEC)

Admin control & PPE Training, Briefing, Signalman, Safe Work Practice & Safety Helmet

12

II

1. All formwork support such as scaffold must be check frequently to avoid any miss use or damage by the competent/train person. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide training & safe work practice. 4. Monitoring and supervise the works..

Falling from Height

Body injuries / fatality

OSHA Sec 15 & 24 FMA (BOWEC)

Engin. & Admin Control Walking Platform, Safety Harness /belt, Training & Briefing

12

II

1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide training & safe work practice. 4. Monitoring and supervise the works.. 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide training & safe work practice. 4. Monitoring and supervise the works.. 1. Erected by competent/training person only. 2. PE Design required for any scaffold erected more than 15 meters. 3. Inspection and supervising of competent person every time before its to be used. 4. Record keeping. 5. Ensure the material is in good condition/serviceable

Falling of construction material from height

Fatality /body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Admin control & PPE Training, Briefing, Signalman, Safe Work Practice & Safety Helmet

12

II

Failure of formwork/ temporary platform

Body injuries / fatality

OSHA Sec 15. FM (BOWEC) (Scaffold) Part 10 Reg 72-98

Enggin. & Admin. Control Safety awareness, Competent, PE Design, Training, Briefing & Monitoring

12

II

R/W

Struck or hit by concrete bucket/ mixer

Body injuries / fatality

OSHA Sec 15. FMA (BOWEC)

Admin. Control - Safety awareness Signalman, Training, Briefing & Monitoring

1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Appoint a Signalman.

20

Concretting (Vibrator machine, mortar pump & etc) Splashes of conrete in eyes and contact with skin Eye or body injuries OSHA Sec 15, FMA Sec. 24

Admin control & PPE Training, Briefing, Protective clothing & hand glove.

Falling of concrete bucket from height

Fatality /body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Admin control & PPE Training, Briefing, Signalman, Safe Work Practice & Safety Helmet

12

II

1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide training & safe work practice. 4. Monitoring and supervise the works.. 1. Electrical Hand Tool must be in good condition. 2. Workers must be inducted before start work. 3. Work monitoring and supervising. 4. Workers must have a good health and fit to work. 5. Competent/Training. 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Stop work immediatly.

Body/Hand-arm vibration

Body injuries

OSHA Sec 15 FMA (BOWEC)

Admin. Control Training, Briefing, Job Rotation & Safe work practice

NR/W

Lightning

Body injuries / fatality

OSHA Sec 15. FMA Sec 23

Admin Control Safe work practice & Briefing.

Hazard Identification Applicable OSH Leg/Reg/COP (in addition to OSHA Sec 15, FM(SHW) reg)

Risk Assessment Legal Compliance F C, PC, NC L S Significant Hazard? (Y/N)

No.

Sub-Activity

Condition of assessment

Hazards

Consequences

Existing Control Measures (ECM)

Risk Rating

Control Determination of control hierarchy: 1. Elimination of hazards Risk 2. Substitution Categ. 3. Engineering 4. Administrative 5. Personal Protective Equipment (PPE)

R/W

Ergonomic- awkward position & repetitive motion

Body strain

Admin. Control Info from: DOSH,Niosh, CROSH, Training, Briefing, Job Rotation CCOHS, Miosh & etc & Safe work practice

Falling from Height

Body injuries / fatality

OSHA Sec 15 & 24 FMA (BOWEC)

Engin. & Admin Control Walking Platform, Safety Harness /belt, lifelines, Training & Briefing

12

II

1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Provide training & safe work practice. 4. Monitoring and supervise the works. 5. Follow working at height procedure. 6. Training workers. 1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. practically to provide Catch Platform or catch netting at a potential area. 4. Appoint a signalman with a good communication to operator. 5. Safe work practice.

Falling of construction material from height

Fatality /body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Admin control & PPE Training, Briefing, Signalman, Safe Work Practice & Safety Helmet

Lightning

Body injuries / fatality

OSHA Sec 15. FMA Sec 23

Admin Control Safe work practice & Briefing.

12

II

1. All workers must be inducted before commencing of work. 2. All workers must be briefing before commencement and weekly toolbox talks to explain the hazards. 3. Stop work immediatly. 1. Electrical Hand Tool must be in good condition. 2. Monitoring and analyze the potential of hazard. 3. Briefing/Toolbox Talk before start work. 4. Competent/Training. 5. Proper PPE must be worn. 1. Proper PPE must be worn. 2. Briefing before start work. 3. Supervise and monitoring potential impact to workers. 4. Provide shelter/cool place for rest if necessary. 5. Wear a appropriate clothing. 1. All equipment must be place correctly and check daily to prevent from any falling material when raining or heavy wind occurs. 2. Immediate action must be taken when comes the unwanted condition that may prevent damage/injury to property or people. 4. Safe work practice and prosedure working at height must be follow. 1. Proper PPE must be worn. 2. Briefing before start work. 3. Supervise and monitoring potential impact to workers. Issued an appropriate grip shoe. 5. Wear a appropriate clothing.

21

Installation of Roof

R/W Electrocution Fatality /body injuries OSHA Sec 15, FM (BOWEC) Reg. 16

Admin control & PPE Training, Briefing, Protective clothing & hand glove. Engineering, admin control & PPE Shelter, Briefing & Protective clothing

12

II

Heat Stress

Fatigue/ skin rash

OSHA Sec 15 & 24, FMA Sect. 23

12

II

Wind/Rain

Structure Collapse/ disturbed/budge

OSHA Sec 15. FMA (BOWEC)

Admin. Control work practice

Safe

12

II

Slippery & poor access/egress

Slip, trip & fall - body injuries

OSHA Sec 15 & 24 FMA (BOWEC)

Engineering, Admin Control Provided proper access/egress, training/information

4.

22

Falling from Height

Body injuries / fatality

OSHA Sec 15 & 24 FMA (BOWEC)

Engin. & Admin Control Walking Platform, Safety Harness /belt, Training & Briefing

12

II