Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Waffle Slabs

Cargado por

ahsana2878%(9)78% encontró este documento útil (9 votos)

14K vistas9 páginasA two-way waffle slab system consists of concrete ribs that normally intersect at right angles. The top slabs with each rib form a T-section, with considerable depth relative to flat plates. Waffle SLABS also provide an attractive ceiling, which is achieved by leaving the rib pattern or integrating lighting fixtures.

Descripción original:

Derechos de autor

© Attribution Non-Commercial (BY-NC)

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoA two-way waffle slab system consists of concrete ribs that normally intersect at right angles. The top slabs with each rib form a T-section, with considerable depth relative to flat plates. Waffle SLABS also provide an attractive ceiling, which is achieved by leaving the rib pattern or integrating lighting fixtures.

Copyright:

Attribution Non-Commercial (BY-NC)

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

78%(9)78% encontró este documento útil (9 votos)

14K vistas9 páginasWaffle Slabs

Cargado por

ahsana28A two-way waffle slab system consists of concrete ribs that normally intersect at right angles. The top slabs with each rib form a T-section, with considerable depth relative to flat plates. Waffle SLABS also provide an attractive ceiling, which is achieved by leaving the rib pattern or integrating lighting fixtures.

Copyright:

Attribution Non-Commercial (BY-NC)

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 9

I1A1 Waffle Slabs oat

Shab

Drop panel

Column

Torsional pat

of the drop panel

(e)

Figure 17.32 (continued)

The width of column strip in each direction is 4 = 10 ft, whereas the width of the middle strip

is 10 ft in the long direction and 14 ft in the short direction.

5, Calculations of moments and steel reinforcement are shown in Table 17.11. Use an average

d= 10 ~ 1.5 = 85 in. in the column strip and d = 8 ~ 1.5 = 65 in. in the middle strip.

Bars are chosen for adequate distribution in both the column and middle strip. Reinforce-

ment details are similar to those in at-plate examples.

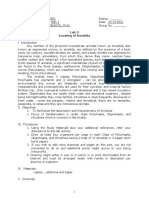

{111 WAFFLE SLABS

A two-way waffle slab system consists of concrete ribs that normally intersect at right angles.

These slabs might be constructed without beams, in which case a solid column head is made

over the column to prevent any punching due to shear. Wide beams can also be used on the

column centerlines for uniform depth construction. Square metal or fiberglass pans are commonly

used to form these joists. A thin slab of 3 to 5 in. is cast with these joists to form the waffle

slab.

Each panel is divided into a column and a middle strip. The column strip includes all joists

that frame into the solid head; the middle strip is located between consecutive column strips.

Straight or bent bars could be used as a reinforcement in a waffle slab. The design of a two-way

waffle slab is similar to that of flat slabs by considering the solid head as a drop panel. To prevent

any excess in the diagonal tension in the head, a sufficient size of column must be used or a

shear cap must be provided.

In the design of a wafffe slab, the top slabs with each rib form a T-section, with considerable

depth relative to flat plates. Consequently, long spans carrying heavy loads may be designed with

great savings in concrete. Waffle slabs also provide an attractive ceiling, which is achieved by

leaving the rib pattern or by integrating lighting fixtures. The standard pans that are commonly

used in waffle slabs can be one of the following two types:

Chapter 17 Design of Two-Way Slabs

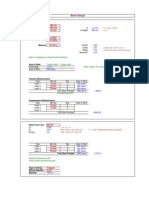

Table 17.11 Design of an Interior Flat-Slab Floor System

Long Direction

My, = 358 K-ft Column Strip Middle Strip

M factor -0.49M, 021M, —0.16M, 04M,

M, (K-ft) -175.4 +75.2 57.3 #501

Width of strip (in.), b 120 120 120 120

Effective depth (in.), d 8.5 65 65 65

R= a (psi) 243 178 129 19

Steel ratio p (%) 0.48 0.34 0.25 0.23

A, = pbd (in.?) 49 2.65 1.95 aoe

Min. A, = 0.0018bh, (in.*) 2.16 2.16 173 1B

Selected bars 16 no. 5 14 no. 4 10 no. 4 9no.4

Short Direction

Middle Strip

MQ. = 289.3 K-ft

M factor 0.49M, 021M, —0.16M, 0.14M,

M, (K-ft) 142 +608 =46.3 £405

Width of strip (in.), b 120 120 168 168

Effective depth (in.), d 85 65 65 65

196 144 B 6&8

R, (psi)

Steel ratio p (%) 0.38 0.28 0.15 0.13

A, = pbd (in) 3.9 22 1.64 1.42

Min. A, = 0.0018bh, (in2) 2.16 2.16 2.42 242

Selected bars 13 no. 5 11 n0. 4 12 no. 4 12 m0.4

1, 30 X 30-in. square pans with a 3-in. top slab, from which 6-in.-wide ribs at 36 in. (@ f)

on centers are formed. These are available in standard depths of 8 to 20 in, in 2-in, incre:

ments, Refer to Example 17.12 and Fig. 17.33.

2. 19 x 19-in. square pans with a 3-in, top slab, from which 5-in.-wide ribs at 24 in, (2 ft)

on centers are formed. These are available in standard depths of 4, 6, 8, 10, and 12 in

Other information about pans is shown in Table 17.12 [21]. Other types, ranging from

19 X 19-in, pans to 40 x 40-in. pans, are available in the construction industry.

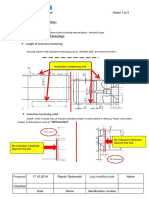

Example 17.12: Waffle Slab

Design a waffle floor system that consists of square panels without beams considering the following

data (Fig. 17.33):

Span, center to center of columns = 33 ft

Width of rib = 6 in,, spaced at 36 in. on centers

Depth of rib = 14 in, and slab thickness = 3 in,

Column size = 20 20 in.

“CLLt edu

qu pue ued

‘speey pijos jo suoisuewip pue Bulseds (p) pue ‘suorsuewip

jond@s Ssouo (q) ‘GEIS aYJeEM UR JO URId (©) ELE eaNBIg

(e)

SU x ST

\ (qs) __ (eau 9) f

eau pulos [dans wanes dow oireny

i

i

WW

i

POU

7 i

(dus eunjod) ,¢-91 7

(Guns a1ppuy) 6°91 ] | eos

Oo

aE

Chapter 17. Design of Two-Way Slabs

Solid head

Pans Ribs

(b)

38 i

(a)

Figure 17.33 (continued)

Dead load (excluding setf-weight) = 50 psf

Live load = 100 psf

Sksif, = 60 ksi

Solution

1. Determine minimum slab thickness using Table 17.1: Minimum h = 1,/30, |, = 33 - #=

31.33 ft, A = 31.33(12)/30 = 12.5 in. for exterior panels, and A = 1,/33 = 11.4 in. for interio

panels. Equations 17.1 and 17.2 may be used. Assume the total depth is 17 in. consisting of.

in, slab thickness and 14-in. rib depth.

2, Calculate loads on the waffle slab:

111 Waffle Slabs 645

Table 17.12 Gross Section Properties [21]

For the Joists (30 x 30-in. pans)

‘Top Slab Rib Depth Volume Gross Area

fin) (in) (cf/pan) (in)

3 8 3.85 1393

3 10 478 2307

3 12 5.53 3541

3 14 6.54 5135

3 16 7.44 na

3 20 9.16 12,469

4s 8 3.85 2058

45 10 4.78 3227

45 12 553 4783

45 14 6.54 6773

45 16 744 9238

45 20 9.16 15,768

For the Joists (19 x 19-1

3 6 1.09 105 2.886 598

3 8 141 117.4 3.564 1098

3 10 19 130.4 4.303 1824

3 12 214 144 5.083 2807

45 6 1.09 14 3.457 957

45 8 141 153 4.051 1618

45 10 19 166.4 4.709 2550

45 12 2.14 180 5.417 3794,

a, Factored load of solid head part = 1,2(150)(17/12) = 255 psf.

b. Voided volume of 14-in, rib = 6.54 ft on 3 x 3-1

1.2(150\9 x 43 = 6.54) = 1118 Ib. Weight per square foot is “* = 125 psf.

area. Total weight of 9-ft® area is

¢. Factored additional dead plus live load is 1.2(50) + 1.6(100) = 220 psf. Uniform w,, (at

solid head) = 255 + 220 = 500 psf. Uniform w, (at ribbed area) = 125 + 220 = 345 psf

d. Loads on one panel (refer to Fig. 17.34): At the solid head, W = 0.5(12) + 0.345(21) =

13.22 K/ft. At the ribbed area, W = 0.345(33) = 11.39 K/f.

3. Calculate shear and total static moment:

V, (at the face of column) = 13.225.17) + aspen = 188K

M, (at midspan) = 188(15.67) ~ 13.226.17)(13.09) Hos = 1424 Ket

4, Check punching shear (refer to Fig. 17.35)

a, In solid head at d/2 from column face, h = 17 in., d = 17 ~ 1.25 = 15.75 in., c (column)

= 20 in, b, = 4(20 + 15.75) = 143 in., V, = 11.3921 ft) + 13.22(12 ft) - 0.5G7.75/

12)? = 393.4 K and @V. = d4Vfib,d = 0.75(4)(V'5000) (143)(15.75) = 478 K > V,,

b. In the slab at distance d/2 from the edge of the solid head, slab thickness is 3 in.; let d =

2.15 in. Then

Chapter 17 Design of Two-Way Slabs

Waffle slab (looking upward).

6,

4(150 + 2.5) = 610 in.

152.5

Vy, = 11.3921) + 13,2212) — os(323) =3174K

$V, = 0.75(4)(V5000\(610)(2.5) = 324 K > V,

5. Design moments and reinforcement:

a, Exterior panel: M, = 1424 K-ft

Exterior negative moment = 0.26M, = -370 K-ft

Positive moment = 0.52M, = + 740 K-ft

Interior negative moment = 0.7M, = —997 K-ft

b. Interior panel: M, = 1424 K-ft

Negative moment = 0.65(1424) = —925.6 K-ft

Positive moment = 0.35(1424) = 498.4 K-ft

Design details are shown in Table 17.13 and Fig. 17.36. Note that all steel ratios are low

and ¢ = 0.9.

Calculate the unbalanced moments in columns and check shear for V, and M,, as in Examples

17.8 and 17.9.

7.11 Waffle Slabs a

Column face i

fe

11.39 Kite T |

Colunn centetine —ol

|

cs . 3 _

1

|

|

i

105" sar

oe >|

188K

97K

(b)

M, = 1424 Kft

(c)

Figure 17.34 Load, shear, and moment diagrams: (a) load distribution on the span,

(6) shear force diagram, and (c) bending moment diagram.

Chapter 17 Design of Two-Way Slab

35.75"

Figure 17.35 Punching shear locations: (a) punching shear in column head and (b)

punching shear in slab.

17.12 Equivalent Frame Method

Table 17.13 Design of an Exterior and an Interior Waffie Slab (5 Ribs in Column Strip and 6 Ribs in Middle

Strips)

Column Strip Middle Strip

Exterior Interior

Exterior Panel (-™) +M M -M *M

Moment factor (%) 100 60 75 28 40

M, (Kf) 370 444 748 249 296

Stip width, b (in.) 150 198 150 36 (6 ribs) 198

d(in) 15.75 15.75 15.75 15.15 15.75

Re i (psi) 120 108 241 334 n

Steel ratio, p (%) 0.226 0.465 0.657 0.135

A, = pbd (in2) 5.33 36 11.0 3.73 42

Min, A, = 0.00186h 26 1.22 46 1M 1.47

Bars selected 14 n0. 6 2 no. 8/rib 26 no. 6 10 no. 6 2. no. 7/rib

Column Strip Middle Strip

Exterior Interior

Interior Panel (tM +M —M -M +M

Moment factor (%) _ 60 15, 25 40

M, (K-ft) a 299 694.2 214 200

Stip width, b (in.) = 198 150 36 (6 ribs) 198

ain) - 15.75 15.75 15.75 15.75

M,

MM — 22: 4

R= Fp os) B 4 31 9

Stel ratio, p (%) - 0.137 0.431 0.61 0.091

A, = pbd (in.”) - 4.27 10.18 3.45 2.84

Min. A, = 0.10018bh - 1.22/rib 46 Ll 147

Bars selected - 2 no. 7/rib 24 no. 6 10 no. 6 2 no. 6/rib

17.12 EQUIVALENT FRAME METHOD

When two-way floor systems do not satisfy the limitations of the direct design method, the design

moments must be computed by the equivalent frame method. In the latter method, the building

is divided into equivalent frames in two directions and then analyzed elastically for all conditions

of loadin;

i difference between the direct design and equivalent frame methods lies in the

way by which the longitudinal moments along the spans of the equivalent rigid frame are deter-

mined. The design requirements can be explained as follows.

1. Description of the equivalent frame: An equivalent frame is a two-dimensional building

frame obtained by cutting the three-dimensional building along lines midway between col:

umns (Fig. 17.4). The resulting equivalent frames are considered separately in the longi-

tudinal and transverse directions of the building. For vertical loads, each floor is analyzed

separately, with the far ends of the upper and lower columns assumed to be fixed, The slab-

beam may be assumed to be fixed at any support two panels away from the support con-

sidered, because the vertical loads contribute very little to the moment at that support. For

También podría gustarte

- Preliminary Structural DesignDocumento8 páginasPreliminary Structural Designaikaless100% (1)

- Structural design and analysis of a low-rise buildingDocumento42 páginasStructural design and analysis of a low-rise buildingMohammed SumerAún no hay calificaciones

- Design of Shear Walls Using ETABSDocumento97 páginasDesign of Shear Walls Using ETABSYeraldo Tejada Mendoza88% (8)

- RCC Design SheetsDocumento40 páginasRCC Design SheetsAnonymous nwByj9L100% (2)

- Manual For Design and Detailing of RCCDocumento340 páginasManual For Design and Detailing of RCCimranmehfoozAún no hay calificaciones

- Design of Pile FoundationDocumento17 páginasDesign of Pile FoundationNarnindi Venkata Ramananda SagarAún no hay calificaciones

- Analysis and Design of Flat Slabs Using Various Codes: Dr. Pradeep Kumar RamancharalaDocumento53 páginasAnalysis and Design of Flat Slabs Using Various Codes: Dr. Pradeep Kumar RamancharalaSwapnilAún no hay calificaciones

- ETABS RC Slab Design PDFDocumento29 páginasETABS RC Slab Design PDFLim Wee BengAún no hay calificaciones

- ACI 318-14 RC Shear Wall Design - Short Walls PDFDocumento9 páginasACI 318-14 RC Shear Wall Design - Short Walls PDFHuzil FernandezAún no hay calificaciones

- RCC Design Based in Indian CodesDocumento43 páginasRCC Design Based in Indian Codeschaos_atulAún no hay calificaciones

- Axially Loaded RC Column DesignDocumento17 páginasAxially Loaded RC Column DesignBert EngAún no hay calificaciones

- Design of FootingDocumento67 páginasDesign of FootingHarlene Marie M. Ilagan100% (1)

- Behavior of Two Way SlabsDocumento18 páginasBehavior of Two Way Slabsnirmal sutharAún no hay calificaciones

- Box Culvert by R.S.vasneyDocumento10 páginasBox Culvert by R.S.vasneyShreedhar33% (3)

- Design of Raft Foundations for Low Bearing SoilDocumento1 páginaDesign of Raft Foundations for Low Bearing SoilAhmed Al-AmriAún no hay calificaciones

- RCC Design SheetsDocumento40 páginasRCC Design SheetsIbrahim El SharAún no hay calificaciones

- Ribbed Slab DesignDocumento11 páginasRibbed Slab DesignJavier_GL100% (2)

- Shear Walls-Frame DesignDocumento150 páginasShear Walls-Frame Designsaikiran100% (4)

- RCC Design SheetsDocumento40 páginasRCC Design SheetsAnonymous 9iK0i8h0dPAún no hay calificaciones

- Two-Way-Joist-Concrete Slab-Floor - (Waffle-Slab) - System-Analysis-and-DesignDocumento51 páginasTwo-Way-Joist-Concrete Slab-Floor - (Waffle-Slab) - System-Analysis-and-DesignJeisson CastilloAún no hay calificaciones

- Lecture 10 Analysis and Design of Waffle Slabs - 2011Documento62 páginasLecture 10 Analysis and Design of Waffle Slabs - 2011José Pablo Rosales Sánchez100% (1)

- Deflection Flat SlabDocumento4 páginasDeflection Flat SlabAjaykumar MistryAún no hay calificaciones

- ETABS 2016 StepsDocumento2 páginasETABS 2016 StepsMohiminulIslamFardin100% (1)

- Design of reinforced concrete columns: Short column vs long columnDocumento25 páginasDesign of reinforced concrete columns: Short column vs long columndashne134100% (4)

- RCC Design SheetsDocumento40 páginasRCC Design Sheetsashuswara84% (25)

- Design of Waffle SlabDocumento4 páginasDesign of Waffle SlabAriel Mayer100% (1)

- Design of one-way and two-way slabsDocumento12 páginasDesign of one-way and two-way slabsGeorge GeorgianAún no hay calificaciones

- Deep Beam Flexure and Shear DesignDocumento40 páginasDeep Beam Flexure and Shear DesignPragya Roy95% (39)

- Design of Circular DomesDocumento8 páginasDesign of Circular Domesrshyams100% (1)

- UNIT-2 Design of Spur GearDocumento56 páginasUNIT-2 Design of Spur GearMarthandeAún no hay calificaciones

- 425 Footing Design ExamplesDocumento60 páginas425 Footing Design ExamplesKakaAún no hay calificaciones

- AISC ExamI1&2&3Documento11 páginasAISC ExamI1&2&3Dhurai KesavanAún no hay calificaciones

- Etabs Tutorials ListDocumento4 páginasEtabs Tutorials ListDanielAún no hay calificaciones

- Good Flat Slab Example Acc To EC2 (The Concrete Centre)Documento14 páginasGood Flat Slab Example Acc To EC2 (The Concrete Centre)Nitish Ramdawor100% (4)

- Induction Hardening - Interpretation of Drawing & Testing PDFDocumento4 páginasInduction Hardening - Interpretation of Drawing & Testing PDFrajesh DESHMUKHAún no hay calificaciones

- Analysis and Design of Circular Beams-2017Documento49 páginasAnalysis and Design of Circular Beams-2017Ragheb Ibrahim0% (1)

- Design of RCC ColumnsDocumento14 páginasDesign of RCC Columnsprashmce100% (1)

- Analysis of Circular Flat Slab in Residential Building Using STAAD ProDocumento42 páginasAnalysis of Circular Flat Slab in Residential Building Using STAAD ProKarthik Naidu67% (6)

- Analysis and Design of A Continuous R. C. Raker Beam Using Eurocode 2Documento13 páginasAnalysis and Design of A Continuous R. C. Raker Beam Using Eurocode 2Ubani Obinna Ranks100% (7)

- Design of Flat Slab with Reinforcement DetailsDocumento8 páginasDesign of Flat Slab with Reinforcement DetailsMeganathan Mega100% (1)

- CVEN 444 - Homework 5 - Concrete beam and slab design problemsDocumento9 páginasCVEN 444 - Homework 5 - Concrete beam and slab design problemsOmar Calisaya RamosAún no hay calificaciones

- ADDC Construction QuestionairesDocumento19 páginasADDC Construction QuestionairesUsman Arif100% (1)

- Steel Tips - Composite Beam Design With Metal Deck PDFDocumento9 páginasSteel Tips - Composite Beam Design With Metal Deck PDFmateus456Aún no hay calificaciones

- Analysis & Design of Multi Storeyed Buildings V.M.RAJAN, M.E. (Struct), FIE, Former CE/Civil/TANGEDCODocumento25 páginasAnalysis & Design of Multi Storeyed Buildings V.M.RAJAN, M.E. (Struct), FIE, Former CE/Civil/TANGEDCOV.m. RajanAún no hay calificaciones

- Flat SlabDocumento16 páginasFlat SlabPrashil21100% (4)

- Pages From Reynolds-Steedman-helicoidal Stair and Sawtooth - EserciziDocumento8 páginasPages From Reynolds-Steedman-helicoidal Stair and Sawtooth - EserciziMaurizio FalconieriAún no hay calificaciones

- Analysis of Ribbed SlabDocumento12 páginasAnalysis of Ribbed Slabmickymat100% (1)

- Waffle Slab Two WayDocumento19 páginasWaffle Slab Two WayMuhammad MusaabAún no hay calificaciones

- Column Design As Per BS 8110-1:1997: PHK/JSNDocumento16 páginasColumn Design As Per BS 8110-1:1997: PHK/JSNopulithe0% (1)

- 22 - (Slabs) Hollow Blocks Hordi Slabs Waffle SlabsDocumento308 páginas22 - (Slabs) Hollow Blocks Hordi Slabs Waffle Slabsusama anter100% (1)

- Analysis of Waffle Slabs PDFDocumento49 páginasAnalysis of Waffle Slabs PDFShashankAthreya57% (7)

- (LECT-21,22) Prestressed Concrete SlabsDocumento22 páginas(LECT-21,22) Prestressed Concrete SlabsSushil MundelAún no hay calificaciones

- Design of Structural ElementsDocumento22 páginasDesign of Structural Elementsengsam777Aún no hay calificaciones

- LRFD-Composite Beam Desing With MetaldeckDocumento12 páginasLRFD-Composite Beam Desing With MetaldeckMaria FabianaAún no hay calificaciones

- Chapter - 4Documento25 páginasChapter - 4Wai Yann ZawAún no hay calificaciones

- Full Beam Design Example: GivenDocumento17 páginasFull Beam Design Example: Giventap ramosAún no hay calificaciones

- Two Way Rib Slab ACI ExampleDocumento9 páginasTwo Way Rib Slab ACI Exampleahmed nssrAún no hay calificaciones

- Nama: Ichan M Maulana Nim: 2111141079 Kelas: S1-B Tugas Teknik Manufaktur 3Documento6 páginasNama: Ichan M Maulana Nim: 2111141079 Kelas: S1-B Tugas Teknik Manufaktur 3Ichan M MaulanaAún no hay calificaciones

- Concrete Analysis and DesignDocumento99 páginasConcrete Analysis and DesignAdil Javed ChaudharyAún no hay calificaciones

- Eigen Modes - PDF Timesaving-Torsiondesign-Ia PDFDocumento32 páginasEigen Modes - PDF Timesaving-Torsiondesign-Ia PDFGeorge GeorgianAún no hay calificaciones

- Ce591plategirders F13Documento67 páginasCe591plategirders F13cocococo1100% (1)

- Steel ProjectDocumento34 páginasSteel ProjectHein Zin HanAún no hay calificaciones

- Substation Structure DesignDocumento27 páginasSubstation Structure Designpaulc227Aún no hay calificaciones

- Chapter 12Documento37 páginasChapter 12ahsana28100% (1)

- Slender ColumnsDocumento22 páginasSlender Columnsahsana28Aún no hay calificaciones

- Torsion NHDocumento32 páginasTorsion NHahsana28Aún no hay calificaciones

- Unsymmetrical Bending, Shear Centre - C&yDocumento32 páginasUnsymmetrical Bending, Shear Centre - C&yahsana2875% (4)

- Beams On Elastic Foundation - C&yDocumento26 páginasBeams On Elastic Foundation - C&yahsana28100% (13)

- List Sessional Marks: 2009-2010 Civil Engineering Third Year Section-B Engineering Construction (CE-303) TheoryDocumento1 páginaList Sessional Marks: 2009-2010 Civil Engineering Third Year Section-B Engineering Construction (CE-303) Theoryahsana28Aún no hay calificaciones

- Nigeria - S Niger Delta Crisis, Root Causes of Peacelessness (Hassan Tai Ejibunu)Documento41 páginasNigeria - S Niger Delta Crisis, Root Causes of Peacelessness (Hassan Tai Ejibunu)Ionescu FloAún no hay calificaciones

- Sundar KandvalmikiDocumento98 páginasSundar Kandvalmikifactree09Aún no hay calificaciones

- Meningitis & EncephalitisDocumento7 páginasMeningitis & EncephalitisABAKADAAún no hay calificaciones

- EVOLUTION Class Notes PPT-1-10Documento10 páginasEVOLUTION Class Notes PPT-1-10ballb1ritikasharmaAún no hay calificaciones

- DerbyCityCouncil Wizquiz Presentation PDFDocumento123 páginasDerbyCityCouncil Wizquiz Presentation PDFShubham NamdevAún no hay calificaciones

- Very Low Altitude Drag-Free Satellites: R D UpdatesDocumento5 páginasVery Low Altitude Drag-Free Satellites: R D Updatesraa2010Aún no hay calificaciones

- Chapter 4 Cost MinimizationDocumento6 páginasChapter 4 Cost MinimizationXavier Hetsel Ortega BarraganAún no hay calificaciones

- Blood Group 3Documento29 páginasBlood Group 3Hamirie JoshuaAún no hay calificaciones

- EiaDocumento14 páginasEiaRamir FamorcanAún no hay calificaciones

- CSC-1321 Gateway User Guide: Downloaded From Manuals Search EngineDocumento48 páginasCSC-1321 Gateway User Guide: Downloaded From Manuals Search EngineKislan MislaAún no hay calificaciones

- Tipologie Break in OutDocumento17 páginasTipologie Break in OutGiorgio FantauzziAún no hay calificaciones

- Print Date:: Container No NO Size Seal No Seal Party Supplier Status Movement TypeDocumento3 páginasPrint Date:: Container No NO Size Seal No Seal Party Supplier Status Movement TypeYudha PermanaAún no hay calificaciones

- The Quill Vol. LVIII Issue 1 1-12Documento12 páginasThe Quill Vol. LVIII Issue 1 1-12Yves Lawrence Ivan OardeAún no hay calificaciones

- Tec Relay 52GDocumento3 páginasTec Relay 52Gimmer nainggolanAún no hay calificaciones

- Unit 4.2Documento45 páginasUnit 4.2Gundrathi Narendra GoudAún no hay calificaciones

- Supply Chain Management: Tata Tea's Global OperationsDocumento15 páginasSupply Chain Management: Tata Tea's Global OperationsAmit Halder 2020-22Aún no hay calificaciones

- Personality Types and Character TraitsDocumento5 páginasPersonality Types and Character TraitspensleepeAún no hay calificaciones

- Elemental Composition of Dalang': A Food Condiment From Evaporated Extract of Borassus Aethiopum Fruit AshDocumento3 páginasElemental Composition of Dalang': A Food Condiment From Evaporated Extract of Borassus Aethiopum Fruit AshsardinetaAún no hay calificaciones

- BiologyDocumento21 páginasBiologyHrituraj banikAún no hay calificaciones

- Khasi Community of MeghalayaDocumento3 páginasKhasi Community of MeghalayaMidhat FatimaAún no hay calificaciones

- 19 - Speed, Velocity and Acceleration (Answers)Documento4 páginas19 - Speed, Velocity and Acceleration (Answers)keyur.gala100% (1)

- 3 Variable Cramers Rule PDFDocumento4 páginas3 Variable Cramers Rule PDFElton DiocsonAún no hay calificaciones

- Lesson 1 - Simple StressDocumento5 páginasLesson 1 - Simple StressJohn Philip NadalAún no hay calificaciones

- Knowing Annelida: Earthworms, Leeches and Marine WormsDocumento4 páginasKnowing Annelida: Earthworms, Leeches and Marine WormsCherry Mae AdlawonAún no hay calificaciones

- 2021 - Tet Purchase Behavior Report - INFOCUSDocumento15 páginas2021 - Tet Purchase Behavior Report - INFOCUSGame AccountAún no hay calificaciones

- Anxiolytics Sedatives Hypnotics Pharm 3Documento38 páginasAnxiolytics Sedatives Hypnotics Pharm 3Peter Harris100% (1)

- AMYLOIDOSISDocumento22 páginasAMYLOIDOSISMohan ChoudharyAún no hay calificaciones