Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Flotacion

Cargado por

Jenny P Calvachi CDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Flotacion

Cargado por

Jenny P Calvachi CCopyright:

Formatos disponibles

Separation and Purication Technology 55 (2007) 173181

Effects of operating variables on modied otation parameters in the mineral separation

M. Ucurum a, , O. Bayat b

b

Cukurova University, Vocational College of Karaisali, 01770 Adana, Turkey Cukurova University, Mining Engineering Department, Balcali, 01330 Adana, Turkey

Received 25 August 2006; received in revised form 25 November 2006; accepted 26 November 2006

Abstract An attempt has been made in this paper to investigate effect of collector type, particle size distribution, collector dosage, air ow rate, pulp density and wash water rate parameters on modied otation parameters on sphalerite otation in a otation column. In the experimental studies, the fractional recoveries after 0.5, 1, 2, 3, 5, 10 and 20 min of otation time were tted to rst-order kinetic model R = R [1 exp(kt)], where R is recovery at t time, R is ultimate recovery and k is the rst-order rate constant was used to draw the timerecovery curves. Two parameters, the ultimate recovery (R ) and rst-order rate constant (k), were then obtained from the model to t an experimental timerecovery curve. A modied otation rate constant (Km ) dened as product of R and k, i.e., Km = R k, and selectivity index (SI) dened as the ratio of the modied rate constant of mineral I to the modied rate constant of mineral II (SI = Km of mineral I/Km of mineral II), which could be collectively called modied otation parameters, were calculated for each test and it was used to measure of otation separation selectivity of sphalerite over pyrite. Timed batch tests on ground ore using a pilot otation column and subsequent recovery and grade of experimental data and modied otation parameters indicated that the optimum parameters are as follows: Dithiophospates collector type, ner particle size distribution (d80 = 0.125 mm), low collector dosage (500 g/t), low air ow rate (1.30 cm/s), high pulp density (20% solids) and high wash water rate (0.5 L/min). 2006 Elsevier B.V. All rights reserved.

Keywords: Mineral separation; Froth otation; Flotation kinetics

1. Introduction Flotation is one of the most complex mineral processing operations as it is affected by a very large number of variables. Many of these are beyond the control of the mineral engineer, and some cannot be even measured quantitatively with the available instruments. The relations between measured and controlled variables are intricately related. Sometimes simultaneously changing various component settings will reinforce a particular attribute. In addition, various component settings can cancel or counteract each other if changes are not chosen wisely [1]. Froth otation is the separation method most commonly used to concentrate minerals. Conventionally, the separation is conducted in mechanical cells where the entrainment of ne gangue (hydrophilic) particles in the froth phase, due to the inherent mechanics of the phenomenon, had a deleterious effect on the metallurgical per-

Corresponding author. Tel.: +90 322 551 20 57; fax: +90 322 551 22 55. E-mail address: cevher@cu.edu.tr (M. Ucurum).

formance of the process. An effective method to hinder such ne gangue entrainment emerged with the invention of the column otation cell, which uses a deep froth zone (0.52 m) counter currently washed with water (termed wash water) to induce a cleaning action of the froth. This is one of the reasons that explain the metallurgical benets gained by the introduction of the column to the conventional otation circuits [2]. During the last decades, extensive research has been done on column otation reecting the increased interest in this technology. As a result, many aspects of column otation have been studied. Satisfactory models of collection mechanism and scale-up have been developed and applied successfully [3]. Such as, Jameson Cell which was developed jointly by Mount Isa Mines and Professor G.J. Jameson of the University of Newcastle [4] and Turbo otation column which has been developed by Multotec Process Equipment Ltd. in South Africa [5]. Columns out perform conventional mechanical cells in cleaning operations (better product grade) due to their particular froth operation, discussed in detail by Finch and Dobby [6]. More degrees of freedom in operating variables of otation columns have led to large variations

1383-5866/$ see front matter 2006 Elsevier B.V. All rights reserved. doi:10.1016/j.seppur.2006.11.019

174

M. U urum, O. Bayat / Separation and Purication Technology 55 (2007) 173181 c

in metallurgical performance and have therefore provided much scope for improving their control [7]. Traditionally, the evaluation of otation tests is based largely on a rougher recovery value achieved at a dened time. Since the cumulative recovery of a component in the concentrate is proportional to otation time, the otation process can be considered as a timerate recovery process. Therefore, a mathematical otation model that incorporates both a recovery and a rate function can completely describe otation timerecovery proles. They provide an excellent tool to evaluate otation tests [8]. Lynch et al. [9] have conveniently dened three categories for these models: (i) empirical models, (ii) probability models, and (iii) kinetic models. The main advantage of the empirical models is that they are often less expensive in personnel and time. However, predictions outside the range of the models database should be treated warily, while estimation of the performance of alternate circuits for a particular ore is not possible. Unlike the empirical approach, the probability approach does allow recognition of the individual compartments and more importantly the pulp and froth volumes in each compartment [10,11]. The probability models basically consider the probabilities of particle bubble collision, adhesion, froth stability, etc. The simple form of the probability approach is similar to the simplest form of the kinetic model [12]. In froth otation, air bubbles are injected into a moving stream of aqueous slurry containing a mixture of particles, so that only hydrophobic ores collected on the bubble surface and exit the stream. Owing to its simplicity, the process is widely used for separating a great variety of solid particles. However, a number of complex chemical and physical interaction aspects are involved in the literature on the study of this process, which has been studied from contact angles. Of these, kinetic approach has been highly instrumental in better understanding leading to reasonably accurate predictions [13]. Kinetic models can be used to analyze batch otation results. Two parameters which are R (ultimate recovery) and k (rstorder rate constant) are obtained from the model t to an experimental recoverytime curve. They can be effectively used to evaluate variables affecting otation process [14]. Understanding and interpreting changes in the values of R and k are very important and can often be misleading [15]. In many laboratory studies, changing one condition leads to a change in both R and k values. This can make it difcult to compare otation rate data between tests or to establish a trend for R and k values under different conditions. For instance, changing one condition may lead to an increase in k but a decrease in R , while selectivity between the valuable and gangue minerals might be unchanged, increased or decreased depending only on the combined measure of k and R . One way to overcome the difculty of comparing k and R values is to introduce a modied rate constant (Km ), which takes into account both ultimate recovery, and rate constant [16]. Consequently, a selectivity index (SI) based on the modied rate constant between different minerals in a otation system can be obtained. The two could be collectively called modied otation parameters [12]. The value of a otation concentrate containing a given mineral from which a desired metal is extracted by a metallurgical

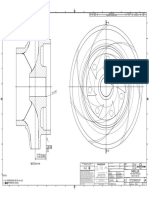

process decreases with an increase in the presence of minerals containing metals other than that of prime interest. It is thus necessary to design specic selective otation collectors to separate the desired mineral from the gangue [17]. Sulphide mineral ores remain the major source of base metals. The otation of valuable minerals of copper, lead and zinc from pyrite, the main sulphide gangue, has received considerable attention [18,19]. 2. Experimental 2.1. Materials The otation experiments were carried out using samples of sphalerite ore obtained from Postalli Mining Company, Kayseri, Turkey. Chemical analysis indicated that the ore contained mainly 16.47% Zn, 23.72% Fe, 0.87% Pb, 22.52% SiO2 and 8.82% MgO (Table 1). X-ray diffraction analysis pointed out that sphalerite and pyrite were the primary sulphides and quartz, and dolomite as gangue minerals (Fig. 1). Cytec International, Holland and SELSAN Metal Limited Company, Turkey supplied the collecting agents which were Dithiophospates (Aerooat 7048 + Aerooat 7279) and Potassium Amyl Xanthate. Sodium silicate and copper sulphate were obtained from Sigma and Fluka Co., respectively. Tap water was used throughout the experiments. The pulp pH was adjusted using lime. 2.2. Flotation The individual otation tests were performed in a otation column. The experimental column set-up with auxiliary instrumentation is shown in Fig. 2. The column was constructed in stainless steel, 13.5 cm in diameter and 280 cm in total length. The downcomer was 4.5 cm in diameter and 100 cm in length. The gas entry point was located in the column bottom section and was pointed upwards and the slurry was introduced into the downcomer via a nozzle to form a jet, compared to the conventional column where the feed was introduced near the froth/slurry interface. Feed was introduced into the feed sump and a xed speed feed pump feeds the material into the aerator where slurry was injected into the feed downcomer. Air was selfTable 1 Chemical composition of the ore sample Species SiO2 CaO MgO Pb Zn Fe Cu Cd Mn Au Ag Loss of ignition wt.% 22.52 1.70 8.82 0.87 16.47 23.72 0.29 0.09 0.04 Trace 0.007 22.60

M. U urum, O. Bayat / Separation and Purication Technology 55 (2007) 173181 c

175

Fig. 1. X-ray diffraction patterns of the ore (Sp: sphalerite; Py: pyrite; Qz: quartz; Dm: dolomite).

induced into the cell. A fast otation occurs in the downcomer prior to the mixture being discharged into the otation column. The induced bubbles with oatable particles attached to them, rise to the column top to be discharged as concentrate (which is usually washed). The remainder of the feed slurry containing oatable and non-oatable material settles down to the otation columns base. The column base was equipped with a secondary bubble injection system via a sparger system that introduces small air bubbles. The oatable material has a second opportunity for bubble attachment, thus simulating two otation units in series. The non-oatable material discharges via the column base as tailings at a controlled rate. Instead of the tailings discharging directly to the tailings sump, it was fed to a dummy

sump inside the feed sump. The dummy sump was designed with two outlets, a high level overow that feeds the tails sump and a non-return orice communicating with the feed sump. Volumetric uctuations in the feed to the otation column were eliminated as a constant volumetric ow rate is pumped to the otation column through a xed speed pump. As the level of the feed sump dropped, more tailings slurry owed from the dummy sump to the feed sump due to larger level differences and vice versa. The excess tailings overowed to the actual tails sump. Much shorter time periods were required to re-stabilize the plant when fresh feed was re-introduced. For a standard otation test, a sub-sample (0.5 kg) was ground in a stainless steel mill at a pulp density of 70 wt.%. The ball

Fig. 2. Schematic representation of the experimental otation column.

176

M. U urum, O. Bayat / Separation and Purication Technology 55 (2007) 173181 c Table 2 Flotation column design and operating specications Column variable Diameter (mm) Total height (mm) Downcomer diameter (mm) Downcomer height (mm) Froth height (mm) Sparger type Supercial feed velocity (cm/s) d80 (mm) Supercial air velocity (cm/s) Pulp density (%) Wash water rate (L/min) pH Na2 SiO3 (g/t) CuSO4 (g/t) Aerooat 7048 + Aerooat 7279 (g/t) Pilot column 135 3200 45 1000 Variable Internal 2.20 0.180, 0.125 1.30, 2.20 7.5, 20 0, 0.5 12 (with lime) 250 575 250 + 250, 300 + 300

Fig. 3. Particle size distribution of the sphalerite sample after two different grinding times.

mill had the dimensions, 200 mm 200 mm, and was charged with 5 kg of stainless steel balls. The grinding times were 5 and 10 min, giving particle size distributions of d80 = 0.180 and 0.125 mm, respectively. The size analyses of the feed and two individual fractions are shown in Fig. 3. Firstly, optimum collector type and size distribution were determined using pH 12 (with lime), 2.20 cm/s feed velocity, 1.30 cm/s air ow rate, 7.5 wt.% pulp density, 600 g/t collector dosage, 250 g/t Na2 SiO3 , 575 g/t CuSO4 and 0 L/min wash water rate in the otation column. Then, other parameters were studied with optimum collector type (Aerooat 7048 + Aerooat 7279) and particle size distribution (d80 = 0.125 mm) [20]. In this study, the fractional recoveries after 0.5, 1, 2, 3, 5, 10 and 20 min of otation time were tted to the model. To determine kinetic parameters such as, otation rate constant k and the ultimate recovery R , a statistical programme SPSS for Windows 9.0 was used to treat the data in the mode non-linear regression. The oating and sinking fractions were recovered, vacuum ltered and dried in an oven at 90 5 C to constant weight and assayed for Zn and Fe contents using an atomic absorption spectrophotometer. Design and otation test parameters are presented in Table 2. 3. Results and discussion 3.1. Effect of collector type In this study, collector performance of Potassium Amyl Xanthate was compared with Dithiophospates (Aerooat 7048 + Aerooat 7279) on the separation of sphalerite from

Fig. 4. Comparison Zn and Fe recovery vs. concentrate Zn and Fe grade for Dithiophospate (Aerooat 7048 + Aerooat 7279) and Potassium Amyl Xanthate (Dp: Dithiophospate; PAX: Potassium Amyl Xanthate).

pyrite using modied otation parameters. Fig. 4 shows Zn recovery versus concentrate Zn grade and Fe recovery versus concentrate Fe grade for the effect of type of collectors. Table 3 presents the ultimate recovery (R ), otation rate constant (k), modied rate constant (Km ), selectivity index (SI) and correlation coefcient (R2 ). Dithiophospates give better grade and recovery curve for Zn while Potassium Amyl Xanthate produces better grade and recovery for Fe. Dithiophospates appear to have a higher modied rate constant (0.252) while Potassium Amyl Xanthate has a lower value (0.192) for Zn. The modied rate constant of Potassium Amyl Xanthate collector is higher (0.059) than Dithiophospates collectors (0.032) for Fe. In terms of Zn/Fe

Table 3 Parameters obtained from model (R = R [1 exp(kt)]) t to data set for Zn and Fe Collector type Zn R Dithiophospate Potassium Amyl Xanthate 0.895 0.874 k 0.282 0.220 Km 0.252 0.192 R2 0.993 0.991 Fe R 0.226 0.424 k 0.140 0.139 Km 0.032 0.059 R2 0.980 0.956 7.88 3.25 SI

M. U urum, O. Bayat / Separation and Purication Technology 55 (2007) 173181 c

177

Fig. 5. Fitted to data set for collectors on Zn and Fe recovery for Dithiophospate (Aerooat 7048 + Aerooat 7279) and Potassium Amyl Xanthate (Exp. = experimental).

Fig. 6. Zn and Fe recovery vs. concentrate Zn and Fe grade for d80 = 0.180 and 0.125 mm size distribution.

selectivity index, Dithiophospates give a much better result than Potassium Amyl Xanthate with a value of 7.88. The xanthates have been the workhorse of sulphide mineral otation since the 1920s and represent the largest volume of any sulde mineral collector. Xanthates are very good at recovering in unselective manner bulk sulde minerals, including iron suldes. The dithiophosphate collector family is the second major class of sulphide collectors from a collector volume viewpoint. Dithiophosphates generally show better iron sulde rejection capability than do the xanthates [21]. In this study, the experimental trials show that Dithiophosphate collectors (Aerooat 7048 + Aerooat 7279) are better than xanthate collector (Potassium Amyl Xanthate) in terms of modied otation parameters in the separation from sphalerite to pyrite. Results in Fig. 5 conrm that the model ts the experimental data very well for both collectors. 3.2. Effect of size distribution Particle liberation plays an important role in otation processes, as demonstrated by studies on the detachment of particles during bubble coalescence, or by comparison of kinetic parameters for liberated or locked particles. The size to which ore to be processed should be ground in order to optimise processing protability while taking into account metallurgical balance and size-reduction cost is a very important parameter [22]. This study examined the effects of particle size distribution (i.e. d80 = 0.180 and 0.125 mm) on the otation behaviour of sphalerite. Table 4 gives the ultimate recovery (R ), otation rate constant (k), modied rate constant (Km ), selectivity index (SI) and corre-

lation coefcient (R2 ). Fig. 6 also presents recovery and grade curves for Zn and Fe. d80 = 0.125 mm size distribution gives better results for ultimative recovery (R ), otation rate constant (k), modied rate constant (Km ) and recovery and grade values for Zn. Furthermore, the size distribution is higher than d80 = 0.180 mm in terms of selectivity index (12.58 and 7.88, respectively). This study has examined the effects of particle size distribution on the otation behaviour of sphalerite. Timed batch tests on ground ore using a pilot otation column and subsequent statistical analysis of experimental data indicated that the optimum feed size for the ore should be d80 = 0.125 mm. In tests, ner size particles were also observed to form smaller and more stable bubbles, resulting in more efcient otation. Modelling indicated that a

Fig. 7. Fitted to data set for size distribution on Zn and Fe recovery.

Table 4 Parameters obtained from model (R = R [1 exp(kt)]) t to data set for Zn and Fe Size distribution, d80 (mm) Zn R 0.180 0.125 0.895 0.954 k 0.282 0.409 Km 0.252 0.390 R2 0.993 0.994 Fe R 0.226 0.259 k 0.140 0.118 Km 0.032 0.031 R2 0.980 0.982 7.88 12.58 SI

178

M. U urum, O. Bayat / Separation and Purication Technology 55 (2007) 173181 c

Table 5 Parameters obtained from model (R = R [1 exp(kt)]) t to data set for Zn and Fe Aerooat 7048 + Aerooat 7279 (g/t) Zn R 500 600 0.937 0.942 k 0.316 0.317 Km 0.296 0.299 R2 0.997 0.993 Fe R 0.190 0.315 k 0.186 0.165 Km 0.035 0.052 R2 0.982 0.995 8.46 5.75 SI

Fig. 8. Zn and Fe recovery vs. concentrate Zn and Fe grade for 500 and 600 g/t of collector dosages.

Fig. 9. Fitted to data set for collector dosages on Zn and Fe recovery.

rst-order kinetic model incorporating a rectangular distribution of oatabilities gave the best t for experimental data (Fig. 7). 3.3. Effect of collector dosage It is well known that the collector dosage of sulphide ores otation is an important variable. The effect of collector dosage on modied otation parameters was investigated using 500 and 600 g/t of Aerooat 7048 + Aerooat 7279. Table 5 gives the ultimate recovery (R ), otation rate constant (k), modied rate constant (Km ), selectivity index (SI) and correlation coefcient (R2 ). Fig. 8 also presents recovery and grade curves for Zn and Fe. As can be seen from the gure, in terms of recovery and grade values, 500 g/t collector dosage presents better results for Zn, 600 g/t collector dosage for Fe. For the selectivity index, based on the modied rate constant between Km of Zn modied rate constant and Km of Fe modied rate constant can be obtained, 500 g/t of collector dosage gives higher result with 8.46 values. Therefore, lower collector dosage (500 g/t) can be chosen as an optimum value for sphalerite otation. The model could present the timerecovery curves of otation tests for both collector dosages quite well for Zn and Fe (Fig. 9).

Fig. 10. Zn and Fe recovery vs. concentrate Zn and Fe grade for 1.30 and 2.20 cm/s air ow rates.

3.4. Effect of air ow rate In this study, two tests in batch operation were performed at two different air ow rates such as, 1.30 and 2.20 cm/s. Fig. 10 shows Zn recovery versus Zn grade and Fe recovery versus Fe grade. Table 6 presents ultimate recovery (R ), otation rate constant (k) obtained from tting, including the modied

Table 6 Parameters obtained from model (R = R [1 exp(kt)]) t to data set for Zn and Fe Air ow rate (cm/s) Zn R 1.30 2.20 0.954 0.942 k 0.408 0.317 Km 0.390 0.299 R2 0.994 0.993 Fe R 0.259 0.315 k 0.118 0.165 Km 0.031 0.052 R2 0.989 0.995 12.58 5.75 SI

M. U urum, O. Bayat / Separation and Purication Technology 55 (2007) 173181 c

179

Fig. 11. Fitted to data set for air ow rates on Zn and Fe recovery. Fig. 13. Fitted to data set for pulp densities on Zn and Fe recovery.

Fig. 12. Zn and Fe recovery vs. concentrate Zn and Fe grade for 7.5 and 20 wt.% pulp densities.

rate constant (k) obtained from tting, including the modied rate constant (Km ) and correlation coefcient (R2 ). In terms of recovery and grade values 20 wt.% of pulp density shows better results than 7.5% for Zn, but 7.5% solids confers a better value for Fe. 7.5 wt.% of pulp density gives higher results for ultimate recovery (R ), rate constant (k) and modied rate constant (Km ) for Zn. However, it has lower ratio with 5.75 for calculation of Zn/Fe selectivity index. Furthermore, 20% solids are strongly higher than 7.5% solids in terms of selectivity index with 12.00. The increase selectivity in otation between sphalerite and pyrite observed when the pulp density is enhanced from 7.5 to 20 wt.%. Therefore, 20% solids is the optimum pulp concentration for the sphalerite otation. The rst-order otation model ts the pulp densities experimental data very well (Fig. 13) for Zn and Fe. 3.6. Effect of wash water rate The froth phase is extremely important in the operation of a otation cell, seeing that, it is critical in determining the amount of unwanted gangue collected to the concentrate and thus the purity of product [23]. To achieve this, the effect of wash water was examined using two different rates (0 and 0.50 L/min). Recovery and grade curves are given Fig. 14 for Zn and Fe. Fig. 15 shows the recovery of Zn and Fe as a function of otation time and model ts at the two different wash water rates. Table 8 presents kinetic parameters (k, R ), modied rate constant (Km ), selectivity index and correlation coefcients (R2 ) from the ttings for Zn and Fe. In terms of recovery and grade values 0.50 L/min wash water rate gives better results for Zn but for Fe, 0 L/min wash water rate put forward better results. In the laboratory column otation tests with the studied wash water rates,

rate constant (Km ) and correlation coefcient (R2 ). 1.30 cm/s air ow rate gives better result in terms of grade and recovery for Zn while 2.20 cm/s air ow rate presents a better result for Fe. However the air ow rate shows better result for the modied rate constant with a value of 0.390 for Zn while 2.20 cm/s air ow rate presents a better value (0.052) for Fe. As well as 1.30 cm/s air ow rate gives higher value (12.58) for selectivity index. The results show that an improved separation of sphalerite from pyrite can be obtained with 1.30 cm/s. Model ts the experimental data very well for Zn and Fe as indicated in Fig. 11. 3.5. Effect of pulp density In order to examine the effect of pulp density on the otation, 7.5 and 20 wt.% of pulp densities were used and the results are given Fig. 12. Table 7 presents ultimate recovery (R ), otation

Table 7 Parameters obtained from model (R = R [1 exp(kt)]) t to data set for Zn and Fe Pulp density (wt.%) Zn R 7.5 20 0.942 0.910 k 0.317 0.303 Km 0.299 0.276 R2 0.993 0.998 Fe R 0.315 0.139 k 0.165 0.166 Km 0.052 0.023 R2 0.995 0.994 5.75 12.00 SI

180

M. U urum, O. Bayat / Separation and Purication Technology 55 (2007) 173181 c

Table 8 Parameters obtained from model (R = R [1 exp(kt)]) t to data set for Zn and Fe Wash water rate (L/min) Zn R 0 0.50 0.942 0.946 k 0.317 0.448 Km 0.299 0.424 R2 0.993 0.998 Fe R 0.315 0.161 k 0.165 0.202 Km 0.052 0.033 R2 0.995 0.993 5.75 12.85 SI

Table 9 Cleaner and scavenger otation conditions Variable Froth height (cm) Wash water rate (L/min) d80 (mm) Air ow rate (cm/s) Cleaner otation conditions pH Na2 SiO3 (g/t) CuSO4 (g/t) Aerooat 7048 + Aerooat 7279 (g/t) Scavenger otation conditions pH Na2 SiO3 (g/t) CuSO4 (g/t) Aerooat 7048 + Aerooat 7279 (g/t) Value Variable 0.5 0.125 1.30 12 50 37.5 + 37.5 12 50 + 50

Fig. 14. Zn and Fe recovery vs. concentrate Zn and Fe grade for 0 and 0.5 L/min wash water rate.

0.5 L/min, gives better result for otation kinetics parameters (R , k), modied rate constant (Km ) as 0.946, 0.448 and 0.424, respectively. Increasing wash water rate from 0 to 0.5 L/min increased Zn/Fe selectivity (5.75 for 0 L/min, 12.85 for 0.5 L/min). Therefore, 0.5 L/min wash water rate for the Zn otation was judged to result in better overall otation performance. With no wash water addition, the Zn/Fe selectivity was too low. However, with wash water, the Zn/Fe selectivity increased sharply with wash water rate up to 0.5 L/min. Fig. 15 shows that the model ts the experimental data quite well for Zn and Fe. 3.7. Optimization This study has examined the effect of collector types, particle size distribution, collector dosages, air ow rates, pulp

densities and wash waters rate on modied otation parameters for sphalerite otation. Results indicated that Dithiophospate collectors (Aerooat 7048 + Aerooat 7279), ner size distribution (d80 = 0.125 mm), low collector dosage (500 g/t), low air ow rate (1.30 cm/s), high pulp density (20% solids) and high wash water rate (0.5 L/min) gave the best results for grade and recovery and modied otation parameters. Two otation tests were made under optimum otation conditions and then concentrations of the rough otation tests were unied. The rougher concentrate (46.73% Zn) was subjected to a cleaner otation and scavenger otation as the optimum conditions were detailed in Table 9. Consequently, nal concentrate was obtained with 93.74% recovery and 55.23% Zn grade. The tailings were discharged with 4.55% recovery and 0.99 Zn grade. 4. Conclusions (i) Zn and Fe recovery data; collector types (Dithiophospate and Potassium Amyl Xanthate), size distribution (d80 = 0.180 and 0.125 mm), collector dosages (500 and 600 g/t), air ow rates (1.30 and 2.20 cm/s), pulp densities (7.5 and 20 wt.%) and wash water rates (0 and 0.5 L/min) tted to rst-order kinetic model, R = R [1 exp(kt)]. The tted to data sets gures and correlation coefcients (R2 ) showed that rst-order kinetic model could represent the timerecovery curves of otation tests very well. (ii) The modied otation rate constant Km dened as the product of fractional ultimate recovery (R ) and rst-order rate constant (k), i.e., Km = R k and selectivity index (SI) dened as the ratio of the modied rate constant of Zn to the modier rate constant of Fe (SI = Km of Zn/Km of Fe)

Fig. 15. Fitted to data set for wash water rates on Zn and Fe recovery.

M. U urum, O. Bayat / Separation and Purication Technology 55 (2007) 173181 c

181

and recovery and grade curves of Zn and Fe were used to determine optimum otation parameters. In this study, used above approaches, the rst conclusions to be drawn from results is that Dithiophospates (Aerooat 7048 + Aerooat 7279) more selective collector than Potassium Amyl Xanthate and d80 = 0.125 mm is better size distribution for the separation of sphalerite from pyrite for the ore. In the mean time, it was found that low collector dosage (500 g/t), low air ow rate (1.30 cm/s), high pulp density (20% solids) and high wash water rate (0.5 L/min) could be used to separate efciently sphalerite from pyrite. (iii) In the experimental studies showed that modied otation rate constant and selectivity index are useful parameters in the otation studies. Acknowledgements This work has been supported by Cukurova University, Scientic Research Projects Directorate (BAP), project FBE.2002.D.215. References

[1] P.K. Naik, P.S.R. Reddy, V.N. Misra, Interpretation of interaction effects and optimization of reagent dosages for ne coal otation, Int. J. Miner. Process. 75 (2005) 8390. [2] A.S. Uribe, V. Vazquez, R.G. Perez, F.A. Nava, A statistical model for the concentrate water in otation columns, Miner. Eng. 12 (8) (1999) 937948. [3] M. Falutsu, Column otation froth characteristicsstability of the bubbleparticle system, Int. J. Miner. Process. 40 (1994) 225243. [4] G.J. Harborts, B.R. Jackson, E.V. Manlapig, Recent advances in Jameson otation cell technology, Miner. Eng. 7 (1994) 319332. [5] A.N. Terblanche, W.A. Grobler, G. Onal, A. G ney, Turbo Flotation Colu umn with Enhanced Flotation Performance, Balkema, Rotterdam, 1998, ISBN: 90 5809 0132. [6] J.A. Finch, G.S. Dobby, Column Flotation, Pergamon Press, Oxford, 1990. [7] L.G. Bergh, J.B. Yianatos, A. Leon, Multivariate projection methods applied to otation columns, Miner. Eng. 18 (7) (2005) 721723.

[8] X.M. Yuan, B.I. Palsson, K.S.E. Forssberg, Statistical interpretation of otation kinetics for a complex sulphide ore, Miner. Eng. 9 (4) (1996) 429442. [9] A.J. Lynch, N.W. Johnson, E.V. Manlapig, C.G. Thorne, Mineral and coal otation circuits, Chapter 3: mathematical models of otation, in: D.W. Fuerstenau (Ed.), Development in Mineral Processing, Elseiver, Amsterdam, 1981. [10] E.C. Dowling, R.R. Klimpel, F.F. Aplan, Use of kinetic model to analyze industrial otation circuits, in: Proceedings of the International Symposium on Innovative Technology and Reactor Design in Extractive Metallurgy, Warrendale, 1987, pp. 533552. [11] C.C. Harris, H.W. Rimmer, Study of a two phase model of the otation process, Inst. Min. Metall. (1996) 153161. [12] R. Sripriya, P.V.T. Rao, R.B. Choudhury, Optimization of operating variables of ne coal otation using a combination of modied otation parameters and statistical techniques, Int. J. Miner. Process. 68 (2003) 109127. [13] F. Hern inz, M. Calero, Froth otation: kinetic models based on chemical a analogy, Chem. Eng. Process. 40 (2001) 269275. [14] M. Xu, Modied otation rate constant and selectivity index, Miner. Eng. 11 (3) (1998) 271278. [15] P. Kind, Design criteria recent developments on large capacityWemco otation cells, The South African Institute of Mining and Metallurgy. 76 (8) (1976) 345362. [16] G.E. Agar, R. Stralton-Crawly, T.J. Bruce, Optimising the design of otation circuits, CIM Bull. 73 (1986) 173181. [17] M. Barbaro, L. Piga, Comparison of PbZn selective collectors using statistical methods, Miner. Eng. 12 (4) (1999) 355366. [18] G.S. Dobby, S.R. Rao, Processing of Complex Ore, CIM, Montreal, 1989. [19] K.S.E. Forssberg, Flotation of Sulphide Minerals, Elsevier, New York, 1985. [20] M. Ucurum, PhD Thesis, Cukurova University, Adana, Turkey, 2004. [21] K.N. Han, E.C. Dowling, in: B.K. Parekh, J.D. Miller (Eds.), Suldes and Precious Metals, Advanced in Flotation Technology, Society for Mining, Metallurgy, and Exploration, Inc., Littleton, 1999, pp. 117 118. [22] G. Morizot, P. Conll, M.V. Durance, F.G. Badri, Liberation and its role in otation-based owsheet development, Int. J. Miner. Process. 51 (1977) 3949. [23] S.J. Neethling, J.J. Cilliers, Simulation of the effect of froth washing on otation performance, Chem. Eng. Sci. (2001) 63036311.

También podría gustarte

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- Silo Cement CalculationDocumento11 páginasSilo Cement CalculationFikriaraz AfifAún no hay calificaciones

- Centrifugal Compressor Operation and MaintenanceDocumento16 páginasCentrifugal Compressor Operation and MaintenanceNEMSAún no hay calificaciones

- Mitsubishi diesel forklifts 1.5-3.5 tonnesDocumento2 páginasMitsubishi diesel forklifts 1.5-3.5 tonnesJoniAún no hay calificaciones

- Max Born, Albert Einstein-The Born-Einstein Letters-Macmillan (1971)Documento132 páginasMax Born, Albert Einstein-The Born-Einstein Letters-Macmillan (1971)Brian O'SullivanAún no hay calificaciones

- Alpha New Bp12Documento54 páginasAlpha New Bp12AUTO HUBAún no hay calificaciones

- Drager Fabius Gs Technical Service ManualDocumento350 páginasDrager Fabius Gs Technical Service ManualLeonardo Chirinos100% (3)

- FMDS0129Documento49 páginasFMDS0129hhAún no hay calificaciones

- LTE and SchedulingDocumento25 páginasLTE and SchedulingKrunoslav IvesicAún no hay calificaciones

- Bottazzini RiemannDocumento36 páginasBottazzini RiemanncedillaAún no hay calificaciones

- Reliability EngineeringDocumento9 páginasReliability Engineeringnvaradharajan1971Aún no hay calificaciones

- PF-CIS-Fall 2022 LABDocumento4 páginasPF-CIS-Fall 2022 LABMuhammad FaisalAún no hay calificaciones

- Impeller: REV Rev by Description PCN / Ecn Date CHK'D A JMM Released For Production N/A 18/11/2019 PDLDocumento1 páginaImpeller: REV Rev by Description PCN / Ecn Date CHK'D A JMM Released For Production N/A 18/11/2019 PDLSenthilkumar RamalingamAún no hay calificaciones

- Electrocraft EAD BLDC CatalogDocumento16 páginasElectrocraft EAD BLDC CatalogElectromateAún no hay calificaciones

- Austenitic Stainless SteelsDocumento10 páginasAustenitic Stainless SteelsbramAún no hay calificaciones

- A Design and Analysis of A Morphing Hyper-Elliptic Cambered Span (HECS) WingDocumento10 páginasA Design and Analysis of A Morphing Hyper-Elliptic Cambered Span (HECS) WingJEORJEAún no hay calificaciones

- UniversulDocumento56 páginasUniversulGabriel DutuAún no hay calificaciones

- Sem 2Documento128 páginasSem 2Agustin A.Aún no hay calificaciones

- Scramjet EngineDocumento2 páginasScramjet EngineSãröj ShâhAún no hay calificaciones

- Apex Ch10c1 Chassis At2408s Ch04t1002 Om8839ps Tda4605 TV SMDocumento61 páginasApex Ch10c1 Chassis At2408s Ch04t1002 Om8839ps Tda4605 TV SMAlejo Alex CondeAún no hay calificaciones

- Regeln Map 2Documento2 páginasRegeln Map 2bruno.wetzelAún no hay calificaciones

- Module 1 Introduction To Highway and Railroad EngineeringDocumento43 páginasModule 1 Introduction To Highway and Railroad EngineeringKenneth FajardoAún no hay calificaciones

- Algebra Translating Algebraic Phrases 001Documento2 páginasAlgebra Translating Algebraic Phrases 001crazyomnislash25% (4)

- Time TableDocumento7 páginasTime TableChethan .H.GAún no hay calificaciones

- Lsantos - Reflecting Writing For Optimization ProjectDocumento2 páginasLsantos - Reflecting Writing For Optimization Projectapi-341418797Aún no hay calificaciones

- Pumps - IntroductionDocumento31 páginasPumps - IntroductionSuresh Thangarajan100% (1)

- 3RP15 05-1aDocumento3 páginas3RP15 05-1atycristinaAún no hay calificaciones

- Tutorial CorelDRAW-X8Documento10 páginasTutorial CorelDRAW-X8Ajay BhargavaAún no hay calificaciones

- Digital Logic Design - Switch Logic & Basic GatesDocumento27 páginasDigital Logic Design - Switch Logic & Basic GatesTroon SoonAún no hay calificaciones

- Displaymax JR 1500 SpecsDocumento1 páginaDisplaymax JR 1500 SpecsFRANCISCOAún no hay calificaciones

- Numeri OrdinaliDocumento2 páginasNumeri OrdinaliClaudioAún no hay calificaciones