Documentos de Académico

Documentos de Profesional

Documentos de Cultura

PREQUALIFIED STRUCTURAL WELDING PROCEDURE SPECIFICATIONS

Cargado por

walitedisonDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

PREQUALIFIED STRUCTURAL WELDING PROCEDURE SPECIFICATIONS

Cargado por

walitedisonCopyright:

Formatos disponibles

PREQUALIFIED STRUCTURAL WELDING PROCEDURE SPECIFICATIONS

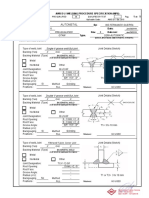

WPS No.

BC-L1a

Revision No.

0

X

PQR No. Prequalified Semi-Automatic

JOINT DETAIL

Code

AWS D1.1 Automatic

Page

1 of 1

Welding Process(es) SMAW

JOINT DESIGN AWS Joint Designation Joint Type

Butt or Corner Joint B-L1a & C-L1a

Type-Manual

Machine

Weld Type No

Square-Groove

Backing Strip/Ring: Yes Backing Material Back Gouging: BASE METAL AWS Group No.

I & II

T1

T1 R T2

C.S. similar to BM

Min Thickness Method

N/A

4.8 mm

Yes

No X

To Group No.

I & II

Material Specification & Grade: BM Thickness:

Carbon Steel, e.g. ASTM A36, A572 Gr. 50, A516, A53, A106, API 5L Gr. B

Root Opening = Root Face =

T1 +1/16, -0

N/A

Groove T 1= 6.4mm max Fillet

N/A

T 2= Unlimited Groove Angle =

N/A

Pipe Diameter Range: FILLER METAL AWS Specification AWS Classification Size of Filler Metals SAMS S/N Other

Groove

Unlimited

Fillet

N/A

POSITION

A5.1 E7018 2.4mm 20-483-069 A5.1 E7018 3.2mm 20-483-071

Groove

All V-Up

Fillet

N/A

Vertical Progression GAS Shielding Gas (Type) Gas Cup Size

N/A

N/A

Flow Rate Other

N/A None

Larger sizes, i.e 4.0 mm, may be used on thick sections

TECHNIQUE String or Weave Bead Multiple or Single Passes Peening Initial & Interpass Cleaning PREHEAT T of Thickest Part (mm) Min Preheat/Interpass Max Interpass Temp. SIDE

1 1 1 1

Stringer and Weave Multiple

ELECTRICAL CHARACTERISTICS Contact Tube to Work Distance Tungsten Electrode Size and Type Transfer Mode (GMAW) Current Type POST WELD HEAT TREATMENT 3 to 19

10 C

315 C N/A N/A N/A DCRP

None

Brushing & Grinding

>19 to 38

10 C

>38 to 63

66 C

>63

107 C

Temperature Range Time Range

None N/A

PASS

Root Fill/Cap Root Fill/Cap

PROCESSFILLER METAL SIZE POLARITY AMP SMAW E7018 (mm) DCRP 2.4 70-110

SMAW SMAW SMAW E7018 E7018 E7018 3.2 3.2 4.0 DCRP DCRP DCRP 90-165 90-165 125-220

VOLT SPEED (cm/min)

19-25 20-26 20-26 21-27 8-20 8-20 8-20 8-20

NOTES

Orientation of one member may vary within + 45.

Department

Consulting Services Department

Date

October 14, 2000

Approval Restrictions

Not approved for cyclic loaded structures, crane applications, T, Y, K tubular connections, or offshore structures to API RP 2A.

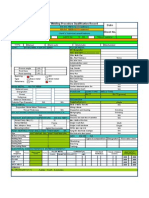

PREQUALIFIED STRUCTURAL WELDING PROCEDURE SPECIFICATIONS

WPS No.

B-L1b

Revision No.

0

X

PQR No. Prequalified Semi-Automatic

JOINT DETAIL

Code

AWS D1.1 Automatic

Page

1 of 1

Welding Process(es) SMAW

JOINT DESIGN AWS Joint Designation Joint Type

Butt Joint B-L1b

Type-Manual

Machine

Weld Type No X

Square-Groove

Backgouge

Backing Strip/Ring: Yes Backing Material Back Gouging: BASE METAL AWS Group No.

I None

Min Thickness

X

N/A

T1 R

Yes

No

Method

Arc Air and/or Grinding

To Group No.

Material Specification & Grade: BM Thickness:

Carbon Steel, e.g. ASTM A36, A516 Gr. 60, A53, A106, API 5L Gr. B

Root Opening = Root Face =

T1/2 +1/16, -0

N/A

Groove T 1= 6.4mm max Fillet

N/A

T 2= N/A Groove Angle =

N/A

Pipe Diameter Range: FILLER METAL AWS Specification AWS Classification Size of Filler Metals SAMS S/N Other

Groove

610mm and Over

Fillet

N/A

POSITION

A5.1 E6010 2.4mm 20-484-021 A5.1 E6010 3.2mm 20-484-024

Groove

All V-Up

Fillet

N/A

Vertical Progression GAS Shielding Gas (Type) Gas Cup Size

N/A

N/A

Flow Rate Other

N/A None

Larger sizes, i.e. 4.0mm, may be used on thick sections

TECHNIQUE String or Weave Bead Multiple or Single Passes Peening Initial & Interpass Cleaning PREHEAT T of Thickest Part (mm) Min Preheat/Interpass Max Interpass Temp. SIDE

1 2 1, 2 1, 2

Stringer and Weave Multiple

ELECTRICAL CHARACTERISTICS Contact Tube to Work Distance Tungsten Electrode Size and Type Transfer Mode (GMAW) Current Type POST WELD HEAT TREATMENT 3 to 19

10 C

315 C N/A N/A N/A DCRP

None

Brushing & Grinding

>19 to 38

N/A

>38 to 63

N/A

>63

N/A

Temperature Range Time Range

None N/A

PASS

Front Side Back Side All All

PROCESSFILLER METAL SIZE POLARITY AMP SMAW E6010 (mm) DCRP 2.4 40-100

SMAW SMAW SMAW E6010 E6010 E6010 2.4 3.2 4.0 DCRP DCRP DCRP 40-100 70-130 110-165

VOLT SPEED (cm/min)

20-26 20-26 21-27 22-28 8-20 8-20 8-20 8-20

NOTES

1. Backgouge root before welding second side. 2. Orientation of one member may vary within + 45.

Department

Consulting Services Department

Date

October 14, 2000

Approval Restrictions

Not approved for cyclic loaded structures, crane applications, T, Y, K tubular connections, or offshore structures to API RP 2A.

PREQUALIFIED STRUCTURAL WELDING PROCEDURE SPECIFICATIONS

WPS No.

TC-L1b

Revision No.

0

X

PQR No. Prequalified Semi-Automatic

JOINT DETAIL

Code

AWS D1.1 Automatic

Page

1 of 1

Welding Process(es) SMAW

JOINT DESIGN AWS Joint Designation Joint Type

T- or Corner Joint TC-L1b

Type-Manual

Machine

Weld Type No X

Square-Groove

Backgouge

Backing Strip/Ring: Yes Backing Material Back Gouging: BASE METAL AWS Group No.

I None

Min Thickness

X

N/A

T1

Yes

No

Method

Arc Air and/or Grinding

T2

To Group No.

I Carbon Steel, e.g. ASTM A36, A516 Gr. 60, A53, A106, API 5L Gr. B

Material Specification & Grade: BM Thickness:

Root Opening = Root Face =

T1/2 +1/16, -0

N/A

Groove T 1= 6.4mm max Fillet

Unlimited

T 2= Unlimited Groove Angle =

N/A

Pipe Diameter Range: FILLER METAL AWS Specification AWS Classification Size of Filler Metals SAMS S/N Other

Groove

610mm and Over

Fillet

Similar

POSITION

A5.1 E6010 2.4mm 20-484-021 A5.1 E6010 3.2mm 20-484-024

Groove

All V-Up

Fillet

All

Vertical Progression GAS Shielding Gas (Type) Gas Cup Size

N/A

N/A

Flow Rate Other

N/A None

Larger sizes, i.e. 4.0mm, may be used on thick sections

TECHNIQUE String or Weave Bead Multiple or Single Passes Peening Initial & Interpass Cleaning PREHEAT T of Thickest Part (mm) Min Preheat/Interpass Max Interpass Temp. SIDE

1

Stringer and Weave Multiple

ELECTRICAL CHARACTERISTICS Contact Tube to Work Distance Tungsten Electrode Size and Type Transfer Mode (GMAW) Current Type POST WELD HEAT TREATMENT 3 to 19

10 C

315 C N/A N/A N/A DCRP

None

Brushing & Grinding

>19 to 38

66 C

>38 to 63

107 C

>63

150 C

Temperature Range Time Range

None N/A

PASS

Front Side Back Side All All

PROCESSFILLER METAL SIZE POLARITY AMP SMAW E6010 (mm) DCRP 2.4 40-100

SMAW SMAW SMAW E6010 E6010 E6010 2.4 3.2 4.0 DCRP DCRP DCRP 40-100 70-130 110-165

VOLT SPEED (cm/min)

20-26 20-26 21-27 22-28 8-20 8-20 8-20 8-20

NOTES

1

1, 2 1, 2

1. Backgouge root before welding second side. 2. Fillet welds shall be 1/4 T1 minimum, but not more than 10mm. 3. Depth of shallower groove shall be no less than 1/4 T of thinner part joined. 4. Orientation of one member may vary within + 45.

Department

Consulting Services Department

Date

October 14, 2000

Approval Restrictions

Not approved for cyclic loaded structures, crane applications, T, Y, K tubular connections, or offshore structures to API RP 2A.

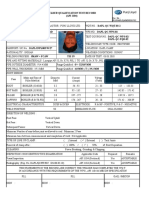

PREQUALIFIED STRUCTURAL WELDING PROCEDURE SPECIFICATIONS

WPS No.

B-U2a

Revision No.

0

X

PQR No. Prequalified Semi-Automatic

JOINT DETAIL

Code

AWS D1.1 Automatic

Page

1 of 1

Welding Process(es) SMAW

JOINT DESIGN AWS Joint Designation Joint Type

Butt Joint B-U2a

Type-Manual

Machine

Weld Type

X

Single-V-Groove

Backing Strip/Ring: Yes Backing Material Back Gouging: BASE METAL AWS Group No.

I & II

No Min Thickness

X

4.8 mm

C.S. similar to BM

T1 R

Yes

No

Method

N/A

To Group No.

I & II

Material Specification & Grade: BM Thickness:

Carbon Steel, e.g. ASTM A36, A572 Gr. 50, A516, A53, A106, API 5L Gr. B

Root Opening = Root Face =

1/14 or 3/8 or 1/2

N/A

Groove T 1= Unlimited Fillet

N/A

T 2= N/A Groove Angle =

45 or 30 or 20

Pipe Diameter Range: FILLER METAL AWS Specification AWS Classification Size of Filler Metals SAMS S/N Other

Groove

Unlimited

Fillet

N/A

POSITION

A5.1 E7018 3.2mm 20-483-071 A5.1 E7018 4.0mm 20-483-074

Groove

Refer to the above V-Up

Fillet

N/A

Vertical Progression GAS Shielding Gas (Type) Gas Cup Size

N/A

N/A

Flow Rate Other

N/A None

Larger sizes, i.e 4.8mm, may be used on thick sections

TECHNIQUE String or Weave Bead Multiple or Single Passes Peening Initial & Interpass Cleaning PREHEAT T of Thickest Part (mm) Min Preheat/Interpass Max Interpass Temp. SIDE

1

Stringer and Weave Multiple

ELECTRICAL CHARACTERISTICS Contact Tube to Work Distance Tungsten Electrode Size and Type Transfer Mode (GMAW) Current Type POST WELD HEAT TREATMENT 3 to 19

10 C

315 C N/A N/A N/A DCRP

None

Brushing & Grinding

>19 to 38

10 C

>38 to 63

66 C

>63

107 C

Temperature Range Time Range

None N/A

PASS

Root Fill/Cap Root Fill/Cap

PROCESSFILLER METAL SIZE POLARITY AMP SMAW E7018 (mm) DCRP 3.2 90-165

SMAW SMAW SMAW E7018 E7018 E7018 4.0 4.0 4.8 DCRP DCRP DCRP 125-220 125-220 170-280

VOLT SPEED (cm/min)

20-26 21-27 21-27 22-28 8-20 8-20 8-20 8-20

NOTES

Orientation of one member may vary within + 45.

1

1 1

Department

Consulting Services Department

Date

October 14, 2000

Approval Restrictions

Not approved for cyclic loaded structures, crane applications, T, Y, K tubular connections, or offshore structures to API RP 2A.

PREQUALIFIED STRUCTURAL WELDING PROCEDURE SPECIFICATIONS

WPS No.

B-U2

Revision No.

0

X

PQR No. Prequalified Semi-Automatic

JOINT DETAIL

Code

AWS D1.1 Automatic

Page

1 of 1

Welding Process(es) SMAW

JOINT DESIGN AWS Joint Designation Joint Type

Butt Joint B-U2

Type-Manual

Machine

Weld Type No X

Single-V-Groove

Backgouge

Backing Strip/Ring: Yes Backing Material Back Gouging: BASE METAL AWS Group No.

I & II None

Min Thickness

X

N/A

f R

T1

Yes

No

Method

Arc Air and/or Grinding

To Group No.

I & II

Material Specification & Grade: BM Thickness:

Carbon Steel, e.g. ASTM A36, A572 Gr. 50, A516, A53, A106, API 5L Gr. B

Root Opening = Root Face =

0 to 1/8 +1/16, -0

0 to 1/8 +1/16, -0

Groove T 1= Unlimited Fillet

N/A

T 2= N/A Groove Angle =

60 +10, -0

Pipe Diameter Range: FILLER METAL AWS Specification AWS Classification Size of Filler Metals SAMS S/N Other

Groove

610mm and Over

Fillet

N/A

POSITION

A5.1 E6010 3.2mm 20-484-024 A5.1 E7018 3.2mm 20-483-071

Groove

All V-Up

Fillet

N/A

Vertical Progression GAS Shielding Gas (Type) Gas Cup Size

N/A

N/A

Flow Rate Other

N/A None

Larger sizes, i.e 4.0mm and 4.8mm, may be used on thick sections

TECHNIQUE String or Weave Bead Multiple or Single Passes Peening Initial & Interpass Cleaning PREHEAT T of Thickest Part (mm) Min Preheat/Interpass Max Interpass Temp. SIDE

1

Stringer and Weave Multiple

ELECTRICAL CHARACTERISTICS Contact Tube to Work Distance Tungsten Electrode Size and Type Transfer Mode (GMAW) Current Type POST WELD HEAT TREATMENT 3 to 19

10 C

315 C N/A N/A N/A DCRP

None

Brushing & Grinding

>19 to 38

66 C

>38 to 63

107 C

>63

150 C

Temperature Range Time Range

None N/A

PASS

Root Fill/Cap Back Weld Fill/Cap Fill/Cap

PROCESSFILLER METAL SIZE POLARITY AMP SMAW E6010 (mm) DCRP 3.2 70-130

SMAW SMAW SMAW SMAW E7018 E7018 E7018 E7018 3.2 3.2 4.0 4.8 DCRP DCRP DCRP DCRP 90-165 90-165 125-220 170-280

VOLT SPEED (cm/min)

21-27 20-26 20-26 21-27 22-28 8-20 8-20 8-20 8-20 8-20

NOTES

1. Backgouge root before welding second side. 2. Orientation of one member may vary within + 45.

1

2 1, 2 1, 2

Department

Consulting Services Department

Date

October 14, 2000

Approval Restrictions

Not approved for cyclic loaded structures, crane applications, T, Y, K tubular connections, or offshore structures to API RP 2A.

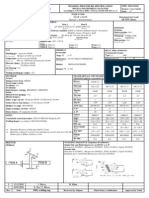

PREQUALIFIED STRUCTURAL WELDING PROCEDURE SPECIFICATIONS

WPS No.

B-U3b

Revision No.

0

X

PQR No. Prequalified Semi-Automatic

JOINT DETAIL

Code

AWS D1.1 Automatic

Page

1 of 1

Welding Process(es) SMAW

JOINT DESIGN AWS Joint Designation Joint Type

Butt Joint B-U3b

Type-Manual

Machine

Weld Type No X

Double-V-Groove

f R

Backgouge

Backing Strip/Ring: Yes Backing Material Back Gouging: BASE METAL AWS Group No.

I & II None

Min Thickness

X

N/A

T1

Yes

No

Method

Arc Air and/or Grinding

To Group No.

I & II 0 to 1/8 +1/16, -0

Material Specification & Grade: BM Thickness:

Carbon Steel, e.g. ASTM A36, A572 Gr. 50, A516, A53, A106, API 5L Gr. B

Root Opening = Root Face =

0 to 1/8 +1/16, -0

Groove T 1= Unlimited Fillet

N/A

T 2= N/A Groove Angle =

60 +10, -0

Pipe Diameter Range: FILLER METAL AWS Specification AWS Classification Size of Filler Metals SAMS S/N Other

Groove

610mm and Over

Fillet

N/A

POSITION

A5.1 E6010 3.2mm 20-484-024 A5.1 E7018 3.2mm 20-483-071

Groove

All V-Up

Fillet

N/A

Vertical Progression GAS Shielding Gas (Type) Gas Cup Size

N/A

N/A

Flow Rate Other

N/A None

Larger sizes, i.e 4.0mm and 4.8mm, may be used on thick sections

TECHNIQUE String or Weave Bead Multiple or Single Passes Peening Initial & Interpass Cleaning PREHEAT T of Thickest Part (mm) Min Preheat/Interpass Max Interpass Temp. SIDE

1

Stringer and Weave Multiple

ELECTRICAL CHARACTERISTICS Contact Tube to Work Distance Tungsten Electrode Size and Type Transfer Mode (GMAW) Current Type POST WELD HEAT TREATMENT 3 to 19

10 C

315 C N/A N/A N/A DCRP

None

Brushing & Grinding

>19 to 38

66 C

>38 to 63

107 C

>63

150 C

Temperature Range Time Range

None N/A

PASS

Root Fill/Cap Back Weld Fill/Cap Fill/Cap

PROCESSFILLER METAL SIZE POLARITY AMP SMAW E6010 (mm) DCRP 3.2 70-130

SMAW SMAW SMAW SMAW E7018 E7018 E7018 E7018 3.2 3.2 4.0 4.8 DCRP DCRP DCRP DCRP 90-165 90-165 125-220 170-280

VOLT SPEED (cm/min)

21-27 20-26 20-26 21-27 22-28 8-20 8-20 8-20 8-20 8-20

NOTES

1

2 1, 2 1, 2

1. Backgouge root before welding second side. 2. Depth of shallower groove shall be no less than 1/4 T of thinner part joined. 3. Orientation of one member may vary within + 45.

Department

Consulting Services Department

Date

October 14, 2000

Approval Restrictions

Not approved for cyclic loaded structures, crane applications, T, Y, K tubular connections, or offshore structures to API RP 2A.

PREQUALIFIED STRUCTURAL WELDING PROCEDURE SPECIFICATIONS

WPS No.

B-U4a

Revision No.

0

X

PQR No. Prequalified Semi-Automatic

JOINT DETAIL

Code

AWS D1.1 Automatic

Page

1 of 1

Welding Process(es) SMAW

JOINT DESIGN AWS Joint Designation Joint Type

Butt Joint B-U4a

Type-Manual

Machine

Weld Type

X

Single-Bevel-Groove

Backing Strip/Ring: Yes Backing Material Back Gouging: BASE METAL AWS Group No.

I & II

No Min Thickness

X

4.8 mm

C.S. similar to BM

Yes

No

Method

N/A

T1

To Group No.

I & II Carbon Steel, e.g. ASTM A36, A572 Gr. 50, A516, A53, A106, API 5L Gr. B

Material Specification & Grade: BM Thickness:

Root Opening = Root Face =

1/4 or 3/8

N/A

Groove T 1= Unlimited Fillet

N/A

T 2= N/A Groove Angle =

45 or 30

Pipe Diameter Range: FILLER METAL AWS Specification AWS Classification Size of Filler Metals SAMS S/N Other

Groove

Unlimited

Fillet

N/A

POSITION

A5.1 E7018 3.2mm 20-483-071 A5.1 E7018 4.0mm 20-483-074

Groove

All V-Up

Fillet

N/A

Vertical Progression GAS Shielding Gas (Type) Gas Cup Size

N/A

N/A

Flow Rate Other

N/A None

Larger sizes, i.e 4.8mm, may be used on thick sections

TECHNIQUE String or Weave Bead Multiple or Single Passes Peening Initial & Interpass Cleaning PREHEAT T of Thickest Part (mm) Min Preheat/Interpass Max Interpass Temp. SIDE

1

Stringer and Weave Multiple

ELECTRICAL CHARACTERISTICS Contact Tube to Work Distance Tungsten Electrode Size and Type Transfer Mode (GMAW) Current Type POST WELD HEAT TREATMENT 3 to 19

10 C

315 C N/A N/A N/A DCRP

None

Brushing & Grinding

>19 to 38

10 C

>38 to 63

66 C

>63

107 C

Temperature Range Time Range

None N/A

PASS

Root Fill/Cap Root Fill/Cap

PROCESSFILLER METAL SIZE POLARITY AMP SMAW E7018 (mm) DCRP 3.2 90-165

SMAW SMAW SMAW E7018 E7018 E7018 4.0 4.0 4.8 DCRP DCRP DCRP 125-220 125-220 170-280

VOLT SPEED (cm/min)

20-26 21-27 21-27 22-28 8-20 8-20 8-20 8-20

NOTES

Orientation of one member may vary within + 45.

1

1 1

Department

Consulting Services Department

Date

October 14, 2000

Approval Restrictions

Not approved for cyclic loaded structures, crane applications, T, Y, K tubular connections, or offshore structures to API RP 2A.

PREQUALIFIED STRUCTURAL WELDING PROCEDURE SPECIFICATIONS

WPS No.

TC-U4a

Revision No.

0

X

PQR No. Prequalified Semi-Automatic

JOINT DETAIL

Code

AWS D1.1 Automatic

Page

1 of 1

Welding Process(es) SMAW

JOINT DESIGN AWS Joint Designation Joint Type

T- or Corner Joint TC-U4a

Type-Manual

Machine

Single-Bevel-Groove

Weld Type

X

Backing Strip/Ring: Yes Backing Material Back Gouging: BASE METAL AWS Group No.

I & II

No Min Thickness Method

N/A 4.8 mm

C.S. similar to BM

T1

Yes

No X

T2

To Group No.

I & II

Material Specification & Grade: BM Thickness:

Carbon Steel, e.g. ASTM A36, A572 Gr. 50, A516, A53, A106, API 5L Gr. B

Root Opening = Root Face =

1/4 or 3/8

N/A

Groove T 1= Unlimited Fillet

Unlimited

T 2= Unlimited Groove Angle =

45 or 30

Pipe Diameter Range: FILLER METAL AWS Specification AWS Classification Size of Filler Metals SAMS S/N Other

Groove

Unlimited

Fillet

Unlimited

POSITION

A5.1 E7018 3.2mm 20-483-071 A5.1 E7018 4.0mm 20-483-074

Groove

Refer to the above V-Up

Fillet

Refer to the above

Vertical Progression GAS Shielding Gas (Type) Gas Cup Size

N/A

N/A

Flow Rate Other

N/A None

Larger sizes, i.e 4.8mm, may be used on thick sections

TECHNIQUE String or Weave Bead Multiple or Single Passes Peening Initial & Interpass Cleaning PREHEAT T of Thickest Part (mm) Min Preheat/Interpass Max Interpass Temp. SIDE

1

Stringer and Weave Multiple

ELECTRICAL CHARACTERISTICS Contact Tube to Work Distance Tungsten Electrode Size and Type Transfer Mode (GMAW) Current Type POST WELD HEAT TREATMENT 3 to 19

10 C

315 C N/A N/A N/A DCRP

None

Brushing & Grinding

>19 to 38

10 C

>38 to 63

66 C

>63

107 C

Temperature Range Time Range

None N/A

PASS

Root Fill/Cap Root Fill/Cap

PROCESSFILLER METAL SIZE POLARITY AMP SMAW E7018 (mm) DCRP 3.2 90-165

SMAW SMAW SMAW E7018 E7018 E7018 4.0 4.0 4.8 DCRP DCRP DCRP 125-220 125-220 170-280

VOLT SPEED (cm/min)

20-26 21-27 21-27 22-28 8-20 8-20 8-20 8-20

NOTES

1

1 1

1. Fillet welds shall be 1/4 T1 minimum, but not more than 10mm./4 T of thinner part joined. 2. Orientation of one member may vary within + 45.

Department

Consulting Services Department

Date

October 14, 2000

Approval Restrictions

Not approved for cyclic loaded structures, crane applications, T, Y, K tubular connections, or offshore structures to API RP 2A.

PREQUALIFIED STRUCTURAL WELDING PROCEDURE SPECIFICATIONS

WPS No.

B-U4b

Revision No.

0

X

PQR No. Prequalified Semi-Automatic

JOINT DETAIL

Code

AWS D1.1 Automatic

Page

1 of 1

Welding Process(es) SMAW

JOINT DESIGN AWS Joint Designation Joint Type

Butt Joint B-U4b

Type-Manual

Machine

f

Single-Bevel-Groove

Weld Type No X

Backgouge

Backing Strip/Ring: Yes Backing Material Back Gouging: BASE METAL AWS Group No.

I & II None

Min Thickness

X

N/A

Yes

No

Method

Arc Air and/or Grinding

T1

To Group No.

I & II

Material Specification & Grade: BM Thickness:

Carbon Steel, e.g. ASTM A36, A572 Gr. 50, A516, A53, A106, API 5L Gr. B

Root Opening = Root Face =

0 to 1/8 +1/16, -0

0 to 1/8 +1/16, -0

Groove T 1= Unlimited Fillet

N/A

T 2= N/A Groove Angle =

45 +10 , -0

Pipe Diameter Range: FILLER METAL AWS Specification AWS Classification Size of Filler Metals SAMS S/N Other

Groove

610mm and Over

Fillet

N/A

POSITION

A5.1 E6010 3.2mm 20-484-024 A5.1 E7018 3.2mm 20-483-071

Groove

All V-Up

Fillet

N/A

Vertical Progression GAS Shielding Gas (Type) Gas Cup Size

N/A

N/A

Flow Rate Other

N/A None

Larger sizes, i.e 4.0mm and 4.8mm, may be used on thick sections

TECHNIQUE String or Weave Bead Multiple or Single Passes Peening Initial & Interpass Cleaning PREHEAT T of Thickest Part (mm) Min Preheat/Interpass Max Interpass Temp. SIDE

1

Stringer and Weave Multiple

ELECTRICAL CHARACTERISTICS Contact Tube to Work Distance Tungsten Electrode Size and Type Transfer Mode (GMAW) Current Type POST WELD HEAT TREATMENT 3 to 19

10 C

315 C N/A N/A N/A DCRP

None

Brushing & Grinding

>19 to 38

66 C

>38 to 63

107 C

>63

150 C

Temperature Range Time Range

None N/A

PASS

Root Fill/Cap Back Weld Fill/Cap Fill/Cap

PROCESSFILLER METAL SIZE POLARITY AMP SMAW E6010 (mm) DCRP 3.2 70-130

SMAW SMAW SMAW SMAW E7018 E7018 E7018 E7018 3.2 3.2 4.0 4.8 DCRP DCRP DCRP DCRP 90-165 90-165 125-220 170-280

VOLT SPEED (cm/min)

21-27 20-26 20-26 21-27 22-28 8-20 8-20 8-20 8-20 8-20

NOTES

1. Backgouge root before welding second side. 2. Orientation of one member may vary within + 45.

1

2 1, 2 1, 2

Department

Consulting Services Department

Date

October 14, 2000

Approval Restrictions

Not approved for cyclic loaded structures, crane applications, T, Y, K tubular connections, or offshore structures to API RP 2A.

PREQUALIFIED STRUCTURAL WELDING PROCEDURE SPECIFICATIONS

WPS No.

TC-U4b

Revision No.

0

X

PQR No. Prequalified Semi-Automatic

JOINT DETAIL

Code

AWS D1.1 Automatic

Page

1 of 1

Welding Process(es) SMAW

JOINT DESIGN AWS Joint Designation Joint Type

T- or Corner Joint TC-U4b

Type-Manual

Machine

Single-Bevel-Groove

Weld Type No X

Backgouge

Backing Strip/Ring: Yes Backing Material Back Gouging: BASE METAL AWS Group No.

I & II None

Min Thickness

X

N/A

T1

Yes

No

Method

Arc Air and/or Grinding

T2

To Group No.

I & II

Material Specification & Grade: BM Thickness:

Carbon Steel, e.g. ASTM A36, A572 Gr. 50, A516, A53, A106, API 5L Gr. B

Root Opening = Root Face =

0 to 1/8 +1/16, -0

0 to 1/8 +1/16, -0

Groove T 1= Unlimited Fillet

Unlimited

T 2= Unlimited Groove Angle =

45 +10 , -0

Pipe Diameter Range: FILLER METAL AWS Specification AWS Classification Size of Filler Metals SAMS S/N Other

Groove

610mm and Over

Fillet

Similar

POSITION

A5.1 E6010 3.2mm 20-484-024 A5.1 E7018 3.2mm 20-483-071

Groove

All V-Up

Fillet

All

Vertical Progression GAS Shielding Gas (Type) Gas Cup Size

N/A

N/A

Flow Rate Other

N/A None

Larger sizes, i.e 4.0mm and 4.8mm, may be used on thick sections

TECHNIQUE String or Weave Bead Multiple or Single Passes Peening Initial & Interpass Cleaning PREHEAT T of Thickest Part (mm) Min Preheat/Interpass Max Interpass Temp. SIDE

1

Stringer and Weave Multiple

ELECTRICAL CHARACTERISTICS Contact Tube to Work Distance Tungsten Electrode Size and Type Transfer Mode (GMAW) Current Type POST WELD HEAT TREATMENT 3 to 19

10 C

315 C N/A N/A N/A DCRP

None

Brushing & Grinding

>19 to 38

66 C

>38 to 63

107 C

>63

150 C

Temperature Range Time Range

None N/A

PASS

Root Fill/Cap Back Weld Fill/Cap Fill/Cap

PROCESSFILLER METAL SIZE POLARITY AMP SMAW E6010 (mm) DCRP 3.2 70-130

SMAW SMAW SMAW SMAW E7018 E7018 E7018 E7018 3.2 3.2 4.0 4.8 DCRP DCRP DCRP DCRP 90-165 90-165 125-220 170-280

VOLT SPEED (cm/min)

21-27 20-26 20-26 21-27 22-28 8-20 8-20 8-20 8-20 8-20

NOTES

1

2 1, 2 1, 2

1. Backgouge root before welding second side. 2. Fillet welds shall be 1/4 T1 minimum, but not more than 10mm.inner part joined. 3. Orientation of one member may vary within + 45.

Department

Consulting Services Department

Date

October 14, 2000

Approval Restrictions

Not approved for cyclic loaded structures, crane applications, T, Y, K tubular connections, or offshore structures to API RP 2A.

PREQUALIFIED STRUCTURAL WELDING PROCEDURE SPECIFICATIONS

WPS No.

B-U5a

Revision No.

0

X

PQR No. Prequalified Semi-Automatic

JOINT DETAIL

Code

AWS D1.1 Automatic

Page

1 of 1

Welding Process(es) SMAW

JOINT DESIGN AWS Joint Designation Joint Type

Butt Joint B-U5a

Type-Manual

Machine

f

Double-Bevel-Groove

Weld Type No X

Backgouge R

Backing Strip/Ring: Yes Backing Material Back Gouging: BASE METAL AWS Group No.

I & II None

Min Thickness

X

N/A

Yes

No

Method

Arc Air and/or Grinding

T1

To Group No.

I & II

Material Specification & Grade: BM Thickness:

Carbon Steel, e.g. ASTM A36, A572 Gr. 50, A516, A53, A106, API 5L Gr. B

Root Opening = Root Face =

0 to 1/8 +1/16, -0

0 to 1/8 +1/16, -0

Groove T 1= Unlimited Fillet

N/A

T 2= N/A Groove Angle =

45 +10 , -0

Pipe Diameter Range: FILLER METAL AWS Specification AWS Classification Size of Filler Metals SAMS S/N Other

Groove

610mm and Over

Fillet

N/A

POSITION

A5.1 E6010 3.2mm 20-484-024 A5.1 E7018 3.2mm 20-483-071

Groove

All V-Up

Fillet

N/A

Vertical Progression GAS Shielding Gas (Type) Gas Cup Size

N/A

N/A

Flow Rate Other

N/A None

Larger sizes, i.e 4.0mm and 4.8mm, may be used on thick sections

TECHNIQUE String or Weave Bead Multiple or Single Passes Peening Initial & Interpass Cleaning PREHEAT T of Thickest Part (mm) Min Preheat/Interpass Max Interpass Temp. SIDE

1

Stringer and Weave Multiple

ELECTRICAL CHARACTERISTICS Contact Tube to Work Distance Tungsten Electrode Size and Type Transfer Mode (GMAW) Current Type POST WELD HEAT TREATMENT 3 to 19

10 C

315 C N/A N/A N/A DCRP

None

Brushing & Grinding

>19 to 38

66 C

>38 to 63

107 C

>63

150 C

Temperature Range Time Range

None N/A

PASS

Root Fill/Cap Back Weld Fill/Cap Fill/Cap

PROCESSFILLER METAL SIZE POLARITY AMP SMAW E6010 (mm) DCRP 3.2 70-130

SMAW SMAW SMAW SMAW E7018 E7018 E7018 E7018 3.2 3.2 4.0 4.8 DCRP DCRP DCRP DCRP 90-165 90-165 125-220 170-280

VOLT SPEED (cm/min)

21-27 20-26 20-26 21-27 22-28 8-20 8-20 8-20 8-20 8-20

NOTES

1

2 1, 2 1, 2

1. Backgouge root before welding second side. 2. Depth of shallower groove shall be no less than 1/4 T of thinner part joined. 3. Orientation of one member may vary within + 45.

Department

Consulting Services Department

Date

October 14, 2000

Approval Restrictions

Not approved for cyclic loaded structures, crane applications, T, Y, K tubular connections, or offshore structures to API RP 2A.

PREQUALIFIED STRUCTURAL WELDING PROCEDURE SPECIFICATIONS

WPS No.

TC-U5b

Revision No.

0

X

PQR No. Prequalified Semi-Automatic

JOINT DETAIL

Code

AWS D1.1 Automatic

Page

1 of 1

Welding Process(es) SMAW

JOINT DESIGN AWS Joint Designation Joint Type

T- or Corner Joint TC-U5b

Type-Manual

Machine

Weld Type No X

Double-Bevel-Groove

Backgouge

Backing Strip/Ring: Yes Backing Material Back Gouging: BASE METAL AWS Group No.

I & II None

Min Thickness

X

N/A

f T1 R T2

Yes

No

Method

Arc Air and/or Grinding

To Group No.

I & II

Material Specification & Grade: BM Thickness:

Carbon Steel, e.g. ASTM A36, A572 Gr. 50, A516, A53, A106, API 5L Gr. B

Root Opening = Root Face =

0 to 1/8 +1/16, -0

0 to 1/8 +1/16, -0

Groove T 1= Unlimited Fillet

Unlimited

T 2= Unlimited Groove Angle =

45 +10 , -0

Pipe Diameter Range: FILLER METAL AWS Specification AWS Classification Size of Filler Metals SAMS S/N Other

Groove

610mm and Over

Fillet

Similar

POSITION

A5.1 E6010 3.2mm 20-484-024 A5.1 E7018 3.2mm 20-483-071

Groove

All V-Up

Fillet

All

Vertical Progression GAS Shielding Gas (Type) Gas Cup Size

N/A

N/A

Flow Rate Other

N/A None

Larger sizes, i.e 4.0mm and 4.8mm, may be used on thick sections

TECHNIQUE String or Weave Bead Multiple or Single Passes Peening Initial & Interpass Cleaning PREHEAT T of Thickest Part (mm) Min Preheat/Interpass Max Interpass Temp. SIDE

1

Stringer and Weave Multiple

ELECTRICAL CHARACTERISTICS Contact Tube to Work Distance Tungsten Electrode Size and Type Transfer Mode (GMAW) Current Type POST WELD HEAT TREATMENT 3 to 19

10 C

315 C N/A N/A N/A DCRP

None

Brushing & Grinding

>19 to 38

66 C

>38 to 63

107 C

>63

150 C

Temperature Range Time Range

None N/A

PASS

Root Fill/Cap Back Weld Fill/Cap Fill/Cap

PROCESSFILLER METAL SIZE POLARITY AMP SMAW E6010 (mm) DCRP 3.2 70-130

SMAW SMAW SMAW SMAW E7018 E7018 E7018 E7018 3.2 3.2 4.0 4.8 DCRP DCRP DCRP DCRP 90-165 90-165 125-220 170-280

VOLT SPEED (cm/min)

21-27 20-26 20-26 21-27 22-28 8-20 8-20 8-20 8-20 8-20

NOTES

1

2 1, 2 1, 2

1. Backgouge root before welding second side. 2. Fillet welds shall be 1/4 T1 minimum, but not more than 10mm. 3. Depth of shallower groove shall be no less than 1/4 T of thinner part joined. 4. Orientation of one member may vary within + 45.

Department

Consulting Services Department

Date

October 14, 2000

Approval Restrictions

Not approved for cyclic loaded structures, crane applications, T, Y, K tubular connections, or offshore structures to API RP 2A.

También podría gustarte

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocumento4 páginasWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremAún no hay calificaciones

- Ilcs-Smaw-D1.3-Deck (G) WPSDocumento3 páginasIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- PREQUALIFIED WELDING PROCEDURE SPECIFICATIONDocumento1 páginaPREQUALIFIED WELDING PROCEDURE SPECIFICATIONErick VazquezAún no hay calificaciones

- Wps SmawDocumento1 páginaWps SmawFedericoC67% (3)

- WPQR Welding Procedure QualificationDocumento3 páginasWPQR Welding Procedure QualificationThanasis KyrgiazoglouAún no hay calificaciones

- Welding ReportDocumento52 páginasWelding ReportalidadAún no hay calificaciones

- Aluminium WPSDocumento2 páginasAluminium WPSAnonymous yCpjZF1rF100% (1)

- AUT-GMAW-2 Rev.0 PDFDocumento5 páginasAUT-GMAW-2 Rev.0 PDFDarioAún no hay calificaciones

- 25 Tack Welder - ABSDocumento7 páginas25 Tack Welder - ABSvudinhnambrAún no hay calificaciones

- Aws D1.6 - SS316 WPSDocumento1 páginaAws D1.6 - SS316 WPSBoby Thomas0% (1)

- Stainless steel welding procedure qualification recordDocumento1 páginaStainless steel welding procedure qualification recordchandraAún no hay calificaciones

- Welder Performace Qualification Report 2014..Documento132 páginasWelder Performace Qualification Report 2014..Kayra Riri ChirulAún no hay calificaciones

- PQRDocumento2 páginasPQRafqzfieAún no hay calificaciones

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Documento2 páginas(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- WABO Welder Qualification StandardDocumento77 páginasWABO Welder Qualification StandardJuan Martinez100% (1)

- WELDER QUAL TEST REPORTDocumento1 páginaWELDER QUAL TEST REPORTtantri.hellyanti100% (1)

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocumento3 páginasWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanAún no hay calificaciones

- Wps Butt AWSDocumento4 páginasWps Butt AWSMohd Ashraf75% (4)

- WQTDocumento1 páginaWQTRamkunwar YadavAún no hay calificaciones

- ASME IX-Welder Performance Qualification (WPQ) : Welding and NDT Purposed FormatDocumento1 páginaASME IX-Welder Performance Qualification (WPQ) : Welding and NDT Purposed FormatArshadAliAún no hay calificaciones

- Gtaw WPQDocumento3 páginasGtaw WPQMuhammadShabbirAún no hay calificaciones

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocumento2 páginasProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXAún no hay calificaciones

- For Fillet Weld Joint Project:Production ManifoldDocumento1 páginaFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- WPQR SMAW EN-2 - 30mm (Under Modification)Documento2 páginasWPQR SMAW EN-2 - 30mm (Under Modification)Mohamed Reda HusseinAún no hay calificaciones

- Weld Matrix Format 1Documento7 páginasWeld Matrix Format 1Arslan WaheedAún no hay calificaciones

- Draft WPSDocumento3 páginasDraft WPSWale OyeludeAún no hay calificaciones

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocumento1 páginaWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavAún no hay calificaciones

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocumento6 páginasWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberAún no hay calificaciones

- Welding Procedure Specification Register (Structural Steel) : AWS D1.1Documento14 páginasWelding Procedure Specification Register (Structural Steel) : AWS D1.1murshid badshah100% (2)

- GTAW Welding Process ParametersDocumento12 páginasGTAW Welding Process Parametersmiteshpatel191Aún no hay calificaciones

- JIMT Visual Inspection ReportDocumento1913 páginasJIMT Visual Inspection Reportgomathyselvi100% (1)

- Song Hong Co., Ltd Welding Procedure SpecificationDocumento5 páginasSong Hong Co., Ltd Welding Procedure SpecificationTrinh DungAún no hay calificaciones

- WPS - 023Documento10 páginasWPS - 023MAT-LION0% (1)

- AWS D1.2 GuidesDocumento3 páginasAWS D1.2 GuidesTuan DangAún no hay calificaciones

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Documento3 páginasWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielAún no hay calificaciones

- Aluminum Welding ProceedureDocumento14 páginasAluminum Welding ProceedureGregEverett2Aún no hay calificaciones

- Welding Procedure Qualification Record: Shipyard LogoDocumento4 páginasWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- WQT - WPS 02Documento33 páginasWQT - WPS 02Gururaj P KundapurAún no hay calificaciones

- Reports - QAQC - R0Documento10 páginasReports - QAQC - R0talupurumAún no hay calificaciones

- Approved Welding Procedures List RegioDocumento2 páginasApproved Welding Procedures List Regiogabriel__regio100% (1)

- WPSDocumento2 páginasWPSAlam MD Sazid100% (1)

- Destructive Test ReportDocumento5 páginasDestructive Test ReportAnonymous r4Pd1KR0100% (1)

- 01 - WELDING DEFECTS (Surface) - May 2021Documento28 páginas01 - WELDING DEFECTS (Surface) - May 2021Gerry Dan ChanliongcoAún no hay calificaciones

- Wps PQR Aws d11 FormDocumento2 páginasWps PQR Aws d11 Formflakosisas100% (1)

- Blank Sample PQR Form (SAW - Page 1) Procedure Qualification Record (PQR)Documento2 páginasBlank Sample PQR Form (SAW - Page 1) Procedure Qualification Record (PQR)GMAún no hay calificaciones

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Documento1 páginaWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- Welding Procedure Specification GuideDocumento2 páginasWelding Procedure Specification GuidepoulmackAún no hay calificaciones

- AWS D1.1 Welding Code GuideDocumento10 páginasAWS D1.1 Welding Code GuideGautam SunnyAún no hay calificaciones

- WELDING PROCEDURE SPECIFICATION FOR TANK TK 5109/5110/5111Documento15 páginasWELDING PROCEDURE SPECIFICATION FOR TANK TK 5109/5110/5111surya1960Aún no hay calificaciones

- PQR Sample PrintoutDocumento2 páginasPQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- Welding QualificationDocumento45 páginasWelding QualificationeswarAún no hay calificaciones

- Wps & PQR and Weld Map and Test PlanDocumento67 páginasWps & PQR and Weld Map and Test PlanmarghoobAún no hay calificaciones

- Draft WPSDocumento32 páginasDraft WPSAnilkumar G NairAún no hay calificaciones

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Documento12 páginasPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXAún no hay calificaciones

- GMAW welding parameters for SS400 pipeDocumento2 páginasGMAW welding parameters for SS400 pipeAnonymous zfC1zo9C100% (1)

- Aws Eg4 0 1996Documento150 páginasAws Eg4 0 1996Mario MendozaAún no hay calificaciones

- PQR-WPS-WPQR XXX Rev 0Documento6 páginasPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- WPS 856110.016 Rev 3Documento1 páginaWPS 856110.016 Rev 3laz_kAún no hay calificaciones

- Manual Overlay WeldingDocumento8 páginasManual Overlay Weldingcarlmac6183% (6)

- Manual Overlay WeldingDocumento8 páginasManual Overlay Weldingaamirtec301100% (2)

- Senior Welding InspectorDocumento1 páginaSenior Welding InspectorwalitedisonAún no hay calificaciones

- Installation of Tripper Gallery PWIDocumento14 páginasInstallation of Tripper Gallery PWIwalitedisonAún no hay calificaciones

- Valve List Test LimitDocumento37 páginasValve List Test LimitwalitedisonAún no hay calificaciones

- Final Alignment Monitoring ReportDocumento2 páginasFinal Alignment Monitoring ReportwalitedisonAún no hay calificaciones

- Yuhan Welder List - Nov.22017 PDFDocumento2 páginasYuhan Welder List - Nov.22017 PDFwalitedisonAún no hay calificaciones

- Hydrostatic Test Procedure PDFDocumento2 páginasHydrostatic Test Procedure PDFLuis Pullas86% (43)

- Gag For Pressure Safety Valve JimCaseyDocumento1 páginaGag For Pressure Safety Valve JimCaseywalitedisonAún no hay calificaciones

- T0rque Value of A193 B7Documento2 páginasT0rque Value of A193 B7walitedisonAún no hay calificaciones

- Boiler and Piping ToolsDocumento4 páginasBoiler and Piping ToolswalitedisonAún no hay calificaciones

- Final Alignment Monitoring ReportDocumento2 páginasFinal Alignment Monitoring ReportwalitedisonAún no hay calificaciones

- T0rque Value of A193 B7Documento2 páginasT0rque Value of A193 B7walitedisonAún no hay calificaciones

- List of Inspection Report For Turnover Package For WWTDocumento1 páginaList of Inspection Report For Turnover Package For WWTwalitedisonAún no hay calificaciones

- NDT TrainingDocumento1 páginaNDT TrainingwalitedisonAún no hay calificaciones

- Yuhan Welder List - Nov.22017Documento2 páginasYuhan Welder List - Nov.22017walitedisonAún no hay calificaciones

- Yuhan Welder List - Nov.22017Documento1 páginaYuhan Welder List - Nov.22017walitedisonAún no hay calificaciones

- Review of Radiographic Examination ReportDocumento1 páginaReview of Radiographic Examination ReportwalitedisonAún no hay calificaciones

- AGP Welder List - Nov.032017Documento7 páginasAGP Welder List - Nov.032017walitedisonAún no hay calificaciones

- Yuhan Welder List - Oct.312017Documento3 páginasYuhan Welder List - Oct.312017walitedisonAún no hay calificaciones

- Correct Welding of Main Steam LineDocumento2 páginasCorrect Welding of Main Steam LinewalitedisonAún no hay calificaciones

- Tension Test Plate: G-Gage Length W-Width 200 0.25 MM 40 +3 - 6 MMDocumento4 páginasTension Test Plate: G-Gage Length W-Width 200 0.25 MM 40 +3 - 6 MMwalitedisonAún no hay calificaciones

- Ut Formate1Documento187 páginasUt Formate1walitedisonAún no hay calificaciones

- Woolim Welder List - Oct.302017Documento1 páginaWoolim Welder List - Oct.302017walitedisonAún no hay calificaciones

- Welding Properties and Chemical Composition SelectionDocumento84 páginasWelding Properties and Chemical Composition SelectionwalitedisonAún no hay calificaciones

- Steel Material Thickness RequestDocumento1 páginaSteel Material Thickness RequestwalitedisonAún no hay calificaciones

- Xwell StickerDocumento1 páginaXwell StickerwalitedisonAún no hay calificaciones

- Equipment Inventory SummaryDocumento16 páginasEquipment Inventory SummarywalitedisonAún no hay calificaciones

- Xwell StickerDocumento1 páginaXwell StickerwalitedisonAún no hay calificaciones

- Review of Radiographic Examination ReportDocumento1 páginaReview of Radiographic Examination ReportwalitedisonAún no hay calificaciones

- B31.1 Nde RequirementsDocumento1 páginaB31.1 Nde RequirementswalitedisonAún no hay calificaciones

- NDT Advantage and DisadvantageDocumento4 páginasNDT Advantage and DisadvantagewalitedisonAún no hay calificaciones

- PNL November 2021Documento19 páginasPNL November 2021putripandeanAún no hay calificaciones

- WORK EFFECTIVELY WITH DIVERSITYDocumento31 páginasWORK EFFECTIVELY WITH DIVERSITYettharAún no hay calificaciones

- Critical Paper On The True Cost DocumentaryDocumento3 páginasCritical Paper On The True Cost DocumentaryJoseph Peter Daculan100% (1)

- Canhs Physical Inventory Plan 2021Documento3 páginasCanhs Physical Inventory Plan 2021JMAR ALMAZANAún no hay calificaciones

- Topic I - Introduction To SCMDocumento9 páginasTopic I - Introduction To SCMHobiAún no hay calificaciones

- High TechDocumento3 páginasHigh TechTI NafisAún no hay calificaciones

- Ohsc Assignment 4Documento5 páginasOhsc Assignment 4Kumar MangalamAún no hay calificaciones

- Balance Sheet and Income Statement (2016-2020)Documento20 páginasBalance Sheet and Income Statement (2016-2020)XienaAún no hay calificaciones

- Project Report On Trading FirmDocumento5 páginasProject Report On Trading FirmMathan RajAún no hay calificaciones

- Digitizing The Agriculture Industry in BangladeshDocumento20 páginasDigitizing The Agriculture Industry in BangladeshRakaAún no hay calificaciones

- Raui Machinery StoreDocumento1 páginaRaui Machinery StoresunitachanchaliyaAún no hay calificaciones

- IS MATTER AROUND US PUREDocumento45 páginasIS MATTER AROUND US PUREsabirafrinAún no hay calificaciones

- Business EthicsDocumento2 páginasBusiness EthicsDiana Rose MotolAún no hay calificaciones

- Bangalla New Client Form: Check MarkDocumento1 páginaBangalla New Client Form: Check MarkKamber AliAún no hay calificaciones

- Kronospan Schweiz AG OverviewDocumento34 páginasKronospan Schweiz AG OverviewSanay MittalAún no hay calificaciones

- CV Udpated-Ac-2 PDFDocumento4 páginasCV Udpated-Ac-2 PDFTahir SirtajAún no hay calificaciones

- Group 1A: UCB: Data Is The New DrugDocumento17 páginasGroup 1A: UCB: Data Is The New DrugRakshana SrikanthAún no hay calificaciones

- The Reliability of MeasuringDocumento50 páginasThe Reliability of MeasuringYury FedichkinAún no hay calificaciones

- Saa For Dummies 3rdeditionDocumento64 páginasSaa For Dummies 3rdeditionParameswaran LakshmynarayananAún no hay calificaciones

- DOLE Phils V EstevaDocumento2 páginasDOLE Phils V EstevaBert NazarioAún no hay calificaciones

- NeckbandDocumento1 páginaNeckbandVaibhavAún no hay calificaciones

- MANAGEMENT-22509 MCQ's 1.6.2021Documento63 páginasMANAGEMENT-22509 MCQ's 1.6.2021Arvind YadavAún no hay calificaciones

- ANANDDocumento13 páginasANANDATAún no hay calificaciones

- White Collar CrimeDocumento57 páginasWhite Collar CrimeShashi DasAún no hay calificaciones

- Virtual Stock Trading StrategiesDocumento10 páginasVirtual Stock Trading StrategiesJan Jovirin GelicameAún no hay calificaciones

- PERT/CPM Project Planning, Scheduling and ControlDocumento58 páginasPERT/CPM Project Planning, Scheduling and ControlJayson J. PagalAún no hay calificaciones

- Porter's Five Forces Analysis of Indian Steel IndustryDocumento3 páginasPorter's Five Forces Analysis of Indian Steel IndustrySrinivas Nandikanti67% (3)

- Raz-Kids Dreambox Letter To ParentsDocumento2 páginasRaz-Kids Dreambox Letter To Parentsapi-265873147Aún no hay calificaciones

- Introduction To DTCCDocumento11 páginasIntroduction To DTCCefx8x75% (4)

- Alibaba's Founding and Rapid GrowthDocumento3 páginasAlibaba's Founding and Rapid Growthtayyab malikAún no hay calificaciones