Documentos de Académico

Documentos de Profesional

Documentos de Cultura

John Crane Presentation - Mechanical Training Document - 070810

Cargado por

Trung Quan VoDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

John Crane Presentation - Mechanical Training Document - 070810

Cargado por

Trung Quan VoCopyright:

Formatos disponibles

Hydrocarbon Sealing Selection

Seal Selection Light Hydrocarbons

The main difficulty in sealing light hydrocarbons is preventing flashing of the liquid to gas between the seal faces. This is caused when the liquid is close to vapour point, the heat of the seal faces pushes the fluid film into the gas phase. For duties close to the vapour point (under the API 682 line) such as these we must;

Move the duty point by cooling the seal Will require some sort of refrigeration to give sufficient cooling

Supply a stable fluid film independent of the process by introducing a pressurised barrier fluid between the seal faces. This fluid has much lower vapour pressure therefore flashing is no longer a problem

Seal Selection Light Hydrocarbons

John Crane recommend the type 3648 dual pressurised seal for these types of duties. This is a API 682 qualified seal specifically designed for such duties. (see attached layout). For seal pressurisation, dependant on site utilities API plan 53 or plan 53m (modified) can be used.

Seal Selection Cryogenic Hydrocarbon

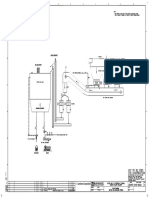

Cryogenic Hydrocarbon For safety and good service operation in low temperature applications dual pressurised seals are normally employed. A seal design which minimises the effects of temperature on the dynamic seal components is recommended, i.e. it places the seal springs & elastomer in the controlled environment of the barrier fluid. John Crane recommend the type 3648 dual pressurised seal arranged in a back to back format for this duty. (see attached simplified layout). This complies with API 682 as an engineered seal.

For seal pressurisation, dependant on site utilities API plan 53m (modified) is recommended.

Double Seal (Back to back arrangment)

Plan 53m Accumulator System

Circul ation loop

Air cooler RV

High Point Vent

Mechanic al Seal

Charge pi pe coil (thermal conducti on break) Mobile pressure unit

PI

PT

Accumulator

Accumulator System Circulation By Pumping Ring In Seal

También podría gustarte

- Centrifugal Pumps and SealDocumento32 páginasCentrifugal Pumps and SealAnatoli KarpobAún no hay calificaciones

- Dry Gas Seal System StandarDocumento8 páginasDry Gas Seal System StandarRonny AjaAún no hay calificaciones

- Operation and Maintenance ManualDocumento104 páginasOperation and Maintenance ManualTrung Quan Vo100% (4)

- 500Mw BHEL-KWU Erection ManualDocumento127 páginas500Mw BHEL-KWU Erection ManualRajagopal GanapathyAún no hay calificaciones

- Gas Enginee Vs Gas TurbineDocumento13 páginasGas Enginee Vs Gas TurbineTrung Quan VoAún no hay calificaciones

- Caterpillar Taurus 70 Users Manual 536177 PDFDocumento83 páginasCaterpillar Taurus 70 Users Manual 536177 PDFTrung Quan Vo100% (1)

- Gas Enginee Vs Gas TurbineDocumento13 páginasGas Enginee Vs Gas TurbineTrung Quan VoAún no hay calificaciones

- Sealing Extreme Cold Application - FSADocumento3 páginasSealing Extreme Cold Application - FSASulaiman Kadher KAún no hay calificaciones

- Mar14 PDFDocumento2 páginasMar14 PDFsudhindra_tiwariAún no hay calificaciones

- Api 23Documento3 páginasApi 23sapu11jagat5855Aún no hay calificaciones

- John Crane MaterialsDocumento46 páginasJohn Crane MaterialsLuis YañezAún no hay calificaciones

- 2007 C 1 Mechanical Seal System Reliability Through SpecificationDocumento36 páginas2007 C 1 Mechanical Seal System Reliability Through SpecificationReyes SanchezAún no hay calificaciones

- Double Mechanical Seals, Tandem ArrangementDocumento10 páginasDouble Mechanical Seals, Tandem ArrangementViwek MertiyaAún no hay calificaciones

- Sealing Sense: Where Mechanical Seals Meet Pumps: What Is The Next Generation?Documento3 páginasSealing Sense: Where Mechanical Seals Meet Pumps: What Is The Next Generation?madairkifAún no hay calificaciones

- 1648 ManualDocumento29 páginas1648 ManualSherif Adel100% (2)

- L Uk SugarDocumento16 páginasL Uk SugarnarupvAún no hay calificaciones

- EagleBurgmann - E07111 - E1 - Mechanical Seal H75VN in Cumene Pump Station - 11.10Documento1 páginaEagleBurgmann - E07111 - E1 - Mechanical Seal H75VN in Cumene Pump Station - 11.10lendiaAún no hay calificaciones

- John Crane Type FFETDocumento6 páginasJohn Crane Type FFETUntung S PrawotoAún no hay calificaciones

- KSB Mechanical Seals - Failure Analysis PDFDocumento34 páginasKSB Mechanical Seals - Failure Analysis PDFWaqas WakeelAún no hay calificaciones

- Flowserve Pusher Seal ManualDocumento16 páginasFlowserve Pusher Seal ManualNikhil Princeton AndradeAún no hay calificaciones

- Mechanical Seals According To StandardsDocumento6 páginasMechanical Seals According To StandardsSunit MishraAún no hay calificaciones

- Fitting InstructionDocumento6 páginasFitting InstructionAan Sarkasi AmdAún no hay calificaciones

- TF Seal SelectionDocumento42 páginasTF Seal SelectionPete PompesAún no hay calificaciones

- Shaft Sealing Mechanical Seals 1662138716Documento195 páginasShaft Sealing Mechanical Seals 1662138716eslam zainAún no hay calificaciones

- Pressurized Mech Seals Piping PlansDocumento9 páginasPressurized Mech Seals Piping PlanssachinumaryeAún no hay calificaciones

- EagleBurgmann H7N enDocumento5 páginasEagleBurgmann H7N enbryandownAún no hay calificaciones

- Seal Material and Arrangement GuideDocumento48 páginasSeal Material and Arrangement Guideleo100% (2)

- Sealing Concept-RwDocumento20 páginasSealing Concept-RwnuradiadnanAún no hay calificaciones

- 13 Ways To Kill A Mechanical Seal FINALDocumento16 páginas13 Ways To Kill A Mechanical Seal FINALRanjit Koshy AlexanderAún no hay calificaciones

- FAS Seal School 101 Phase 1 - Intro To Mechanical SealsDocumento87 páginasFAS Seal School 101 Phase 1 - Intro To Mechanical SealsGonzalo Alonso QuintanaAún no hay calificaciones

- ISOMAG - Pump - Zone - Reprint-Bearing Protection DevicesDocumento5 páginasISOMAG - Pump - Zone - Reprint-Bearing Protection DevicesChandra SimanjuntakAún no hay calificaciones

- Mechanical Seal Failure Troubleshooting Guide: Bell & Gossett Centrifugal PumpsDocumento18 páginasMechanical Seal Failure Troubleshooting Guide: Bell & Gossett Centrifugal Pumpsmasterplumber100% (2)

- Acoples FLOWSERVE - Instalación PDFDocumento12 páginasAcoples FLOWSERVE - Instalación PDFJenny Cecilia Ureña ZuriAún no hay calificaciones

- JOhnCrane Dry Gas Seal Pumps PF - 2874Documento2 páginasJOhnCrane Dry Gas Seal Pumps PF - 2874Mohammed Al-BrashdiAún no hay calificaciones

- Aes Api682 01Documento9 páginasAes Api682 01meghanahariAún no hay calificaciones

- Module 04.4 - Seal ArrangementsDocumento15 páginasModule 04.4 - Seal ArrangementsMostafaAún no hay calificaciones

- Burgmann CartexDocumento8 páginasBurgmann CartexAnonymous r3MoX2ZMTAún no hay calificaciones

- TD 5610V 5610VQ 5620VP 2PG BW Oct2015Documento2 páginasTD 5610V 5610VQ 5620VP 2PG BW Oct2015Pham Thien TruongAún no hay calificaciones

- PV LimitDocumento9 páginasPV Limitadam100% (1)

- John CraneDocumento16 páginasJohn CraneMenta Basita Bangun100% (1)

- Mech Seal System Difference 53 A B CDocumento3 páginasMech Seal System Difference 53 A B CAmol PatkiAún no hay calificaciones

- Failure Analysis John CraneDocumento83 páginasFailure Analysis John CraneIulian Luncan96% (23)

- EagleBurgmann - Cartex Single Seals - ENDocumento5 páginasEagleBurgmann - Cartex Single Seals - ENsaroat moongwattanaAún no hay calificaciones

- Double Mechanical Seal For PumpsDocumento7 páginasDouble Mechanical Seal For PumpsNikeshAún no hay calificaciones

- 100 Mechanical SealsDocumento20 páginas100 Mechanical SealsDeepa VpAún no hay calificaciones

- Mechanical Seal Installation InstructionDocumento4 páginasMechanical Seal Installation InstructionSandi AslanAún no hay calificaciones

- Royal Purple BarrierDocumento14 páginasRoyal Purple BarrierAnonymous H3I29yjAún no hay calificaciones

- Bomba CPKDocumento20 páginasBomba CPKPatricio Andres Silva SanzanaAún no hay calificaciones

- EagleBurgmann ESPU6 Circulation Pump enDocumento2 páginasEagleBurgmann ESPU6 Circulation Pump enserdarAún no hay calificaciones

- FSD101eng FSG Seals Catalog A4Documento64 páginasFSD101eng FSG Seals Catalog A4ASHOKAún no hay calificaciones

- EXXI-4130-00-00-VD-MAN-5251 - 00x-Sellos MecanicosDocumento33 páginasEXXI-4130-00-00-VD-MAN-5251 - 00x-Sellos MecanicosrodolfostiAún no hay calificaciones

- S 28AT XP EXP EngDocumento6 páginasS 28AT XP EXP EngpramodtryAún no hay calificaciones

- JC 2648 Seal IOM Manual PDFDocumento4 páginasJC 2648 Seal IOM Manual PDFRené Mora-CasalAún no hay calificaciones

- Mechanical SealsDocumento3 páginasMechanical Sealsapi-3848429100% (2)

- Piping Plan Designs For Pressurised Dual Mechanical Seals 1680216954Documento9 páginasPiping Plan Designs For Pressurised Dual Mechanical Seals 1680216954Stenlyn LayaAún no hay calificaciones

- Gw/Baw: Flow Solutions DivisionDocumento2 páginasGw/Baw: Flow Solutions DivisionLuis CuaxiloAún no hay calificaciones

- What Determines Seal Leakage?Documento3 páginasWhat Determines Seal Leakage?Pradeep MotaparthyAún no hay calificaciones

- Explosive DecompressionDocumento11 páginasExplosive DecompressionAndrey EkkertAún no hay calificaciones

- Valves Overview Service enDocumento12 páginasValves Overview Service enBalraj PadmashaliAún no hay calificaciones

- Piping Plan 62Documento9 páginasPiping Plan 62Net WalkerAún no hay calificaciones

- 19xr CLT 13ssDocumento116 páginas19xr CLT 13ssRicardoAún no hay calificaciones

- Plan Api 23Documento20 páginasPlan Api 23JAIMEAún no hay calificaciones

- Mechanical Seal Sept10Documento4 páginasMechanical Seal Sept10sureshbabu7374Aún no hay calificaciones

- API 682 4th Edition Category 1 Configurations: 3CW-FBDocumento19 páginasAPI 682 4th Edition Category 1 Configurations: 3CW-FBtuliofilipeAún no hay calificaciones

- Muhga35vb PDFDocumento36 páginasMuhga35vb PDFMihaela CondratAún no hay calificaciones

- ANNEX 7.1 - MLK-0-P-001-01-00002 - Plot Plan - 2017.11.02.rev.1 - RDocumento1 páginaANNEX 7.1 - MLK-0-P-001-01-00002 - Plot Plan - 2017.11.02.rev.1 - RTrung Quan VoAún no hay calificaciones

- Installation and Maintenance LSF46.2 AlternatorDocumento20 páginasInstallation and Maintenance LSF46.2 AlternatorTrung Quan VoAún no hay calificaciones

- Exhaust Backpressure - 40kW Gas Genset - 4 in Tie-In R1Documento1 páginaExhaust Backpressure - 40kW Gas Genset - 4 in Tie-In R1Trung Quan VoAún no hay calificaciones

- Fuel - Consumption - Chart - Standard Diesel EngineDocumento1 páginaFuel - Consumption - Chart - Standard Diesel EngineCaptIsqanAún no hay calificaciones

- ANNEX 7 - Steam Turbine Reference Project GADocumento2 páginasANNEX 7 - Steam Turbine Reference Project GATrung Quan VoAún no hay calificaciones

- Dry Low NOx CombustorDocumento0 páginasDry Low NOx CombustorTrung Quan VoAún no hay calificaciones

- Presentation of Turbine Erection 1Documento42 páginasPresentation of Turbine Erection 1Trung Quan Vo100% (1)

- Pump Fundamental PDFDocumento104 páginasPump Fundamental PDFTrung Quan VoAún no hay calificaciones

- Reciprocating Compressor SpecDocumento26 páginasReciprocating Compressor SpecTrung Quan VoAún no hay calificaciones

- Solid Mechanics Balancing Tutorial - Balancing of Rotating BodiesDocumento0 páginasSolid Mechanics Balancing Tutorial - Balancing of Rotating BodiesIman SatriaAún no hay calificaciones

- BLACK & VEATCH Flow Digrams and ArrangementDocumento74 páginasBLACK & VEATCH Flow Digrams and ArrangementTrung Quan VoAún no hay calificaciones

- Pressure Surge Damage in PipelineDocumento16 páginasPressure Surge Damage in PipelinebbmokshAún no hay calificaciones

- Bulletin210-B 2005Documento24 páginasBulletin210-B 2005rudrakrAún no hay calificaciones

- Compressors and Compressed Air Systems PDFDocumento24 páginasCompressors and Compressed Air Systems PDFTrung Quan VoAún no hay calificaciones

- Dry Low NOx CombustorDocumento0 páginasDry Low NOx CombustorTrung Quan VoAún no hay calificaciones

- Airtek Heatless Air Dryers SpecificationDocumento12 páginasAirtek Heatless Air Dryers SpecificationTrung Quan Vo0% (1)

- Balance Grades As Per ISO 1940Documento0 páginasBalance Grades As Per ISO 1940ADITYA_PATHAKAún no hay calificaciones

- Balancing of Reciprocating MassesDocumento25 páginasBalancing of Reciprocating Massesyash_ganatraAún no hay calificaciones

- Selected Material PumpDocumento12 páginasSelected Material PumpTrung Quan VoAún no hay calificaciones

- NOx Permit LimitDocumento15 páginasNOx Permit LimitTrung Quan VoAún no hay calificaciones