Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Especificacion Tecnica LED

Cargado por

Jorge Herrero GarcíaDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Especificacion Tecnica LED

Cargado por

Jorge Herrero GarcíaCopyright:

Formatos disponibles

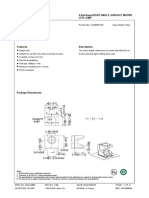

SPECIFICATIONS FOR LEDMAN LAMP LED

Model Q No. : Document No. : Revision No. :

LL2508PLBL4-A02(02) LML-25-096 01

Description: 5mm Oval Lamp Lens Color: Colored Diffused Emission Color: Blue Viewing Angle : 100 Stopper

Dice Material:

InGaN

ATTENTION

OBSERVE PRECAUTIONS

ELECTROSTATIC SENSITIVE DEVICES

Add: Building 8,Block 2,Baimang Baiwangxin Industrial Park, Xili Area,Nanshan District,Shenzhen, P.R.China Tel: 86-755-86139688 Fax: 86-755-86139001

Model I.. No.: LL2508PLBL4-A02(02) Document No.: LML-25-096 RevisionNo.: 01

Outline Drawing

10.50+/-0.5

1.00min 25.40min 3.80

LQW-017-D REV.03

0.50

2.54

5.20

NOTES: 1. All dimensions area in mm tolerance is 0.25mm unless otherwise noted. 2. An epoxy meniscus may extend about 1.5mm down the leads. 3. Burr around bottom of epoxy may be 0.5mm max.

Page 2 of 10

1.00min

1.50max

7.00

Model I.. No.: LL2508PLBL4-A02(02) Document No.: LML-25-096 RevisionNo.: 01

Applications:

1 2 3 Full Color Display Moving Message Board Screen Wall

Absolute Maximum Ratings (Ta = 25C)

Items DC Forward Current Peak Forward Current* Reverse Voltage Power Dissipation Operation Temperature Storage Temperature Lead Soldering Temperature *pulse width <=0.1msec duty <=1/10 Symbol IF IFP VR PD Topr Tstg Tsol Absolute maximum Rating 30 100 5 108 -20 ~ +75 -30 ~ +80 Unit mA mA V mW C C

Max.260C for 5 sec Max. (3mm from the base of the epoxy bulb)

Typical Electrical & Optical Characteristics ( Ta = 25C)

Items Forward Voltage Reverse Current Color Temperature Luminous Intensity 50% power Angle Symbol VF IR D IV 2H-H 2V-V Condition IF = 20mA VR = 5V IF = 20mA IF = 20mA IF = 20mA IF = 20mA Min. ------485 ----Typ. 3.0 --470 600 100 50 Max. 3.6 10 --------Unit V A nm mcd deg deg

Important Notes: 1) All ranks will be included per delivery, rank ratio will be determined by Ledman. 2) Tolerance of measurement of luminous intensity is 15%. 3) Tolerance of measurement of VF is 0.05 V. 4) Tolerance of measurement of dominant wavelength is 1nm. 5) Packaging methods are available to be chosen , please refer to Packaging section on page 9 and 10 . 6) For reliability test conditions and data, Please refer to Reliability Test section on page 5. 7) For how to use Ledman LED product safely, Please refer to Application Notes section on page7and 8. 8) As we are making continuous efforts to improve the performance of LED, Specifications are subject to change without notice. 9) Information is tentative and subject to change without notice.

Page 3 of 10

LQW-017-D REV.03

Model I.. No.: LL2508PLBL4-A02(02) Document No.: LML-25-096 RevisionNo.: 01

Typical Optical-Electronic Characteristic Curves:

IF(mA) 120 100 80

Ta=25

5.0

Ta=25

4.0

3.0

60 40

2.0

1.0

20 0 2.6 VF(V) 4.6

0.0

IF(mA)

3.0

3.4

3.8

4.2

Fig.1 Forward Current vs. Forward Voltage

1.0

0 20 40 60 80 100 Fig.2 Relative Luminous Intensity vs. Forward Current Domi WL=470nm

IF=20mA

2.0 IF=20mA

Ta=25

0.8

1.0

0.6

0.5

0.4

0.2

0.2

Ta(.)

0.1

20 40 60 80 100 Fig.3 Relative Luminous Intensity vs. Ambient Temperature

0.0

WL(nm)

450

500

550

600

650

Fig.4 Relative Luminous Flux vs. Wavelength

If(mA) 50

40

100%

IF=20mA Ta=25

30

10 20 30 40 50

20

50%

60 70

10

80 90

Ta(.)

0 20 40 60 80 100 Fig.5 Maximum Forward Current vs. Ambient Temperature

0%

90

60

30

50%

100%

Fig.6 Relative Luminous Intensity vs.Radiation Angle

Page 4 of 10

LQW-017-D REV.03

Model I.. No.: LL2508PLBL4-A02(02) Document No.: LML-25-096 RevisionNo.: 01

Reliability Test Standards

Type Test item Temperature cycles Thermal shock High humidity heat cycles High temperature storage Low temperature storage High temperature & high humidity storage Normal temperature life test life test High temperature & high humidity life test Low temperature life test destructive experiment Resistance to soldering heat Solderability Electrostatic discharge test Vibration Drop JEITA ED-4701 300 302 JEITA ED-4701 300 303 JEITA ED-4701 300 304 JEITA ED-4701 400 403 Applicable standard Test condition Duration Sampling number 100 100 100 100 100 100 100 100 100 20 20 10 10 10 Accept criteria 0/100 0/100 0/100 0/100 0/100 0/100 0/100 0/100 0/100 0/20 0/20 0/10 0/10 0/10 JEITA ED-4701 -402510025 100cycles 30min 5min 30min 5min 100 105 MIL-STD-202G JEITA ED-4701 200 203 JEITA ED-4701 200 201 JEITA ED-4701 200 202 JEITA ED-4701 100 103 -40100 15min 15min 3065 RH=90% 24hrs/1 cycle Ta=100 Ta=-40 Ta=60 RH=90% 300cycles 50cycles 1000hrs 1000hrs 1000hrs

environment test

Ta=25 1000hrs IF=30mA(R,G,Y)/20mA(W,B) Ta=60 RH=90% 1000hrs IF=20mA(R,G,Y)/15mA(W,B) Ta=-30 1000hrs IF=20mA(R,G,Y)/15mA(W,B) Tsol=2605,10sec 3mm from the base of the epoxy bulb Tsol=2355,5sec using flux Human body model 1000V forward and reverse 20G 20-2000HZ 4mins X,Y,Z 3directions 75CM one time one time each 3 times each 4cycles 3 times

Failure Criteria: Item Forward Voltage Reverse Current Luminous Intensity Solderability Vibration Drop IF=20mA IF=20mA Symbol VF IR IV Test Condition IF=20mA VR=5V IF=20mA Criteria for Judgment Initial Data10% 10A Single led degradation 50% and Average degradation 30% Over 95% No dead lamps or visual damage No dead lamps or visual damage

Remark: RH:Environment humidity;Ta:Environment temperature;Tsol:Tin temperature;IF:Forward current;VR:Reverse voltage.

physical ESD experiment

Page 5 of 10

LQW-017-D REV.03

Model I.. No.: LL2508PLBL4-A02(02) Document No.: LML-25-096 RevisionNo.: 01

Lamp LED Product Naming Rule

L X X X X X X X X X X X X X X X

1 2 3

10 product development of Serial numbe 9 PIN 1 No Stopper 2 Stopper 8 50% Power Angle 10 10 15 15 A0 100 B0 110 7 Colloid colour 1 Water Clear 2 White Diffused 3 Colored Transparent 4 Colored Diffused 6 Chip colour 5 Chip, code-named 1 chip company code 2 chip lighteness rank code 3 Generally omitted 4 Colloidal shape code 3 Product code size 3 3mm series 4 4mm series 5 5mm series 2 Product appearance of the shape code 1 round 2 oval 3 quadrate 5 especial 1 Product Type L LED LAMPseries Ledman code

Page 6 of 10

LQW-017-D REV.03

Model I.. No.: LL2508PLBL4-A02(02) Document No.: LML-25-096 RevisionNo.: 01

Application Note

1.Storage condition 10-2640%-65% RH. Store the product in sealed package. 2. It is recommended to use a wrist band or an antistatic glove when handling the LEDs. Operation tables must be earthed, and in order to avoid the oxidizing of the Lamp leads make sure you will seal the package soon after it is opened. 3. Please pay attention to antistatic steps during Insertation Procedure: AThe equipments should be properly earthed. BThe wrist bands are OK ,make sure the metal on the wrist band contacts closely with the skin. CIt is recommended that workers wear antistatic gloves when inserting LEDs. DThe operation table needs to be covered by antistatic rubberized fabric which is earthed. ELEDs should be used within 24 hours after opening the package. Otherwise the lamp leads might be oxidized. 4. Four methods to solder LED lamp: hand soldering, dip soldering and wave soldering. AHand soldering: in general, the temperature of soldering iron can be set at around 315. Ideally the soldering time is within 3 seconds, and it must be no longer than 5 seconds .Soldering should be less than 3 times for a LED. The temperature of the soldering iron which might vary, is generally set according to the ingredients of the tin soldering wire. BDip soldering: the temperature is set according to the ingredients of the tin soldering wire. Set the soldering time to be 3 seconds or less. CWave soldering: it is a more advanced soldering technology. The choice of flux is very important as different types of flux have different requirement as to cleanness of the soldering point. The pre-heating time can also have effect on the soldering quality. Normally, the liquid tin needs to be regularly checked and replaced. The temperature of the oven needs to be adjusted according to the ingredients of tin, but it can not be higher than 260 5, and the soldering time should be less than 5 seconds. All the equipments/operation tables need to be earthed while soldering. The static electricity of equipments/operation tables should not exceed 30 V, and of the human body no more than 50 V. Recommend to choose constant temperature soldering iron for manual soldering. In the cold and dry seasons, you need minimize personnel moving in workshops in order to avoid generating static electricity. 5. With increase on forward current and temperature, LEDs life time will decrease .The electricity leakage will increase significantly as a result of temperature increase, and result in a quick degradation of the LEDs life time. Please refer to Ledmans specification sheets. 6. A grounding circuit is necessary in the design of PCB. Pay special attention to the environment: -20 to 70 ,50%RH to 80%RH, otherwise electro-static discharge might break down the LEDs and large current might cause the invalidation of the LEDs. when Ta = 25, blue and green LEDs with 12 mil chip:

Page 7 of 10 LQW-017-D REV.03

Model I.. No.: LL2508PLBL4-A02(02) Document No.: LML-25-096 RevisionNo.: 01

The maximum value of the constant current should not exceed 30 mA, with 9mil chip should not exceed 15 mA. Red and yellow LEDs with 12 mil chip: The maximum value of the constant current should not exceed 50 mA, with 9mil chip should not exceed 30 mA. 7. Pay particular attention to the use of white-light LEDs: A: Do not mix white-light LEDs of different Bins, specially of the Color Ranks. B: LEDs with different forward voltages can not be used in parallel. C: Recommend to drive with constant current. 8. When the LEDs are shaping up, the distance between the bending points of the LED leads and the bottom of the lens should be at least 3 mm. Do not bend the LED leads while soldering or after soldering. If you must bend it, please do it before soldering. Please read carefully about the working environment and parameters of LEDs before use.

Page 8 of 10

LQW-017-D REV.03

Model I.. No.: LL2508PLBL4-A02(02) Document No.: LML-25-096 RevisionNo.: 01

Packaging

1. Antistatic bag packaging:

Cardboard 500PCS/bag

30bags/carton Cardboard

ledman Lptoelectronic Co.,Ltd

TYPE: RANK:

15000pcs/carton

ledman Lptoelectronic Co.,Ltd

TYPE: RANK:

COLOR: LOT: QTY: AT NO:

IV: VF: HUE

Add:Building8,Block2,BaimanBaiwangxin Industrial Park Xili Area,Nanshan District,Shenzhen,P.R.China Lighting the world

ROHS

COLOR: LOT: QTY: AT NO:

IV: VF: HUE

Add:Building8,Block2,BaimanBaiwangxin Industrial Park Xili Area,Nanshan District,Shenzhen,P.R.China Lighting the world

ROHS

30000pcs/carton

60000pcs/carton

Page 9 of 10

LQW-017-D REV.03

Model I.. No.: LL2508PLBL4-A02(02) Document No.: LML-25-096 RevisionNo.: 01

2. Brede packaging:

A space of to 15 or more elements is left

ledman Lptoelectronic Co.,Ltd

TYPE: RANK:

COLOR: LOT: QTY: AT NO:

IV: VF: HUE

Add:Building8,Block2,BaimanBaiwangxin Industrial Park Xili Area,Nanshan District,Shenzhen,P.R.China Lighting the world

ROHS

4040pcs/carton(5mm Oval lamp)

Page 10 of 10

LQW-017-D

REV.03

También podría gustarte

- D+led-Ld5rDocumento6 páginasD+led-Ld5rJulia EchazarretaAún no hay calificaciones

- Property of Lite-On Only FeaturesDocumento11 páginasProperty of Lite-On Only FeaturesBLUEE009Aún no hay calificaciones

- 333 2SYGDS530 E2 - DatasheetDocumento7 páginas333 2SYGDS530 E2 - Datasheetvikas_ojha54706Aún no hay calificaciones

- Mini TOP Views LEDsDocumento11 páginasMini TOP Views LEDsRicky CoxAún no hay calificaciones

- NTC Thermistor SMD Type Specification SheetDocumento25 páginasNTC Thermistor SMD Type Specification SheetwoodyyinAún no hay calificaciones

- Led 5mm yDocumento6 páginasLed 5mm yMarcos PainenahuelAún no hay calificaciones

- DS-0035 3W PM2L-3LLx-SD v1.6Documento13 páginasDS-0035 3W PM2L-3LLx-SD v1.6Pavan KumarAún no hay calificaciones

- 104 K5C CapacitorDocumento54 páginas104 K5C CapacitorsotaquitoAún no hay calificaciones

- Specification LR770D: SSC CustomerDocumento12 páginasSpecification LR770D: SSC CustomerMangesh GaikwadAún no hay calificaciones

- Full-Color LED Lamp Specification SheetDocumento8 páginasFull-Color LED Lamp Specification SheetNicholas RichardsonAún no hay calificaciones

- Technical Data Sheet for STLA-2835DB TOP LEDDocumento20 páginasTechnical Data Sheet for STLA-2835DB TOP LEDjayveeAún no hay calificaciones

- Luckylight: 0.56" Triple Digit Numeric Displays Technical Data SheetDocumento6 páginasLuckylight: 0.56" Triple Digit Numeric Displays Technical Data SheetSergiu BadalutaAún no hay calificaciones

- Radial Lead Type Monolithic Ceramic Capacitors: Cat - No.C49E-21Documento54 páginasRadial Lead Type Monolithic Ceramic Capacitors: Cat - No.C49E-21davidninrioAún no hay calificaciones

- Product Specification: PLBT3-WDRG2613Documento6 páginasProduct Specification: PLBT3-WDRG2613api-62031994Aún no hay calificaciones

- American Opto Plus LED C/A561E-5 G/W 0.56Documento5 páginasAmerican Opto Plus LED C/A561E-5 G/W 0.56RaulJoseRainieriAún no hay calificaciones

- Sddje: 10A 250V AC Qualified TypeDocumento6 páginasSddje: 10A 250V AC Qualified TypeshyhuAún no hay calificaciones

- LEDTECH 0.43Documento6 páginasLEDTECH 0.43ordenador90Aún no hay calificaciones

- Data Sheet For 8mm Super Bright White LED Dip Type 1/2watt High Power LED SeriesDocumento2 páginasData Sheet For 8mm Super Bright White LED Dip Type 1/2watt High Power LED SeriesEtbn SnoaAún no hay calificaciones

- Data Sheet: HLMP-RL20, HLMP-SL20Documento9 páginasData Sheet: HLMP-RL20, HLMP-SL20Anonymous pMVR77x1Aún no hay calificaciones

- Fujifilm Finepix S1000fd Service ManualDocumento112 páginasFujifilm Finepix S1000fd Service ManualAstronom SuceavaAún no hay calificaciones

- Everlight Electronics Co.,Ltd.: 5.0mm Round Type LED Lamps Part No.: FeaturesDocumento4 páginasEverlight Electronics Co.,Ltd.: 5.0mm Round Type LED Lamps Part No.: FeaturesDhuck DhAún no hay calificaciones

- CERAMIC CAPACITORS TITLEDocumento12 páginasCERAMIC CAPACITORS TITLEcostpopAún no hay calificaciones

- Varistor 222k.6kvDocumento5 páginasVaristor 222k.6kvJess AJAún no hay calificaciones

- Manual de Servicio Sony KDL-32BX300 Chasis AZ1-FKDocumento32 páginasManual de Servicio Sony KDL-32BX300 Chasis AZ1-FKLogicooltechAún no hay calificaciones

- 9619 Sony KDL-22BX300 KDL-32BX300 Chassis AZ1-FK Televisor LCD Manual de ServicioDocumento32 páginas9619 Sony KDL-22BX300 KDL-32BX300 Chassis AZ1-FK Televisor LCD Manual de ServicioFavgFavgAún no hay calificaciones

- Guide to Achieving Best Performance from RTDs and Pt100 SensorsDocumento12 páginasGuide to Achieving Best Performance from RTDs and Pt100 SensorsghrairiAún no hay calificaciones

- Agm 1602B 802Documento25 páginasAgm 1602B 802WellingtonAún no hay calificaciones

- TermistoresDocumento8 páginasTermistoresingcreAún no hay calificaciones

- MCD288 DVD Micro Theatre: /all VersionsDocumento39 páginasMCD288 DVD Micro Theatre: /all VersionsLeonelHernandezAún no hay calificaciones

- S 5800Documento114 páginasS 5800elenoremailAún no hay calificaciones

- DLP Panasonic Pt50dl54 Pt60dl54Documento93 páginasDLP Panasonic Pt50dl54 Pt60dl54SonnyandDawn BerryAún no hay calificaciones

- NTC Thermistors For Inrush Current Limiting: Leaded and Coated DisksDocumento14 páginasNTC Thermistors For Inrush Current Limiting: Leaded and Coated DisksLuis GuevaraAún no hay calificaciones

- 6204 6214LEDTubeT8Documento7 páginas6204 6214LEDTubeT8Hytham Ramdan El BardecyAún no hay calificaciones

- Panasonic Quasar SP 2725f Chasis Sc363 (ET)Documento20 páginasPanasonic Quasar SP 2725f Chasis Sc363 (ET)fercikeAún no hay calificaciones

- 4.0X4.0Mm Right Angle Surface Mount Led LampDocumento6 páginas4.0X4.0Mm Right Angle Surface Mount Led LampAlberto Valenzuela UrzúaAún no hay calificaciones

- 7 Segment LA5622-S2 DatasheetDocumento6 páginas7 Segment LA5622-S2 Datasheetcris_itdAún no hay calificaciones

- Novabrite RGB Full Color High Power Led Application Note: R&D CenterDocumento15 páginasNovabrite RGB Full Color High Power Led Application Note: R&D CenterVinu KumarAún no hay calificaciones

- White Backlight LED Technical SpecificationDocumento6 páginasWhite Backlight LED Technical SpecificationanzuresinkAún no hay calificaciones

- PT1302B C2Documento7 páginasPT1302B C2G Ivan Torres RAún no hay calificaciones

- Fujifilm Finepix s8000fdDocumento134 páginasFujifilm Finepix s8000fdzilikonAún no hay calificaciones

- 333 2SDRD S530 A3 DatasheetDocumento6 páginas333 2SDRD S530 A3 Datasheetvikas_ojha54706Aún no hay calificaciones

- Ordering Information: Sealed Snap Action SwitchDocumento6 páginasOrdering Information: Sealed Snap Action SwitchG Sandeep KumarAún no hay calificaciones

- L17,1950S BNDocumento30 páginasL17,1950S BNWalter AlvarengaAún no hay calificaciones

- Nec Tokin Oe128 DatasheetDocumento2 páginasNec Tokin Oe128 DatasheetAfwan Al Fauzan Assalafy100% (2)

- Soldering electronic circuits: Beginner's guideDe EverandSoldering electronic circuits: Beginner's guideCalificación: 4.5 de 5 estrellas4.5/5 (9)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsAún no hay calificaciones

- Beginning Digital Electronics through ProjectsDe EverandBeginning Digital Electronics through ProjectsCalificación: 5 de 5 estrellas5/5 (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionDe EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionCalificación: 4.5 de 5 estrellas4.5/5 (3)

- Digital LED Thermometer with Microcontroller AVR ATtiny13De EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Calificación: 5 de 5 estrellas5/5 (1)

- 110 Semiconductor Projects for the Home ConstructorDe Everand110 Semiconductor Projects for the Home ConstructorCalificación: 4 de 5 estrellas4/5 (1)

- Weld Like a Pro: Beginning to Advanced TechniquesDe EverandWeld Like a Pro: Beginning to Advanced TechniquesCalificación: 4.5 de 5 estrellas4.5/5 (6)

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsDe EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsCalificación: 3 de 5 estrellas3/5 (2)

- Switching in Electrical Transmission and Distribution SystemsDe EverandSwitching in Electrical Transmission and Distribution SystemsAún no hay calificaciones

- Memories Rubric and Poject MatrixDocumento2 páginasMemories Rubric and Poject MatrixJorge Herrero GarcíaAún no hay calificaciones

- Exercises Technical DrawingDocumento14 páginasExercises Technical DrawingJorge Herrero García78% (9)

- Worksheet Computing2Documento2 páginasWorksheet Computing2Jorge Herrero GarcíaAún no hay calificaciones

- Worksheet Computing1Documento2 páginasWorksheet Computing1Jorge Herrero GarcíaAún no hay calificaciones

- Canonical HuffmanDocumento13 páginasCanonical HuffmanMarius IonitaAún no hay calificaciones

- Service Manual: Skyworth RGB R&D Centre Technical DocumentDocumento32 páginasService Manual: Skyworth RGB R&D Centre Technical DocumentlalgalleAún no hay calificaciones

- Compact NSX - 630A - LV429741Documento3 páginasCompact NSX - 630A - LV429741معين عزامAún no hay calificaciones

- Elpida S1216aata 75 eDocumento49 páginasElpida S1216aata 75 eErRobert ChAún no hay calificaciones

- Important Safety Instructions: Deltran Battery Tender PlusDocumento7 páginasImportant Safety Instructions: Deltran Battery Tender PlusdikkilonaAún no hay calificaciones

- Semiconductor Laser Diode Technology and ApplicationsDocumento388 páginasSemiconductor Laser Diode Technology and ApplicationsJosé RamírezAún no hay calificaciones

- PMI VS Power MetersDocumento4 páginasPMI VS Power MetersJulio Cesar Bolivar GonzalezAún no hay calificaciones

- Networks: Example: Elevator ControllerDocumento15 páginasNetworks: Example: Elevator ControllerPaayal SasiAún no hay calificaciones

- KLCP Codec LogDocumento7 páginasKLCP Codec LogAntonio ChipanaAún no hay calificaciones

- Module 24 SAHITA Electrical InstallationDocumento16 páginasModule 24 SAHITA Electrical InstallationLungisaniAún no hay calificaciones

- Technical Data: Atom Fire Rated DownlightsDocumento3 páginasTechnical Data: Atom Fire Rated DownlightsEugenioAún no hay calificaciones

- Xyce Reference GuideDocumento634 páginasXyce Reference GuideVojislav MedićAún no hay calificaciones

- Unit 1 Principles of Electrical Machine DesignDocumento8 páginasUnit 1 Principles of Electrical Machine Designbenh-aldj100% (1)

- 7806697Documento8 páginas7806697Muhammad OmerAún no hay calificaciones

- 1383817411Documento610 páginas1383817411ryanrahman0% (2)

- 4-bit synchronous counter designDocumento2 páginas4-bit synchronous counter designmirosehAún no hay calificaciones

- AD-99 Encatalog 1705 SankoshaDocumento100 páginasAD-99 Encatalog 1705 SankoshaLiliek Prasetyo WidiyonoAún no hay calificaciones

- Wenling Yuhai Electromechanical 180sy-M35015 Sg-50a DatasheetDocumento62 páginasWenling Yuhai Electromechanical 180sy-M35015 Sg-50a DatasheetJoimir PerezAún no hay calificaciones

- Essentials of MOSFETs: Transistors, Digital Circuits, and ApplicationsDocumento24 páginasEssentials of MOSFETs: Transistors, Digital Circuits, and ApplicationsJeff HoAún no hay calificaciones

- Multi-Function Air Conditioner GuideDocumento21 páginasMulti-Function Air Conditioner GuideLaura VillarroelAún no hay calificaciones

- Electric Power Transmission System Engineering Analysis and DesignDocumento10 páginasElectric Power Transmission System Engineering Analysis and DesignJyothsna VayyalaAún no hay calificaciones

- HCD GT555Documento118 páginasHCD GT555rgbelectronics0% (1)

- Digital Control For UPS InvertersDocumento6 páginasDigital Control For UPS InvertersLazhar Ben-BrahimAún no hay calificaciones

- Yaskawa V1000 CIMR VC ManualDocumento418 páginasYaskawa V1000 CIMR VC Manualdanghe2006Aún no hay calificaciones

- Comparing Communication MethodsDocumento4 páginasComparing Communication MethodsKenny VillafanaAún no hay calificaciones

- A New High-Speed Foreign Fiber Detection System With Machine VisionDocumento23 páginasA New High-Speed Foreign Fiber Detection System With Machine VisionijtrobinAún no hay calificaciones

- Distributor Sales ReportDocumento8 páginasDistributor Sales ReportRonie JumilAún no hay calificaciones

- Vpt7 DocumentationDocumento70 páginasVpt7 Documentationurbster1Aún no hay calificaciones

- Ch13 Magnetic Effects of Current Exam Style SolutionDocumento14 páginasCh13 Magnetic Effects of Current Exam Style SolutionRiyansh WarikooAún no hay calificaciones

- Network Devices GuideDocumento51 páginasNetwork Devices GuideTasya ZumarAún no hay calificaciones